Technical Contents

Engineering Guide: Cnc 5Th Axis

Engineering Insight: The Precision Imperative in CNC 5th Axis Machining

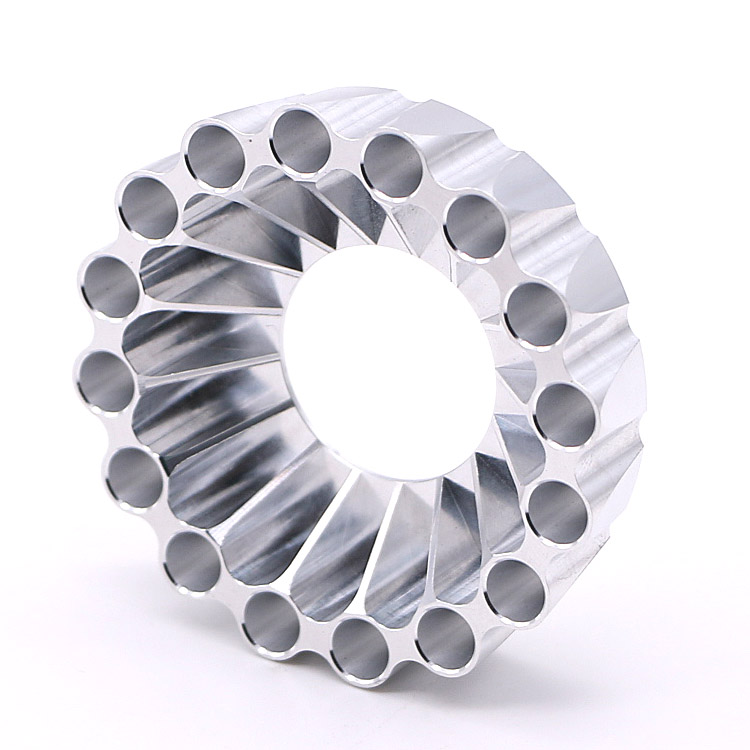

The integration of a 5th axis fundamentally transforms CNC machining capability, moving beyond simple multi-sided operations to enable the production of complex, organic geometries previously requiring extensive manual intervention or multiple setups. However, the true value of a 5th axis system is not merely its rotational capability; it is critically defined by its precision and stability under dynamic cutting conditions. In high-value sectors like aerospace, medical implant manufacturing, and advanced optics, tolerances routinely demand sub-micron accuracy across all five axes simultaneously. A poorly engineered 5th axis introduces cumulative errors – angular deviations, lost motion, or thermal drift – that propagate through the entire machining process, rendering the theoretical capability useless for mission-critical components. Precision isn’t an optional feature; it is the non-negotiable foundation determining part yield, functional performance, and ultimately, the return on investment in advanced multi-axis technology.

Achieving this level of precision demands rigorous engineering far beyond basic rotary table integration. It requires monolithic structural design to minimize deflection, high-resolution feedback systems on every axis (including the rotary), sophisticated real-time thermal compensation algorithms, and advanced kinematic calibration routines that account for complex error mapping across the entire work envelope. The machine must maintain geometric integrity not just at rest, but under the significant inertial and cutting forces encountered during high-speed, high-torque 5-axis contouring. Compromises in any of these areas lead to surface finish defects, dimensional inaccuracies, and unacceptable scrap rates in demanding production environments. True 5-axis precision ensures that the theoretical toolpath executed in the CAM system is replicated identically on the physical part, batch after batch.

Wuxi Lead Precision Machinery has engineered its 5-axis platforms specifically for this uncompromising precision requirement. Our systems are the result of deep expertise forged through supplying components for critical infrastructure projects, including precision elements for Olympic venue construction and stringent defense applications where failure is not an option. This experience ingrained in us the absolute necessity of metrology-grade performance under real-world production pressures. We understand that our clients’ reputations and project timelines depend on machines that deliver certified accuracy, not just rotational motion.

