Technical Contents

Engineering Guide: Machining Service

Engineering Insight: The Non-Negotiable Imperative of Precision in Machining Services

Precision in CNC machining transcends mere specification adherence; it is the fundamental bedrock of functional integrity, performance reliability, and long-term value in critical metal components. In high-stakes industries like aerospace, medical device manufacturing, and advanced automation, dimensional deviations measured in microns can cascade into catastrophic system failures, costly recalls, or compromised safety. Achieving true precision demands more than advanced machinery; it requires an integrated ecosystem of rigorous process control, deep material science understanding, continuous metrology validation, and unwavering operational discipline. Tolerances below 0.0002 inches are not theoretical targets but mandatory requirements for parts operating under extreme stress, vacuum, or sterile conditions. The cost of imprecision – in rework, scrap, delayed time-to-market, and reputational damage – consistently dwarfs the investment in achieving it correctly the first time.

Wuxi Lead Precision Machinery operates at this demanding apex of manufacturing capability. Our engineering heritage is forged in projects where failure is not an option. We have delivered mission-critical components for major international sporting events, including precision structural elements subjected to global scrutiny during the Olympic Games. Furthermore, our facility maintains stringent protocols certified for defense and aerospace supply chains, producing parts where dimensional accuracy directly impacts national security and operational safety. This experience instills a culture where every micrometer matters, and every process step is validated. It is not simply about meeting a drawing; it is about guaranteeing that the physical part performs exactly as the engineer designed it, under the most demanding real-world conditions, batch after batch.

Our commitment manifests in measurable capability. The table below outlines core precision parameters consistently achieved across our production floor, reflecting the baseline standard for complex, high-value components:

| Specification Category | Standard Capability | Advanced Capability (Specialized Processes) |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) |

| Geometric Tolerance (GD&T) | IT Grade 5 | IT Grade 3-4 |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.2 µm (8 µin) |

| Repeatability (Cp/Cpk) | ≥1.67 / ≥1.33 | ≥2.00 / ≥1.67 |

| Material Range | Aluminum, Steel, Stainless, Titanium, Exotic Alloys | Inconel, Hastelloy, Beryllium Copper |

This level of consistent output is engineered through our investment in state-of-the-art multi-axis CNC centers with sub-micron positioning accuracy, climate-controlled metrology labs housing CMMs and optical comparators, and a quality management system audited to AS9100 and ISO 9001 standards. Crucially, it is sustained by our engineering team’s decades of hands-on experience solving the most complex precision challenges. When you partner with Lead Precision, you gain more than a machining service; you secure a precision assurance system built on proven performance where the margin for error is measured in millionths of an inch. Precision is not our claim – it is our documented foundation.

