Technical Contents

Engineering Guide: Molding Tool

Engineering Insight: The Critical Role of Precision in Molding Tool Design

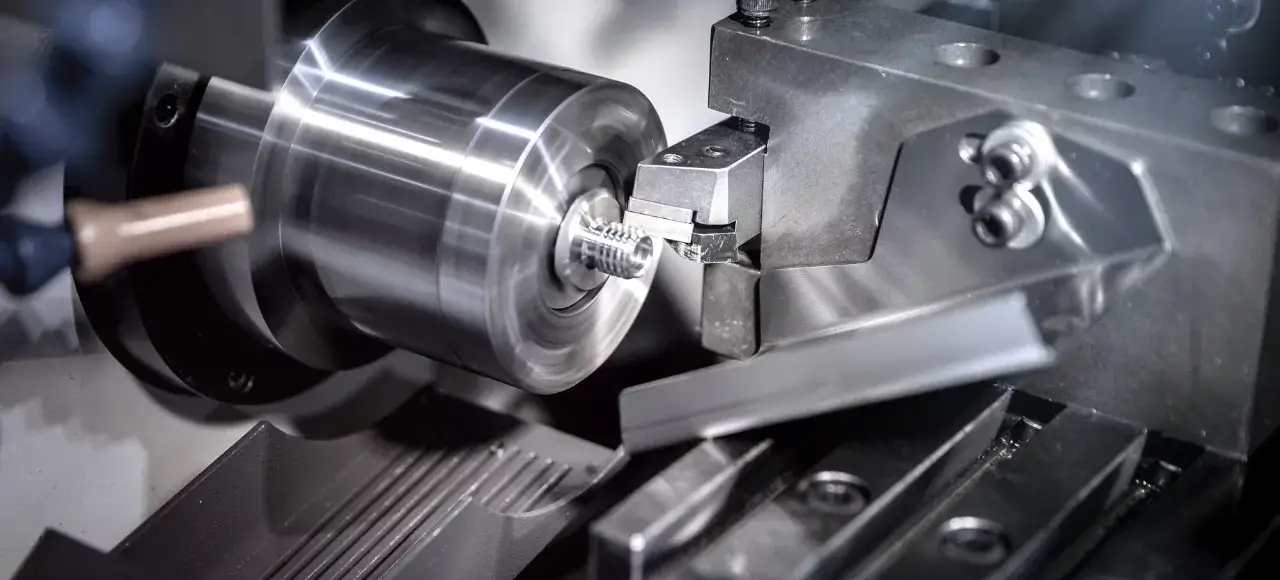

In the realm of custom metal manufacturing, the performance and longevity of a molding tool are directly tied to the precision with which it is engineered and produced. Molding tools—whether used in die casting, injection molding, or stamping operations—serve as the foundational interface between design intent and physical output. Even minor deviations in dimensional accuracy or surface integrity can result in part defects, increased scrap rates, and costly downtime. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a technical specification; it is a strategic imperative.

High-precision molding tools ensure consistent replication of complex geometries, tight tolerances, and fine surface finishes across thousands or even millions of production cycles. This consistency is especially critical in industries where component failure is not an option—such as aerospace, defense, and high-performance automotive systems. Our engineering team applies advanced simulation software, multi-axis CNC machining, and rigorous quality control protocols to guarantee that every molding tool meets exacting standards from the first shot to the final cycle.

Wuxi Lead Precision Machinery brings over a decade of specialized experience in producing mission-critical tooling solutions for elite industrial applications. Our portfolio includes contributions to projects aligned with Olympic-standard equipment manufacturing and precision components for military-grade systems. These engagements demanded not only micron-level accuracy but also exceptional material integrity and thermal stability under extreme operating conditions. The knowledge gained from these high-stakes environments directly informs our approach to every molding tool we produce, ensuring robustness, repeatability, and operational excellence.

