Technical Contents

Engineering Guide: Aluminium Cnc Fräsen

Engineering Insight: Precision Imperatives in Aluminium CNC Milling

Achieving micron-level precision in aluminium CNC milling demands more than advanced machinery; it requires systematic mastery of material behavior, thermal dynamics, and process control. Aluminium alloys—particularly 6061-T6 and 7075-T6—present unique challenges: low rigidity induces chatter, high thermal conductivity causes dimensional drift during machining, and fine surface finishes are easily compromised by tool deflection. At Wuxi Lead Precision Machinery, we treat these variables not as obstacles but as engineering parameters to be rigorously managed. Our approach integrates real-time spindle load monitoring, adaptive feed-rate algorithms, and cryogenic cooling strategies to neutralize thermal expansion within ±0.002mm tolerances. This level of control is non-negotiable for sectors where failure is not an option.

Our validation extends beyond ISO 9001 certification. Lead Precision has delivered mission-critical components for Olympic infrastructure projects—including load-bearing structural elements for Beijing Winter Games venues—and supplied classified aerospace subsystems for military platforms requiring MIL-STD-810G compliance. These engagements demanded not only precision but absolute repeatability across 50,000+ part runs. Success hinged on our closed-loop metrology system: every machining cycle is verified via Zeiss coordinate measuring machines (CMM), with data fed back to adjust toolpaths dynamically. For aluminium, this means compensating for micro-vibrations induced by high-speed spindle rotation (up to 24,000 RPM), ensuring geometric integrity even in thin-walled geometries under 1mm thickness.

The table below defines the baseline specifications achievable for aluminium CNC milling at Lead Precision under controlled production conditions:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Positional Tolerance | ±0.010 mm | ±0.002 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm |

| Max Work Envelope | 1,200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Spindle Speed Range | 50–18,000 RPM | 50–24,000 RPM |

| Supported Alloys | 2024, 6061, 7075 | 5052, 2014, Custom Forgings |

Precision in aluminium CNC milling transcends technical specifications—it is a commitment to eliminating uncertainty in every micro-millimeter. When your application involves flight-critical components or structural systems bearing public safety responsibilities, tolerances cannot be theoretical. They must be empirically proven across thousands of cycles. Lead Precision’s decade-long refinement of aluminium-specific machining protocols—forged in Olympic-scale deadlines and military-grade scrutiny—ensures your components perform exactly as engineered, without deviation. This is the standard we uphold, and the assurance we deliver.

