Technical Contents

Engineering Guide: Robot Components

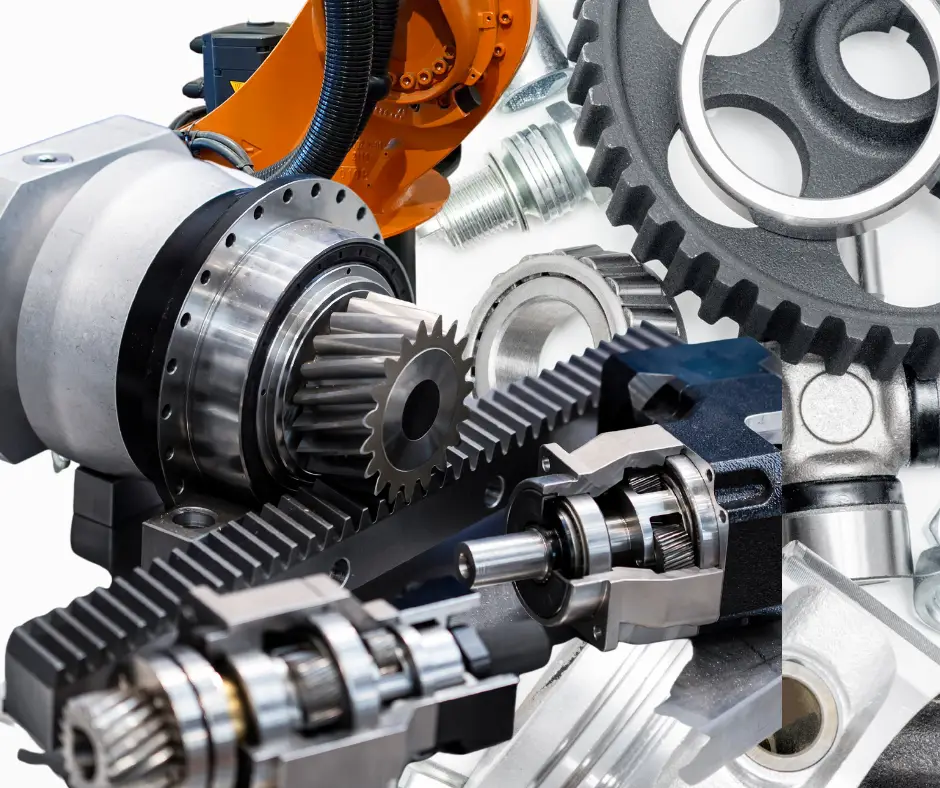

Engineering Insight: The Critical Role of Precision in Robot Components

In the realm of advanced automation and robotics, precision is not merely a performance metric—it is the foundation upon which reliability, repeatability, and operational longevity are built. Robot components, particularly those used in industrial arms, servo systems, and motion control units, demand micron-level accuracy to ensure seamless integration and optimal function. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in a gear housing, shaft bore, or mounting flange can cascade into system inefficiencies, accelerated wear, or catastrophic failure under high-cycle operations.

Our engineering philosophy centers on the principle that precision manufacturing begins with material integrity and extends through every stage of machining, inspection, and finishing. Utilizing state-of-the-art CNC milling, turning, and grinding technologies, we produce components that meet or exceed international tolerance standards. This commitment is reinforced by our ISO-certified quality control systems, including CMM (Coordinate Measuring Machine) verification and 100% in-process inspection for critical dimensions.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in high-precision metal manufacturing for mission-critical applications. Our track record includes supplying components for defense-grade robotic systems and automated machinery used in Olympic-standard training and competition equipment. These projects demanded not only extreme dimensional accuracy but also exceptional material consistency and surface finish—requirements that mirror the demands of today’s advanced robotics sector.

