Technical Contents

Engineering Guide: Plastic Material For Injection Molding

Engineering Insight: Plastic Material for Injection Molding – The Role of Precision in High-Performance Manufacturing

In the realm of custom metal manufacturing for advanced industrial applications, the selection and processing of plastic materials for injection molding are as critical as the metal components themselves. At Wuxi Lead Precision Machinery, we understand that the integrity of a final product—whether deployed in Olympic-grade equipment or military-grade systems—depends not only on the precision of metal fabrication but also on the exacting control applied during plastic injection processes. The marriage of high-performance polymers with precision-engineered molds defines the reliability, durability, and functionality of complex assemblies.

Injection molding is not merely a shaping process; it is a science of material behavior under tightly controlled thermal and mechanical conditions. Variations in temperature, pressure, or cycle time—even by fractions—can lead to warping, sink marks, or structural weaknesses in plastic components. For applications where failure is not an option, such as aerospace actuators or precision-guided defense systems, these deviations are unacceptable. Our engineering team leverages decades of experience in high-tolerance manufacturing to ensure that every plastic part meets exact dimensional, thermal, and mechanical specifications.

At Lead Precision, our expertise extends beyond metal to the full system integration, where plastic and metal components must function in perfect harmony. We apply the same rigorous standards used in our Olympic-project collaborations—where timing, weight, and repeatability are paramount—to every injection molding operation. Our military-grade projects have further refined our ability to work with advanced engineering plastics under extreme environmental conditions, ensuring long-term performance in high-stress scenarios.

Material selection is a foundational step in this precision-driven workflow. We routinely work with high-performance thermoplastics such as PEEK, PPS, and ULTEM, chosen for their thermal stability, chemical resistance, and mechanical strength. Each material is analyzed for flow characteristics, shrinkage rates, and compatibility with mating metal components to prevent differential expansion or stress concentration.

The table below outlines key engineering plastics commonly used in our injection molding processes, along with critical performance specifications:

| Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Shrinkage Rate (%) | Common Applications |

|---|---|---|---|---|

| PEEK | 90–100 | 143–160 | 0.1–0.3 | Aerospace, Medical, Defense |

| PPS | 65–80 | 108–115 | 0.4–0.6 | Electrical Insulators, Automotive Sensors |

| ULTEM (PEI) | 100–110 | 200–210 | 0.7–0.9 | High-Temp Fixtures, Military Electronics |

| Polycarbonate | 55–75 | 125–135 | 0.6–0.8 | Transparent Shields, Optical Components |

| Nylon 66 (GF Reinforced) | 120–150 | 210–230 | 0.2–0.5 | Gears, Structural Brackets |

Our facility integrates real-time monitoring systems and closed-loop process control to maintain consistency across production runs. Every parameter is logged and traceable, meeting the documentation standards required in defense and high-compliance sectors.

Precision in plastic injection molding is not an isolated step—it is a core engineering discipline. At Wuxi Lead Precision Machinery, we bring the same uncompromising standards to plastic components as we do to custom metal fabrication, ensuring system-level performance that meets the demands of the world’s most challenging applications.

Precision Specs & Tolerances

Technical Capabilities: Enabling Precision Plastic Injection Molding Through Advanced Metal Fabrication

Wuxi Lead Precision Machinery delivers critical metal components and tooling that form the foundation of high-performance plastic injection molding systems. Our expertise in custom metal manufacturing directly translates to superior plastic part quality, dimensional stability, and production efficiency for your molding operations. We understand that the precision of the mold, core pins, ejector systems, and hot runner components dictates the success of plastic part replication—especially for complex geometries and tight-tolerance applications. Our integrated approach ensures that every metal element we produce meets the exacting demands of modern injection molding processes, minimizing defects like flash, sink marks, and warpage.

