Technical Contents

Engineering Guide: Steel 1018 Properties

Engineering Insight: Steel 1018 Properties and the Precision Imperative

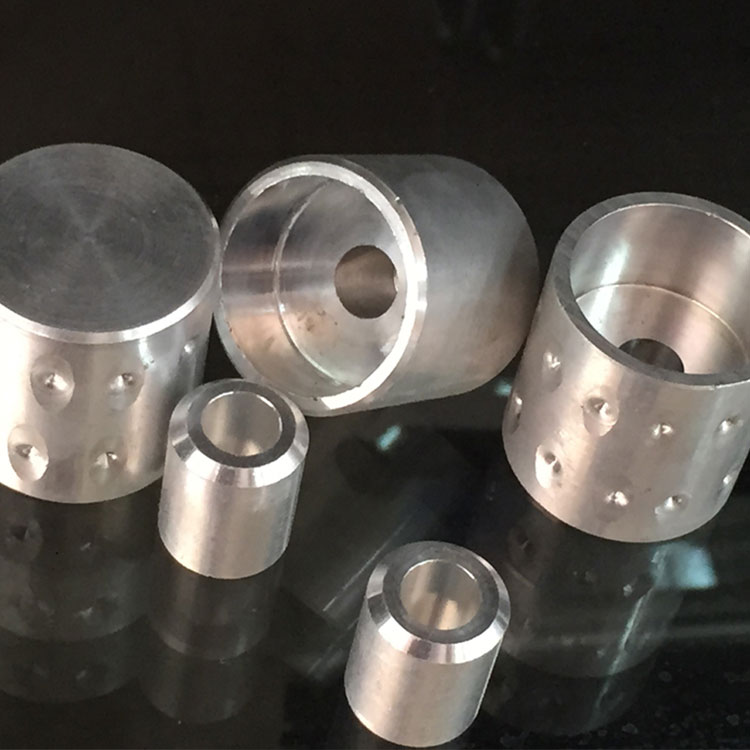

In the landscape of custom metal manufacturing, few materials offer the balance of machinability, weldability, and cost-effectiveness found in AISI 1018 steel. As a low-carbon steel, 1018 occupies a critical niche in high-volume and precision-driven applications across industries ranging from automation and robotics to military systems and Olympic-grade equipment. At Wuxi Lead Precision Machinery, our deep engagement with mission-critical components has underscored the necessity of not only selecting the right material but also applying precision engineering to fully leverage its inherent properties.

Steel 1018 is prized for its uniform composition and predictable behavior during machining. With a carbon content of approximately 0.18%, it exhibits excellent ductility and relatively low hardness in its annealed state, making it highly suitable for cold forming and bending operations. However, its true potential is realized only when paired with tight tolerance control, advanced CNC processing, and rigorous quality assurance. Even minor deviations in dimensional accuracy can compromise performance—especially in dynamic systems where load distribution, fatigue resistance, and alignment are paramount.

Our experience at Wuxi Lead has included manufacturing components for defense applications and precision subsystems used in Olympic training and competition equipment. In these environments, material consistency and geometric fidelity are non-negotiable. A 1018 steel shaft used in a servo-driven actuator, for example, must maintain concentricity within microns to prevent vibration and premature wear. Similarly, structural brackets fabricated from 1018 must be dimensionally stable across thermal cycles and mechanical stress—requirements that exceed standard fabrication practices.

Precision transforms 1018 from a generic construction material into a high-performance engineering solution. Through controlled heat treatment processes such as case hardening, selective areas of a 1018 component can be hardened to improve wear resistance while retaining a tough, ductile core. When combined with our multi-axis CNC machining and in-process metrology systems, these treatments ensure that every part meets exacting specifications.

The following table outlines key mechanical and physical properties of AISI 1018 steel in its cold-drawn and hot-rolled conditions:

| Property | Cold-Drawn Condition | Hot-Rolled Condition |

|---|---|---|

| Tensile Strength (Ultimate) | 63,800 psi | 53,700 psi |

| Yield Strength (Minimum) | 53,700 psi | 45,000 psi |

| Elongation at 2″ (Minimum) | 15% | 25% |

| Hardness (Brinell, 3000 kg) | 126 HB | 119 HB |

| Density | 0.2836 lb/in³ | 0.2836 lb/in³ |

| Machinability (Relative, %) | 72% | 72% |

| Carbon Content | ~0.18% | ~0.18% |

At Wuxi Lead Precision Machinery, we bring over a decade of specialized expertise to the processing of 1018 steel, integrating material science with micron-level manufacturing control. Whether supporting industrial automation or high-stakes defense systems, our commitment is to deliver not just parts—but precision-engineered solutions.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining of Steel 1018

Wuxi Lead Precision Machinery delivers exceptional value in custom manufacturing for low-carbon steel 1018, a material prized for its weldability, machinability, and cost-effectiveness in structural and mechanical applications. Understanding its properties—moderate strength, excellent cold-forming characteristics, and susceptibility to distortion during aggressive machining—is fundamental to achieving high-integrity components. Our engineering approach transforms these inherent material traits into consistent, high-precision outputs through integrated technical capabilities and rigorous process control.