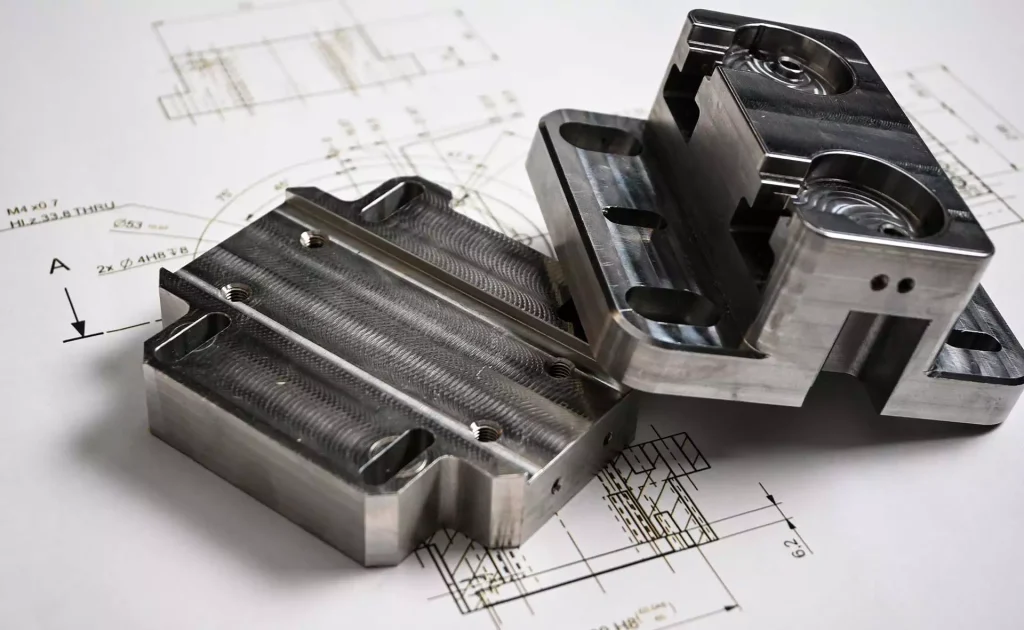

Our integrated manufacturing process begins with a comprehensive design review, incorporating mold flow analysis and structural simulation to anticipate and mitigate potential defects. We then leverage state-of-the-art CNC machining centers, EDM, and surface grinding technologies to achieve tolerances down to ±0.002 mm. All tools undergo in-process inspections and final validation using coordinate measuring machines (CMM) and 3D scanning to verify conformity to design specifications.

Below are key technical specifications that define our molding tool capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 µm |

| Maximum Tool Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Materials Supported | H13, S136, 718H, 2738, P20, and custom alloys |

| Mold Life Expectancy | Up to 1,000,000 cycles (depending on material) |

| Cooling Channel Optimization | Conformal cooling via 3D printing (optional) |

| Quality Assurance | Full CMM reporting, first-article inspection |

Precision in molding tool engineering is the cornerstone of manufacturing excellence. At Wuxi Lead Precision Machinery, we combine technical mastery with real-world experience from the most demanding sectors to deliver tooling solutions that perform—consistently, reliably, and at the highest level.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Molding Tool Fabrication

