Technical Contents

Engineering Guide: Injection Mold Services

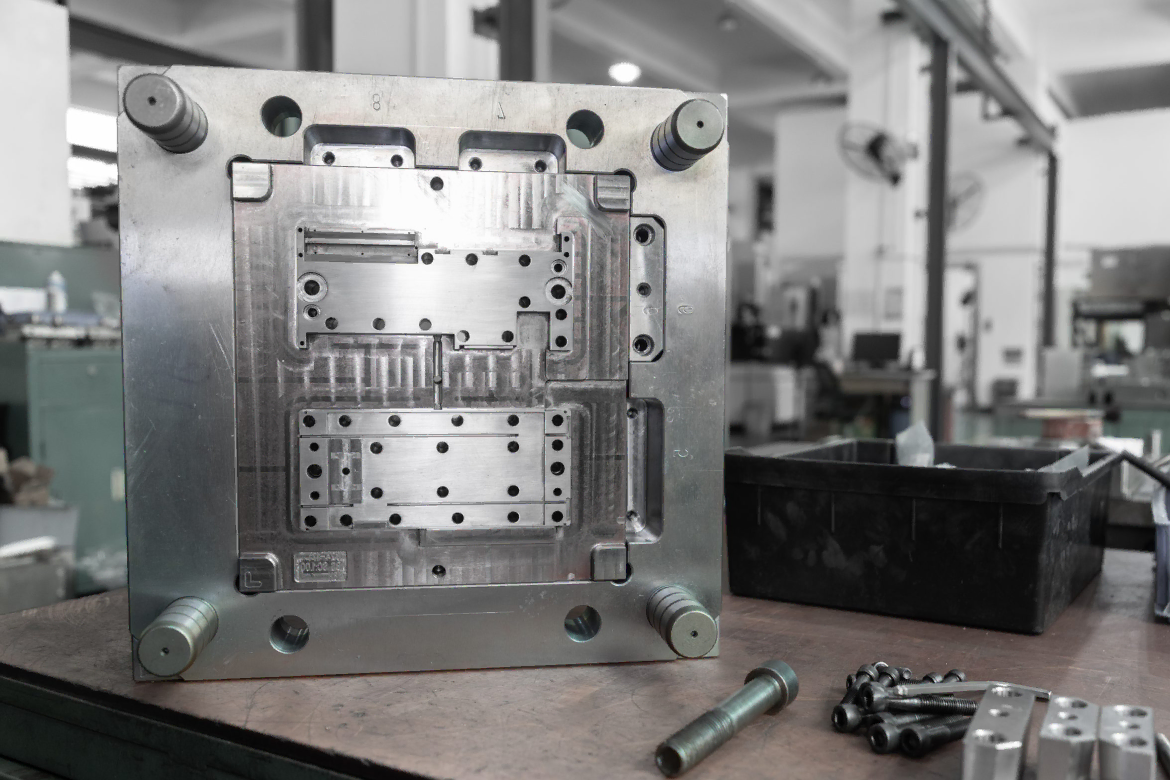

Engineering Insight Precision Injection Molding Services

Precision in injection mold manufacturing is non-negotiable for high-performance industrial applications. Sub-micron deviations in mold geometry directly translate to part warpage, inconsistent wall thickness, and premature wear—compromising structural integrity and lifecycle performance. At Wuxi Lead Precision Machinery, we treat mold cavity tolerances as critical flight parameters. Our engineering process begins with tolerance stack-up analysis using Siemens NX, simulating thermal expansion, pressure differentials, and material flow to preempt defects before steel cutting. This eliminates costly iterations and ensures first-article compliance with AS9100 and ISO 2768-mK standards.

