Technical Contents

Engineering Guide: Wilmington Sheet Metal

Engineering Insight Precision in Wilmington Sheet Metal Fabrication

Precision in sheet metal fabrication is non-negotiable for critical applications, especially within demanding sectors like aerospace, defense, and advanced medical equipment prevalent in regions such as Wilmington. Tolerances measured in thousandths of an inch directly impact part functionality, assembly integrity, and final product performance. Inadequate precision leads to costly rework, assembly failures, compromised structural integrity, and potential safety hazards. For Wilmington manufacturers and their global supply chains, achieving micron-level accuracy isn’t merely desirable; it is a fundamental requirement for competitiveness and reliability in high-stakes markets. The complexity of modern designs, featuring intricate geometries and tight inter-part relationships, demands fabrication processes controlled to the absolute limit of machine capability and material behavior.

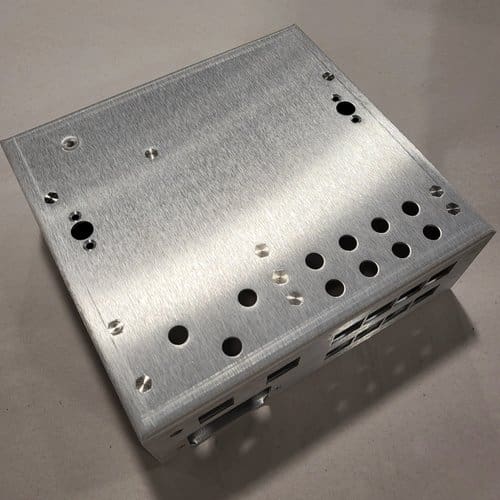

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in meeting these extreme precision demands. Our engineering team understands the unique challenges of sheet metal, where material springback, thermal distortion during cutting, and tooling deflection can derail even the most sophisticated designs. We have successfully delivered components for projects where failure was not an option, including critical structural elements for Olympic venue construction and precision enclosures for advanced military communication systems. These experiences forged our methodology: rigorous material characterization, adaptive process programming, and multi-stage in-process inspection protocols. We treat every Wilmington sheet metal project with the same uncompromising standards applied to national defense contracts, ensuring dimensional stability and repeatability batch after batch.

Our commitment is backed by advanced technology and stringent quality control. We utilize state-of-the-art fiber laser cutting systems, high-tonnage CNC press brakes with real-time angle correction, and automated bending cells. Every process step incorporates metrology, from initial flat pattern verification to final first-article inspection using calibrated CMMs. This integrated approach guarantees that parts meet or exceed the most challenging specifications required by Wilmington’s advanced manufacturing ecosystem.

The following table outlines key capabilities essential for high-precision Wilmington sheet metal work:

| Process | Material Thickness Range | Standard Tolerance | High-Precision Tolerance | Max Speed (Mild Steel) |

|---|---|---|---|---|

| Fiber Laser Cutting | 0.5 mm – 25 mm (0.02″ – 1.0″) | ±0.1 mm (±0.004″) | ±0.05 mm (±0.002″) | 40 m/min (63 ipm) |

| CNC Press Brake | 0.8 mm – 6.0 mm (0.03″ – 0.24″) | ±0.2° | ±0.1° | 12 bends/min |

| Automated Bending | 1.0 mm – 4.0 mm (0.04″ – 0.16″) | ±0.15 mm (±0.006″) | ±0.08 mm (±0.003″) | 8 parts/min |

Achieving true precision requires more than just machinery; it demands deep engineering insight into material science, process physics, and geometric dimensioning. Wuxi Lead Precision Machinery partners with Wilmington manufacturers to transform complex sheet metal designs into flawless reality, ensuring every component meets the exacting standards of performance-critical applications. Contact us to discuss how our precision engineering discipline can elevate your next project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries and tight-tolerance components that meet the rigorous demands of aerospace, medical, and high-end industrial sectors. Unlike conventional 3-axis systems, our 5-axis CNC platforms allow simultaneous movement across five planes, significantly enhancing contour accuracy, surface finish, and production efficiency. This capability is particularly critical when fabricating sheet metal components with intricate cutouts, compound angles, and multi-faceted forms where traditional methods fall short.