The following table outlines the core precision specifications defining our high-end 5-axis machining centers, validated per ISO 230-2 standards:

| Specification | Performance Level | Significance |

|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±1.5 µm | Ensures dimensional fidelity on complex surfaces |

| Positioning Accuracy (A, C) | ±2.5 arc-seconds | Critical for precise angular feature placement |

| Repeatability (All Axes) | ≤0.8 µm | Guarantees consistent part quality in production |

| Volumetric Compensation | Full 3D Error Map | Corrects for machine geometry across work volume |

| Thermal Drift Control | <1.0 µm/°C | Maintains accuracy during extended operations |

| Rotary Axis Rigidity | >500 Nm/arc-sec | Minimizes deflection under cutting load |

This commitment to measurable, verifiable precision engineering allows manufacturers to confidently tackle the most intricate 5-axis programs, knowing the machine itself is the reliable foundation for success, not a source of uncertainty. It transforms the 5th axis from a novelty into a predictable, high-value production asset.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced 5-axis CNC machining capabilities designed for high-complexity, high-precision components across aerospace, medical, energy, and industrial automation sectors. Our 5-axis CNC platforms integrate simultaneous multi-axis motion, enabling the machining of intricate geometries with superior surface finish and dimensional accuracy. These systems eliminate the need for multiple setups, reducing cumulative error and improving part consistency. Equipped with high-torque spindles, thermal compensation systems, and real-time tool monitoring, our machines maintain peak performance during extended production runs.

All 5-axis operations are supported by a rigorous quality control framework anchored in CMM (Coordinate Measuring Machine) inspection. Every critical dimension is verified post-machining using Zeiss and Hexagon CMM systems, ensuring full compliance with AS9100, ISO 13485, and other industry-specific standards. Our inspection protocols include first-article inspection (FAI), in-process checks, and final batch validation, providing traceable, auditable data for every component produced.

Our technical team combines deep process engineering expertise with advanced CAM programming using Mastercam and Siemens NX, enabling optimized toolpaths that maximize material removal rates while preserving tight tolerances. We support a wide range of materials, including titanium alloys, Inconel, aluminum 7075-T6, stainless steel 17-4 PH, and high-performance engineering plastics such as PEEK and ULTEM. Work envelope capacity reaches up to 1,200 mm × 800 mm × 750 mm, accommodating mid-to-large-sized precision components without compromising accuracy.

The integration of 5-axis technology allows undercuts, deep cavities, and organic contours to be machined in a single setup, significantly reducing lead times and enhancing repeatability. This capability is particularly critical for prototyping and low-volume production runs where flexibility and precision are paramount. Our facility operates under a closed-loop manufacturing system, where CMM feedback is used to adjust ongoing production parameters, ensuring continuous quality improvement.

All machined parts are documented with full inspection reports, including GD&T analysis and surface roughness measurements. Customers receive digital quality dossiers alongside physical parts, enabling seamless integration into downstream assembly and certification processes.

The following table outlines our standard technical specifications and achievable tolerances:

| Parameter | Specification |

|---|---|

| Axis Configuration | 5-Axis Simultaneous (X, Y, Z, A, B) |

| Maximum Work Envelope | 1,200 mm × 800 mm × 750 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance | ±0.010 mm per 100 mm |

| Angular Tolerance | ±0.02° |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Materials Supported | Aluminum, Titanium, Stainless Steel, Inconel, PEEK, ULTEM, Brass, Tool Steels |

| Quality Standards | ISO 9001, AS9100, ISO 13485 |

| Inspection Equipment | Zeiss & Hexagon CMM, Optical Comparators, Micrometers, Calipers |

Wuxi Lead Precision Machinery maintains full process ownership from CAD model to certified component delivery, ensuring technical excellence and supply chain reliability for mission-critical applications.

Material & Finish Options

Material Selection for Precision 5-Axis CNC Machining

Material selection is a critical determinant of success in complex 5-axis CNC machining operations. The interplay between material properties, intricate geometry, and continuous multi-directional tool engagement demands careful evaluation. At Wuxi Lead Precision Machinery, we emphasize that optimal material choice directly impacts achievable tolerances, surface finish quality, tool life, cycle time, and ultimately, the functional performance of the finished component. Understanding the unique machining characteristics of aluminum, steel, and titanium is essential for leveraging the full capabilities of modern 5-axis systems.