Our commitment to micron-level accuracy is validated through mission-critical projects. We engineered molds for timing system components in the Beijing Winter Olympics infrastructure, where thermal stability within ±0.005mm across 80°C gradients was mandatory. Similarly, aerospace-grade hydraulic manifolds produced for military avionics demanded Cpk ≥1.67 across 50,000+ cycles—achieved through hardened H13 tool steel with PVD coatings and balanced cooling channels verified via Moldflow analysis. These projects underscore that precision isn’t theoretical; it’s the margin between operational success and catastrophic failure in extreme environments.

Wuxi Lead’s technical edge stems from integrated metrology and process control. All molds undergo 100% CMM validation against nominal CAD data, with surface finishes measured to Ra 0.05μm using Taylor Hobson profilometers. Below are core capabilities enabling this rigor:

| Specification Category | Performance Metric | Verification Standard |

|---|---|---|

| Linear Tolerance | ±0.002 mm | ISO 2768-fine |

| Surface Roughness | Ra 0.02–0.05 μm | ISO 1302 |

| Thermal Stability | 0.002 mm/°C drift | ASTM E228 |

| Cavity Pressure Control | ±0.5% full scale | ISO 4915 |

| Tool Steel Hardness | 52–54 HRC (post-PVD) | ASTM E18 |

Beyond specifications, we prioritize process repeatability. Each mold’s cooling circuit is optimized via computational fluid dynamics to maintain uniform thermal distribution, reducing cycle times by 18% while eliminating sink marks. Our Makino MAG4 and DMG MORI SHW 65 machines operate under constant environmental monitoring (20±0.5°C), ensuring dimensional stability during multi-week builds. Crucially, we document every process parameter—from mold clamping force to polymer residence time—creating a digital twin for predictive maintenance and rapid troubleshooting.

For industries where failure is not an option, mold precision defines product reliability. Wuxi Lead Precision Machinery delivers this through military-grade discipline in engineering and manufacturing. We partner with clients from initial DFM review through production validation, transforming tolerance challenges into competitive advantages. Contact our engineering team to discuss how our Olympic-proven methodology can secure your next high-stakes project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced injection mold services tailored for high-precision industrial applications. Our technical capabilities are built upon a foundation of state-of-the-art equipment, rigorous quality control, and deep expertise in custom metal manufacturing. Central to our production workflow is the integration of 5-axis CNC machining systems, which enable us to produce complex mold geometries with exceptional accuracy and surface finish. These multi-axis platforms allow for simultaneous movement across five planes, reducing setup times and minimizing cumulative tolerances associated with multiple fixtures. This capability is particularly critical when manufacturing intricate mold cores, cavities, and sliders that demand tight alignment and micron-level precision.

Our 5-axis CNC centers are operated by experienced machinists who utilize industry-leading CAD/CAM software to optimize toolpaths and ensure consistent part replication. This digital-to-physical workflow supports rapid prototyping, mold trials, and full-scale production runs with seamless scalability. Materials commonly processed include P20, 718H, NAK80, H13, and S136 stainless tool steels, all machined under controlled environmental conditions to maintain dimensional stability.

Quality assurance is embedded throughout our manufacturing process. Every injection mold undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This high-accuracy metrology system verifies critical dimensions, geometric tolerances, and surface relationships in three-dimensional space. Data from CMM reports are used to validate conformance to customer specifications and support continuous process improvement. Additionally, our inspection protocols include first-article inspection (FAI) reporting and in-process checks to ensure defects are identified and corrected in real time.

We maintain strict adherence to international quality standards, ensuring that every mold meets or exceeds functional requirements for longevity, cycle time efficiency, and part consistency. Our facility is equipped to support full documentation packages, including 3D model comparisons, GD&T analysis, and mold certification reports upon request.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection processes:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.008 mm |

| Positional Tolerance | ±0.015 mm | ±0.01 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Parallelism | 0.01 mm | 0.005 mm |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm (polished) |

| Angular Tolerance | ±0.05° | ±0.02° |

These technical specifications reflect our commitment to delivering injection molds that perform reliably in high-volume production environments. At Wuxi Lead Precision Machinery, we combine advanced machining technology with disciplined quality control to provide custom mold solutions that meet the most demanding engineering requirements.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Selecting the optimal material for injection molds is critical to achieving part quality, production efficiency, and cost-effectiveness. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your project’s volume, part complexity, and environmental demands. Aluminum, steel, and titanium each offer distinct advantages, while surface treatments like anodizing enhance durability and performance. Understanding these options ensures your mold investment delivers maximum return.

