Technical Contents

Engineering Guide: High-Precision Machining Services

Engineering Insight: The Strategic Imperative of High-Precision Machining

In advanced manufacturing, precision transcends mere specification; it defines functional integrity, safety, and lifecycle performance. High-precision machining services are the cornerstone of industries where microscopic deviations induce catastrophic failure—medical implants, aerospace propulsion, and semiconductor tooling demand tolerances measured in microns. At Wuxi Lead Precision Machinery, we engineer solutions where ±0.001mm is not an aspiration but a baseline requirement. This level of accuracy ensures dimensional stability under extreme thermal cycles, vibration, and load conditions, directly impacting product reliability and regulatory compliance. Without sub-micron repeatability, complex assemblies fail at the interface, eroding efficiency and escalating total cost of ownership.

Our process integrates multi-axis CNC technology with rigorous metrology protocols. Every component undergoes iterative validation using calibrated coordinate measuring machines (CMM) and laser interferometry, ensuring geometric integrity across all features. Material science expertise guides optimal parameter selection for challenging alloys like Inconel 718 and titanium Grade 5, mitigating thermal distortion during cutting. Real-time tool wear compensation and environmental controls maintain consistency batch after batch. This systematic approach transforms design intent into physical reality, where surface finishes of Ra 0.1μm and true positions within 0.002mm are consistently achieved.

Wuxi Lead Precision Machinery’s validation extends beyond commercial standards. We delivered critical components for the Beijing 2008 Olympic Stadium’s structural articulation systems, where thermal expansion tolerances dictated seismic resilience. Similarly, our aerospace division produces flight-critical actuation components for military platforms, adhering to AS9100D and NADCAP requirements. These projects demanded zero-defect delivery under stringent traceability protocols—proving our capability in mission-critical environments.

The following table outlines our core precision capabilities versus industry benchmarks:

| Parameter | Wuxi Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Tolerance Range | ±0.001mm to ±0.005mm | ±0.01mm to ±0.025mm |

| Surface Finish (Ra) | 0.1μm to 0.4μm | 0.8μm to 1.6μm |

| Positional Accuracy | ≤0.002mm over 300mm | ≤0.01mm over 300mm |

| Materials | Titanium, Inconel, Tool Steels, Composites | Aluminum, Mild Steel |

| Validation Method | 5-axis CMM, Laser Tracker, GD&T Analysis | 2D Measuring |

Precision engineering is a strategic investment, not a cost center. When components interface at microscopic levels, tolerances compound—exacting machining prevents assembly drift, reduces field failures, and extends operational life. Wuxi Lead Precision Machinery operates at the convergence of metrology science and production pragmatism. Our Olympic and defense heritage proves we deliver where precision is non-negotiable. Partner with us to transform your most demanding designs into reality, backed by 15 years of validated high-mix, low-volume expertise. The margin for error is zero; our commitment to accuracy ensures your success.

Precision Specs & Tolerances

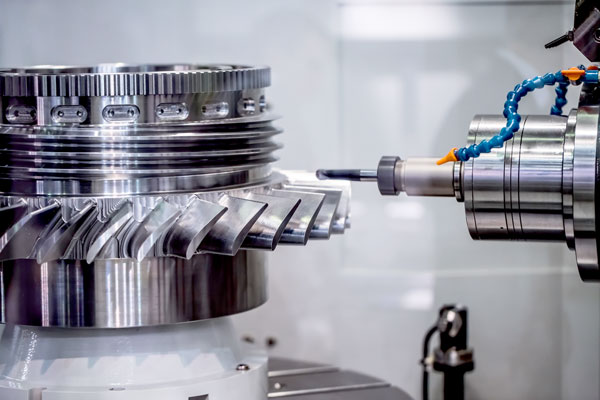

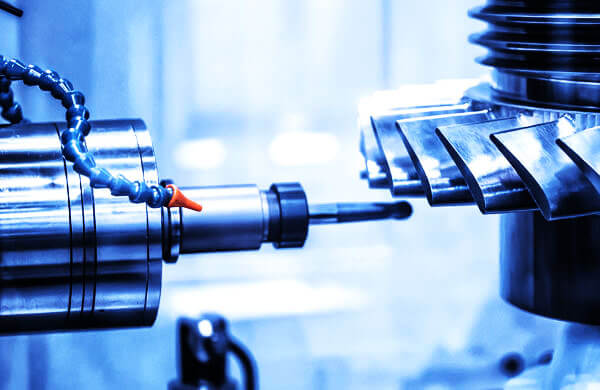

Advanced 5-Axis CNC Machining for Mission-Critical Components

Wuxi Lead Precision Machinery delivers high-precision machining services tailored to the most demanding industries, including aerospace, medical, semiconductor, and advanced industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling the production of complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across all five axes, minimizing setup cycles and eliminating cumulative tolerances associated with multiple fixturing stages. This results in faster turnaround times and superior part consistency, especially for components with intricate contours, deep cavities, or compound angles.