Precision Specs & Tolerances

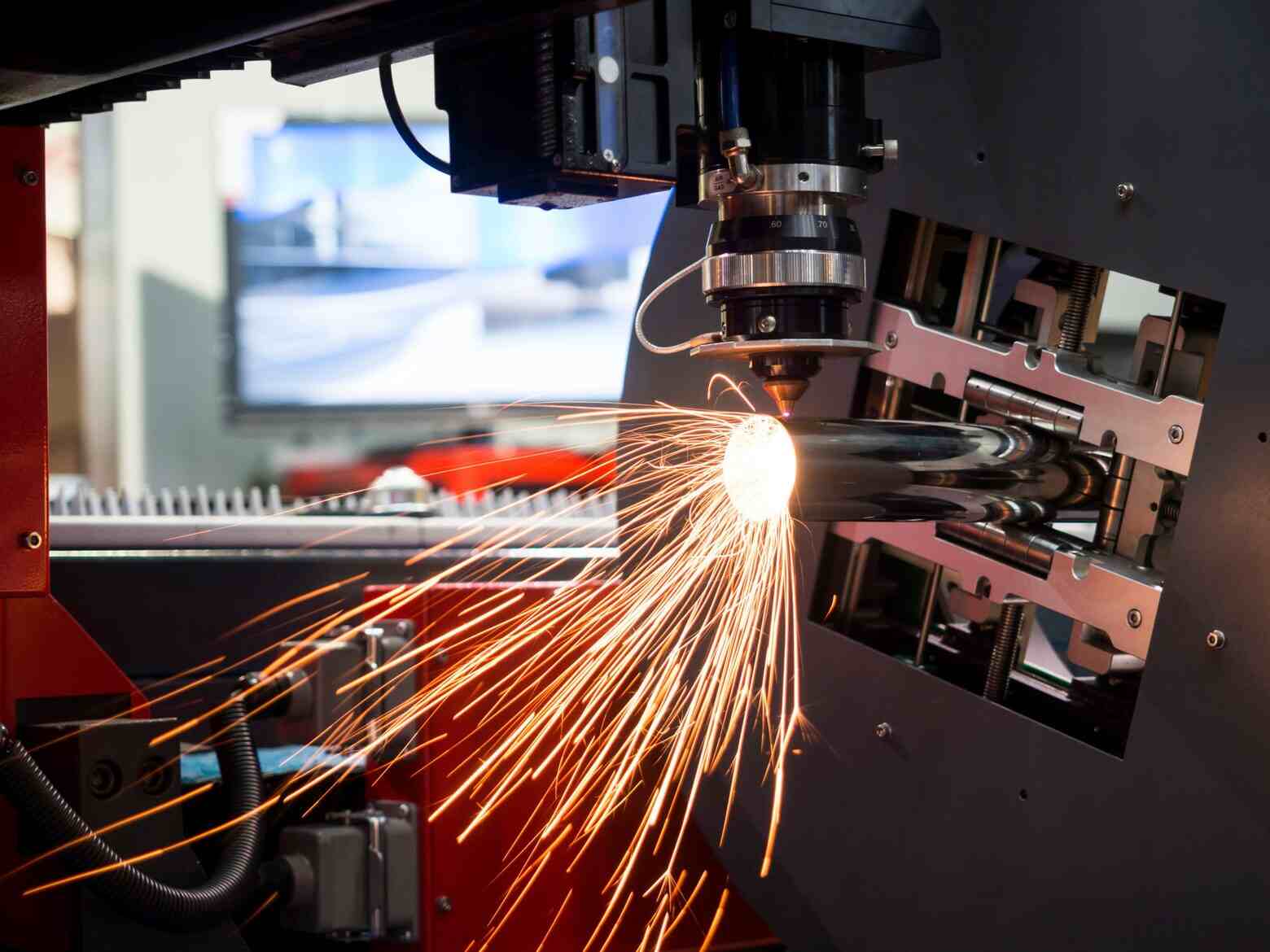

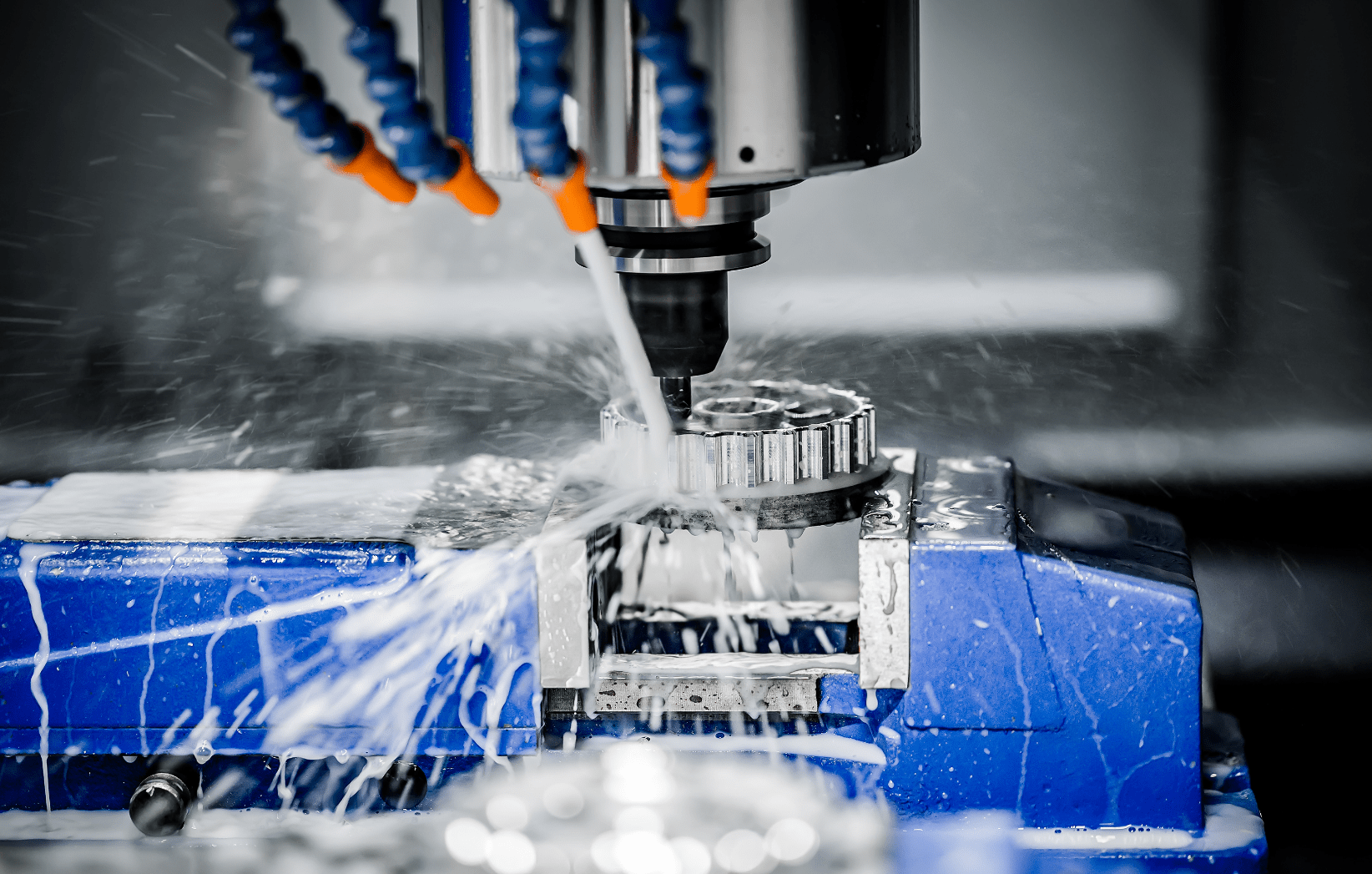

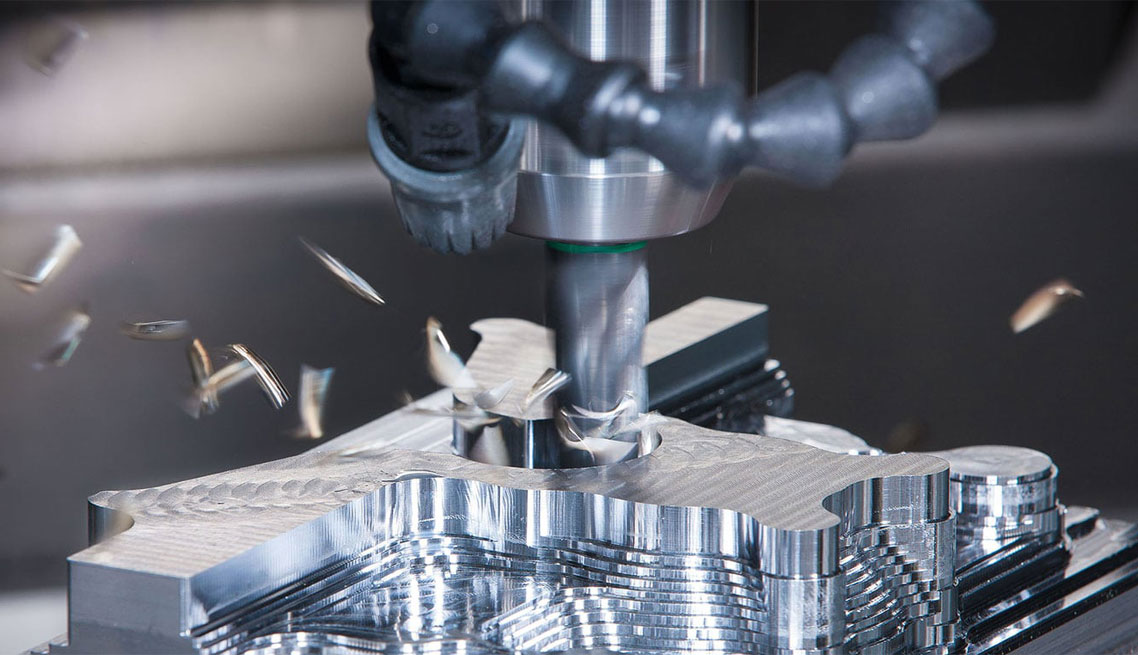

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the most demanding industrial applications. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce highly complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across five planes, drastically reducing setup time, minimizing part handling, and ensuring superior dimensional consistency across multi-faceted components. This capability is particularly critical for aerospace, medical, robotics, and high-performance automotive sectors where precision and repeatability are non-negotiable.