Technical Contents

Engineering Guide: Injection Mold Screw

Engineering Insight: Precision Imperatives in Injection Mold Screw Manufacturing

The injection mold screw represents the dynamic heart of any thermoplastic processing system. Its precision directly dictates material homogeneity, melt quality, energy efficiency, and ultimately, part consistency. Minute deviations in geometry—thread profile, lead accuracy, or concentricity—translate directly into flow instability, inconsistent melt temperatures, increased shear degradation, and unacceptable part defects like sink marks or dimensional drift. In high-value, high-volume production environments, especially for medical, aerospace, or optical components, such deviations are economically catastrophic. Achieving micron-level tolerances across the entire screw length, under continuous thermal cycling and abrasive polymer loads, demands advanced metallurgical understanding, ultra-precise CNC grinding capabilities, and rigorous process validation. This is not merely machining; it is the synthesis of materials science and sub-micron manufacturing discipline.

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC engineering team possesses deep expertise in the critical interplay between screw geometry, polymer rheology, and thermal management. We do not manufacture generic screws; we engineer bespoke solutions where every helix angle, compression ratio, and land width is optimized for the specific polymer and application. Our facility’s foundation in mission-critical manufacturing is proven through components operating under the relentless production schedules of Olympic Games infrastructure projects and meeting the zero-failure mandates of military-grade polymer systems. These engagements demanded not only extreme dimensional stability but also exceptional wear resistance and thermal fatigue performance under continuous 24/7 operation—benchmarks far exceeding standard industrial requirements. This heritage informs every screw we produce, embedding reliability into the core design and manufacturing process.

The following table outlines the critical precision parameters we rigorously control and validate for high-performance injection mold screws, reflecting standards essential for demanding applications:

| Specification Parameter | Target Tolerance Range | Measurement Standard | Critical Impact |

|---|---|---|---|

| Core Diameter Concentricity | ≤ 0.005 mm | ISO 1940-1 | Prevents vibration, ensures uniform barrel gap |

| Thread Profile Accuracy | ± 0.01 mm | Optical Comparator | Governs melt homogeneity & shear control |

| Lead Accuracy (Full Length) | ± 0.02 mm | CMM Verification | Ensures consistent compression & melting |

| Surface Finish (Ra) | 0.2 – 0.4 µm | Profilometer | Minimizes material hang-up & degradation |

| Hardness (Critical Zones) | 58-62 HRC | Rockwell C Scale | Balances wear resistance with fracture toughness |

Precision in screw manufacturing transcends meeting a drawing. It requires anticipating the thermal expansion dynamics during operation, compensating for material wear mechanisms, and validating performance under simulated production loads. At Wuxi Lead, our Olympic and military project experience provides the uncompromising framework for this validation. We subject every custom screw design to finite element analysis for thermal and stress behavior, followed by rigorous in-house functional testing against application-specific polymer recipes. This end-to-end engineering commitment ensures your injection molding process achieves the repeatability, efficiency, and part quality demanded by the most advanced manufacturing sectors. Precision isn’t an option; it is the fundamental engineering requirement for competitive, high-integrity production.