Precision Specs & Tolerances

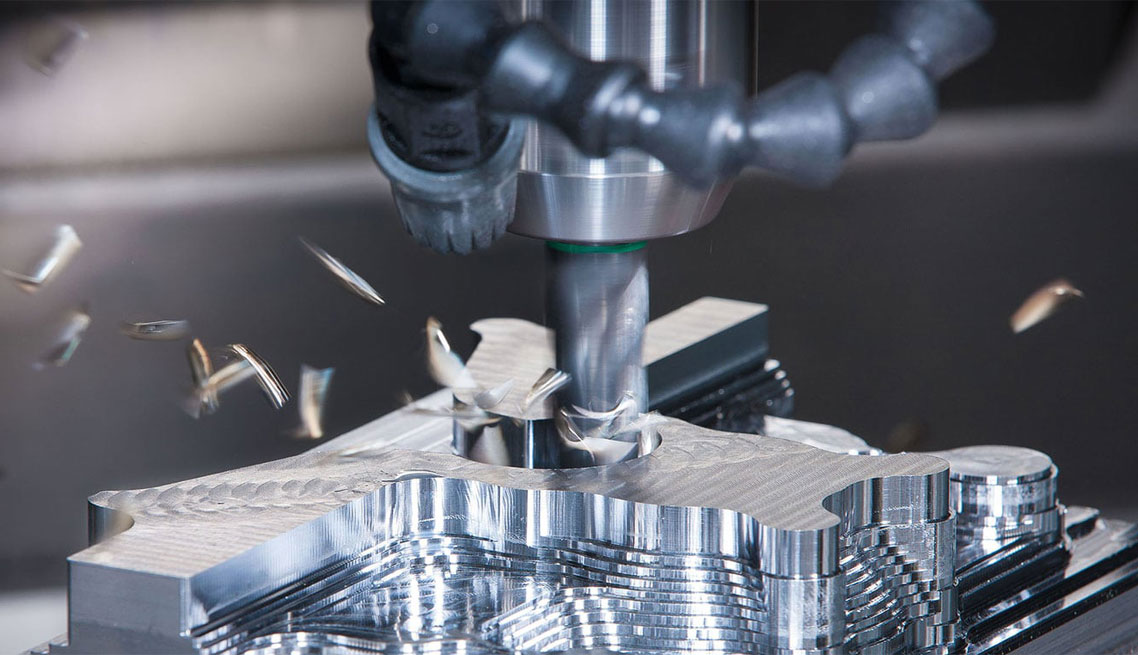

Advanced 5-Axis CNC Machining for Aluminium Components

Wuxi Lead Precision Machinery delivers high-precision 5-axis CNC machining services tailored specifically for complex aluminium components used in aerospace, automotive, medical, and industrial automation sectors. Our advanced manufacturing capabilities enable us to produce intricate geometries with superior surface finishes and tight dimensional accuracy, meeting the most stringent engineering requirements. The use of 5-axis simultaneous machining allows for multi-faceted part processing in a single setup, reducing cycle times and eliminating cumulative errors associated with repositioning.

Our facility is equipped with state-of-the-art 5-axis CNC machining centers from leading global manufacturers, optimized for high-speed aluminium cutting. These machines feature high RPM spindles, dynamic tool path control, and rigid construction to maintain precision during prolonged operation. With full 360° rotational capability on two axes, we achieve unparalleled access to complex contours, deep pockets, and undercuts—common challenges in high-performance aluminium parts. This level of flexibility supports rapid prototyping as well as high-volume production runs with consistent repeatability.

Material integrity is preserved through optimized toolpaths and high-efficiency cooling strategies. We utilize specialized carbide tooling and coatings designed for aluminium, minimizing built-up edge and ensuring clean, burr-free finishes. Our programming team employs advanced CAM software to generate efficient, collision-free toolpaths, maximizing machine uptime and part quality.

Quality assurance is integral to our process. Every aluminium component undergoes rigorous inspection using a Zeiss DuraMax and Wenzel LH876 coordinate measuring machine (CMM), ensuring compliance with geometric dimensioning and tolerancing (GD&T) standards. In addition to CMM verification, we implement in-process gauging, first-article inspection reports (FAIR), and statistical process control (SPC) for critical dimensions during production runs.

Our commitment to metrology extends beyond dimensional accuracy. We also validate surface roughness, flatness, and positional tolerances to ensure functional performance in final assembly. All inspection data is documented and traceable, supporting full compliance with ISO 9001:2015 and customer-specific quality systems.

The following table outlines our standard achievable tolerances for aluminium CNC machining under controlled conditions:

| Feature Type | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 300 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed/precision bored |

| Positional Tolerance | ±0.020 mm | ±0.010 mm | GD&T compliant |

| Flatness | 0.025 mm | 0.010 mm | Over 100 mm span |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | As machined or polished |

| Angular Features | ±0.05° | ±0.02° | 5-axis interpolated |

All tolerances are achievable in common aluminium alloys including 6061, 7075, 2024, and 5083, with material certification available upon request. At Wuxi Lead Precision Machinery, our technical capabilities are engineered to deliver excellence in every aluminium component we produce.

Material & Finish Options

Material Selection for Precision Aluminium CNC Fräsen Applications

Selecting the optimal material is foundational for successful Aluminium CNC Fräsen outcomes, directly impacting part performance, manufacturability, and lifecycle cost. While aluminum alloys dominate high-precision sectors like aerospace, medical devices, and automotive due to their exceptional strength-to-weight ratio and thermal conductivity, understanding the nuanced trade-offs against steel and titanium is critical for engineering excellence. Our production environment confirms that misaligned material choice remains a primary cause of project delays and budget overruns in complex machining.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer the best balance for most high-volume precision milling. 6061 provides excellent weldability and corrosion resistance for structural components, while 7075 delivers superior strength for highly stressed aerospace fittings. However, steel alloys like 304 stainless or 4140 chrome-moly are indispensable where extreme wear resistance or high-temperature stability is non-negotiable, despite their significantly higher machining costs and weight penalty. Titanium Grade 5 (Ti-6Al-4V) excels in corrosive environments and ultra-high-strength applications but demands specialized tooling and slower feed rates, increasing production time by 30-50% compared to aluminum. Material selection must always prioritize functional requirements over initial cost, as secondary operations and premature failure incur far greater expenses.