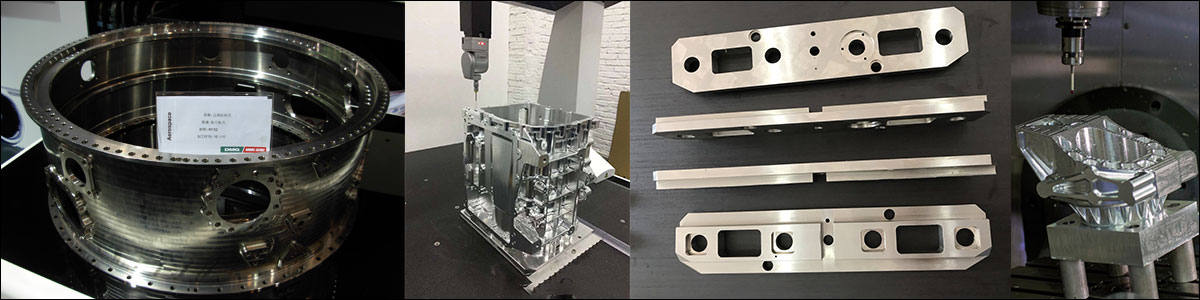

Our core strength lies in advanced 5-axis CNC machining centers, specifically optimized for the thermal and chip-flow dynamics of 1018 steel. These systems enable complex geometries in a single setup, minimizing cumulative error and critical for parts requiring tight positional tolerances across multiple features. High-speed spindles and adaptive toolpath strategies ensure optimal surface finishes while mitigating heat buildup that can induce warpage in this low-alloy steel. Material-specific cutting parameters, coolant management, and vibration damping protocols are embedded in every program, directly addressing 1018’s tendency toward built-up edge and chatter during prolonged operations.

Quality assurance is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA CMM systems, providing metrology-grade validation of form, position, and surface integrity. Our inspection protocols extend beyond dimensional checks; we analyze microstructure consistency and surface hardness variations post-machining to confirm material integrity aligns with ASTM A29 standards. Statistical process control (SPC) data from in-process probes and final CMM reports are documented per ISO 9001, ensuring traceability and enabling proactive process refinement for batch continuity.

The table below defines achievable geometric tolerances for 1018 steel components under controlled production conditions. These values reflect our standard capability for features machined in a single thermal cycle; tighter tolerances are attainable with specialized fixturing and extended inspection protocols.

| Feature Type | Standard Tolerance | Enhanced Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / Micrometer |

| Geometric Position | ±0.015 mm | ±0.008 mm | CMM |

| Flatness | 0.025 mm | 0.010 mm | CMM / Surface Plate |

| Concentricity | 0.020 mm | 0.010 mm | CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | Profilometer |