Precision Specs & Tolerances

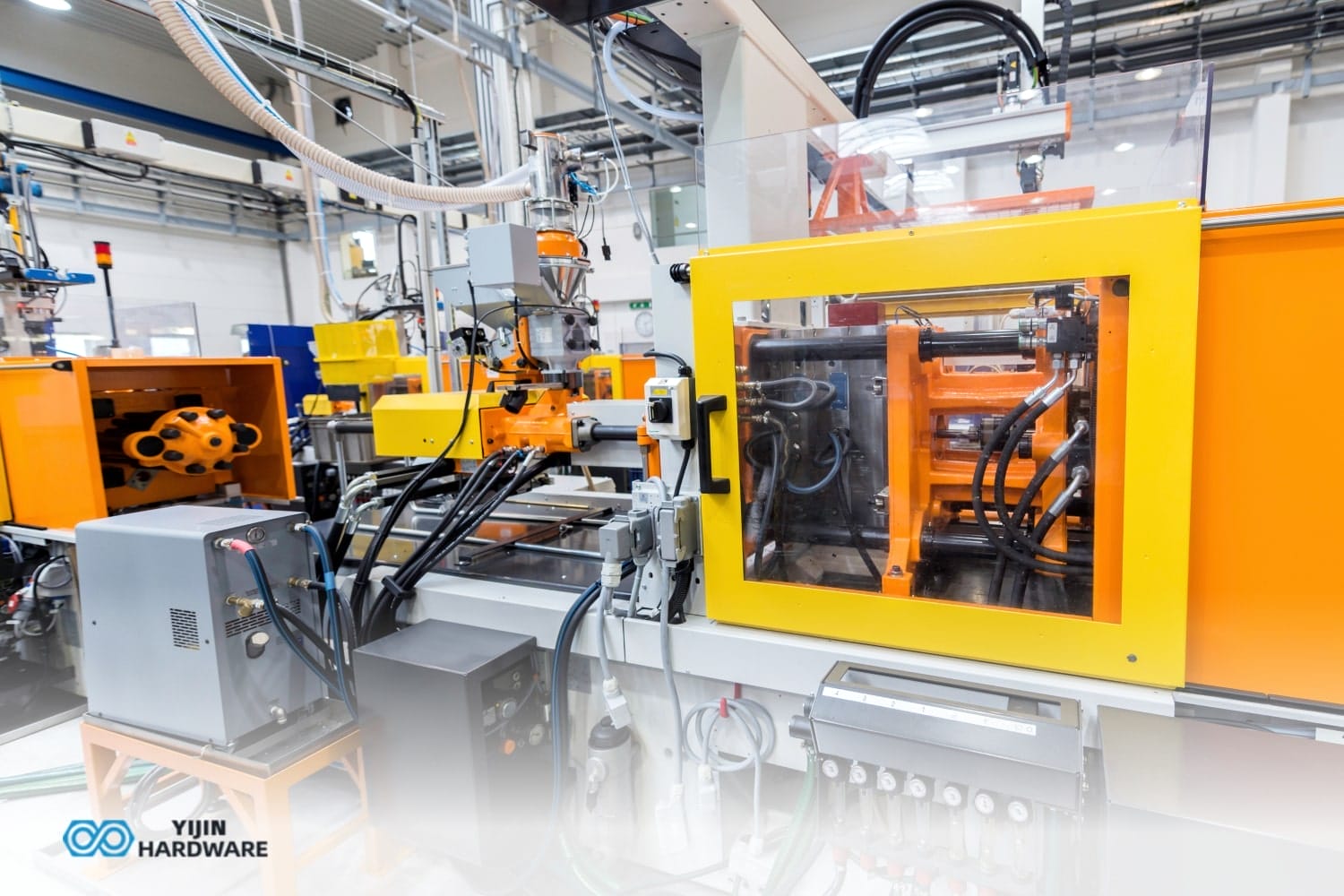

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision injection mold screws for demanding industrial applications. Our integrated production environment combines state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every component meets exacting performance and reliability standards. The complexity and functional demands of injection mold screws require exceptional dimensional accuracy, superior surface finish, and consistent material integrity—all of which are achieved through our engineered manufacturing approach.

Our 5-axis CNC machining centers enable full contouring and simultaneous multi-axis movement, allowing us to produce injection mold screws with complex geometries, deep helical features, and tight lead tolerances. This level of machining precision ensures uniform material flow, optimal shear control, and extended service life—critical factors in high-volume plastic processing environments. The use of high-rigidity machines with thermal compensation systems minimizes deflection and maintains accuracy across long production runs, ensuring repeatability down to the micron level.

All critical dimensions and geometrical features are verified using coordinate measuring machines (CMM) in our metrology laboratory. CMM inspection provides comprehensive data on form, position, and surface conformity, ensuring full compliance with customer engineering specifications and international standards. Our inspection routines include first-article inspection (FAI), in-process checks, and final batch validation, with full traceability maintained for every production lot. This disciplined quality assurance process supports industries where failure is not an option, including medical device manufacturing, automotive, and aerospace.

We work with a range of high-performance materials, including nitrided steels, tool steels, and corrosion-resistant alloys, tailored to the thermal and mechanical demands of specific molding applications. Each screw is surface-finished to reduce friction and resist wear, with optional coatings such as titanium nitride (TiN) or duplex treatments applied based on operational requirements.

The following table outlines the standard technical specifications and tolerances achievable for injection mold screw manufacturing at Wuxi Lead Precision Machinery:

| Parameter | Standard Tolerance | Capability Range |

|---|---|---|

| Diameter Tolerance | ±0.01 mm | Up to ±0.005 mm |

| Lead Accuracy | ±0.02 mm per 100 mm | ±0.01 mm per 100 mm |

| Pitch Uniformity | ±0.015 mm | ±0.01 mm |

| Concentricity (Runout) | ≤ 0.015 mm | ≤ 0.01 mm |

| Surface Roughness (Ra) | ≤ 0.4 µm | As low as 0.2 µm |

| Thread Profile Accuracy | ±0.01 mm | ±0.008 mm |

| Total Length Tolerance | ±0.05 mm | ±0.03 mm |

| Hardness Range | 50–62 HRC | Up to 65 HRC (coated) |

Wuxi Lead Precision Machinery combines engineering expertise with advanced manufacturing technology to deliver injection mold screws that exceed performance expectations. Our capabilities are built on a foundation of precision, consistency, and technical accountability, ensuring that every component supports efficient, reliable production in high-duty-cycle environments.

