Technical Contents

Engineering Guide: Custom Prototypes

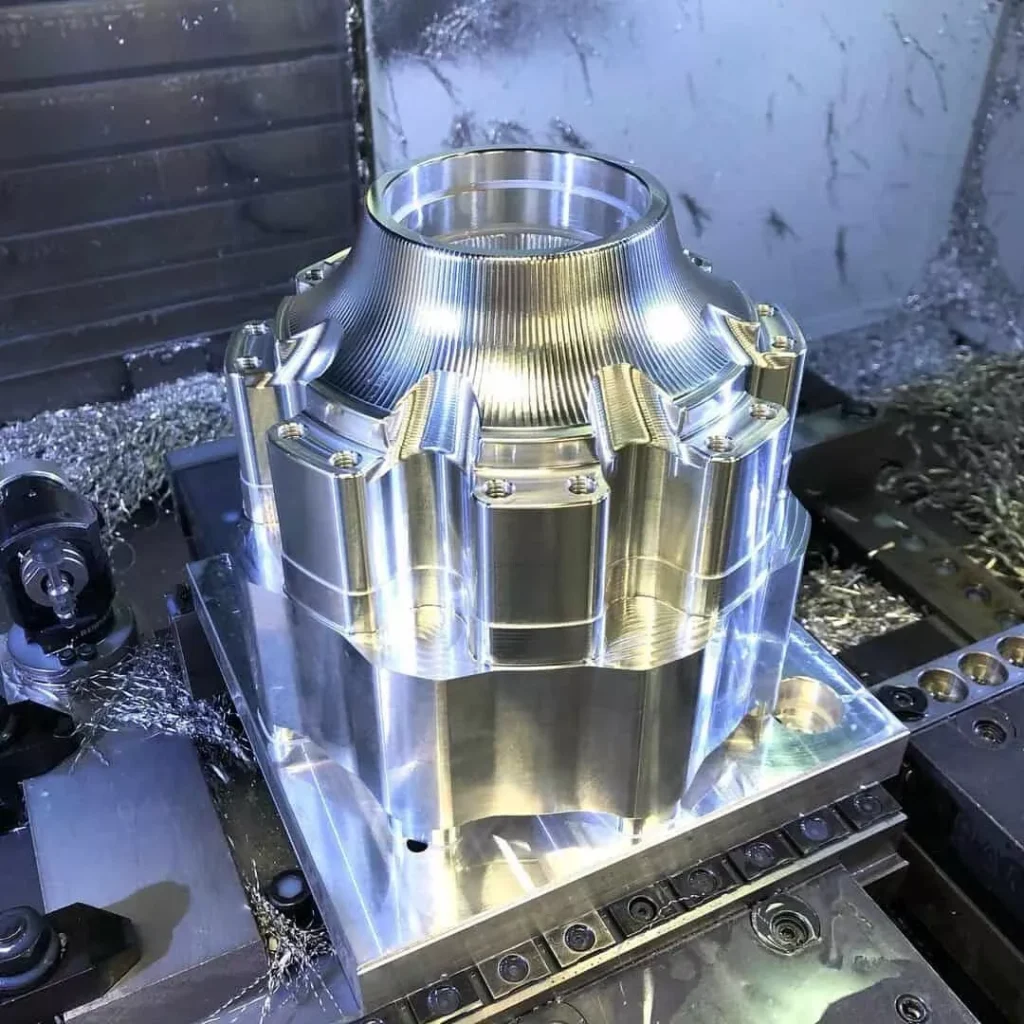

Engineering Insight: Custom Prototypes Demand Absolute Precision

In high-stakes custom metal manufacturing, prototype precision is not merely desirable—it is the foundational determinant of product viability, regulatory compliance, and market success. Tolerances measured in microns directly impact functionality, safety, and scalability. A deviation of ±0.01mm in an aerospace hydraulic component or medical implant interface can trigger catastrophic system failure or regulatory rejection. Prototyping transcends form validation; it rigorously stress-tests material behavior, thermal dynamics, and assembly interoperability under real-world conditions. For industries like defense, energy, and advanced robotics, where failure is non-negotiable, this phase separates theoretical design from deployable engineering.