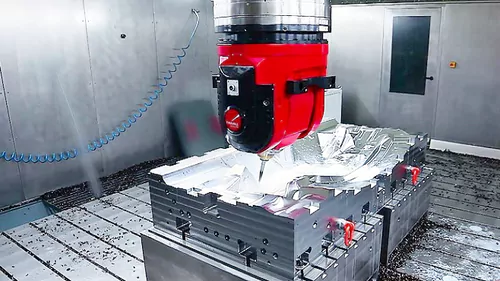

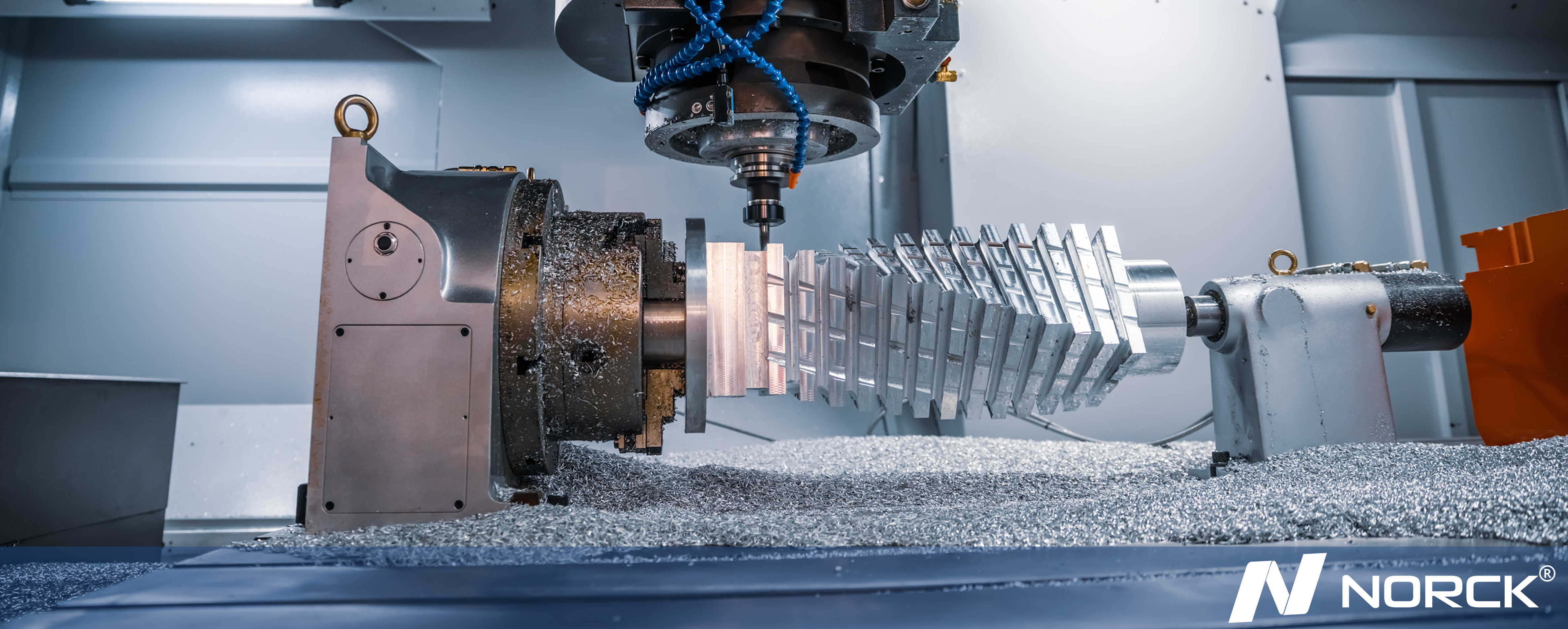

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal molding tool production through integrated advanced manufacturing systems. Our core competency centers on multi-axis CNC machining, specifically leveraging DMG MORI and MAZAK 5-axis vertical machining centers. These platforms enable simultaneous five-axis contouring, eliminating secondary setups and ensuring geometric integrity for complex mold cavities, cores, and electrodes. Critical capabilities include deep cavity machining with minimal tool deflection, high-speed finishing of freeform surfaces, and precise undercut generation—essential for injection molds, die-casting tools, and composite forming dies. All equipment operates within temperature-controlled environments (±1°C) and undergoes daily laser calibration to maintain volumetric accuracy per ISO 230-2 standards.

Precision execution is intrinsically tied to our closed-loop quality control framework. Every critical feature undergoes mandatory Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA systems with VAST XT gold probes. This process validates dimensional conformity against 3D CAD models, capturing full GD&T datasets including position, flatness, and profile tolerances. Our inspection protocol extends beyond first-article checks; in-process CMM verification occurs at defined machining milestones for high-complexity tools, ensuring deviations are corrected before final finishing. This methodology guarantees zero rework during mold assembly and directly translates to reduced client downtime in production environments.

Material optimization is equally critical. We specialize in machining hardened tool steels (H13, S136, NAK80 up to 60 HRC), aluminum alloys, and copper EDM electrodes with tailored cutting strategies. High-pressure through-spindle coolant systems enable dry machining for non-ferrous materials while maintaining thermal stability in hardened steel operations. Surface finishes as fine as Ra 0.2 µm are consistently achieved without manual polishing—a decisive advantage for optical-grade and high-gloss cosmetic molds.