For instance, robotic joint housings must maintain concentricity within ±0.005 mm to prevent binding and ensure smooth torque transmission. Similarly, harmonic drive output cups require precise wall thickness control to avoid deformation under load. Our ability to consistently achieve such tolerances stems from a combination of advanced tooling strategies, thermal compensation systems in our machining centers, and a deep understanding of material behavior under stress.

We work primarily with aerospace-grade aluminum alloys, stainless steels, and hardened tool steels, tailoring material selection and heat treatment processes to the operational environment of the robot—whether it’s a cleanroom assembly arm or a heavy-duty material handling unit.

The following table outlines typical precision specifications we achieve for key robot components:

| Component Type | Material Options | Tolerance (Linear) | Geometric Tolerance | Surface Finish (Ra) | Production Process |

|---|---|---|---|---|---|

| Robotic Joint Housings | 7075-T6, 6061-T6 Aluminum | ±0.01 mm | ±0.005 mm (Concentricity) | 0.8–1.6 μm | 5-Axis CNC Milling |

| Motor Mounting Flanges | 304, 316 Stainless Steel | ±0.015 mm | ±0.01 mm (Flatness) | 1.6 μm | CNC Turning + Milling |

| Gearbox Carriers | 4140 Steel, Hardened | ±0.008 mm | ±0.005 mm (Parallelism) | 0.4–0.8 μm | Precision Grinding + Milling |

| Harmonic Drive Cups | 17-4PH Stainless Steel | ±0.005 mm | ±0.003 mm (Roundness) | 0.4 μm | Swiss Machining + CMM Inspection |

Precision in robot components is not an optional upgrade—it is a necessity. At Wuxi Lead Precision Machinery, we combine technical expertise, advanced manufacturing capabilities, and a legacy of excellence in high-stakes applications to deliver components that empower the next generation of robotic systems.

Precision Specs & Tolerances

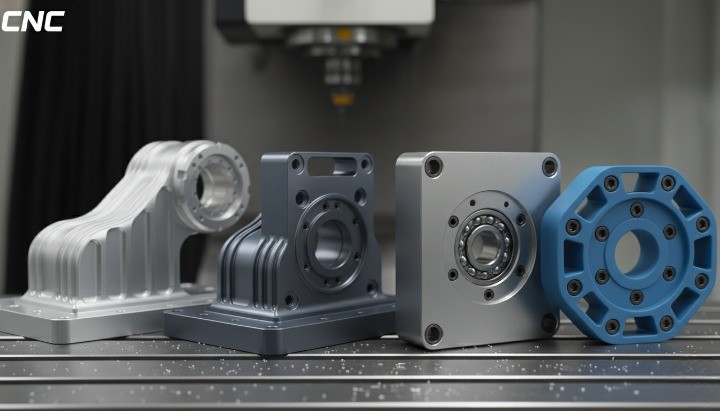

Technical Capabilities for Precision Robot Component Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components for advanced robotics through integrated high-precision manufacturing and rigorous quality assurance. Our expertise centers on producing complex structural and functional elements—such as harmonic drive housings, servo motor mounts, and articulated arm joints—where dimensional stability directly impacts robotic repeatability, lifespan, and performance under dynamic loads.

Our core capability leverages a dedicated fleet of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms, operating under strict thermal and vibration control protocols. Simultaneous 5-axis machining eliminates secondary operations, ensuring geometric integrity for intricate contours like internal gear profiles, asymmetric bearing seats, and integrated cooling channels. This approach maintains critical relationships between datums—such as the coaxial alignment of motor shaft bores within housing assemblies—to within micron-level deviations. Material versatility spans aerospace-grade aluminum alloys (7075-T6), stainless steels (17-4 PH), and wear-resistant tool steels, all processed with optimized cutting strategies to prevent microstructural distortion.