Wuxi Lead Precision Machinery operates at this critical threshold. Our facility executes prototypes where tolerances of ±0.001mm are routine, leveraging decades of refinement in multi-axis milling, turning, and micro-machining. This capability stems from direct experience delivering mission-critical components for Olympic sporting equipment—where material fatigue resistance and dimensional stability under extreme stress define podium outcomes—and classified military systems requiring absolute repeatability in corrosive, high-vibration environments. We understand that a prototype is not a singular artifact but the first link in a validated production chain. Our engineers collaborate from CAD stage to final inspection, embedding manufacturability insights that prevent costly redesigns during volume production. This proactive approach reduces time-to-market by up to 30% while eliminating hidden tolerance stack-up risks.

Precision is quantifiable. Below are core specifications achievable across our prototype workflows, reflecting the standards demanded by Tier-1 defense contractors and global medical OEMs:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001mm to ±0.005mm | Critical for fluid dynamics interfaces and sensor housings |

| Surface Finish (Ra) | 0.2µm to 0.8µm | Mandatory for biocompatible implants and vacuum-sealed systems |

| Material Complexity | Titanium Gr5, Inconel 718, 17-4PH Stainless, Custom Alloys | Meets MIL-DTL-46027 and ASTM F138 standards |

| Geometric Complexity | 5-axis simultaneous machining, sub-0.1mm features | Enables monolithic drone structural components |

Our ISO 13485 and AS9100-certified processes ensure every prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, with full traceability from raw material certs to CMM reports. This discipline transforms prototypes from validation tools into production blueprints. When your design demands zero compromise—whether for a satellite deployment mechanism or next-generation surgical robotics—Wuxi Lead Precision Machinery delivers the dimensional integrity that turns innovation into reality. Contact our engineering team to integrate precision prototyping into your development lifecycle.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the exacting demands of high-performance industries such as aerospace, medical devices, automotive engineering, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce highly complex geometries with superior surface finish and dimensional accuracy. Unlike conventional 3-axis systems, our 5-axis machining centers allow simultaneous movement across all five axes, minimizing setup changes and eliminating cumulative tolerances. This results in faster production cycles and higher consistency, particularly for intricate components with compound angles, deep cavities, or organic contours.

Our machining fleet comprises state-of-the-art CNC equipment from leading global manufacturers, maintained to stringent operational standards and operated by certified engineers with over a decade of precision machining experience. These machines support a broad range of materials, including aerospace-grade aluminum alloys (e.g., 7075-T6), stainless steels (303, 304, 316), titanium (Grade 5), brass, and high-temperature superalloys such as Inconel 718. Each machining program is optimized using advanced CAM software to ensure toolpath efficiency, reduced cycle times, and minimized thermal deformation.

Quality control is embedded at every stage of production. All critical dimensions on custom prototypes are verified using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), calibrated annually to ISO 17025 standards. The CMM provides full 3D metrology reporting with GD&T analysis, ensuring compliance with ASME Y14.5 and ISO 1101 specifications. In addition to first-article inspection reports (FAIR), we provide comprehensive quality documentation packages, including material certifications, process routings, and traceability records.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across diverse part configurations. The following table outlines our standard and precision capability ranges, validated through continuous process monitoring and statistical process control (SPC) methods.

| Feature Type | Standard Tolerance (mm) | Precision Capability (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.01 | Up to 500 mm |

| Hole Diameter | ±0.03 | ±0.01 | Reamed/precision bored |

| Positional Tolerance | ±0.05 | ±0.02 | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined surfaces |

| Angular Tolerance | ±0.1° | ±0.05° | Critical interfaces |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm span |

By combining advanced 5-axis CNC technology with rigorous quality assurance protocols, Wuxi Lead Precision Machinery ensures that every custom prototype meets or exceeds functional and engineering requirements. Our technical team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce lead times, and ensure seamless transition from prototype to volume production.

