Technical Contents

Engineering Guide: Injection Molding Online Quote

Engineering Insight Precision in Injection Molding Online Quoting

Precision is not merely a specification in custom metal injection molding; it is the foundational requirement determining part functionality, assembly integrity, and long-term reliability. Generic online quoting systems often fail to capture the nuanced engineering realities critical for high-performance applications. They may accept basic geometry and material inputs but frequently overlook subtle factors like micro-shrinkage compensation, gate vestige impact on sealing surfaces, or thermal management requirements inherent to complex alloys. This oversight leads to inaccurate cost projections and, critically, quotations for parts that cannot meet stringent performance demands upon production. The true value of an online quote lies not in speed alone, but in its ability to integrate deep engineering judgment from the outset.

At Wuxi Lead Precision Machinery, our online quotation platform is engineered by veteran toolmakers and process engineers with decades of hands-on experience. We do not rely on automated algorithms alone. Every submitted geometry undergoes preliminary review by our technical team to identify potential precision pitfalls invisible to purely digital systems. We assess critical dimensions, draft angles for ultra-tight tolerances, and material flow characteristics specific to aerospace-grade stainless steels or titanium alloys. This proactive engineering analysis ensures the initial quote reflects achievable precision, not theoretical ideals, preventing costly redesigns or production failures later. Our system prompts for essential context – such as functional load points or environmental exposure – that directly influence tolerance stack-up and surface finish requirements.

This commitment to engineered quoting is validated by our track record in mission-critical sectors. We have supplied precision-molded components for Olympic timing systems demanding micron-level consistency under dynamic stress and for military communication housings requiring hermetic seals and EMI shielding at extreme temperatures. These projects demanded tolerances and material properties far beyond standard commercial requirements, necessitating quoting processes grounded in proven manufacturing science, not estimation.

Our core capabilities for precision metal injection molding are reflected in the following achievable specifications:

| Specification Category | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance (per ISO 2768) | ±0.1% of dimension | ±0.005 mm (critical features) |

| Surface Roughness (Ra) | 0.8 – 1.6 µm | 0.4 µm (polished cavities) |

| Material Density | >96% theoretical | >98% theoretical (special processes) |

| Feature Repeatability (CpK) | ≥1.33 | ≥1.67 (monitored production) |

| Alloy Compatibility | 17-4PH, 316L common | Custom tooling for Inconel, Ti-6Al-4V |

An accurate injection molding quote for precision metal components must transcend basic geometry and volume. It requires the integration of metallurgical expertise, tooling physics, and real-world process validation. Wuxi Lead Precision Machinery embeds this engineering rigor into our online quotation workflow, ensuring the price you receive is the price for a part that meets your exacting performance standards – a standard forged through delivering for the world’s most demanding applications. Trust precision quoting to engineers who build it daily.

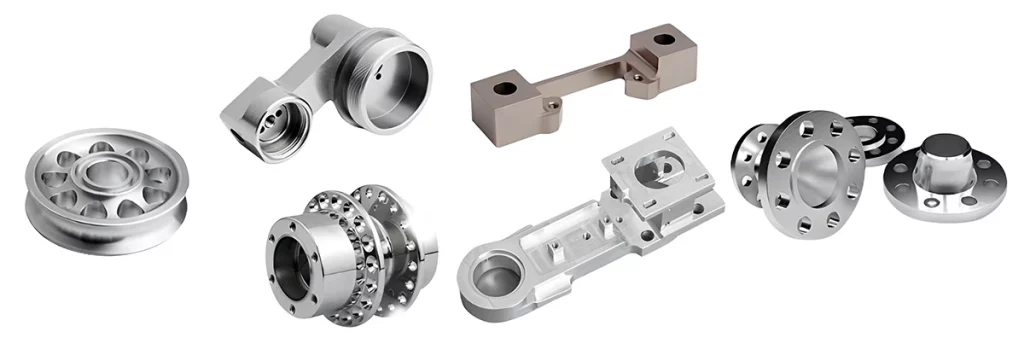

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is a state-of-the-art 5-axis CNC machining platform, enabling us to produce highly complex geometries with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous movement across five planes, drastically reducing setup time, minimizing part handling, and ensuring tighter tolerances across intricate features. This capability is particularly critical for components requiring undercuts, deep cavities, or organic contours that cannot be achieved through traditional milling methods.

