Technical Contents

Engineering Guide: Maple Mold Technologies

Engineering Insight Precision as the Non-Negotiable Foundation in Mold Manufacturing

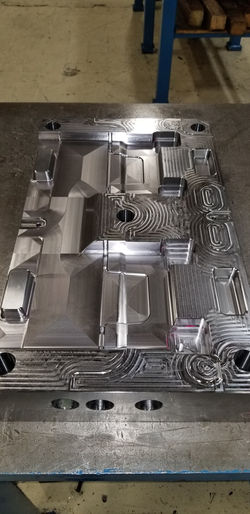

In the realm of custom metal manufacturing, particularly for high-integrity mold technologies, precision transcends mere specification; it is the absolute cornerstone of functional success and economic viability. Sub-micron deviations in critical mold cavities or cores cascade into catastrophic part failures, assembly defects, accelerated wear, and unacceptable scrap rates downstream. For industries demanding zero-failure performance—such as aerospace, medical device production, and advanced automotive systems—the mold itself must embody dimensional stability and surface perfection that consistently exceeds nominal requirements. This level of precision ensures not only the geometric accuracy of the final component but also guarantees repeatability across thousands of production cycles, directly impacting client yield rates, total cost of ownership, and brand reputation. Tolerances are not targets; they are non-negotiable commitments enforced through rigorous process control.

Wuxi Lead Precision Machinery operates at this uncompromising standard daily. Our engineering heritage is forged in projects where failure is not an option, directly shaping our approach to every mold technology challenge. We engineered critical structural components for Beijing Olympic venue infrastructure, where millimeter-level alignment across vast assemblies was paramount for safety and longevity. Simultaneously, we consistently deliver molds and precision components certified to stringent military aerospace specifications (AS9100, MIL-STD), where micron-level tolerances and material integrity are validated under extreme operational stresses. This dual-domain experience—marrying large-scale structural precision with micro-scale component accuracy—provides unparalleled insight into the systemic demands of mold performance. We understand that the mold is not an isolated tool but the kinetic heart of a production ecosystem; its precision dictates the entire value stream.

Our capability is systematically quantified through advanced metrology and process validation. The table below reflects the baseline precision thresholds we achieve and sustain for critical mold parameters, far exceeding typical industry norms:

| Parameter | Standard Industry Capability | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Tolerance (mm) | ±0.025 | ±0.005 |

| Geometric Tolerance (GD&T) | ±0.05 | ±0.01 |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Material Hardness Range | Up to 52 HRC | Up to 62 HRC |

| Critical Feature Repeatability | ±0.015 mm (Cpk 1.33) | ±0.003 mm (Cpk > 1.67) |

This performance is enabled by our integrated ecosystem: German and Japanese multi-axis CNC machining centers operating within temperature-stable environments, real-time in-process probing, and a dedicated CMM lab certified to ISO 17025. Every mold undergoes comprehensive validation against the client’s functional requirements, not just dimensional prints. For Maple Mold Technologies and partners demanding the ultimate in reliability, Wuxi Lead Precision Machinery delivers the engineered certainty that transforms precision from an objective into a guaranteed outcome. The cost of imprecision is measured in scrap, delays, and reputational damage; the investment in true precision yields immediate ROI through flawless production.

