Technical Contents

Engineering Guide: Thermoplastic Moulding

Engineering Insight: Precision as the Non-Negotiable Foundation in Thermoplastic Moulding

Thermoplastic moulding transcends simple material shaping; it is a high-stakes interplay of physics, material science, and micron-level engineering control. The ultimate performance, longevity, and functionality of the finished component are irrevocably determined by the precision achieved during the moulding process. Minute deviations in cavity dimensions, thermal distribution, or pressure application propagate through the part, manifesting as warpage, sink marks, inconsistent mechanical properties, or assembly failures. In critical applications—medical devices, aerospace components, or high-performance automotive systems—such deviations are not merely cosmetic flaws but potential points of catastrophic system failure. Precision moulding is therefore not an optional specification; it is the fundamental engineering prerequisite for thermoplastic parts operating under stringent functional demands. Achieving this demands tooling manufactured to exacting standards far beyond nominal requirements, where the metal mould itself becomes the primary vector for dimensional and structural integrity transfer.

The engineering challenge lies in mastering complex thermal dynamics and material behavior under extreme conditions. Thermoplastics exhibit significant volumetric shrinkage upon cooling, non-linear flow characteristics, and sensitivity to shear rates and cooling gradients. Compensating for these factors requires predictive simulation validated by empirical data and executed via tooling with exceptional thermal management capabilities and geometric fidelity. Surface finish replication, critical for optical clarity or biocompatibility, hinges on the mirror-like perfection of the mould cavity steel and its ability to maintain temperature uniformity. Warpage control demands symmetrical cooling channels machined to micron tolerances and cavity geometries incorporating precise shrinkage allowances derived from material-specific databases. This level of control is impossible without CNC-machined tooling possessing sub-5μm positional accuracy and surface finishes measured in nanometers.

Our critical precision parameters consistently achieved in production tooling are non-negotiable:

| Critical Parameter | Industry Standard | Wuxi Lead Precision Capability | Impact on Final Part |

|---|---|---|---|

| Dimensional Tolerance (Cavity) | ±0.05 mm | ±0.005 mm | Ensures perfect assembly fit & function |

| Surface Roughness (Cavity) | Ra 0.8 μm | Ra 0.02 μm | Enables optical clarity & reduces friction |

| Warpage Control (Flatness) | 0.5 mm/m | 0.05 mm/m | Guarantees structural integrity & sealing |

| Thermal Channel Position | ±0.10 mm | ±0.02 mm | Eliminates sink & ensures uniform cooling |

| Parting Line Match | 0.05 mm step | < 0.01 mm step | Prevents flash & maintains aesthetics |

This relentless focus on precision engineering is validated through our execution of projects where failure is not an option. Wuxi Lead Precision Machinery has delivered mission-critical mould tooling for components integrated into Beijing Winter Olympics infrastructure, demanding absolute reliability under extreme environmental stress. Similarly, our adherence to military-grade specifications for defence applications underscores our capability to meet the most rigorous dimensional, material, and traceability requirements. These projects are not exceptions; they exemplify our standard operating philosophy. When thermoplastic parts must perform flawlessly in life-critical or high-value systems, the precision engineered into the metal mould by Wuxi Lead is the indispensable foundation upon which all subsequent performance rests. We engineer certainty at the micron level.