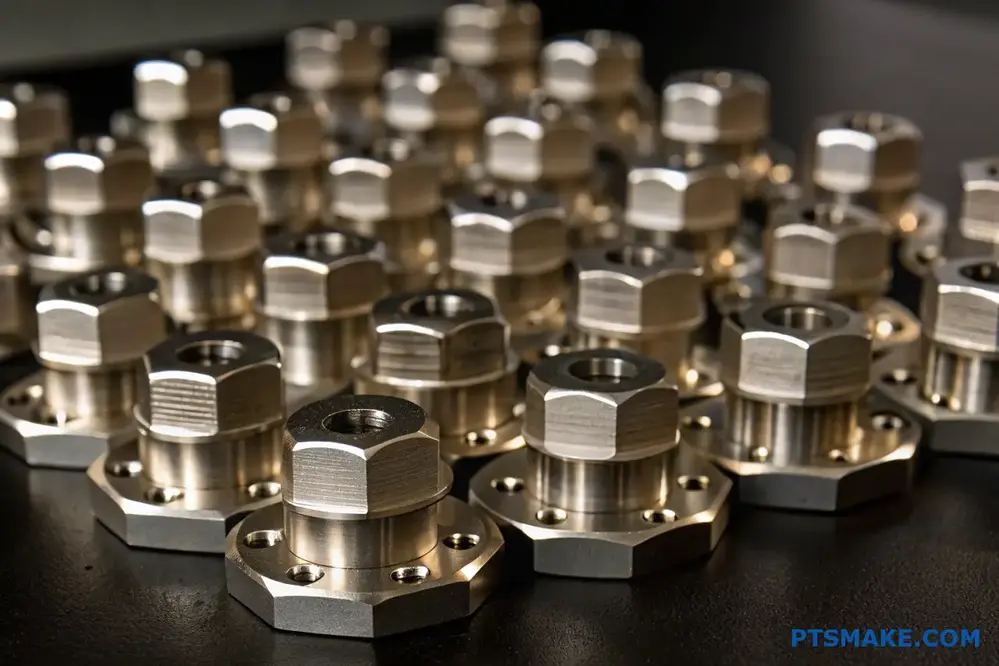

Mastery of 1018 steel demands more than equipment—it requires material science insight applied through disciplined engineering. Wuxi Lead’s fusion of 5-axis precision, metrology-grade validation, and material-specific process knowledge ensures your 1018 components meet the exacting demands of aerospace fixtures, automotive tooling, and industrial machinery. We translate the inherent properties of this versatile steel into components where dimensional stability and functional reliability are uncompromised. Partner with us to convert design intent into manufactured excellence, backed by data-driven quality assurance at every stage.

Material & Finish Options

Understanding Steel 1018: A Precision Engineer’s Guide to Material Selection

In custom metal manufacturing, selecting the right material is critical to balancing performance, cost, and manufacturability. Among low-carbon steels, AISI 1018 stands out as a widely used and versatile option, particularly in applications requiring moderate strength, excellent machinability, and reliable weldability. At Wuxi Lead Precision Machinery, we recognize that informed material decisions drive long-term success in precision components for industries ranging from automation to industrial equipment.

Steel 1018 is a general-purpose carbon steel with a nominal carbon content of 0.18%, placing it in the low-carbon category. This composition results in a material that is easily machined, cold formed, and welded—making it ideal for shafts, pins, fixtures, and structural components where high tensile strength is not the primary requirement. Its relatively low hardness allows for efficient cutting and turning operations, reducing tool wear and machining time, which translates into cost-effective production for high-volume or prototype runs.

One of the key advantages of 1018 steel is its uniformity and dimensional stability. It is typically supplied in cold-drawn or hot-rolled forms, with cold-drawn offering tighter tolerances and a smoother surface finish—important for precision-fitted parts. While not suitable for case hardening to the same degree as 1045 or 4140 steels, 1018 can be carburized or surface-hardened to improve wear resistance in specific applications. However, it does not respond well to heat treatment for significant through-hardening due to its low carbon and alloy content.

When comparing materials for custom manufacturing, 1018 steel occupies a middle ground between aluminum’s lightweight efficiency and titanium’s high strength-to-density ratio. Unlike aluminum, 1018 offers higher strength and stiffness, though at the cost of increased weight. Compared to titanium, it is far more economical and easier to machine, though it lacks corrosion resistance and high-temperature performance. For environments exposed to moisture or corrosive agents, protective coatings such as zinc plating, powder coating, or oil-based finishes are recommended to extend service life.

Below is a comparative overview of key mechanical properties for steel 1018 and common alternatives:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Machinability Rating |

|---|---|---|---|---|---|

| Steel 1018 | 440 | 370 | 15 | 126 | 70% |

| Aluminum 6061 | 310 | 276 | 12 | 95 | 90% |

| Titanium Gr5 | 900 | 830 | 10 | 360 | 30% |

In the broader context of material selection, steel 1018 remains a workhorse in industrial manufacturing. Its predictable behavior, availability, and compatibility with standard finishing processes make it a reliable choice for engineered components where precision and cost-efficiency are paramount. At Wuxi Lead, we support clients in matching material properties to application demands—ensuring optimal performance across the product lifecycle.

Manufacturing Process & QC

Precision Manufacturing Process for AISI 1018 Steel Components

AISI 1018 steel’s balanced machinability, weldability, and moderate strength make it indispensable for precision shafts, pins, and structural brackets. At Wuxi Lead Precision Machinery, we transform its inherent properties into zero-defect components through a rigorously controlled three-phase workflow. Our ISO 9001-certified process begins with collaborative design engineering. Clients provide CAD models or sketches, which our team optimizes for 1018’s characteristics—accounting for its low hardenability, susceptibility to warpage during machining, and optimal chip-breaking parameters. Finite element analysis (FEA) validates stress points, while CAM programming selects toolpaths minimizing thermal distortion. Critical tolerances are flagged early, ensuring design feasibility aligns with 1018’s mechanical behavior.