Precision Specs & Tolerances

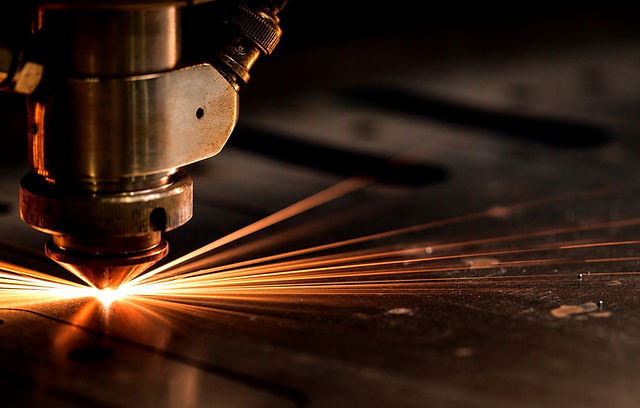

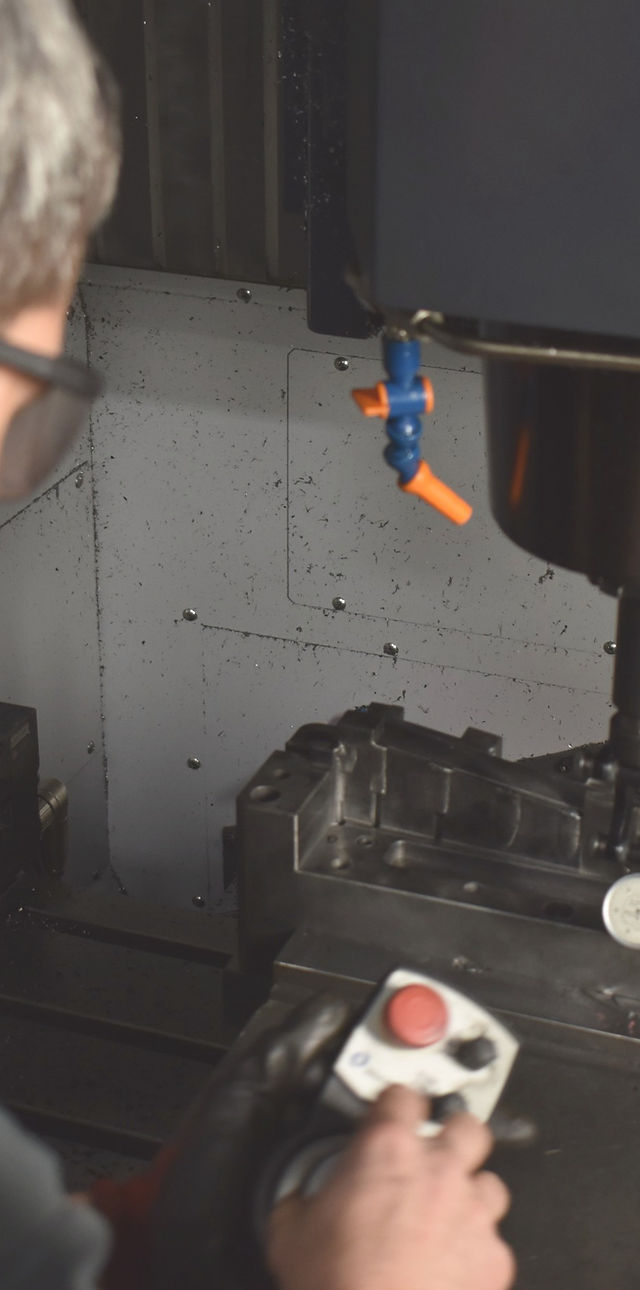

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, automotive, medical, and precision tooling. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with exceptional accuracy and surface finish. Our multi-axis machining centers eliminate the need for multiple setups, reducing cumulative error and significantly improving part consistency. These systems are operated by certified CNC programmers and machinists who utilize industry-leading CAM software to optimize toolpaths, minimize cycle times, and ensure material integrity across a broad range of metals, including titanium, Inconel, aluminum alloys, and hardened steels.

Precision is non-negotiable in high-end manufacturing, which is why every critical component undergoes comprehensive quality verification using state-of-the-art Coordinate Measuring Machine (CMM) inspection. Our metrology lab is equipped with multi-sensor CMM systems capable of full 3D geometric dimensioning and tolerancing (GD&T) analysis. All inspections are conducted under controlled environmental conditions to ensure measurement stability and repeatability. Data from CMM reports is fully traceable and provided with each production batch, supporting compliance with ISO 9001, AS9100, and other international quality standards.

Our manufacturing processes are designed to meet the tightest tolerance requirements demanded by advanced engineering applications. From prototype development to high-volume production runs, we maintain consistent dimensional control through continuous process monitoring and adaptive machining techniques. Material certifications, first-article inspection reports, and in-process quality checks are standard across all projects. This disciplined approach ensures that every component not only meets but exceeds customer expectations for fit, function, and reliability.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection systems:

| Feature | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers, Calipers |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | CMM (GD&T) |

| Angular Accuracy | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Geometric Tolerances (Flatness, Roundness, etc.) | 0.02 mm | 0.005 mm | CMM, Precision Blocks, Dial Indicators |

All tolerances are validated under repeatable conditions and supported by documented measurement uncertainty budgets. Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous quality assurance to deliver custom metal components that perform reliably in the most demanding environments. Our technical team works closely with design and engineering partners to review manufacturability, recommend material and process optimizations, and ensure seamless transition from CAD model to certified finished part.