The following table details achievable tolerance benchmarks for critical molding tool features, verified via CMM:

| Feature Type | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.015 mm | ±0.005 mm | CMM (ISO 10360-2) |

| Core Pin Position | ±0.010 mm | ±0.003 mm | CMM (GD&T Position) |

| Parting Line Flatness | 0.020 mm | 0.008 mm | CMM (ISO 1101) |

| Slider Alignment | ±0.012 mm | ±0.004 mm | CMM (3D Vector) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Portable Profilometer |

These capabilities are not theoretical benchmarks but daily production realities. Our engineers collaborate directly with client design teams during DFM analysis to identify tolerance-critical zones early, applying strategic machining sequences that prioritize functional surfaces. This proactive approach minimizes lead time while maximizing tool longevity and part consistency. For high-volume production molds, we implement statistical process control (SPC) on CMM data to predict wear patterns and optimize maintenance schedules. Partnering with Wuxi Lead ensures your molding tools meet the exacting demands of modern manufacturing—where precision directly defines productivity and part quality.

Material & Finish Options

Material Selection for High-Performance Molding Tools

Selecting the appropriate material for molding tools is critical to ensuring durability, precision, and cost-efficiency in high-volume or high-precision manufacturing environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions, leveraging advanced CNC machining and material science to deliver molding tools that meet exacting industrial standards. The three primary materials we recommend—aluminum, steel, and titanium—each offer distinct advantages depending on the application, production volume, and environmental conditions.

Aluminum is often the preferred choice for prototyping and low-to-medium volume production due to its excellent machinability, lightweight nature, and good thermal conductivity. It allows for faster cycle times in molding processes and reduces wear on machining equipment. While not as hard as steel or titanium, high-grade aluminum alloys such as 7075-T6 provide sufficient strength for many tooling applications. When enhanced surface performance is required, aluminum is highly compatible with anodizing, a process that increases surface hardness and corrosion resistance.

Steel, particularly tool steels like H13, P20, and S136, remains the standard for high-volume molding operations. These alloys offer superior hardness, wear resistance, and thermal stability, making them ideal for long production runs under high stress. Steel tools maintain dimensional accuracy over thousands of cycles and can be polished to mirror finishes for optical-grade parts. For corrosive environments or applications involving aggressive resins, stainless variants such as 420 stainless steel are recommended.

Titanium, while less commonly used due to higher cost and machining complexity, provides an exceptional strength-to-density ratio and outstanding corrosion resistance. It is particularly suited for specialized molding applications in aerospace, medical, or marine industries where weight reduction and environmental resilience are paramount. Titanium tools require specialized tooling and slower machining parameters but offer longevity in extreme conditions.

Surface finish plays a crucial role in mold release, part aesthetics, and maintenance. Anodizing is a widely used finish for aluminum tools, creating a durable, non-conductive oxide layer that enhances wear and chemical resistance. Type II (sulfuric acid) anodizing provides a clear or dyed finish with moderate hardness, while Type III (hardcoat) anodizing delivers a thicker, abrasion-resistant layer suitable for demanding applications.

Below is a comparative overview of key material properties for molding tool selection.

| Material | Hardness (HB) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 150 | 570 | 130 | Moderate (improved with anodizing) | Prototypes, low-volume molds |

| H13 Steel | 230 | 1600 | 35 | Low to moderate | High-volume injection molds |

| 420 Steel | 250 | 1800 | 25 | High | Corrosion-resistant molds |

| Titanium Grade 5 | 360 | 900 | 7 | Excellent | Aerospace, medical, marine molds |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on functional requirements, lifecycle costs, and production goals. Our engineering team supports every stage—from design to surface treatment—ensuring optimal performance and reliability of your molding tools.

Manufacturing Process & QC

Molding Tool Production Process: Precision Engineered for Zero Defects

At Wuxi Lead Precision Machinery, our molding tool production process is a rigorously controlled sequence designed to eliminate defects before they reach the production floor. We integrate advanced engineering with real-time quality assurance across three critical phases, ensuring every tool meets the exacting demands of high-volume, high-precision metal manufacturing. This systematic approach transforms client specifications into flawless production assets.

The process begins with Engineering Design & Simulation. Our team utilizes industry-leading CAD/CAM platforms to develop 3D models incorporating comprehensive tolerance stack-up analysis and mold flow simulation. This phase focuses on optimizing material selection, cooling channel geometry, and ejection mechanisms to prevent warpage, sink marks, or stress concentrations. Crucially, we conduct virtual Design for Manufacturability (DFM) reviews with the client, identifying potential production risks early. Finite Element Analysis (FEA) validates structural integrity under operational loads, ensuring the tool design inherently supports zero-defect output before any metal is cut.