Material & Finish Options

Material Selection for High-Performance Injection Mold Screws

Selecting the optimal material for injection mold screws is a critical engineering decision directly impacting mold longevity, production efficiency, and final part quality. At Wuxi Lead Precision Machinery, we understand that this choice must balance mechanical properties, environmental resistance, weight constraints, and total lifecycle cost. Generic solutions often fail under demanding production cycles; precision-engineered material selection is non-negotiable for high-end applications. We analyze your specific polymer chemistry, processing temperatures, cycle times, and expected production volume to determine the ideal substrate.

Aluminum alloys, particularly 7075-T6, offer significant weight reduction and excellent thermal conductivity. This facilitates faster cooling cycles, beneficial for prototypes or low-volume production of less abrasive materials. However, aluminum’s lower hardness and wear resistance make it unsuitable for long runs with glass-filled or mineral-reinforced polymers, where galling and thread deformation become immediate concerns. Its primary role is in rapid tooling where speed-to-market outweighs ultimate durability.

Hardened tool steels, such as H13 or S136, represent the industry standard for demanding production environments. Achieving hardness levels of 48-52 HRC after proper heat treatment, these alloys deliver exceptional resistance to wear, galling, and deformation under high clamp forces and abrasive materials. Their superior strength-to-cost ratio makes them the economical choice for the vast majority of high-volume injection molding applications involving engineering thermoplastics. Corrosion resistance requires supplementary surface treatment.

Titanium alloys, notably Ti-6Al-4V, provide the ultimate in strength-to-weight ratio and inherent corrosion resistance, outperforming even stainless steels against acidic or halogenated polymers. While significantly more expensive upfront, titanium’s exceptional durability in highly corrosive environments or where extreme weight savings are mandated (e.g., large molds on hydraulic presses) can yield substantial long-term cost savings through reduced downtime and scrap. Its use is justified for mission-critical, high-value applications.

Anodizing is the essential surface finish for aluminum screws, transforming the outer layer into a hard, non-conductive aluminum oxide ceramic. Type III (Hardcoat) anodizing, achieved at Wuxi Lead to stringent mil-spec standards, provides critical wear and corrosion resistance, extending aluminum screw life significantly in appropriate applications. While primarily for aluminum, specialized anodizing processes can also enhance certain steel grades. The correct anodizing thickness and sealing process are vital for performance.

Material properties must align precisely with your operational demands. The table below summarizes key characteristics for informed decision-making.

| Material | Typical Hardness (HRC) | Corrosion Resistance | Relative Weight | Relative Cost |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 (Base) / 60+ (Anodized Surface) | Low (Base) / High (Anodized) | Very Low | Low |

| Tool Steel (H13) | 48-52 | Moderate | High | Medium |

| Titanium (Ti-6Al-4V) | 32-36 | Very High | Medium | High |

Choosing the right material and finish is not merely a specification; it is an investment in consistent production output and reduced total cost of ownership. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and material science knowledge to recommend and manufacture the optimal screw solution for your unique injection molding challenge. Contact our engineering team to discuss your specific requirements and receive a tailored material selection analysis.

Manufacturing Process & QC

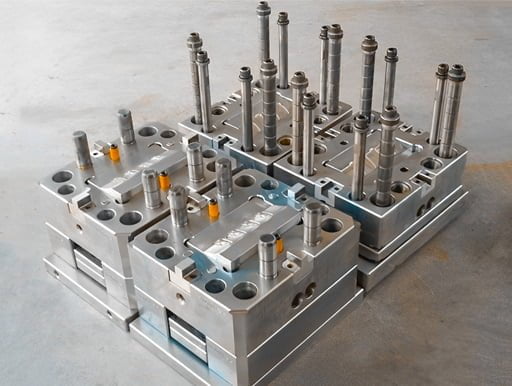

The production process for high-precision injection mold screws at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects and maximum performance consistency. Every phase—from initial design through prototyping to full-scale mass production—is engineered with precision, traceability, and quality assurance at its core.