Our machining fleet consists of precision-engineered equipment calibrated for continuous high-volume production and rapid prototyping. Each machine operates under strict environmental controls to minimize thermal drift and maintain dimensional stability. We work with a broad spectrum of metals, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys such as Inconel and tool steels. Material selection is supported by in-house metallurgical analysis to ensure compatibility with functional and environmental requirements.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using a Zeiss coordinate measuring machine (CMM), providing traceable, high-resolution inspection data in full compliance with ISO 10360 standards. Our CMM system supports both tactile and optical probing, enabling non-contact measurement for delicate or highly polished surfaces. Each production run includes first-article inspection (FAI) reports and process capability (Cp/Cpk) analysis upon request, ensuring statistical process control and long-term repeatability.

In addition to CMM validation, we employ advanced metrology tools such as surface roughness testers, optical comparators, and hardness testers to verify material and geometric integrity. All inspection data is documented and archived digitally, supporting full traceability from raw material to final shipment. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and customer-specific requirements.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled production conditions.

| Feature | Standard Tolerance | Precision Tolerance (Optional) |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.01 mm | ±0.005 mm |

| Linear Dimensions (100–300 mm) | ±0.02 mm | ±0.01 mm |

| Linear Dimensions (300–600 mm) | ±0.03 mm | ±0.015 mm |

| Hole Diameter (reamed) | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished available) |

| Angular Tolerance | ±0.1° | ±0.05° |

These specifications reflect our ability to meet stringent engineering requirements while maintaining scalability and cost-efficiency. For mission-critical applications, we offer custom process validation and PPAP documentation. Wuxi Lead Precision Machinery ensures that every component produced meets the highest standards of precision, reliability, and performance.

Material & Finish Options

Material Selection for Precision Injection Molds: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material for injection molds directly impacts part quality, production longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize technical alignment between material properties and your project’s operational demands. Below is a concise guide to key metals and surface treatments for high-performance molds.

Aluminum Alloys

Aluminum 7075-T6 and 6061-T6 are ideal for rapid prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cycle times by up to 30% compared to steel, reducing energy costs. While 7075-T6 offers superior strength for complex geometries, 6061-T6 provides better machinability for intricate details. Aluminum molds excel in applications requiring quick turnaround but are less suitable for abrasive or high-temperature resins due to lower hardness.

Tool Steels

P20, H13, and 420 stainless steel dominate high-volume production. P20 (hardness 28-32 HRC) balances toughness and polishability for standard thermoplastics. H13 (48-52 HRC) withstands thermal fatigue in high-temperature processes like polycarbonate molding. For corrosive environments or medical-grade resins, 420 stainless (50-54 HRC) delivers exceptional rust resistance. Steel molds justify higher initial costs through lifespans exceeding 1 million cycles.

Titanium Alloys

Titanium Grade 5 (Ti-6Al-4V) is reserved for extreme scenarios: highly abrasive composites, ultra-corrosive chemicals, or weight-sensitive aerospace tooling. Its 60% lower density than steel reduces mold handling costs, while maintaining strength at 400°C+. However, titanium’s machining complexity and material cost necessitate rigorous ROI analysis for volumes under 500,000 parts.

Anodizing for Enhanced Performance

Anodizing transforms aluminum mold surfaces into wear-resistant ceramic layers. Type II (sulfuric acid) anodizing (5-25µm thickness) improves release properties for sticky resins like PVC. For molds facing abrasive glass-filled polymers, hardcoat Type III anodizing (25-50µm) increases surface hardness to 60-70 HRC—tripling tool life without dimensional compromise. Note: Anodizing is incompatible with steel or titanium; these require nitriding or PVD coatings instead.

Comparative Material Specifications

| Property | Aluminum 7075-T6 | P20 Tool Steel | H13 Tool Steel | Titanium Grade 5 |

|---|---|---|---|---|

| Hardness (HRC) | 15-20 | 28-32 | 48-52 | 35-40 |

| Thermal Conductivity (W/m·K) | 130 | 30 | 28 | 7 |

| Corrosion Resistance | Moderate | Low | Medium | Excellent |

| Typical Mold Application | <50k cycles | 100k-500k cycles | 500k-1M+ cycles | Specialized high-abrasion |

Material choice must align with resin type, part complexity, and production volume. Aluminum suits agile development phases, steel delivers volume reliability, and titanium solves niche challenges. Anodizing extends aluminum mold viability but requires precise thickness control to avoid tolerance shifts. For tailored recommendations, submit your CAD files and production parameters via our online quote portal—our engineers will optimize material and finish selection within 24 hours.

Manufacturing Process & QC

Design, prototyping, and mass production form the backbone of Wuxi Lead Precision Machinery’s injection molding workflow, engineered for precision, repeatability, and zero-defect outcomes. Each phase is tightly controlled, integrating advanced simulation, metrology, and process validation to ensure that every metal component meets the highest standards of quality and performance.