Material & Finish Options

Material Selection for Precision Mold Manufacturing

Material selection fundamentally determines mold performance, longevity, and cost efficiency in high-precision manufacturing. At Wuxi Lead Precision Machinery, we prioritize matching material properties to specific application demands, balancing strength, thermal stability, machinability, and surface finish requirements. This guide outlines critical considerations for aluminum, steel, and titanium alloys, alongside essential anodizing processes for enhanced durability.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer exceptional machinability and thermal conductivity, making them ideal for prototype molds, low-volume production, and applications requiring rapid heat dissipation. 6061-T6 provides good corrosion resistance and weldability at moderate strength, while 7075-T6 delivers superior strength approaching some steels but with reduced ductility. Anodizing is highly recommended for aluminum molds, significantly improving surface hardness, wear resistance, and corrosion protection without dimensional change. Steel remains the dominant choice for high-volume production molds due to its unmatched hardness, wear resistance, and dimensional stability. Pre-hardened tool steels like P20 (1.2311) offer excellent machinability before final heat treatment, while H13 (1.2344) excels in demanding hot-runner and high-cavity-pressure applications requiring superior thermal fatigue resistance. Proper heat treatment and stress relief are non-negotiable for steel mold longevity. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are reserved for highly specialized applications in aerospace or medical molding where extreme corrosion resistance, high strength-to-weight ratio, and biocompatibility are critical, despite higher material and machining costs.

Anodizing transforms aluminum mold surfaces into a durable, non-conductive ceramic layer. Type II (Sulfuric Acid Anodizing) provides standard corrosion and mild wear resistance with color dyeing capability, suitable for less abrasive processes. Type III (Hardcoat Anodizing), per MIL-A-8625, creates a significantly thicker, harder layer (up to 125 µm) with superior abrasion resistance for molds handling glass-filled polymers or high-cycle production. Precise control of electrolyte concentration, temperature, and current density during anodizing is essential to achieve consistent, pore-free coatings that prevent part sticking and extend mold life.

The following table summarizes key properties for common mold materials:

| Material | Key Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Index | Typical Mold Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 (6061), 572 (7075) | 2.7 | Excellent (A90+) | Prototypes, low-volume, thermoforming |

| Tool Steel | P20, H13 | 1020 (P20), 1650 (H13) | 7.8 | Good (P20), Fair (H13) | High-volume injection, blow molding |

| Titanium | Grade 5 (Ti-6Al-4V) | 900 | 4.43 | Poor | Aerospace, medical, corrosive environments |

Selecting the optimal material requires analyzing cycle count, polymer type, part geometry, and surface finish requirements. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to advise on material suitability, implement precise heat treatment protocols, and apply controlled anodizing processes. We ensure your mold substrate and surface treatment work cohesively to maximize tool life, minimize downtime, and guarantee consistent part quality in the most demanding production environments. Partner with us to translate material science into manufacturing advantage.

Manufacturing Process & QC

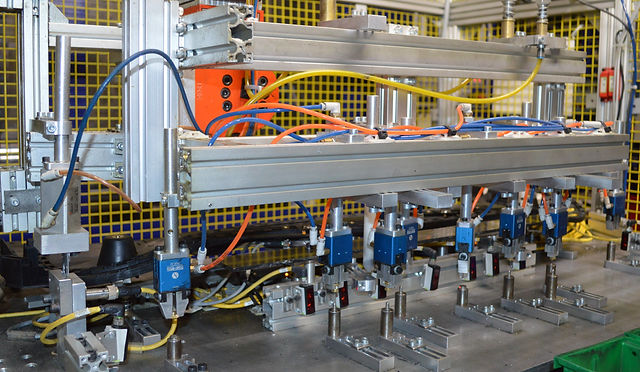

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes, aligning seamlessly with the high-performance demands of partners such as Maple Mold Technologies. Our methodology integrates three core phases—Design, Prototyping, and Mass Production—each governed by strict quality controls and advanced manufacturing protocols to ensure every component meets exacting international standards.

Design begins with a collaborative engineering review, where our technical team works closely with client specifications to optimize part geometry, material selection, and manufacturability. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate performance under operational conditions to preemptively resolve potential structural or thermal issues. This phase emphasizes precision in tolerancing, surface finish requirements, and assembly integration, laying the foundation for defect-free manufacturing.