Precision Specs & Tolerances

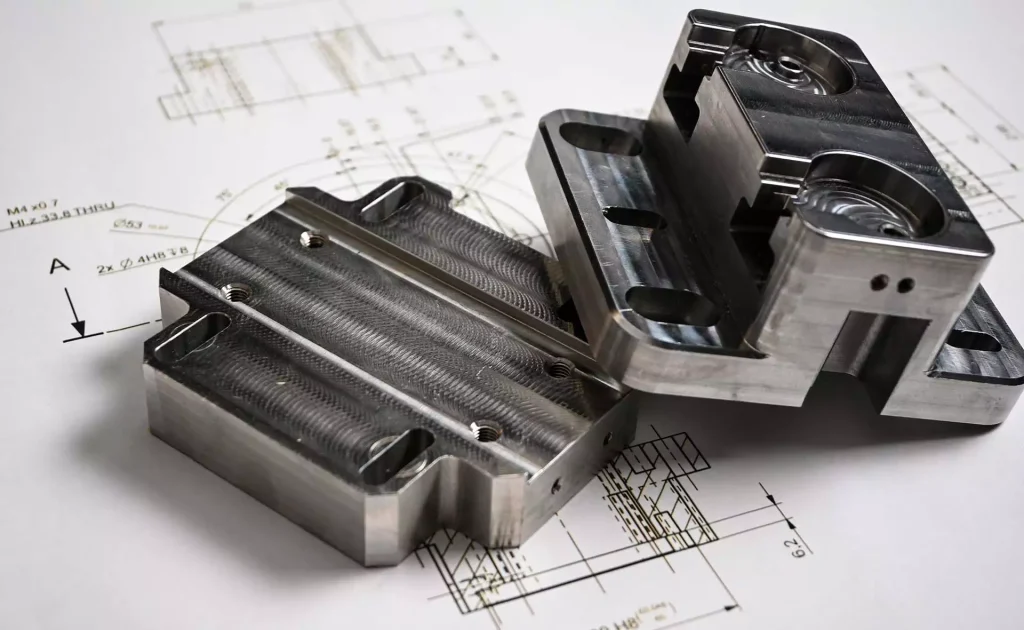

Wuxi Lead Precision Machinery delivers advanced thermoplastic moulding solutions through precision engineering and state-of-the-art metal manufacturing technologies. Our technical capabilities are built around high-performance 5-axis CNC machining centers, enabling us to produce complex, tight-tolerance mould components with exceptional surface finish and dimensional accuracy. These multi-axis systems allow simultaneous machining from five sides of a workpiece, reducing setup times and ensuring superior part consistency—critical for thermoplastic moulds that demand intricate geometries and long service life under repeated thermal cycling.

All mould components are manufactured in-house using premium-grade tool steels and high-thermal-conductivity alloys, selected based on the specific thermoplastic material and production volume requirements. Our machining processes are supported by integrated CAD/CAM systems that ensure seamless translation from design intent to physical part, with real-time toolpath optimization for maximum precision and efficiency. This digital workflow enables rapid prototyping and fast iteration, supporting clients in accelerating time to market.

Quality assurance is central to our manufacturing philosophy. Every component undergoes rigorous inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM system provides micron-level verification of critical dimensions, geometric tolerances, and surface profiles, with full inspection reports generated for every production batch. In addition to dimensional accuracy, we perform thermal conductivity testing and hardness validation to ensure the mould materials meet the required performance criteria under operational conditions.

Our technical expertise extends beyond machining to include electrode fabrication for EDM processes, fine finishing with mirror polishing, and assembly validation under simulated production conditions. This holistic approach ensures that every thermoplastic mould we deliver is not only dimensionally precise but also functionally optimized for high-cycle, high-reliability applications across industries such as medical devices, automotive, and consumer electronics.

The table below outlines the standard tolerance capabilities we achieve across key machining parameters:

| Parameter | Typical Tolerance | Maximum Capability |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm |

| Geometric Tolerances (GD&T) | ±0.01 mm | ±0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Accuracy | ±0.05° | ±0.02° |

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

These specifications reflect our commitment to delivering mould components that meet the most demanding technical requirements. By combining 5-axis CNC precision, advanced metrology, and a disciplined quality management system, Wuxi Lead Precision Machinery ensures that every custom metal part supports high-efficiency, high-integrity thermoplastic moulding operations.

Material & Finish Options

Material Selection for Thermoplastic Moulding: Performance-Driven Choices

Selecting the optimal material for thermoplastic injection moulds is critical for balancing production efficiency, part quality, tool longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your specific polymer, volume requirements, and geometric complexity. Aluminum, steel, and titanium each offer distinct advantages and limitations in high-precision mould construction.

Aluminum alloys, particularly 6061-T6 and 7075-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity significantly reduces cycle times compared to steel, accelerating time-to-market. Aluminum is also easier and faster to machine, lowering initial tooling costs. However, its lower hardness and wear resistance limit its use with abrasive-filled polymers or for very high cavity counts exceeding 100,000 shots. Surface treatments become essential for extended life.

Tool steels remain the industry standard for high-volume production. P20 pre-hardened steel offers a robust balance of machinability, moderate hardness (28-32 HRC), and cost-effectiveness for many commodity plastics. For demanding applications involving high temperatures, abrasive materials, or volumes exceeding 500,000 shots, H13 hardened tool steel (48-52 HRC) is indispensable. Its exceptional resistance to thermal fatigue, wear, and deformation under high cavity pressure ensures consistent part quality and maximizes mould life, justifying the higher initial machining cost and lead time.