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain optimal cutting conditions throughout production. We work with a broad range of metals, including aluminum alloys, stainless steel, titanium, Inconel, brass, and specialty engineering materials. Each machine is operated by experienced CNC programmers and machinists who utilize industry-leading CAM software to optimize toolpaths, reduce cycle times, and ensure material integrity. From prototype development to high-volume production runs, our 5-axis technology supports rapid iteration and scalable manufacturing without compromising on quality.

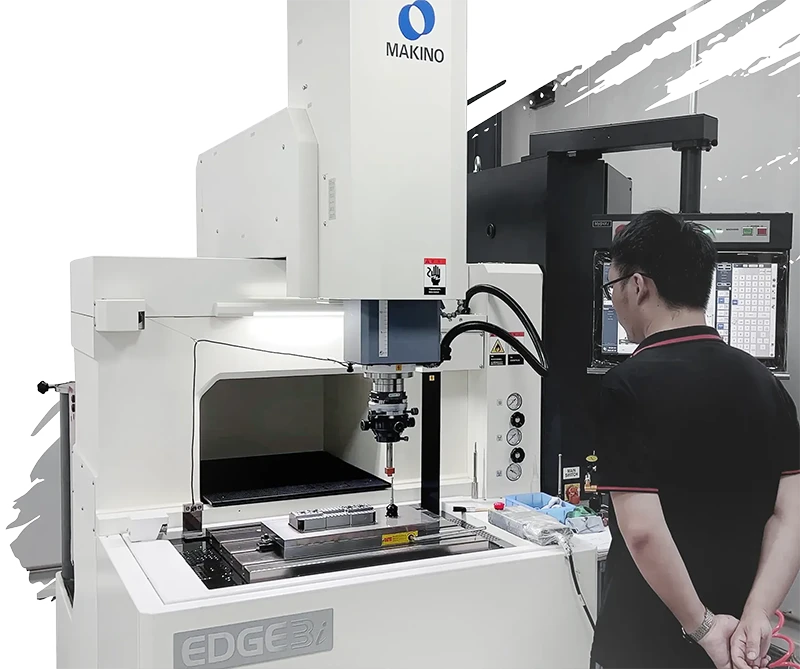

To guarantee that every component meets exacting specifications, we implement a rigorous quality control process anchored by Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and surface profiles. All inspections are documented, and full first-article inspection (FAI) reports can be provided upon request. In addition to CMM, we employ optical comparators, surface roughness testers, and digital calipers to validate part conformity at every stage of production.

The table below outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes. These values serve as a baseline; tighter tolerances can be achieved upon engineering review and with appropriate design considerations.