Material & Finish Options

Material Selection for High-Performance Custom Prototypes

Selecting the optimal material is foundational to prototype success, directly impacting functionality, manufacturability, and validation accuracy. At Wuxi Lead Precision Machinery, our engineers prioritize aligning material properties with your specific application demands, environmental conditions, and final production intent. Misalignment here risks flawed testing data and costly redesigns. Aluminum, steel, and titanium represent the core structural metals for precision prototypes, each offering distinct advantages.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate when weight reduction and thermal conductivity are critical. Their excellent machinability allows for rapid iteration of complex geometries common in aerospace components, consumer electronics enclosures, and automotive heat sinks. While inherently less strong than steel, aluminum provides a superior strength-to-weight ratio and good corrosion resistance, especially when enhanced by finishing processes. Steel remains indispensable for prototypes requiring high strength, rigidity, and wear resistance. Grades like 304 stainless offer robust corrosion performance for medical or marine applications, while 4140 alloy steel provides exceptional toughness for high-stress mechanical parts. Steel prototypes accurately validate designs destined for high-volume steel production but require careful machining due to work hardening. Titanium Grade 5 (Ti-6Al-4V) is the solution for extreme environments demanding the ultimate strength-to-weight ratio combined with outstanding corrosion resistance and biocompatibility. Essential for aerospace structural components, surgical implants, and deep-sea equipment prototypes, titanium machining demands specialized tooling and expertise due to its low thermal conductivity and tendency to gall.

Critical physical and mechanical properties guide this selection. Consider the following comparative overview:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Excellent (A) |

| Steel 304 | 8.0 | 515 | Very Good | Good (B) |

| Titanium Gr5 | 4.4 | 900 | Excellent | Fair (C) |

Anodizing is the premier surface finish for aluminum prototypes, significantly enhancing durability and functionality. Type II (Sulfuric Acid) anodizing provides a standard, corrosion-resistant oxide layer suitable for most general applications and offers excellent dye acceptance for visual identification. For prototypes requiring maximum surface hardness, wear resistance, and superior corrosion protection in harsh environments, Type III (Hardcoat) anodizing is essential. This process creates a much thicker, denser oxide layer, critical for validating parts subject to friction or abrasion in final use. While primarily for aluminum, note that steel prototypes often utilize passivation or electropolishing for corrosion resistance, and titanium benefits from specialized treatments like acid etching or nitriding for specific performance needs.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to advise on the precise material and finish combination ensuring your prototype delivers actionable, production-relevant data. We integrate material science with advanced CNC capabilities to transform your design intent into a physically validated reality.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, repeatability, and zero-defect delivery. We specialize in transforming conceptual designs into high-performance metal prototypes and scalable production solutions. Our integrated workflow ensures seamless progression from initial design through prototyping to full-scale manufacturing, all under stringent quality controls.

The process begins with collaborative design evaluation. Our engineering team partners with clients to analyze CAD models, assess material suitability, and optimize geometries for manufacturability. This phase includes detailed tolerance analysis, surface finish requirements, and material selection—ensuring the design is not only functional but also production-ready. We support a wide range of alloys, including aluminum, stainless steel, titanium, and specialty composites, tailored to application demands such as thermal resistance, structural integrity, or corrosion protection.

Once the design is finalized, we proceed to prototyping. Utilizing advanced CNC machining, 5-axis milling, and precision turning, we produce functional prototypes that mirror final production quality. This stage is critical for validating form, fit, and function. Every prototype undergoes rigorous in-process inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from prototype testing is systematically integrated to refine the design before transitioning to mass production.