Titanium alloys, while possessing remarkable strength-to-weight ratio and corrosion resistance, see extremely limited application in standard thermoplastic moulds due to prohibitively high material and machining costs, coupled with lower thermal conductivity than aluminum. Its niche use is typically confined to specialized, non-core components in highly corrosive environments, not mainstream cavity and core fabrication.

Surface finish, particularly anodizing for aluminum moulds, is not merely cosmetic. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 60-70 HRC equivalent), improving release properties, and providing excellent corrosion resistance without dimensional change. This treatment is crucial for aluminum moulds running abrasive materials or requiring extended service life, directly impacting part surface finish consistency and reducing maintenance downtime.

The following table provides key comparative specifications for common mould materials:

| Material | Hardness (HRC) | Thermal Conductivity (W/mK) | Typical Applications | Key Limitations |

|---|---|---|---|---|

| Aluminum 6061-T6 | 15-20 | 150-180 | Prototypes, low-volume production, large parts | Low wear resistance, limited shot count |

| P20 Tool Steel | 28-32 | 25-30 | Medium-volume production, standard polymers | Moderate wear resistance, thermal fatigue |

| H13 Tool Steel | 48-52 | 25-30 | High-volume production, abrasive/technical polymers | Higher cost, longer lead time, difficult machining |

| Titanium (Grade 5) | 30-36 (as machined) | 7-8 | Highly specialized corrosion applications | Very high cost, low thermal conductivity, niche use |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to match your thermoplastic application with the precise material and surface treatment solution. We rigorously evaluate polymer characteristics, expected volumes, and part tolerances to recommend the most cost-effective, durable mould substrate, ensuring your production meets stringent quality and efficiency targets from the first shot. Contact our engineering team for a tailored material assessment.

Manufacturing Process & QC

The thermoplastic moulding process at Wuxi Lead Precision Machinery is engineered for uncompromising precision, repeatability, and zero defects in custom metal manufacturing applications. Our end-to-end workflow integrates advanced design protocols, rigorous prototyping validation, and tightly controlled mass production cycles to ensure every component meets exacting international standards.

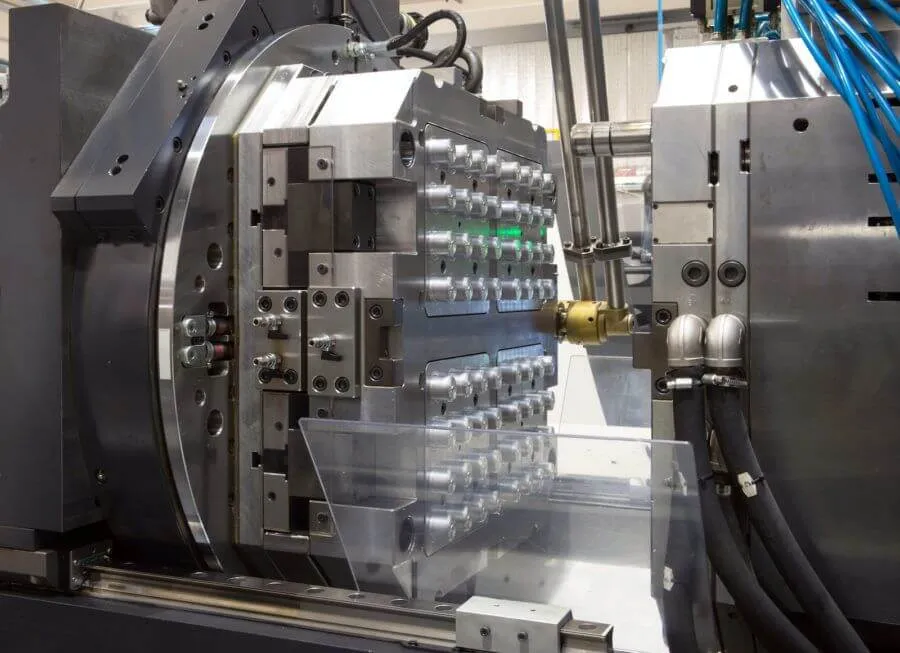

Design begins with a collaborative engineering phase, where our technical team works directly with client specifications to develop optimized 3D models and tooling layouts. Utilizing industry-leading CAD/CAM software and finite element analysis (FEA), we simulate material flow, thermal behavior, and structural integrity under operational conditions. This predictive modeling ensures that mould geometry, gate positioning, and cooling channels are precisely calibrated to prevent warpage, sink marks, or internal stresses in the final part. Design for manufacturability (DFM) reviews are conducted to balance performance, cost, and cycle time without sacrificing quality.