Our fabrication workflow integrates precision cutting, bending, punching, and forming processes, all supported by advanced CNC control systems. High-speed fiber laser cutting ensures clean, burr-free edges with minimal heat-affected zones, preserving material integrity. Automated bending cells, guided by CNC press brakes with real-time feedback, maintain angular consistency across high-volume runs. We process a wide range of sheet metals including stainless steel, aluminum, carbon steel, and specialty alloys, with thicknesses ranging from 0.5 mm to 12 mm, depending on material and geometry.

Quality control is embedded at every stage of production. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, providing metrology-grade validation of part conformity. Our CMM systems operate under temperature-controlled conditions to eliminate thermal drift, ensuring measurement accuracy down to ±0.001 mm. This level of inspection supports full traceability and compliance with ISO 9001 and AS9100 standards. In addition to dimensional verification, we conduct in-process checks for surface finish, edge quality, and geometric alignment to prevent deviation before final inspection.

The following table outlines the standard technical tolerances achievable across our sheet metal fabrication processes:

| Process | Dimensional Tolerance | Angular Tolerance | Positional Tolerance | Surface Roughness (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | ±0.01 mm | 0.8 – 3.2 µm |

| Fiber Laser Cutting | ±0.05 mm | ±0.2° | ±0.1 mm | 6.3 – 12.5 µm |

| CNC Punching | ±0.1 mm | — | ±0.15 mm | 6.3 – 25 µm |

| CNC Bending | ±0.1 mm | ±0.5° | — | — |

| CMM Inspection Capability | Up to ±0.001 mm | ±0.05° | ±0.005 mm | — |

These specifications reflect our commitment to delivering components that meet exacting engineering requirements. By combining 5-axis CNC flexibility with rigorous quality assurance protocols, Wuxi Lead Precision Machinery ensures consistent, high-precision output tailored to the needs of advanced manufacturing clients worldwide.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material selection fundamentally dictates performance, cost, and manufacturability in high-precision sheet metal components. At Wuxi Lead Precision Machinery, our decades of experience machining complex parts for aerospace, medical, and industrial clients reveal that informed choices between Aluminum, Steel, and Titanium directly impact project success. Each material presents distinct advantages and challenges requiring careful evaluation against application demands, environmental exposure, and production requirements. Selecting the optimal base material and finish is not merely a technical specification; it is a critical strategic decision influencing component lifespan, assembly integrity, and total cost of ownership.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring an exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent thermal/electrical conductivity. These properties make aluminum indispensable for aerospace structures, heat sinks, and transportation components. Its relative softness compared to steel facilitates easier machining and forming but necessitates careful handling to avoid surface marring. Steel, especially 304 and 316 stainless grades, provides superior strength, hardness, and wear resistance essential for structural frameworks, enclosures, and high-stress mechanical parts. The chromium content in stainless steel delivers robust corrosion resistance, though 316 offers enhanced protection in chloride-rich environments. Carbon steel variants like 1018 offer high strength and weldability at lower cost but require protective finishes for corrosion-prone applications. Titanium Grade 5 (6Al-4V) represents the premium choice for extreme environments demanding unparalleled strength-to-weight ratio, exceptional corrosion resistance across acids and salts, and biocompatibility. Its use is critical in aerospace critical components, medical implants, and marine hardware, though its high cost and challenging machinability necessitate specialized CNC expertise.