Precision Prototyping & Validation follows, serving as the critical physical checkpoint. We manufacture initial tool inserts and components using our high-accuracy CNC machining centers, EDM, and grinding systems. These prototypes undergo rigorous metrological inspection via coordinate measuring machines (CMM) and optical comparators against the original CAD model. Functional testing occurs on our in-house molding presses, evaluating fill patterns, cycle times, and initial part quality. Any deviations trigger immediate design or process adjustments. This iterative validation loop continues until prototype parts consistently meet all dimensional, surface finish, and mechanical property requirements, proving the design’s manufacturability.

Zero-Defect Mass Production leverages the validated design and process parameters. Our fully automated production cells operate under Statistical Process Control (SPC), with real-time monitoring of critical variables like temperature, pressure, and cycle time. Each component undergoes 100% in-process inspection using automated vision systems and laser scanners. Final assembly occurs in a controlled cleanroom environment, followed by comprehensive performance validation on production-intent machinery. We implement a closed-loop corrective action system where any anomaly triggers immediate containment and root cause analysis, preventing recurrence. This commitment ensures every molding tool shipped delivers consistent, defect-free parts from the first production run.

Our core capabilities enabling this zero-defect outcome are quantified below:

| Critical Specification | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-mK / ASME Y14.5 |

| Surface Roughness (Ra) | 0.05 – 0.4 µm | ISO 4287 / ASME B46.1 |

| Material Hardness Range | HRC 48 – 62 | ASTM E18 / ISO 6508 |

| Tool Life Expectancy | 500,000+ cycles | Client-Specific Validation |

Wuxi Lead Precision Machinery treats zero defects not as a goal, but as the fundamental requirement of our process. By embedding precision engineering, iterative validation, and real-time quality control at every stage—from initial simulation through final production—we deliver molding tools that consistently produce perfect parts, safeguarding your production uptime and product quality. Partner with us for manufacturing certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Molding Tool Manufacturing

When it comes to high-performance molding tools in precision metal manufacturing, Wuxi Lead Precision Machinery stands at the forefront of innovation, quality, and reliability. As a trusted name in custom metal solutions, we specialize in the design, development, and production of advanced molding tools tailored to meet the exact demands of your industrial applications. Whether you’re in automotive, aerospace, medical devices, or consumer electronics, our engineering-driven approach ensures your tooling performs with maximum efficiency, longevity, and repeatability.

At Lead Precision, we understand that molding tools are the backbone of consistent, high-volume production. That’s why every tool we manufacture is engineered with precision tolerances, superior material selection, and advanced surface treatments to withstand rigorous operational environments. Our team of seasoned CNC engineers and tooling specialists leverages state-of-the-art machining centers and simulation software to optimize mold flow, cooling efficiency, and part ejection—delivering tools that reduce cycle times and minimize downtime.

We don’t just build tools—we engineer performance. From initial concept and 3D modeling to final inspection and on-site support, our integrated workflow ensures seamless collaboration and rapid time-to-market. Our facility in Wuxi, China, is equipped with multi-axis CNC machines, EDM systems, and automated quality control stations, enabling us to produce complex molds with micron-level accuracy. Every project is backed by rigorous quality assurance protocols, including CMM inspection, hardness testing, and mold trials under real production conditions.

Our global client base relies on Lead Precision for more than just manufacturing excellence. We offer full technical consultation, design for manufacturability (DFM) analysis, and lifecycle cost optimization to ensure your investment delivers long-term value. Whether you require single-cavity prototypes or multi-cavity production molds, we adapt our processes to your scale, timeline, and performance requirements.

Below are key technical specifications that define our molding tool capabilities:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 800 mm |

| Tolerance Range | ±0.005 mm |

| Materials | P20, 718H, S136, H13, Stainless Steel, Aluminum |

| Surface Finish | Mirror polish up to Ra 0.05 µm |

| Cooling Optimization | Conformal cooling channels via 3D simulation |

| Lead Time (Average) | 30–45 days, depending on complexity |

| Quality Standards | ISO 9001:2015, First Article Inspection Reports, PPAP |

Partnering with Wuxi Lead Precision Machinery means aligning with a team committed to engineering excellence and customer success. We don’t just meet expectations—we redefine them.

For expert consultation or to initiate a project with our molding tool specialists, contact us today at [email protected]. Let us help you transform your manufacturing potential with precision-engineered tooling solutions built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.