Prototyping follows with the construction of a high-precision pre-series mould, typically machined from hardened tool steel or aluminum depending on volume and tolerance requirements. This stage produces functional prototypes using the same thermoplastic materials intended for full-scale production—such as PEEK, ABS, polycarbonate, or nylon—allowing for accurate evaluation of fit, function, and aesthetics. Every prototype undergoes dimensional inspection via coordinate measuring machines (CMM), along with material and mechanical testing to validate compliance with specifications. Any deviations trigger immediate design or process adjustments, ensuring process stability before ramp-up.

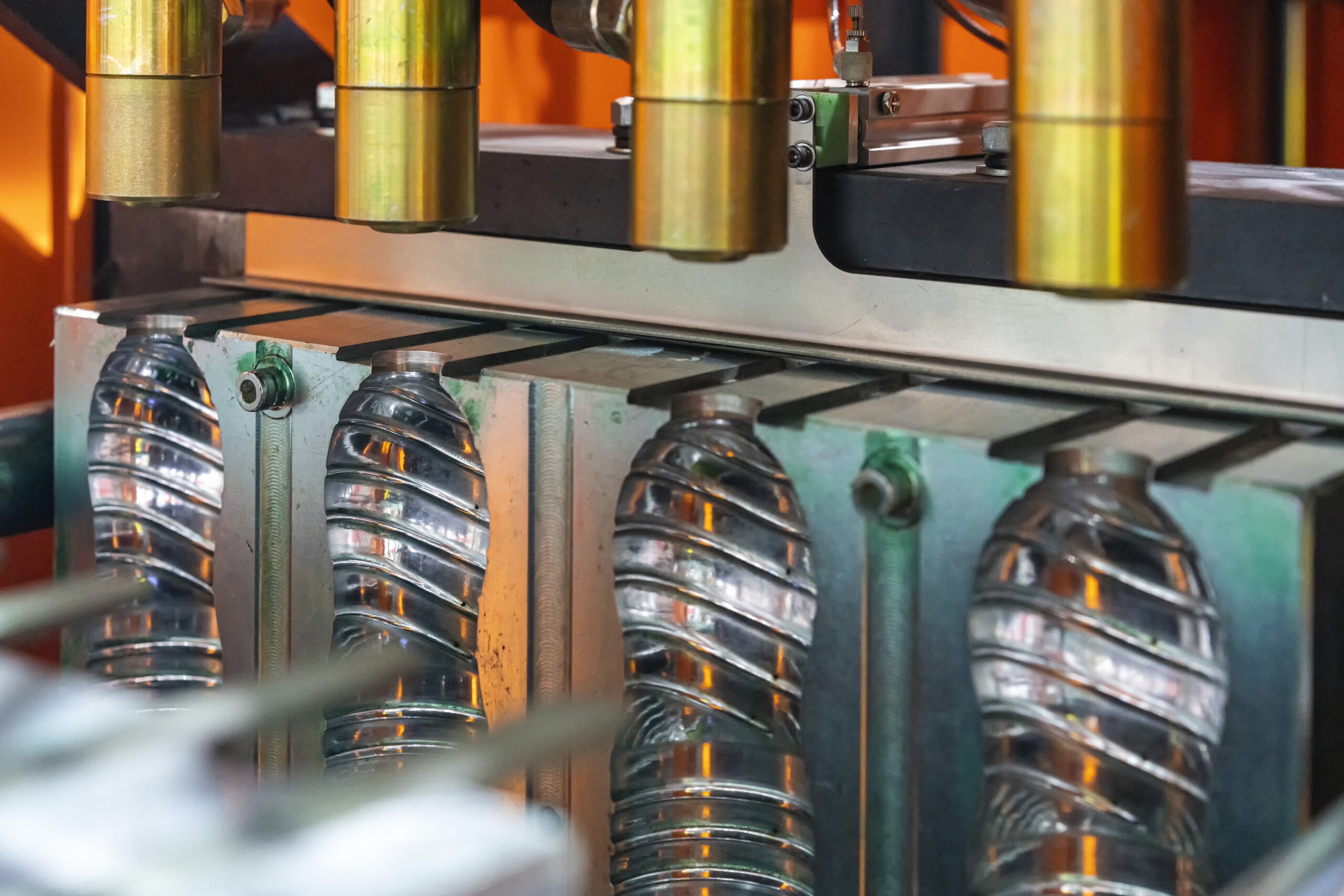

Mass production leverages fully automated, servo-driven injection moulding presses equipped with real-time monitoring systems. Each cycle is tracked for pressure, temperature, fill time, and clamp force, with data logged for full traceability. Our zero-defect philosophy is enforced through in-line vision inspection systems, statistical process control (SPC), and 100% automated defect detection. Parts are handled via robotic systems to minimize contamination and variability. All production batches are subjected to ongoing quality audits, including destructive and non-destructive testing, ensuring long-term consistency across runs of thousands or millions of units.