Surface finish, especially anodizing, is not merely cosmetic but a functional necessity for aluminum components. Hard anodizing (Type III per MIL-A-8625) creates a wear-resistant ceramic layer up to 100µm thick, critical for moving parts in automation. Standard anodizing (Type II) enhances corrosion protection and provides an ideal base for adhesives or paints in medical enclosures. Our quality control data shows properly anodized aluminum parts achieve 1,000+ hours in ASTM B117 salt spray tests, whereas bare aluminum fails within 24 hours. Always specify anodizing requirements during the design phase; attempting it post-machining risks dimensional inaccuracies on tight-tolerance features.

Material performance characteristics guide optimal application suitability. Consider these key parameters:

| Material | Common Grades | Tensile Strength (MPa) | Machinability Rating | Primary Application Sectors |

|---|---|---|---|---|

| Aluminum Alloy | 6061-T6, 7075-T6 | 310 (6061), 572 (7075) | Excellent (A) | Aerospace, Robotics, Electronics |

| Stainless Steel | 304, 17-4PH | 515 (304), 1000 (17-4PH) | Moderate (C) | Medical Implants, Marine Hardware |

| Titanium Alloy | Ti-6Al-4V (Gr 5) | 900 | Poor (D) | Jet Engine Components, Defense |

Precision Aluminium CNC Fräsen demands a holistic view where material properties, machining complexity, and required surface engineering are evaluated concurrently. At Wuxi Lead, we integrate material science expertise with advanced 5-axis milling capabilities to ensure your selected alloy achieves its full functional potential within stringent tolerance envelopes. Consult our engineering team early in the design phase to optimize material selection for manufacturability and long-term performance.

Manufacturing Process & QC

Design: The Foundation of Precision Aluminium CNC Milling

At Wuxi Lead Precision Machinery, the aluminium CNC milling process begins with a rigorous design phase that integrates engineering intent with manufacturability. Our engineering team collaborates closely with clients to analyze 3D CAD models, ensuring dimensional accuracy, material suitability, and compliance with functional requirements. Using advanced simulation software such as Siemens NX and Autodesk PowerMill, we conduct virtual machining trials to detect potential toolpath conflicts, optimize cutting strategies, and minimize material stress. This phase includes detailed tolerance analysis, surface finish specifications, and thermal deformation modeling—critical for high-precision aluminium components used in aerospace, medical, and automation industries. Design for Manufacturability (DFM) reviews are mandatory, reducing complexity and eliminating costly revisions downstream.