Prototyping follows design finalization, serving as a physical validation step before full-scale production. We employ high-speed CNC machining, wire EDM, and selective laser melting (SLM) for rapid fabrication of functional prototypes using production-grade materials. Each prototype undergoes rigorous metrological inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy against the original CAD model. Functional testing, including fit checks, stress evaluation, and thermal cycling, ensures the prototype performs as intended. Feedback from this stage is incorporated iteratively, minimizing risk during mass production.

Mass Production leverages automated CNC machining cells, robotic part handling, and real-time process monitoring to maintain consistency across large volumes. Our facility in Wuxi operates under ISO 9001 and IATF 16949 certifications, enforcing standardized work instructions, first-article inspections, and in-process quality checks at defined intervals. Statistical process control (SPC) systems continuously analyze machining data to detect deviations before they impact output, enabling immediate corrective action. All finished components undergo 100% visual inspection and batch-based destructive testing to validate mechanical properties and material integrity.

Throughout the production lifecycle, traceability is maintained via a digital manufacturing execution system (MES), which logs tooling data, machine parameters, inspection results, and operator inputs for every part produced. This ensures full accountability and supports rapid root cause analysis if anomalies arise.

The following table outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.1 µm |

| Materials Supported | Aluminum Alloys, Stainless Steel, Tool Steel, Titanium, Copper Alloys |

| Max Workpiece Size | 1200 x 800 x 600 mm |

| Prototyping Lead Time | 7–10 days (including inspection) |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001, IATF 16949, 100% inspection |

By integrating precision engineering with closed-loop quality assurance, Wuxi Lead Precision Machinery delivers a zero-defect manufacturing process tailored to the advanced requirements of high-end industrial partners like Maple Mold Technologies.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Manufacturing Excellence

In the demanding landscape of precision mold manufacturing, your choice of metal component supplier directly impacts product performance, production efficiency, and time-to-market. Wuxi Lead Precision Machinery stands as your strategic partner for mission-critical custom metal parts, engineered to meet the exacting standards of high-end mold technologies. We specialize in transforming complex designs into reality with zero tolerance for dimensional deviation, ensuring seamless integration into your mold systems and eliminating costly assembly delays. Our ISO 9001-certified processes, combined with deep expertise in mold-specific materials like H13 tool steel, S7, and premium aluminum alloys, guarantee components that deliver thermal stability, wear resistance, and micron-level accuracy under extreme operating conditions.

Our integrated manufacturing ecosystem leverages advanced 5-axis milling, precision grinding, and wire EDM capabilities within a single facility. This vertical integration eliminates supply chain fragmentation, reduces lead times by up to 30%, and ensures rigorous in-process inspection at every stage. We understand that mold cores, cavities, inserts, and electrodes demand more than standard machining; they require metallurgical insight and process control honed through decades of collaboration with global mold innovators. Below are core capabilities engineered for your success:

| Specification | Capability Detail | Relevance to Mold Manufacturing |

|---|---|---|

| Tolerance Range | ±0.002 mm (±0.00008″) | Ensures perfect part mating and sealing |

| Max Work Envelope | 1,200 x 800 x 650 mm (47 x 31 x 26″) | Accommodates large mold bases and inserts |

| Surface Finish (Ra) | 0.1 µm (4 µin) achievable | Critical for optical-grade mold surfaces |

| Material Expertise | Tool steels, maraging steels, Inconel | Optimized for longevity in high-pressure cycles |

| In-Process Metrology | On-machine probing + CMM validation | Guarantees first-article compliance |

Beyond technical execution, we prioritize partnership agility. Our engineering team collaborates directly with your designers during DFM analysis to identify manufacturability optimizations early, preventing costly iterations. Real-time production tracking portals provide full visibility into order status, while dedicated account managers ensure responsive communication—no call centers, no generic emails. When your project faces urgent deadlines or complex revisions, our rapid prototyping cell delivers qualified parts in 72 hours without compromising quality.

The cost of component failure in mold manufacturing extends far beyond scrap rates; it cascades into production downtime, missed shipments, and reputational damage. Partnering with Lead Precision mitigates these risks through engineered reliability. We invest in your success by aligning our KPIs with your operational outcomes: on-time delivery, first-pass yield, and dimensional integrity across every batch.

Elevate your mold manufacturing capability with a partner who treats your precision requirements as non-negotiable. Contact our engineering team today at [email protected] to discuss your current project specifications. We will provide a detailed capability assessment and lead time proposal within 24 business hours—proving why global leaders in mold technology trust Lead Precision for their most challenging metal components. Your next breakthrough mold system starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.