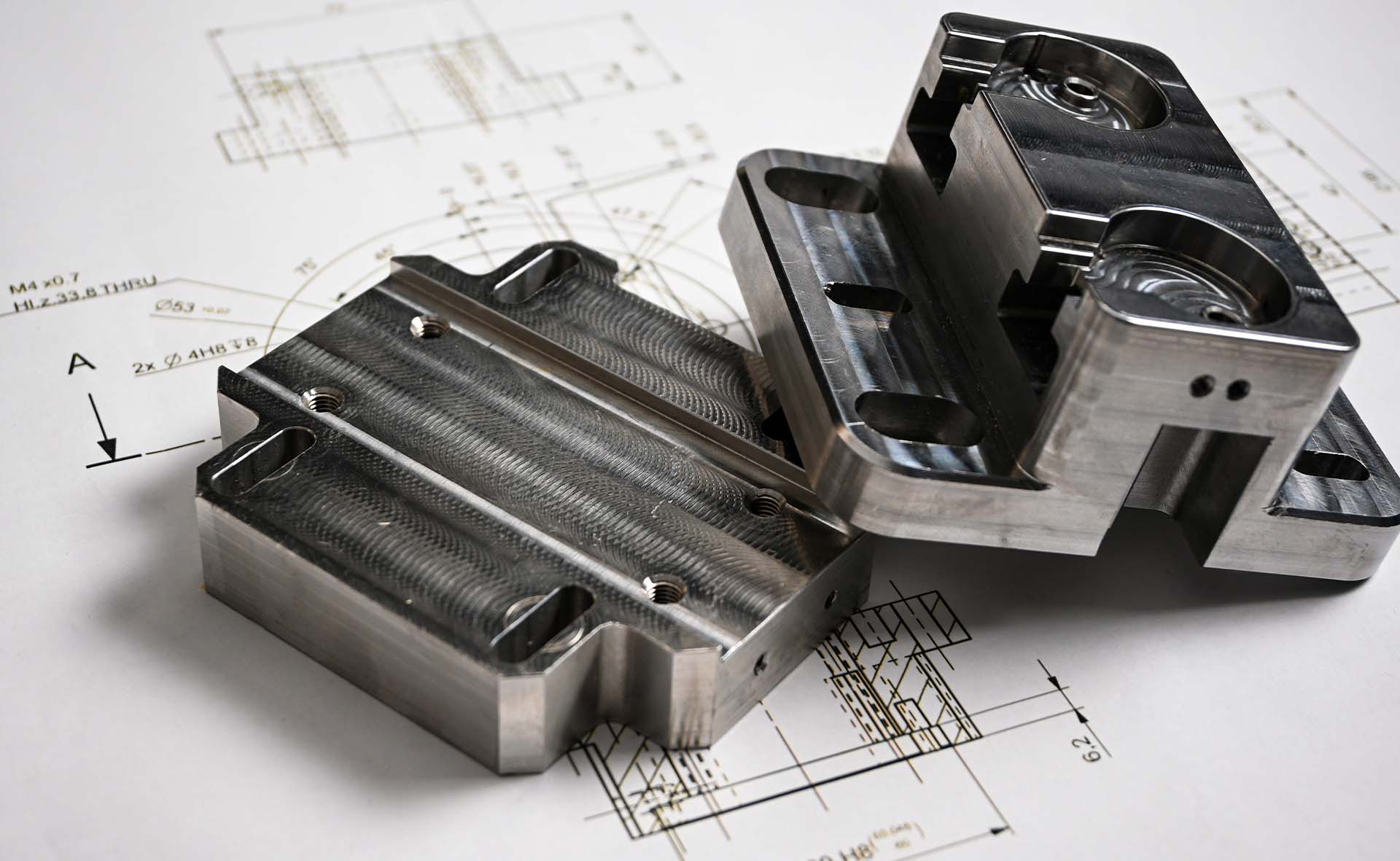

Design begins with a comprehensive analysis of the customer’s technical requirements, including material type, melt viscosity, shot size, and processing temperature. Our engineering team utilizes advanced CAD/CAM software to model the screw geometry, optimizing the compression ratio, flight depth, and L/D (length-to-diameter) ratio for the specific application. Finite element analysis (FEA) is applied to simulate stress distribution and thermal behavior under operational loads, ensuring structural integrity and longevity. All designs comply with international standards such as ISO 9001 and are reviewed by a cross-functional team to validate functionality, manufacturability, and service life.

Once the design is finalized, the prototyping phase commences. A single prototype screw is manufactured using CNC turning, milling, and grinding processes on state-of-the-art Swiss and Japanese machinery. The prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and surface roughness testers to confirm dimensional accuracy within ±0.005 mm tolerances. Material certification, hardness testing (HRC 58–62), and nitriding depth verification are conducted to ensure compliance with performance benchmarks. The prototype is then subjected to a functional trial in a customer-simulated injection molding environment, where melt homogeneity,塑化 rate, and energy efficiency are evaluated. Feedback from this stage informs any necessary design refinements before release to mass production.