Our mass production phase leverages automated CNC cells, robotic material handling, and real-time monitoring systems to maintain consistency and throughput. Each production run is governed by a documented quality plan that includes first-article inspection, statistical process control (SPC), and 100% critical dimension checks where required. We operate under ISO 9001-certified processes, ensuring every component meets the highest standards of accuracy and reliability.

Throughout all stages, traceability is maintained via our digital manufacturing execution system (MES), which logs material batches, machine parameters, and inspection data for full auditability. This end-to-end control is fundamental to our zero-defect philosophy.

The table below outlines key capabilities across our production process:

| Parameter | Design Phase | Prototyping | Mass Production |

|---|---|---|---|

| Lead Time | 1–3 days | 5–10 days | 10–25 days (volume-dependent) |

| Tolerance | ±0.005 mm | ±0.005 mm | ±0.005 mm (SPC-controlled) |

| Surface Finish | As per drawing | Ra 0.8–3.2 µm | Ra 0.8–1.6 µm (standard) |

| Materials | Aluminum, Steel, Titanium, Brass, Plastics | Full range available | Production-optimized grades |

| Quality Checks | Design FMEA | CMM, Visual, Metrology | SPC, CMM, 100% critical checks |

By integrating engineering expertise with precision manufacturing and a relentless focus on quality, Wuxi Lead ensures that every custom prototype and production part exceeds expectations. Our process is not just about making parts—it’s about delivering reliability, performance, and confidence at scale.

Why Choose Wuxi Lead Precision

Elevate Your Prototyping with Engineering Excellence

In high-stakes product development, prototype quality directly impacts time-to-market and final product integrity. Generic manufacturing partners often deliver inconsistent tolerances, communication gaps, and delayed iterations—compromising your innovation cycle. At Wuxi Lead Precision Machinery, we eliminate these risks through integrated engineering oversight and uncompromising process control. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring every custom prototype meets aerospace, medical, and industrial OEM specifications from day one.

We specialize in transforming complex CAD models into precision metal prototypes using advanced 5-axis milling, Swiss turning, and multi-spindle technology. Unlike volume-focused shops, our dedicated prototyping cell prioritizes agility: engineering teams collaborate directly with your designers to resolve manufacturability issues before machining begins. This proactive approach reduces iteration cycles by up to 40% while maintaining micron-level accuracy. Material expertise spans titanium alloys, Inconel, aluminum 7075-T6, and hardened steels—fully traceable with certified mill test reports.

Critical Prototype Specifications Delivered Consistently

| Capability | Specification | Relevance to Your Project |

|---|---|---|

| Geometric Tolerance | ±0.005 mm (±0.0002″) | Ensures seamless assembly validation |

| Surface Finish | Ra 0.4 µm (16 µin) minimum | Critical for functional testing |

| Material Range | Aluminum to Inconel 718 (HRC 45+) | Supports extreme environment validation |

| Lead Time | 7–12 days (complex geometries) | Accelerates design verification |

| First-Pass Yield | 98.7% average | Minimizes costly rework delays |

Our value extends beyond machining. Dedicated project managers provide real-time progress tracking via secure client portals, including in-process inspection reports and 3D scanning validation. When your team requires rapid design adjustments, our engineering review turnaround is under 24 hours—no batch processing bottlenecks. This operational discipline has enabled clients like Siemens Energy and Johnson Controls to compress prototype validation phases by 30% while achieving zero non-conformance rates in pre-production audits.

Do not let substandard prototypes jeopardize your product launch. Wuxi Lead Precision Machinery delivers the technical rigor and responsive partnership essential for mission-critical development. Contact our engineering team directly to discuss your requirements. Submit your CAD files and specifications to [email protected] for a guaranteed 4-hour technical feasibility assessment. Include project urgency and target tolerances to prioritize your evaluation.

Your innovation demands precision manufacturing partners who operate as engineering extensions—not vendors. Initiate the conversation that transforms prototype challenges into competitive advantage. Reach out today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.