Our machining centers are equipped with high-resolution probing systems and tool monitoring technology, ensuring real-time process control and dimensional stability throughout production runs. We work with a wide range of engineering-grade metals, including titanium, Inconel, aluminum alloys, stainless steel, and specialty brasses, supporting both prototyping and high-volume manufacturing. All operations are supported by advanced CAM programming using industry-leading software, enabling optimized toolpaths, reduced cycle times, and maximum material efficiency.

Comprehensive Quality Assurance with CMM Inspection

Precision is only meaningful when it is verifiable. At Wuxi Lead, every critical dimension is validated through a rigorous quality control process anchored in Coordinate Measuring Machine (CMM) inspection. Our metrology lab is equipped with multi-sensor CMM systems capable of sub-micron level accuracy, allowing full 3D dimensional analysis, geometric tolerance verification, and surface profile assessment. Each inspection report is fully documented and traceable, meeting ISO 9001 standards and customer-specific quality requirements. First Article Inspection (FAI) and in-process checks are standard practice to ensure compliance at every stage of production.

We maintain strict environmental controls in the metrology lab to eliminate thermal drift, ensuring measurement repeatability under stable conditions. Our quality engineers are certified in GD&T (Geometric Dimensioning and Tolerancing), enabling precise interpretation and validation of complex engineering drawings.

Dimensional Accuracy and Tolerance Specifications

The following table outlines our standard and achievable tolerance capabilities across key machining parameters. These values reflect typical performance under controlled conditions and may be further tightened based on part geometry and material characteristics.

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Hole Diameter Tolerance | H7 | H6 |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Geometric Tolerances (Flatness, Perpendicularity, etc.) | 0.02 mm/m | 0.01 mm/m |

| Angular Accuracy | ±0.1° | ±0.05° |

Our 5-axis CNC machining and precision inspection capabilities position Wuxi Lead Precision Machinery as a trusted partner for clients requiring uncompromising accuracy, repeatability, and technical expertise in custom metal manufacturing.

Material & Finish Options

Material Selection for High-Precision Machined Components

Material choice fundamentally impacts the performance, cost, and manufacturability of precision-engineered components. At Wuxi Lead Precision Machinery, we guide clients through strategic material selection based on application demands, environmental exposure, and functional requirements. This ensures optimal part longevity and cost efficiency without compromising precision.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. 6061-T6 offers balanced machinability and weldability for structural frames, while 7075-T6 delivers superior strength for high-stress applications like landing gear components. Both exhibit excellent corrosion resistance but require protective finishes in harsh environments. Aluminum’s low density reduces inertia in moving parts, critical for dynamic systems.

Carbon and alloy steels provide unmatched hardness and wear resistance for tooling, shafts, and heavy machinery. 4140 chrome-moly steel withstands high fatigue loads in oil/gas equipment, whereas 4340 offers enhanced toughness for aerospace forgings. Stainless steels like 303 (free-machining) and 304 (corrosion-resistant) serve medical and food processing industries. Steel’s higher density increases part mass but ensures dimensional stability under extreme loads.

Titanium Grade 5 (Ti-6Al-4V) is indispensable in aerospace and biomedical sectors where weight savings and biocompatibility are non-negotiable. It maintains strength at 600°F, resists saltwater corrosion, and integrates seamlessly with human tissue. However, its low thermal conductivity challenges machining, demanding specialized toolpaths and coolant strategies to prevent work hardening. Titanium’s cost premium is justified only when its unique properties are essential.

Anodizing transforms aluminum surfaces into durable, corrosion-resistant barriers. Type II (sulfuric acid) anodizing yields standard decorative/protective layers (1.8–25 µm), while Type III (hardcoat) produces engineering-grade finishes up to 125 µm thick for hydraulic pistons or military hardware. Both enhance paint adhesion and electrical insulation but require precise voltage control to avoid micro-cracking. Note: Anodizing is exclusive to aluminum; steel and titanium use alternatives like passivation or PVD coatings.

Critical mechanical properties for common precision machining alloys are summarized below.

| Material | Yield Strength (MPa) | Hardness (HB) | Density (g/cm³) | Machinability Rating (%) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 276 | 95 | 2.7 | 90 |

| Steel 4140 | 655 | 200 | 7.85 | 65 |

| Stainless 304 | 215 | 201 | 8.0 | 45 |

| Titanium Ti-6Al-4V | 880 | 360 | 4.43 | 20 |

Selecting the right material-finishing combination prevents field failures and reduces lifecycle costs. Our engineering team collaborates early in your design phase to validate material suitability against operational stressors, ensuring your components meet exacting tolerances and performance criteria. Contact Wuxi Lead Precision Machinery to optimize your material strategy for manufacturability and reliability.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our high-precision machining services are engineered to deliver uncompromising quality across every phase of production. We specialize in custom metal manufacturing for industries where performance, reliability, and dimensional accuracy are non-negotiable—such as aerospace, medical devices, and advanced automation. Our end-to-end process is structured to ensure zero defects, from initial design through prototyping to full-scale mass production.