Aluminum alloys, particularly 6061 and 7075, are prevalent in aerospace, automotive, and consumer electronics due to their excellent strength-to-weight ratio, high thermal conductivity, and good machinability. Their relatively low hardness allows for high feed rates and rapid material removal on 5-axis machines, minimizing heat buildup during complex contouring. However, aluminum’s softness requires sharp tooling and precise parameters to avoid built-up edge and achieve fine finishes. Anodizing is the predominant post-machining finish, significantly enhancing surface hardness, corrosion resistance, and wear properties. Type II (sulfuric acid) offers standard protection and dyeing capability, while hardcoat Type III anodizing provides superior abrasion resistance for demanding applications. Careful masking is crucial for critical functional surfaces.

Carbon and alloy steels, such as 4140 and 1018, are chosen for applications requiring high strength, durability, and wear resistance, common in tooling, hydraulics, and structural components. Steel machining generates significant heat and places high demands on tooling and machine rigidity during prolonged 5-axis cuts. Work hardening tendencies necessitate consistent feed rates and robust coolant strategies to prevent premature tool failure and maintain dimensional accuracy. While anodizing is not applicable, common finishes include passivation, powder coating, plating (e.g., zinc, chrome), and precision polishing, each selected based on the operational environment and functional requirements.

Titanium alloys, primarily Ti-6Al-4V, are indispensable in aerospace and medical sectors for their exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance at high temperatures. However, titanium presents significant machining challenges: low thermal conductivity leads to intense localized heat at the cutting edge, high chemical reactivity risks galling, and its strength causes rapid tool wear. Successful 5-axis machining of titanium requires extremely rigid setups, lower surface speeds, higher feed rates per tooth, specialized carbide or ceramic tooling, and copious, targeted coolant application to manage heat and prevent work hardening. Finishing typically involves chemical passivation or specialized coatings like TiN, as anodizing is not standard for titanium.

The following table summarizes key material considerations for 5-axis CNC machining:

| Material | Key Properties for Machining | Critical Machining Considerations for 5-Axis | Common Finishes |

|---|---|---|---|

| Aluminum Alloys | Low density High thermal conductivity Moderate strength | High feed rates possible Risk of built-up edge Requires sharp tools | Type II Anodizing Type III Hardcoat Anodizing |

| Steel Alloys | High strength High density Moderate thermal conductivity | Generates significant heat Work hardening risk Demands rigidity | Passivation Plating Powder Coating Polishing |

| Titanium Alloys | High strength-to-weight ratio Very low thermal conductivity High reactivity | Intense localized heat Rapid tool wear Requires rigid setup Low SFM | Chemical Passivation PVD/CVD Coatings |

Selecting the right material requires balancing application demands with the realities of 5-axis machining efficiency. Wuxi Lead Precision Machinery provides expert consultation to match your component requirements with optimal material and finish selection, ensuring your complex geometries are produced with precision, repeatability, and cost-effectiveness.

Manufacturing Process & QC

From Design to Zero-Defect Mass Production: The CNC 5th Axis Workflow at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, the production process for CNC 5th axis components follows a rigorously controlled sequence from initial design through prototyping to full-scale mass production. This structured workflow ensures precision, repeatability, and adherence to zero-defect manufacturing standards demanded by high-end industries such as aerospace, medical devices, and advanced automation.

The process begins with collaborative design engineering. Our team works closely with clients to translate complex geometries and functional requirements into optimized 3D CAD models. Using advanced simulation software, we conduct finite element analysis (FEA) and kinematic verification to validate tool paths and detect potential interference in 5-axis motion. This stage ensures that the design is not only manufacturable but also optimized for minimal cycle time and maximum structural integrity.

Once the design is finalized, we proceed to prototype development. Utilizing our high-precision 5-axis CNC machining centers, we produce initial samples with tight tolerances typically within ±0.005 mm. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to verify dimensional accuracy and surface finish. Feedback from this stage is integrated into final process adjustments, ensuring any deviations are corrected before scaling to mass production.