Quality control is non-negotiable in robotic applications where cumulative tolerance stack-up causes system failure. Every component undergoes 100% inspection via Zeiss CONTURA CMM systems, programmed to validate full GD&T callouts against native CAD models. Our inspection protocols extend beyond linear dimensions to verify form accuracy—cylindricity of bearing journals, flatness of mating surfaces, and profile tolerances on cam geometries—using automated scanning routines that generate AS9102-compliant first-article reports. Statistical process control (SPC) data is tracked per batch, ensuring capability indices (Cp/Cpk ≥ 1.67) for high-volume production runs.

The following table details achievable tolerances for robotic component features, validated across production lots:

| Feature Category | Standard Tolerance | Tight Tolerance | Typical Robotic Application |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Motor housing bore diameters |

| Geometric (Flatness) | 0.015 mm | 0.008 mm | Encoder mounting surfaces |

| Geometric (Cylindricity) | 0.012 mm | 0.006 mm | Harmonic drive wave generator bores |

| Positional (Hole to Hole) | ±0.015 mm | ±0.007 mm | Bolt circle patterns for joint modules |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Sealing surfaces for hydraulic actuators |

Wuxi Lead’s process discipline ensures these tolerances are sustained across volumes—from prototype to serial production—through closed-loop tool compensation, in-process probing, and material-specific aging protocols. We partner with robotics OEMs during design-for-manufacturability (DFM) reviews to preempt assembly conflicts, reducing field failure risks while accelerating time-to-market. For components demanding uncompromised precision in robotic kinematic chains, our integrated technical framework delivers certified reliability at scale.

Material & Finish Options

Material Selection for High-Performance Robot Components

Selecting the appropriate material and finish is critical in the development of precision robot components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for advanced automation systems, where performance, weight, durability, and environmental resistance directly impact system efficiency and longevity. The three primary materials used in robotic applications—aluminum, steel, and titanium—each offer distinct mechanical and thermal properties suited to specific operational demands.

Aluminum is widely favored in robotics for its excellent strength-to-weight ratio and machinability. Grades such as 6061-T6 and 7075-T6 are commonly used in structural frames, joints, and housings where minimizing inertia without sacrificing rigidity is essential. Its natural corrosion resistance, combined with the ability to accept protective surface treatments like anodizing, makes aluminum ideal for cleanroom environments and applications requiring repeated sterilization or exposure to mild chemicals.

Steel, particularly alloy and stainless variants like 4140 and 304/316 stainless, provides superior tensile strength and wear resistance. It is typically selected for high-load components such as gears, shafts, and mounting brackets subjected to continuous stress or impact. While heavier than aluminum, steel’s dimensional stability under load and excellent fatigue resistance ensure long-term reliability in demanding industrial settings. Stainless steel variants also offer enhanced corrosion resistance, making them suitable for food processing, medical robotics, and outdoor applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density performance and outstanding resistance to extreme temperatures and corrosive environments. Though more costly and challenging to machine, titanium is often used in aerospace robotics, surgical robots, and deep-sea applications where weight savings and material integrity under stress are paramount. Its biocompatibility further extends its utility in medical device manufacturing.

Surface finishing plays a pivotal role in enhancing both performance and lifespan. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is a widely used electrochemical process for aluminum components. It increases surface hardness, improves wear and corrosion resistance, and allows for color coding for assembly or branding. Hard anodizing (Type III) can achieve coating thicknesses of 25–50 µm with hardness values exceeding 60 HRC, making it suitable for sliding or bearing-contact surfaces.

Below is a comparative overview of key material properties and anodizing specifications:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Max Anodizing Thickness (µm) | Hardness (Vickers) |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Frames, enclosures, joints | 25 (Type II), 50 (Type III) | 15–20 (base), 400+ (anodized) |

| Steel 4140 | 950 | 7.85 | Shafts, gears, high-load parts | Not applicable | 200–300 |

| Stainless 304 | 580 | 8.0 | Medical, food-grade robotics | Not applicable | 150–200 |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aerospace, surgical robots | Not applicable | 350 |

At Wuxi Lead, we work closely with engineering teams to match material and finish specifications to application requirements, ensuring optimal performance, cost efficiency, and manufacturability across high-mix, low-to-medium volume production runs.