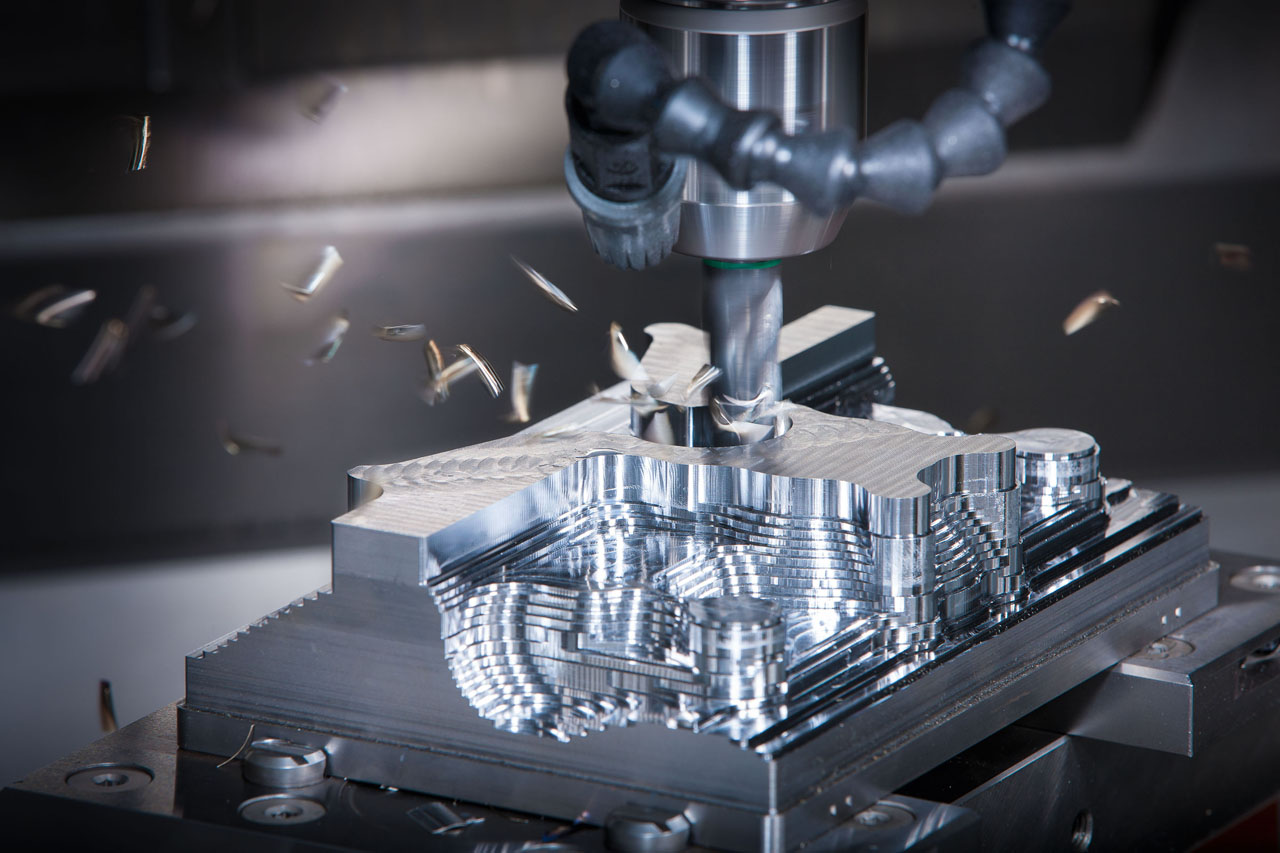

Central to our capability is a comprehensive suite of 5-axis CNC machining centers. These systems enable the production of highly intricate mold bases, cavities, and cores with exceptional geometric complexity and surface finish. Multi-axis simultaneous machining eliminates secondary operations, ensuring critical features maintain micron-level positional accuracy relative to one another. This capability is essential for producing molds that consistently replicate fine details in plastics such as PEEK, ULTEM, or medical-grade resins, where thermal stability and material flow dynamics are paramount. Our machining processes are optimized for tool steels (e.g., H13, S136), aluminum alloys, and hardened inserts, ensuring durability under high-cycle molding conditions.

Quality assurance is non-negotiable. Every component undergoes rigorous inspection using certified Coordinate Measuring Machines (CMM) with sub-micron resolution. Our CMM protocols verify critical dimensions, form tolerances, and geometric relationships against CAD models, providing full traceability and comprehensive inspection reports. This data-driven QC process guarantees that mold components meet specifications before assembly, reducing mold tryout time and preventing costly production delays. All inspections adhere to ISO 9001 standards, with calibration traceable to national standards.