The process begins with design engineering, where our team collaborates directly with clients to analyze part geometry, material selection, and functional requirements. Utilizing 3D CAD modeling and mold flow simulation software, we identify potential stress points, warpage risks, and cooling inefficiencies before tooling begins. This proactive approach minimizes downstream corrections and accelerates time-to-market. Design for manufacturability (DFM) reviews are conducted to optimize wall thickness, gate placement, and ejection systems, ensuring dimensional stability and surface integrity.

Prototyping follows design finalization, using high-precision CNC-machined molds or soft tooling to produce functional samples. These prototypes undergo rigorous testing, including first-article inspection (FAI), dimensional verification via coordinate measuring machines (CMM), and fit/function validation. Any deviations are addressed through iterative refinement, with full traceability maintained across all adjustments. This phase is critical for validating the design under real-world conditions and confirming that the part meets all technical and regulatory criteria.

Once prototype approval is secured, the project transitions into mass production. Our automated injection molding cells operate under strict process controls, with real-time monitoring of temperature, pressure, and cycle time. Each production run is supported by Statistical Process Control (SPC) and in-line inspection systems to detect anomalies instantly. We enforce zero-defect protocols through 100% visual inspection on critical features and random sampling per AQL standards. All tools are maintained on a preventive schedule to ensure longevity and consistency.

Our production environment is ISO 9001 and IATF 16949 certified, reflecting our commitment to quality across every operation. From raw material sourcing to final packaging, traceability is maintained through integrated ERP and MES systems, enabling full batch tracking and audit readiness.

The following table outlines key specifications and capabilities across our injection molding process:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Material Compatibility | Stainless steel, aluminum alloys, tool steels |

| Part Weight Range | 0.1 g – 500 g |

| Cycle Time | 15 – 120 seconds (depending on complexity) |

| Tooling Lifespan | 100,000 – 1,000,000 cycles |

| Surface Finish Options | Mirror polish, texture, bead blast, coating |

| Production Capacity | Up to 5 million parts per month |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAI, SPC compliance |

Through seamless integration of design insight, prototyping agility, and scalable production, Wuxi Lead Precision Machinery delivers injection molded metal components with uncompromising quality—ensuring every part is right the first time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Manufacturing Excellence

In high-stakes industrial applications, component failure is not an option. Your project demands precision-engineered metal parts that withstand extreme environments, rigorous cycles, and exacting performance criteria. Generic suppliers often compromise on material integrity, dimensional accuracy, or process control—introducing risk where reliability is non-negotiable. At Wuxi Lead Precision Machinery, we eliminate this risk through vertically integrated metal manufacturing engineered for mission-critical success.

We specialize in transforming complex metal part designs into certified production reality. Our CNC machining, multi-axis milling, and precision turning capabilities handle challenging alloys—from aerospace-grade titanium and Inconel to medical stainless steel and hardened tool steels—with tolerances down to ±0.002 mm. Unlike injection molding services focused on plastics, we address the unique thermal, structural, and fatigue requirements of metal components. Every process is monitored via real-time SPC (Statistical Process Control), ensuring batch-to-batch consistency and full traceability from raw material certification to final inspection. This disciplined approach prevents costly field failures and secures your supply chain continuity.

Technical Capabilities at a Glance

| Capability | Range | Tolerance | Materials Supported |

|---|---|---|---|

| CNC Milling | Up to Ø1,200 mm | ±0.002 mm | Titanium, Inconel, Stainless Steel, Aluminum, Brass |

| CNC Turning | Ø3–350 mm | ±0.0015 mm | Tool Steels, Copper Alloys, Exotic Metals |

| 5-Axis Machining | Work Envelope 800x600x500 | ±0.003 mm | All aerospace/medical grades |

| Secondary Operations | Deburring, Anodizing, Passivation | N/A | Certified to ASTM, AMS, ISO standards |

Your project requires more than a vendor—it demands a technical partner who anticipates challenges before they reach your assembly line. Our engineering team collaborates from initial design review through production ramp-up, identifying manufacturability improvements that reduce lead times by 22% on average while enhancing part longevity. We validate every process with first-article inspections (FAI) per AS9102 standards and provide full 3D metrology reports, ensuring seamless integration into your quality management system.

Stop accepting trade-offs between speed, precision, and scalability. Wuxi Lead Precision Machinery delivers all three through dedicated production cells, in-house tooling expertise, and a zero-defect culture rooted in Six Sigma methodology. We serve global leaders in aerospace, energy, and medical device manufacturing because we understand that in metal fabrication, millimeters determine mission success.

Initiate Your Precision Manufacturing Partnership Today

Contact our engineering team directly to discuss your metal component requirements. Submit your CAD files and specifications to [email protected] for a detailed technical assessment and competitive quote within 24 business hours. Let us demonstrate how our process rigor becomes your competitive advantage. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.