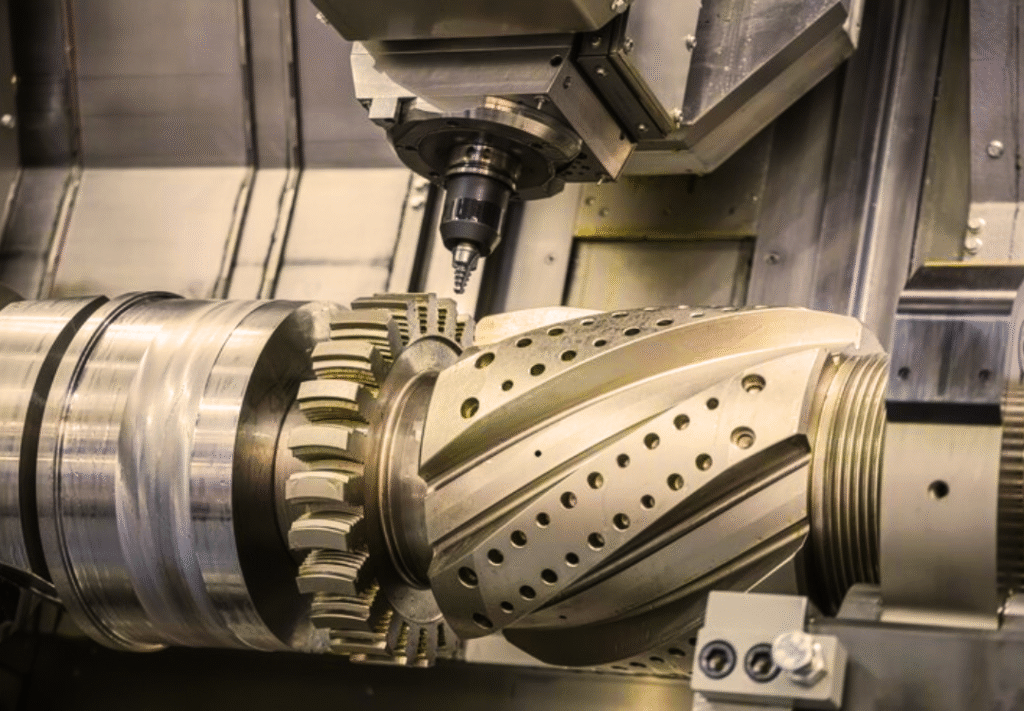

Manufacturing Process & QC

Precision-Driven Robot Component Manufacturing: From Concept to Zero Defects Production

At Wuxi Lead Precision Machinery, our production process for critical robot components is engineered for uncompromising quality and reliability, ensuring seamless integration into demanding automation systems. We strictly adhere to a three-phase methodology—Design, Prototyping, and Mass Production—each stage rigorously controlled to achieve the ultimate objective: Zero Defects. This systematic approach mitigates risk, accelerates time-to-market, and guarantees components that meet exacting robotic performance standards.

The foundation is our collaborative Design phase. Our engineering team works directly with clients to review CAD models, perform comprehensive Design for Manufacturability (DFM) analysis, and optimize geometries for CNC machining efficiency and structural integrity. We focus on material selection (including aerospace-grade aluminum, stainless steel, and titanium alloys), critical tolerance allocation, and surface finish requirements essential for robotic joint precision and longevity. Early identification of potential manufacturability issues prevents costly downstream errors, setting the stage for defect prevention from the outset. This phase culminates in finalized, production-ready digital models and a detailed quality control plan.