The process begins with collaborative design engineering. Our team works closely with clients to analyze CAD models, evaluate material suitability, and optimize geometries for manufacturability. We conduct comprehensive Design for Manufacturability (DFM) reviews to identify potential challenges early, ensuring that every component can be produced with the tightest tolerances and highest repeatability. This phase integrates finite element analysis (FEA) and geometric dimensioning and tolerancing (GD&T) protocols to align design intent with production capability.

Once the design is finalized, we proceed to precision prototyping. Utilizing state-of-the-art 5-axis CNC machining centers, wire EDM, and multi-axis turning, we produce functional prototypes that mirror final production conditions. This allows for rigorous testing of form, fit, and function under real-world operating environments. Each prototype undergoes full metrological validation using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is incorporated iteratively, ensuring that any deviations are corrected before scaling to volume manufacturing.

Mass production is executed on our automated, high-efficiency machining lines, where process stability is maintained through Statistical Process Control (SPC) and real-time tool monitoring systems. Every operation follows standardized work instructions, and in-process inspections are scheduled at critical control points to guarantee consistency. Our production floor is ISO 9001:2015 and IATF 16949 certified, reflecting our adherence to international quality management standards. Traceability is maintained through serialized part tracking, batch documentation, and material certification.

To support our zero-defect objective, we employ a closed-loop quality system. Any non-conformance triggers an immediate root cause analysis using 8D methodology, with corrective actions implemented across all relevant processes. Our commitment to continuous improvement is reinforced through regular supplier audits, employee training, and investment in next-generation machining technology.

The following table outlines key technical capabilities across our production workflow:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Maximum Part Size | 800 mm × 600 mm × 500 mm |

| CNC Machining Accuracy | ±0.001 mm per axis |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS |

| Inspection Equipment | CMM, Optical Comparator, 3D Scanner, Roughness Tester |

By integrating precision engineering, advanced technology, and a zero-defect philosophy, Wuxi Lead Precision Machinery ensures that every component we produce meets the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Manufacturing Excellence

In high-stakes industries like aerospace, medical device manufacturing, and advanced automation, component failure is not an option. The margin for error in critical applications demands a partner with proven technical mastery, rigorous process control, and unwavering commitment to quality. Wuxi Lead Precision Machinery transcends conventional contract manufacturing by integrating decades of CNC engineering expertise with a vertically integrated production ecosystem. We transform complex design challenges into flawless, mission-critical components—on time and within specification. Our facility operates under ISO 9001:2015 and IATF 16949 standards, with full traceability from raw material certification to final inspection. This systematic approach ensures every part meets the extreme tolerances and material integrity required for success in your most demanding projects.

Our technical capabilities are engineered for precision at scale. We deploy state-of-the-art multi-axis CNC machining centers, coordinate measuring machines (CMM), and in-house metrology labs to achieve micron-level accuracy across diverse materials—from titanium alloys and Inconel to medical-grade stainless steel and engineered composites. Unlike fragmented supply chains, Lead Precision controls every phase: design validation, precision machining, surface treatment, and assembly. This eliminates handoff errors and accelerates time-to-market without sacrificing quality. The table below outlines our core manufacturing specifications, reflecting the technical foundation we bring to your partnership.

| Capability | Specification | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.0002 inches (5 µm) | Ensures flawless integration in tight-tolerance assemblies |

| Surface Finish | Ra 0.2 µm to 1.6 µm achievable | Critical for fluid dynamics, sealing, and biocompatibility |

| Material Range | Aluminum, Titanium, Inconel, Stainless Steel, Brass, Plastics | Supports extreme environments and regulatory compliance |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates complex, large-scale components |

| In-House Inspection | 3D CMM, Optical Comparators, Hardness Testing | Full validation against AS9100/ISO 13485 standards |

Choosing a manufacturing partner is a strategic decision that directly impacts your product’s reliability and market reputation. At Lead Precision, we prioritize transparency and collaboration from the initial RFQ through serial production. Our engineering team engages early to optimize designs for manufacturability, reducing costs while enhancing performance. Real-time production data and dedicated project management ensure you maintain full visibility—no surprises, only predictable excellence.

Initiate your project with confidence. Contact our technical sales team at [email protected] to schedule a confidential consultation. Share your design specifications or engineering challenges, and we will provide a detailed capability assessment within 24 hours. Let Wuxi Lead Precision Machinery become the extension of your engineering vision—where precision is not a claim, but a measurable outcome. Your next breakthrough component starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.