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm |

| Positional Tolerance | ±0.02 mm | ±0.005 mm |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm (standard finish) | 0.4 µm (polished finish) |

| Angular Tolerance | ±0.05° | ±0.01° |

| Runout / Concentricity | 0.02 mm | 0.005 mm |

Our technical capabilities are reinforced by a commitment to continuous improvement, certified processes, and close collaboration with engineering teams to optimize manufacturability. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we build trust through precision, transparency, and technical excellence.

Material & Finish Options

Strategic Material Selection for Precision Machined Components

Material choice fundamentally impacts component performance, manufacturability, and lifecycle cost in high-precision CNC machining. At Wuxi Lead Precision Machinery, we guide clients through critical trade-offs between Aluminum, Steel, and Titanium based on application demands. Aluminum alloys like 6061-T6 dominate aerospace and thermal management applications due to exceptional strength-to-weight ratios, corrosion resistance, and machinability. For structural integrity under high stress, 7075-T6 offers superior tensile strength but requires careful toolpath planning to prevent work hardening. Steel selections hinge on environment and load: 303 stainless ensures easy machining for complex geometries in moderate-corrosion settings, while 4140 alloy steel delivers fatigue resistance for heavy machinery shafts and tooling. Titanium Grade 5 (Ti-6Al-4V) is indispensable for medical implants and aerospace where biocompatibility, extreme strength-to-weight, and corrosion resistance outweigh its challenging machinability and higher raw material costs.

Surface finishing, particularly anodizing, transforms aluminum components by enhancing wear resistance, electrical insulation, and aesthetic control. Type II (sulfuric acid) anodizing provides standard corrosion protection with dye compatibility for identification, while Type III (hardcoat) anodizing achieves 50-70 µm thickness for military-grade abrasion resistance in hydraulic systems or firearm components. Note that anodizing dimensional impacts require pre-finishing allowances of ±0.002″ per surface. Steel typically utilizes passivation or electroless nickel plating for corrosion barriers, whereas titanium relies on laser etching or bead blasting for functional surface textures.

The following table summarizes critical properties for common aerospace and industrial materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Excellent |

| Aluminum 7075-T6 | 2.8 | 570 | Moderate | Good |

| Stainless 303 | 8.0 | 620 | Excellent | Very Good |

| Steel 4140 | 7.8 | 655 | Moderate | Fair |

| Titanium Ti-6Al-4V | 4.4 | 895 | Excellent | Poor |

Material selection must align with operational stressors, regulatory requirements, and total cost of ownership—not just initial procurement price. For instance, titanium’s machining time may double versus aluminum, but its longevity in saltwater environments eliminates replacement costs. Similarly, Type III anodizing adds 15-20% to aluminum part cost yet extends service life by 300% in abrasive conditions. Wuxi Lead’s engineering team conducts DFMA reviews to optimize material-finish pairings, ensuring your components meet AS9100 or ISO 13485 standards while minimizing waste. We provide certified material test reports and finish validation per ASTM B117 for salt spray resistance. Consult our application engineers to model material behavior under your specific thermal, vibrational, and chemical exposure conditions—turnkey solutions start with the right substrate.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, consistency, and zero defects. We specialize in delivering high-integrity CNC machining services tailored to the exacting demands of industries such as aerospace, medical, automotive, and industrial automation. Our end-to-end workflow integrates advanced design validation, precision prototyping, and scalable mass production, all governed by stringent quality control protocols.

The process begins with design analysis and engineering collaboration. Our team works closely with clients to review CAD models, perform manufacturability assessments (DFM), and optimize part geometry for performance, material efficiency, and cost-effectiveness. Utilizing Siemens NX and SolidWorks, we conduct full digital simulations to anticipate stress points, thermal behavior, and dimensional stability, ensuring that every design is production-ready before any material is cut.

Prototyping follows as a critical validation phase. Using high-speed 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes in the actual production-grade materials—such as aluminum 7075-T6, titanium Ti-6Al-4V, stainless steel 316L, and Inconel 718. These prototypes undergo comprehensive inspection via coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy is verified against GD&T callouts, ensuring conformity within ±0.005 mm. This stage not only confirms design integrity but also validates toolpaths, fixturing, and process parameters for full-scale production.