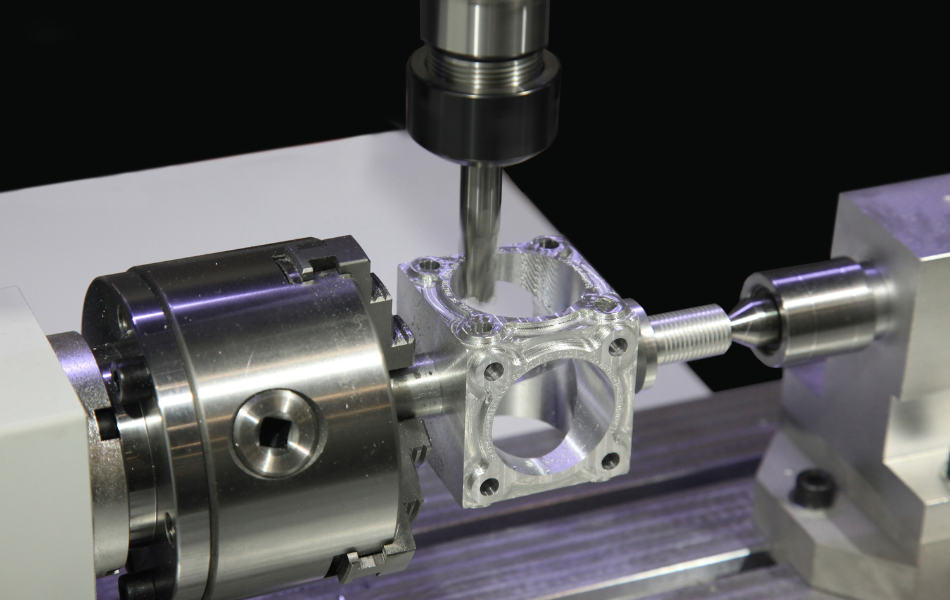

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using high-speed 5-axis CNC milling centres. Prototypes are machined from certified aluminium alloys such as 6061-T6, 7075-T6, and 2024-T3, selected based on strength-to-weight ratio, corrosion resistance, and machinability. Each prototype undergoes full dimensional inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify geometric accuracy within ±0.005 mm. Surface roughness is measured using profilometers to ensure compliance with Ra values as low as 0.4 µm. Functional testing, including fit checks, thermal cycling, and load simulation, validates performance under real-world conditions. Feedback from this stage is incorporated into final process adjustments, ensuring the transition to mass production is seamless and risk-free.

Mass Production: Zero Defects Through Process Control

Our mass production line operates under a Zero Defects philosophy, driven by statistical process control (SPC), real-time tool wear monitoring, and automated in-process inspection. Components are machined on dedicated CNC cells equipped with automatic pallet changers and robotic part handling, ensuring consistency and throughput. Each production batch is traceable via our MES (Manufacturing Execution System), recording machine parameters, tool life, inspection data, and operator inputs. Final quality assurance includes 100% visual inspection, batch sampling for metallurgical analysis, and first-article inspection reports (FAIR) per AS9102 standards. Non-conforming parts are immediately quarantined and root cause analysis initiated using Six Sigma methodologies.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Alloys | 6061-T6, 7075-T6, 2024-T3, 5052, 6082 |

| Tolerance Range | ±0.005 mm to ±0.02 mm (feature-dependent) |

| Surface Roughness (Ra) | 0.4 µm to 3.2 µm (machined), down to 0.2 µm (polished) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis capability) |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.003 mm |

| Inspection Equipment | CMM, 3D Scanner, Optical Comparator, Profilometer |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9100D |

Through seamless integration of design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures every aluminium CNC milled component meets the highest standards of quality, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Aluminum CNC Milling Projects with Precision Engineering

Aluminum CNC milling demands exceptional technical mastery due to the material’s thermal sensitivity, chip evacuation challenges, and stringent tolerance requirements. Substandard machining leads to dimensional drift, surface imperfections, and costly rework—risks no high-stakes manufacturer can afford. At Wuxi Lead Precision Machinery, we engineer solutions for complex aluminum components where micron-level accuracy and structural integrity are non-negotiable. Our German-calibrated 5-axis machining centers, coupled with proprietary coolant strategies and rigid workholding systems, eliminate common pitfalls in aluminum processing. We consistently achieve tolerances down to ±0.005 mm while maintaining optimal surface finishes, even for intricate geometries in aerospace-grade 7075-T6 or medical 6061 alloys.

Our facility operates under ISO 9001:2015 certification with real-time SPC monitoring across all production cells. Unlike generic CNC shops, we deploy material-specific toolpath algorithms that minimize heat buildup and vibration—critical for thin-walled enclosures or fluidic manifolds. Every component undergoes rigorous CMM validation against your CAD model, with full traceability from raw billet to finished part. This disciplined approach ensures zero scrap rates for clients in semiconductor tooling, defense systems, and high-performance automotive sectors.

Technical Capabilities for Aluminum CNC Milling

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Max Work Envelope | 1,200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Surface Finish (Ra) | 0.4 µm to 3.2 µm |

| Supported Alloys | 2024, 5052, 6061, 7075, ADC12 |

| Machine Fleet | HAAS UMC-750, DMG MORI CTX beta 1250 |

Partnering with Wuxi Lead means accessing a dedicated engineering team that collaborates from design-for-manufacturability (DFM) review through production scaling. We reduce lead times by 30% through optimized nesting and 24/7 unmanned machining cells, without compromising quality. Our clients gain a strategic advantage: predictable delivery of mission-critical aluminum components that meet AS9100 and NADCAP standards.

Do not compromise on precision when aluminum performance defines your product’s success. Contact our engineering team directly at [email protected] to request a process audit for your next project. Include your part drawings and volume requirements to receive a tailored capability analysis within 24 hours. Wuxi Lead Precision Machinery—where Chinese manufacturing scale meets German engineering rigor. Your vision, perfected in aluminum.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.