Mass production is executed under a fully documented quality management system compliant with ISO 9001:2015 standards. Our 5-axis machining platforms operate with automated tool changers, real-time tool wear monitoring, and in-process probing to maintain consistency across batches. Every component is traceable through our digital manufacturing execution system (MES), which logs machine parameters, inspection data, and operator inputs. This level of process control is fundamental to achieving zero defects.

Statistical process control (SPC) is applied throughout production, with continuous monitoring of critical dimensions. Any trend toward out-of-specification performance triggers immediate corrective action. Final inspection includes 100% visual checks and sampling-based destructive testing where applicable, ensuring mechanical properties meet required specifications.

Our commitment to zero defects is reinforced by a culture of continuous improvement. Root cause analysis is standard practice for even minor deviations, driving long-term process stability and customer confidence.

Key Technical Specifications of 5-Axis Production Platform

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed Range | 20,000 rpm (HSK-A63 interface) |

| Axis Travel (X/Y/Z) | 760 / 660 / 560 mm |

| Rotary Axis (A/C) Range | A: ±120°, C: 360° continuous |

| Surface Finish (Typical) | Ra 0.4–1.6 µm |

| Maximum Workpiece Size | Ø600 mm × 500 mm height |

| Control System | Siemens 840D Solution Line |

| In-Process Measurement | Touch probe with automated compensation |

| Production Tolerance Range | ±0.005 mm (standard), ±0.002 mm (tight) |

This end-to-end process ensures that every component produced on our 5-axis platforms meets the highest standards of precision, reliability, and consistency.

Why Choose Wuxi Lead Precision

Elevate Complex Manufacturing with Lead Precision’s 5th Axis Expertise

Complex geometries and tight-tolerance components demand more than standard 3-axis machining. At Wuxi Lead Precision Machinery, we engineer industrial-grade 5th axis solutions that eliminate secondary setups, reduce cycle times by up to 40%, and deliver micron-level accuracy for aerospace, medical, and energy sector applications. Our systems integrate seamlessly with existing CNC platforms, transforming production bottlenecks into competitive advantages through proven engineering rigor.

Lead Precision’s 5th axis rotary tables and trunnion units are built for relentless operational integrity. Each unit undergoes 72 hours of thermal stability testing and dynamic load validation to ensure performance consistency under continuous high-load conditions. Unlike generic alternatives, our proprietary backlash compensation algorithm maintains ±2 arc-second precision across 20,000+ operational hours, directly reducing scrap rates in critical part runs. This isn’t theoretical capability—it’s the standard we deploy in global production environments daily.

Technical Specifications Guaranteeing Performance

| Parameter | Specification | Industry Standard |

|---|---|---|

| Positioning Accuracy | ±1.5 arc-seconds | ±5 arc-seconds |

| Repeatability | ±0.8 arc-seconds | ±2 arc-seconds |

| Maximum Torque | 1,200 Nm | 800 Nm |

| Rotary Speed | 60 RPM (continuous) | 40 RPM |

| Tool Interface | HSK-A63 / CAT-40 optional | CAT-40 only |

| Cooling System | Integrated oil-jet + forced air | Air cooling only |

Partnering with Lead Precision means accessing more than hardware. You gain direct engineering collaboration from feasibility analysis through to full production integration. Our team provides onsite process optimization, custom fixture design, and real-time support from our Wuxi-based technical hub—ensuring your 5th axis investment delivers immediate ROI. Clients consistently achieve first-pass yield rates exceeding 98.5% on turbine blades, orthopedic implants, and hydraulic manifolds, where conventional methods struggle with cumulative error.

We understand that machine uptime dictates your profitability. That’s why every 5th axis system ships with predictive maintenance analytics via our LeadSmart IoT platform, forecasting component wear 30 days in advance. This proactive approach minimizes unplanned downtime, a critical factor for high-mix, low-volume manufacturers where schedule adherence is non-negotiable.

Your next-generation components require next-generation motion control. Stop compromising on complexity or tolerances. Contact our engineering team to discuss how Lead Precision’s 5th axis technology can resolve your specific production challenges. We’ll provide a detailed capability assessment and ROI projection within 48 hours of your inquiry.

Initiate your precision transformation today. Email [email protected] with your part specifications and throughput requirements. Let’s engineer excellence together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.