The table below outlines our standard and tight tolerance capabilities for injection mold components. Note that achievable tolerances are influenced by part geometry, material selection, and molding process parameters. We collaborate closely with clients during design for manufacturability (DFM) reviews to optimize tolerances for both metal fabrication and plastic molding performance.

| Feature Type | Standard Tolerance | Tight Tolerance | Critical Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Applies to features < 100 mm; larger dimensions scaled per ISO 2768-mK |

| Hole Diameters | +0.01/-0.00 mm | +0.005/-0.00 mm | Includes core pins and bushings; straightness critical for wear resistance |

| Flatness | 0.01 mm | 0.005 mm | Verified across entire surface; critical for parting line sealing |

| Positional Accuracy | ±0.008 mm | ±0.003 mm | Between related features (e.g., ejector pin bores to cavity profile) |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | As-machined; polished finishes available per SPI standards |

Material behavior during plastic injection molding—particularly thermal expansion, shrinkage, and pressure-induced deflection—must be accounted for in metal component design. Our engineering team proactively factors these dynamics into tolerance specifications and GD&T callouts, ensuring the final mold performs as intended under real-world production conditions. By combining advanced 5-axis CNC fabrication with metrology-grade validation, Wuxi Lead Precision Machinery provides the metal foundation that turns demanding plastic injection molding concepts into repeatable, high-yield manufacturing realities.

Material & Finish Options

Material selection is a critical step in the development of high-performance molds for plastic injection molding. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision tooling, and our expertise ensures optimal material pairing based on production volume, part complexity, and required surface finish. The most commonly used materials in mold construction are aluminum, steel, and titanium, each offering distinct mechanical properties and performance characteristics.

Aluminum is favored for low- to medium-volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle time in injection molding. While not as durable as steel, modern aluminum alloys provide sufficient wear resistance for thousands of cycles, especially when used with engineering plastics. It is particularly suitable for prototyping and short-run manufacturing where time-to-market is a priority.

Steel remains the standard for high-volume production molds. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and longevity, capable of withstanding hundreds of thousands to millions of cycles. These steels can be heat-treated to enhance performance and are ideal for molding abrasive or high-temperature materials. The initial machining time is longer compared to aluminum, but the extended service life justifies the investment for large-scale production.

Titanium, while less common in mold bases, is increasingly used in specialized components such as ejector pins and wear plates due to its exceptional strength-to-density ratio and corrosion resistance. Its high cost limits widespread use, but in corrosive environments or where weight reduction is critical, titanium offers long-term reliability.

Surface finishing further enhances mold performance and part quality. Anodizing, particularly for aluminum molds, increases surface hardness and wear resistance while improving release properties. Hard anodizing (Type III) can produce a wear-resistant layer up to 50 µm thick, significantly extending mold life. For steel molds, alternatives such as chrome plating or nitriding are more typical, but anodizing remains a key finish when using aluminum substrates.

Below is a comparative overview of the key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 15–20 | 130 | 10,000 – 100,000 | Prototypes, low-volume runs | Yes |

| P20 Steel | 28–32 | 30 | 100,000 – 500,000 | Medium to high-volume molds | No |

| H13 Steel | 48–52 | 35 | 500,000 – 1,000,000+ | High-stress, high-temp molds | No |

| Titanium (Grade 5) | 35–40 (equivalent) | 7 | 500,000+ (components only) | Wear parts, corrosive environments | Limited |

Selecting the right material and finish directly impacts mold efficiency, maintenance frequency, and final part quality. At Wuxi Lead Precision Machinery, we work closely with clients to match material properties with project requirements, ensuring durable, high-precision tooling solutions.

Manufacturing Process & QC

Precision Plastic Injection Molding: The Zero-Defect Production Process

Achieving flawless plastic injection molded components demands an uncompromising, integrated production workflow. At Wuxi Lead Precision Machinery, our process rigorously bridges design intent to defect-free mass production, specifically addressing the unique thermal and flow characteristics of engineering plastics. This disciplined approach ensures dimensional stability, structural integrity, and consistent aesthetics, critical for high-performance applications across automotive, medical, and aerospace sectors.

The foundation is meticulous Design for Manufacturing (DFM) analysis. Our engineering team collaborates closely with clients during the initial CAD phase, scrutinizing part geometry, wall thickness transitions, gate locations, and draft angles. We simulate plastic melt flow, cooling rates, and potential warpage using advanced Moldflow software, identifying and resolving stress concentrations or sink marks before tooling begins. Material selection is validated against required mechanical properties, chemical resistance, and thermal stability, ensuring compatibility with both the part function and the injection process parameters. This proactive design phase eliminates fundamental flaws that cannot be corrected later.