Anodizing remains the premier surface treatment for aluminum, significantly enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for adhesion. Type II (Sulfuric Acid) anodizing offers a versatile balance of durability and color options for general industrial use. Type III (Hardcoat) anodizing delivers substantially thicker, harder coatings essential for components subject to severe abrasion or requiring precise dimensional control post-treatment. The porous nature of the anodic layer allows for effective dyeing, meeting both functional and aesthetic requirements. Selecting the appropriate anodizing type and thickness is paramount for ensuring the component meets its operational lifecycle demands.

Material properties must align precisely with fabrication capabilities. The following table summarizes key characteristics for common sheet metal alloys:

| Material | Density (lb/in³) | Tensile Strength (psi) | Corrosion Resistance | Key Applications | Machinability Notes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 0.098 | 45,000 | Very Good | Aerospace frames, structural parts | Excellent, low cutting forces |

| Steel 304 SS | 0.289 | 75,000 | Excellent | Food processing, chemical equipment | Moderate, work hardening |

| Steel 316 SS | 0.289 | 75,000 | Outstanding | Marine, pharmaceutical | Moderate, significant work hardening |

| Titanium Gr5 | 0.176 | 138,000 | Exceptional | Aerospace, medical implants | Poor, low thermal conductivity |

Understanding these material fundamentals allows Wilmington Sheet Metal and its clients to optimize designs for manufacturability, ensuring components meet rigorous performance standards while maximizing cost efficiency. Wuxi Lead Precision Machinery leverages advanced CNC technology and deep metallurgical knowledge to transform these materials into mission-critical parts, providing expert consultation on material and finish selection tailored to your specific project constraints and performance goals. The right choice starts here.

Manufacturing Process & QC

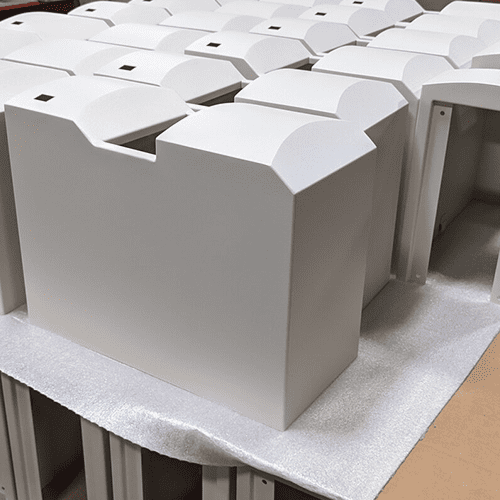

The sheet metal fabrication process at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure precision, repeatability, and zero-defect output for high-end industrial clients. Our methodology integrates advanced engineering with rigorous quality control, beginning with design and culminating in scalable mass production.

Design is the foundation of every successful fabrication project. Our engineering team collaborates closely with client specifications, utilizing 3D CAD software such as SolidWorks, AutoCAD, and Siemens NX to develop optimized sheet metal layouts. Design for Manufacturability (DFM) principles are applied from the outset to identify potential issues related to material selection, bend allowances, weld accessibility, and tolerance stacking. Finite Element Analysis (FEA) is employed when structural integrity is critical, ensuring that each component performs under real-world conditions. All designs undergo internal review and client validation before moving forward, minimizing downstream revisions.

Prototyping follows design approval and serves as a critical validation phase. We produce functional prototypes using the same materials and equipment intended for full-scale production, ensuring accurate performance assessment. Laser cutting, CNC punching, and precision press braking form the core of our prototype fabrication, with tolerances held to ±0.1 mm. Each prototype is subjected to dimensional inspection via CMM (Coordinate Measuring Machine) and, where applicable, fit-check assembly testing. Feedback from this stage informs final adjustments, guaranteeing that the design is not only manufacturable but also optimized for consistency and reliability.

Mass production leverages automated workflows and standardized work instructions to maintain uniformity across thousands of parts. Our production floor integrates fiber laser cutting systems, automated bending cells, and robotic welding stations, all monitored in real time through a centralized manufacturing execution system (MES). Every stage includes in-process quality checkpoints, including first-article inspection (FAI) and statistical process control (SPC) sampling. Final inspection confirms compliance with geometric dimensioning and tolerancing (GD&T) requirements, surface finish, and material certification. Non-conforming parts are quarantined immediately, and root cause analysis is conducted to prevent recurrence.