Mass production is executed under a documented Quality Management System with full process validation. Each screw is machined from high-grade alloy steels such as 38CrMoAlA or SKD61, heat-treated for wear and corrosion resistance, and finished with precision grinding to achieve mirror-like surface finishes. In-process inspections occur at critical control points: post-heat treatment, post-grinding, and post-polishing. 100% dimensional inspection is performed on key parameters, and batch traceability is maintained via laser-etched serial numbers linked to material and inspection data. All finished screws are vacuum-packaged with desiccants to prevent oxidation during transit.

Wuxi Lead Precision Machinery’s commitment to zero defects is reinforced through continuous process monitoring, employee training, and root cause analysis for any non-conformance. Our integrated approach ensures that every injection mold screw delivered meets the highest standards of reliability and performance.

| Parameter | Specification |

|---|---|

| Material | 38CrMoAlA, SKD61, or customer-specified alloy |

| Hardness | HRC 58–62 (after nitriding) |

| Surface Finish | Ra ≤ 0.4 μm (ground and polished) |

| Tolerance | ±0.005 mm (critical dimensions) |

| Nitriding Depth | 0.5–0.7 mm (controlled plasma or gas nitriding) |

| L/D Ratio | 18:1 to 25:1 (customizable) |

| Compression Ratio | 2.0:1 to 3.5:1 (application-specific) |

| Inspection | 100% dimensional and hardness testing |

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Performance Through Precision Engineering

Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing for high-demand injection molding applications. Our injection mold screws are not merely components; they are engineered solutions designed to maximize throughput, minimize downtime, and ensure consistent part quality under the most rigorous production conditions. Partnering with Lead Precision means accessing decades of specialized CNC machining expertise combined with a relentless focus on material science and thermal dynamics. We understand that screw failure or suboptimal performance directly impacts your operational efficiency and bottom line. Our team collaborates closely with your engineers from initial concept through final validation, ensuring every thread, compression zone, and metering section aligns precisely with your polymer chemistry, machine parameters, and output goals. This consultative approach transforms a standard procurement process into a strategic partnership for sustained manufacturing excellence.

Our proprietary manufacturing process leverages advanced CNC grinding and hardening techniques to achieve micron-level tolerances and exceptional surface integrity. We utilize premium alloys and specialized surface treatments to combat wear, corrosion, and material degradation, even when processing abrasive or corrosive compounds. This commitment to precision engineering translates directly into extended screw life, reduced energy consumption, and superior melt homogeneity for your end products. Below are the core specifications defining our standard and premium injection mold screw offerings:

| Parameter | Standard Specification | Premium Specification |

|---|---|---|

| Material Grade | AISI 4140 | AISI 440C / Bimetallic |

| Hardness (Core) | HRC 48-52 | HRC 58-62 |

| Surface Hardness | HRC 60-64 (Nitrided) | HRC 68-72 (Stellite Clad) |

| Tolerance (Diameter) | ±0.015 mm | ±0.005 mm |

| Surface Roughness | Ra 0.2 µm | Ra 0.05 µm |

| Thermal Stability | Up to 280°C | Up to 350°C |

| Lead Accuracy | ±0.02° | ±0.005° |

The distinction between standard and premium specifications is not arbitrary; it is determined by your specific application demands. Whether you require enhanced resistance for engineering plastics like PEEK or ULTEM, or extended service life for high-volume commodity resin production, we tailor the metallurgy, geometry, and finishing processes to your exact operational reality. Our in-house metrology lab, equipped with CMMs and optical comparators, validates every critical dimension against your technical dossier before shipment, eliminating guesswork and ensuring seamless integration into your existing molding systems.

Do not compromise your production efficiency with generic components or reactive supplier relationships. Wuxi Lead Precision Machinery delivers proactive engineering partnership backed by ISO 9001-certified manufacturing processes and rigorous quality control. We are prepared to analyze your current screw performance data, material specifications, and machine parameters to propose a bespoke solution that optimizes your entire molding operation. The path to reduced scrap rates, lower maintenance costs, and higher machine uptime begins with a technical consultation.

Schedule your precision consultation today. Contact our engineering team directly at [email protected] to discuss your injection mold screw requirements. Provide your material type, machine tonnage, and target output metrics for a detailed capability assessment and quotation within 48 hours. Let Lead Precision become your definitive source for mission-critical molding components engineered for uncompromising performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.