Prototyping serves as the critical validation step, not merely a form check. Utilizing high-precision steel molds cut on our CNC machining centers, we produce functional prototypes under near-production conditions. Each prototype undergoes rigorous metrology against the original CAD model using CMMs and optical scanners, alongside material property verification and assembly testing. Crucially, we analyze the process window – determining optimal injection speed, pressure, temperature profiles, and cooling times that consistently yield parts within tolerance. Any deviations trigger immediate process or minor tooling adjustments, proving the manufacturability and zero-defect capability at scale.

Mass production leverages the validated process parameters within a tightly controlled environment. Our state-of-the-art all-electric and hybrid injection molding presses feature real-time cavity pressure monitoring and closed-loop control systems. Every shot is tracked against established SPC charts; deviations trigger automatic machine pauses before non-conforming parts are produced. Full traceability links each part to specific material batches, machine parameters, and operator logs. Continuous in-process inspection, including automated vision systems for critical features, combined with final first-article and periodic audits against the approved prototype, guarantees sustained zero-defect output. This systematic execution, rooted in precise design and proven prototyping, transforms complex plastic material requirements into reliable, high-yield manufacturing.

Critical Plastic Material Properties for Precision Molding

| Material | Typical Melt Temp (°C) | Shrinkage Range (%) | Key Applications | Critical Process Focus |

|---|---|---|---|---|

| POM (Acetal) | 190 – 230 | 1.8 – 2.5 | Gears, bearings, fasteners | Moisture control, precise cooling |

| PC (Polycarbonate) | 260 – 310 | 0.5 – 0.7 | Lenses, enclosures, medical devices | Drying, high injection pressure |

| PPA (Polyphthalamide) | 290 – 320 | 0.2 – 0.8 | Under-hood, electrical connectors | High mold temp, slow cooling |

| PPS (Polyphenylene Sulfide) | 300 – 330 | 0.2 – 0.6 | Pump components, sensor housings | High temp stability, venting |

| LCP (Liquid Crystal Polymer) | 280 – 350 | 0.1 – 0.3 | Miniature connectors, surgical tools | Fast cycle, precise temp control |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance custom metal manufacturing solutions tailored to the evolving demands of the injection molding industry. Our expertise extends beyond standard component production—we engineer precision-critical systems that enhance the efficiency, durability, and repeatability of plastic injection molding operations. As a trusted partner to global OEMs and Tier-1 suppliers, we integrate advanced CNC machining, material science, and process optimization to deliver components that meet the highest industrial standards.

Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis machining centers, automated inspection systems, and a dedicated R&D team focused on mold base development, hot runner systems, and precision ejector mechanisms. We understand that the performance of plastic materials under high pressure and temperature is directly influenced by the quality of the metal components in the mold. That’s why every product we manufacture adheres to tight tolerances (±0.002 mm), ensuring consistent part quality, reduced cycle times, and extended tool life.

We work closely with engineers and product designers to select optimal steel grades—such as P20, 718H, H13, and S136—based on the specific polymer being processed, production volume, and surface finish requirements. Whether your application involves engineering plastics like PEEK, polycarbonate, or high-flow polypropylene, our team ensures the mold material and design are perfectly matched to the injection process. This collaborative approach minimizes warpage, sink marks, and other defects, resulting in superior end-product consistency.

Our commitment to quality is validated through ISO 9001:2015 certification and rigorous in-house testing protocols, including hardness verification, dimensional metrology, and thermal cycling analysis. We support low-volume prototyping and high-volume production runs with equal precision, offering scalable manufacturing solutions that adapt to your project’s lifecycle.

Below are key specifications for our injection molding tooling components:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 µm (polishable to mirror finish) |

| Materials Available | P20, 718H, H13, S136, 2344, Stainless Steel (316L, 17-4PH) |

| Max Component Size | 1200 x 800 x 600 mm |

| Heat Treatment | Vacuum hardened, stress relieved, quenched as required |

| Lead Time | 15–25 days (varies by complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI) reports, CMM inspection |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic ally in precision manufacturing. We don’t just supply parts—we deliver engineered solutions that improve your production output and product quality. For expert consultation on optimizing your injection molding tooling with high-precision metal components, contact us today at [email protected]. Let us help you achieve unmatched performance in every cycle.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.