Throughout the entire process, traceability is maintained via barcode tracking, linking each component to its material lot, machine settings, operator, and inspection data. This closed-loop system is central to our zero-defect philosophy, ensuring accountability and continuous improvement.

Key production capabilities are outlined below:

| Parameter | Specification |

|---|---|

| Material Thickness | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm |

| Max Part Size | 4000 mm × 2000 mm |

| Bending Accuracy | ±0.5° |

| Laser Cutting Precision | ±0.05 mm |

| Surface Roughness (Ra) | ≤1.6 μm (machined), ≤3.2 μm (as-formed) |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

Wuxi Lead Precision Machinery delivers uncompromised quality in sheet metal fabrication by aligning engineering excellence with disciplined production control. From concept to volume output, our process ensures every part meets the highest industrial standards.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Strategic Partnership

Wuxi Lead Precision Machinery represents the pinnacle of advanced sheet metal manufacturing capability for discerning industrial partners like Wilmington Sheet Metal. Our collaboration transcends conventional supplier relationships, integrating deep engineering expertise with state-of-the-art production resources to solve complex fabrication challenges. As your dedicated precision partner, we commit to delivering components that meet exacting aerospace, medical, and industrial equipment specifications while optimizing your total cost of ownership through reduced waste, accelerated lead times, and uncompromised repeatability. Our facility operates under ISO 9001 and IATF 16949 standards, ensuring every process—from initial design consultation to final inspection—is rigorously controlled and traceable.

Our technical infrastructure supports the most demanding sheet metal requirements. We deploy 5-axis laser cutting systems with intelligent nesting software to maximize material yield on exotic alloys and composites, alongside high-tonnage press brakes featuring CNC-controlled backgauging for sub-0.1mm bending accuracy. This precision is sustained across high-mix, low-volume production runs or sustained high-volume campaigns through integrated MES tracking and real-time SPC monitoring. The table below summarizes our core fabrication capabilities relevant to advanced sheet metal applications.

| Capability | Specification Range | Key Technology |

|---|---|---|

| Laser Cutting | 0.5mm – 25mm thickness | 6kW Fiber Laser, ±0.05mm tolerance |

| CNC Punching | 0.8mm – 6.0mm thickness | Turret capacity: 60+ tools |

| Press Brake Forming | 0.5mm – 12mm thickness, 4m length | Crowning systems, ±0.1° angular accuracy |

| Robotic Welding | TIG/MIG, thin-wall to structural | Path compensation, zero-defect focus |

| Secondary Operations | Deburring, tapping, hardware insertion | Automated inline processing |

Wilmington Sheet Metal’s reputation for quality demands partners who anticipate challenges before they impact your production flow. Our engineering team conducts pre-production DFM analysis to identify cost-saving opportunities and potential manufacturability risks, providing actionable feedback within 48 hours of receiving your CAD data. This proactive approach prevents costly revisions and ensures first-article approval rates exceed 98%. Furthermore, our dedicated account management structure guarantees direct access to process engineers—not call center personnel—when technical escalations arise, minimizing downtime during critical production phases.

The competitive landscape for precision sheet metal fabrication requires more than equipment—it demands a partner invested in your operational success. Wuxi Lead Precision Machinery combines Chinese manufacturing scale with German-engineered process discipline, delivering the consistency global OEMs require. We absorb the complexity of advanced material handling, stringent metrology, and just-in-time logistics so you can focus on core value creation.

Initiate a technical dialogue to transform your sheet metal supply chain. Submit your most challenging fabrication requirements to [email protected]. Our engineering team will respond within one business day with a detailed capability assessment and process validation plan tailored to your project. Partner with precision—where every micron matters and every deadline is a commitment.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.