Once approved, the project transitions seamlessly into mass production. Our facility operates over 80 CNC machines with automated pallet systems and real-time monitoring through Siemens SINUMERIK software, enabling lights-out manufacturing and consistent output. Each production run is managed under an ISO 9001-certified quality system, with in-process inspections at defined intervals and full traceability from raw material to final shipment. Statistical process control (SPC) is implemented to detect and correct deviations before they impact output quality.

To ensure zero defects, we deploy a multi-layered quality assurance strategy. This includes first-article inspection reports (FAIR), PPAP documentation, and 100% critical feature inspection when required. Non-destructive testing (NDT) methods such as penetrant testing and ultrasonic inspection are applied for mission-critical components.

Our production capabilities are supported by a skilled team of engineers and machinists with over 15 years of experience in high-precision manufacturing. With a focus on continuous improvement and lean production principles, we maintain high on-time delivery rates while minimizing waste and rework.

Below are key production specifications:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Tolerance Range | IT6 to IT8 (ISO 286) |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Production Capacity | Up to 50,000 units/month |

Every component we produce reflects our commitment to excellence—engineered precisely, validated rigorously, and delivered reliably.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

When your application demands tolerances tighter than 0.001mm, material integrity under extreme conditions, or seamless integration into complex assemblies, Wuxi Lead Precision Machinery delivers engineered certainty. We transcend conventional machining service providers by embedding aerospace-grade discipline into every process—from initial design review to final inspection. Our facility operates under ISO 9001:2015 and IATF 16949 frameworks, with real-time SPC monitoring ensuring zero deviation from your specifications. For industries where failure is not an option—medical implants, semiconductor tooling, or defense systems—our 15-year legacy of precision execution becomes your competitive advantage.

Our technical capabilities are engineered for the most demanding challenges. The table below outlines core specifications achievable across our production floor:

| Parameter | Capability Range | Verification Method |

|---|---|---|

| Dimensional Accuracy | ±0.001mm to ±0.005mm | Zeiss CONTURA CMM (5-axis) |

| Surface Finish | Ra 0.05µm to Ra 1.6µm | Mitutoyo SJ-410 Profilometer |

| Material Range | Aluminum 7075-T73 to Inconel 718 | Spectrochemical Analysis (OES) |

| Max Work Envelope | 1200 x 800 x 600mm (5-axis milling) | Laser Tracker Calibration |

| Lead Time (Prototype) | 7-12 days (from approved CAD) | Digital Workflow Tracking |

Unlike volume-focused workshops, we prioritize traceability and process ownership. Each component receives a dedicated production dossier documenting tool wear compensation, thermal drift adjustments, and first-article inspection data. Our engineers proactively identify manufacturability risks during the RFQ phase—reducing your time-to-market by eliminating design iterations. For urgent projects, our dedicated rapid-response cell maintains 24/7 readiness with pre-qualified material stock and automated tooling systems, compressing delivery cycles without compromising validation.

The true differentiator lies in our partnership model. We assign a single-point engineering contact who speaks your technical language—whether you require AS9100-compliant PPAP documentation or NADCAP-accredited non-destructive testing. This eliminates communication silos common with offshore suppliers. Our facility in Wuxi operates on Central European Time-aligned shifts, enabling real-time collaboration during your business hours. When you share a print, you gain access to metrology reports, process capability studies, and continuous improvement insights—not just a shipped part.

Forward your CAD file or engineering drawing to [email protected] to initiate a technical feasibility assessment. Include your target tolerance stack-up, material certification requirements, and delivery deadline. Within 24 hours, our application team will respond with a detailed process plan, risk analysis, and firm quotation. For urgent requirements exceeding standard capacity, mention “Rapid Response” in the subject line to trigger expedited review. Trust Lead Precision to transform your most exacting metal component challenges into certified, on-time deliverables—where precision is non-negotiable and partnership is measured in microns.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.