Prototyping transforms the validated design into physical reality for rigorous validation. Utilizing our high-precision 5-axis CNC machining centers and wire EDM capabilities, we produce functional prototypes matching final production intent. These prototypes undergo exhaustive metrology using CMMs, optical comparators, and surface roughness testers against the agreed specifications. Crucially, prototypes are subjected to simulated operational stresses and functional testing within representative robotic assemblies. Client feedback on fit, function, and performance is integrated iteratively. This phase is not merely about making a part; it is about proving the manufacturability and performance envelope, eliminating design flaws before committing to volume production.

Mass Production leverages the validated process for flawless execution. We deploy Statistical Process Control (SPC) methodologies with real-time monitoring of critical parameters like tool wear, thermal drift, and dimensional outputs. Every component undergoes 100% in-process inspection at defined checkpoints using automated vision systems and precision gaging, coupled with rigorous final inspection against the master specification. Our integrated quality management system, certified to ISO 9001:2015, ensures traceability from raw material lot to finished component. The result is consistent, high-yield production where deviations are detected and corrected instantly, guaranteeing Zero Defects delivery for your robotic assembly lines.

The following table summarizes our core production capabilities for robot components:

| Process Stage | Key Parameters | Tolerance Capability | Volume Range |

|---|---|---|---|

| Design & DFM | Material Optimization, GD&T Analysis | N/A | N/A |

| Precision Prototyping | 5-Axis CNC, Wire EDM, Metrology | ±0.002 mm (critical features) | 1 – 50 units |

| High-Volume Production | SPC-Controlled Machining, Automated Inspection | ±0.005 mm (standard), ±0.001 mm (micro) | 100 – 100,000+ units |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Robot Component Manufacturing

At Wuxi Lead Precision Machinery, we understand that robot components demand more than just metal and machining—they require precision, reliability, and a deep understanding of automation dynamics. As a leading custom metal manufacturing partner based in China, we specialize in delivering high-performance components engineered specifically for robotic systems, from articulated arms and joint housings to servo motor mounts and precision gears. Our mission is to empower robotics OEMs and integrators with components that meet the exacting standards of modern automation.

When you partner with Lead Precision, you gain access to a vertically integrated manufacturing ecosystem backed by over 15 years of experience in CNC machining, sheet metal fabrication, and precision assembly. Our facility is equipped with state-of-the-art 5-axis CNC machines, Swiss-type lathes, and automated inspection systems, enabling us to produce complex geometries with tolerances as tight as ±0.005 mm. Every component is manufactured under strict ISO 9001:2015 quality protocols, ensuring repeatability, durability, and seamless integration into your robotic platforms.

We work closely with engineering teams from concept to production, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production runs. Whether you require low-volume custom builds or high-volume series production, our agile manufacturing model ensures fast turnaround times without compromising quality. Our expertise spans a wide range of materials, including aerospace-grade aluminum alloys, stainless steel, titanium, and specialty composites—each selected and processed to meet the mechanical, thermal, and environmental demands of robotic applications.

Our clients trust us not only for our technical capabilities but also for our commitment to transparency and collaboration. We provide full production traceability, real-time project updates, and direct engineering support throughout the manufacturing lifecycle. As your strategic partner, we align with your innovation roadmap, enabling faster time-to-market and reduced total cost of ownership.

Below are key technical specifications that define our manufacturing capabilities for robot components:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Maximum Part Size | 1200 x 800 x 600 mm |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Carbon Steel |

| Surface Finishes | Anodizing (Type II & III), Passivation, Powder Coating, Polishing, Sandblasting |

| Secondary Operations | Welding, Heat Treatment, Insert Installation, Precision Assembly |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

| Lead Times | Prototypes: 7–10 days; Production: 15–25 days (varies by volume) |

Partnering with Wuxi Lead Precision Machinery means choosing a manufacturer that treats your robotic innovation as our own. We are committed to delivering components that perform under the most demanding conditions, helping you build smarter, faster, and more reliable robots.

Contact us today at [email protected] to discuss your next robot component project. Let’s engineer the future of automation—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.