Prototyping follows immediate design sign-off. We machine first-article samples using production-intent CNC lathes and mills, applying coolant strategies proven for 1018’s free-machining sulfur content. Each prototype undergoes dimensional verification via Zeiss CMM (accuracy ±0.0002″), hardness testing (targeting 126-148 HB), and functional stress validation. Bend tests confirm ductility, while surface roughness checks (Ra 0.8 µm max) verify absence of tears from improper feed rates. Client approval requires documented conformance to AS9102 standards, with material lot traceability back to mill certificates. Only when prototypes meet all specifications do we transition to mass production.

Mass production leverages our 42-axis CNC cells operating under Statistical Process Control (SPC). For 1018, we implement real-time in-process gauging: laser micrometers monitor diameters on turning centers, while touch probes on mills compensate for tool wear within 0.0005″. Every 50th part undergoes full CMM revalidation, and batch hardness is spot-checked. Our zero-defect mandate is enforced through automated vision systems detecting surface anomalies and 100% final inspection against first-article data. Material consistency is ensured via strict supplier audits and in-house carbon analysis (0.15-0.20% C verified per ASTM E415). This closed-loop system guarantees components perform identically across 10,000+ unit runs.

AISI 1018 Key Properties & Wuxi Lead Tolerances

| Property | Value | Production Control at Wuxi Lead |

|---|---|---|

| Carbon Content | 0.15-0.20% | Verified per batch via OES analysis |

| Tensile Strength | 440 MPa (min) | 100% parts within 440-490 MPa range |

| Yield Strength | 370 MPa (min) | Confirmed via hardness correlation |

| Machinability Rating | 72% (Excellent) | Optimized feeds/speeds per ISO 683-18 |

| Typical Applications | Shafts, pins, brackets, spindles | Tightest tolerances held on critical features |

| Standard Tolerance | ±0.005″ (machined) | Achieves ±0.0005″ on critical dims |

| Surface Roughness (Ra) | 1.6-3.2 µm (as-machined) | Holds 0.8 µm Ra max on functional surfaces |

This end-to-end discipline—rooted in material science and process mastery—ensures your 1018 components deliver consistent performance, eliminating scrap costs and assembly delays. Wuxi Lead’s commitment to zero defects starts with understanding steel 1018’s nuances and ends with parts that exceed dimensional and functional expectations.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Precision Manufacturing in 1018 Steel

When your industrial applications demand consistent quality, dimensional accuracy, and reliable performance, selecting the right material is only the first step. The next, and equally critical, step is choosing a manufacturing partner with deep expertise in working with materials like AISI 1018 steel. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on precision engineering, ensuring that every component you require meets stringent industry standards.

AISI 1018 steel is one of the most widely used low-carbon steels in the manufacturing sector due to its excellent machinability, weldability, and surface hardening capabilities. Its balanced chemical composition and mechanical properties make it ideal for shafts, pins, gears, fixtures, and other high-tolerance parts. However, realizing the full potential of 1018 steel requires more than just access to the material—it demands precision machining, controlled heat treatment, and rigorous quality assurance. These are the capabilities Wuxi Lead brings to every project.

Our facility in Wuxi, China, is equipped with advanced CNC machining centers, automated inspection systems, and a team of experienced engineers who understand the nuances of low-carbon steel processing. We offer end-to-end services from prototype development to high-volume production, all tailored to your exact specifications. Whether you need turned, milled, ground, or fabricated components, our processes are optimized for repeatability, efficiency, and metallurgical integrity.

Below are the key physical and mechanical properties of AISI 1018 steel that we routinely work with and validate during production:

| Property | Value |

|---|---|

| Carbon Content | 0.15–0.20% |

| Tensile Strength | 440–540 MPa |

| Yield Strength | 370 MPa (approx.) |

| Elongation at Break | 15% (in 2″) |

| Hardness (Brinell) | 126–135 HB |

| Density | 7.87 g/cm³ |

| Machinability Rating | 72% (relative to AISI 1112) |

| Modulus of Elasticity | 205 GPa |

| Applications | Shafts, spindles, fasteners, machine parts |

We maintain strict process controls to ensure grain structure uniformity, minimize internal stresses, and achieve optimal surface finishes—critical factors when working with 1018 steel in precision environments. Our quality management system is aligned with ISO standards, and we provide full material traceability and inspection reports upon request.

If you are designing or sourcing components that leverage the versatility of 1018 steel, let Wuxi Lead Precision Machinery be your trusted manufacturing partner. We combine technical depth with scalable production capacity to deliver parts that perform—on time and to specification.

Contact us today at [email protected] to discuss your project requirements, request a quote, or receive technical support on material selection and design optimization. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.