Wuxi Lead Precision Machinery maintains strict adherence to ISO 9001 and IATF 16949 standards throughout the entire process. Our facility in Wuxi, China, combines German-engineered equipment with Chinese manufacturing efficiency, delivering globally competitive lead times and cost structures without compromising on precision.

| Parameter | Specification |

|---|---|

| Material Compatibility | PEEK, ABS, PC, PP, PA (Nylon), POM, PMMA |

| Tolerance Range | ±0.02 mm to ±0.05 mm (depending on part size) |

| Mould Life | 500,000 – 1,000,000 cycles (hardened steel) |

| Injection Pressure | Up to 200 MPa |

| Clamping Force Range | 50–1600 Tons |

| Surface Finish Options | SPI A1, A2, B1, B2, VDI 3400, texture, polish |

| Production Cycle Monitoring | Real-time data logging with SPC integration |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

This systematic approach—from digital design to defect-free mass production—ensures that every thermoplastic component delivered by Wuxi Lead Precision Machinery meets the highest benchmarks in performance, reliability, and consistency.

Why Choose Wuxi Lead Precision

Engineering Excellence Delivered: Your Thermoplastic Moulding Partner

Thermoplastic moulding demands uncompromising precision in tooling to ensure part consistency, cycle efficiency, and material integrity. At Wuxi Lead Precision Machinery, we engineer custom metal solutions that directly address the high-stakes challenges of modern thermoplastic production. Our CNC-machined moulds, cores, and cavities are built for zero-defect output, minimizing scrap rates and maximizing uptime for global manufacturers. Unlike generic suppliers, we integrate deep material science expertise with micron-level machining tolerances, ensuring your tooling withstands aggressive production cycles while maintaining dimensional stability across thousands of shots.

Our commitment begins with collaborative engineering. We analyze your thermoplastic resin properties, part geometry, and production volume to select optimal steel grades and surface treatments. This prevents common failures like weld line weakness, sink marks, or premature wear. Every component undergoes rigorous metrology validation using Zeiss CMM systems, guaranteeing conformity to ISO 2768-mK standards before shipment. The result is tooling that delivers repeatable part quality from the first shot to the millionth, reducing your total cost of ownership through extended service life and reduced maintenance.

Critical performance specifications define our capability:

| Specification | Capability Range | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.005 mm | ±0.025 mm |

| Surface Finish (Ra) | 0.05–0.2 µm | 0.8 µm |

| Steel Hardness | HRC 52–58 (Pre-hardened) | HRC 48–52 |

| Lead Time (Prototype) | 15–25 days | 30–45 days |

| Max Mould Weight | 15,000 kg | 8,000 kg |

These metrics translate to tangible outcomes: reduced cycle times through optimized cooling channels, elimination of flash via precision cavity alignment, and compatibility with engineering-grade resins like PEEK and PEI. Our clients in automotive and medical device manufacturing achieve 99.2% first-pass yield rates, directly impacting their production throughput.

Partnering with Lead Precision means accessing a dedicated engineering team fluent in both Chinese manufacturing efficiency and global quality expectations. We manage complexities—from conformal cooling design to multi-cavity synchronization—so you avoid costly redesigns and delays. Recent projects include moulds for 500-tonne presses producing hermetic medical housings and lightweight automotive connectors, all validated by Tier-1 suppliers.

Do not let substandard tooling compromise your thermoplastic production. Contact our engineering team today to discuss your specific requirements. Email [email protected] with your part drawings or application details for a confidential capability assessment. Our specialists will respond within 12 business hours with a technical feasibility analysis and timeline. For urgent projects requiring rapid prototyping or production ramp support, include “Priority Project” in your subject line. Let Lead Precision become your strategic partner in achieving thermoplastic excellence—where precision engineering meets manufacturing certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.