Aluminum alloys (e.g., 7075-T6) excel in rapid prototyping and low-to-medium volume production. Their high thermal conductivity accelerates cooling cycles, reducing part cycle times by 20–30% compared to steel. Aluminum also machines 3–5x faster, cutting lead times significantly. However, its lower hardness (60–100 HB) limits use in abrasive polymers or high-cavity-count molds. For short runs under 10,000 shots or aggressive timelines, aluminum provides unmatched speed-to-market without compromising dimensional stability.

Tool steels (P20, H13, S136) dominate high-volume manufacturing. P20 (28–32 HRC) balances machinability and wear resistance for 100,000+ cycles, while hardened H13 (48–52 HRC) withstands thermal fatigue in demanding applications like automotive components. Corrosion-resistant grades like S136 (48–52 HRC) are essential for medical or clear polymers requiring mirror finishes. Steel’s superior hardness ensures tight tolerances over extended runs but increases machining time and cost. For volumes exceeding 50,000 parts, steel’s longevity justifies the initial investment.

Titanium alloys (e.g., Ti-6Al-4V) are niche solutions for extreme corrosion resistance or lightweight tooling in aerospace molds. Though costly and challenging to machine, titanium’s strength-to-weight ratio and immunity to chloride-based resins make it viable for specialized, low-volume applications. Its use remains limited due to thermal conductivity constraints but offers unique value where conventional materials fail.

Material Properties Comparison

| Property | Aluminum 7075-T6 | P20 Tool Steel | H13 Tool Steel | Ti-6Al-4V |

|---|---|---|---|---|

| Hardness | 60–100 HB | 28–32 HRC | 48–52 HRC | 36–41 HRC |

| Thermal Conductivity | 130 W/m·K | 28–36 W/m·K | 24–30 W/m·K | 7 W/m·K |

| CTE (×10⁻⁶/°C) | 23.6 | 11.0 | 10.8 | 8.6 |

| Typical Mold Life | 1,000–10,000 | 100,000+ | 500,000+ | 5,000–20,000 |

| Best For | Prototyping | Medium volume | High volume | Corrosive env. |

Anodizing is indispensable for aluminum molds, transforming the surface into a hard, non-conductive oxide layer. Type II (sulfuric acid) anodizing improves wear resistance for 20,000+ cycles, while Type III (hardcoat) reaches 50–70 μm thickness for abrasive-filled polymers. This process also enhances release properties, reducing cycle times and ejection marks. For steel molds, nitriding or PVD coatings address similar wear challenges.

Material choice directly impacts your total cost of ownership. Wuxi Lead’s engineering team collaborates to analyze resin type, part geometry, and production targets, ensuring optimal material and finish selection. Contact us to refine your mold strategy with data-driven precision.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our injection mold services are engineered for precision, consistency, and performance-driven results. We specialize in custom metal manufacturing solutions that adhere to the highest international quality standards. Our integrated production process—spanning design, prototyping, and mass production—is structured to achieve zero defects through rigorous engineering controls, advanced tooling technology, and continuous quality validation.

The process begins with precision-driven design engineering. Our team collaborates closely with clients to analyze part geometry, material specifications, and functional requirements. Utilizing advanced CAD/CAM software and mold flow simulation tools, we optimize gate locations, cooling channels, and ejection systems to prevent warping, sink marks, and other molding defects. Design for manufacturability (DFM) reviews are conducted early to ensure mold longevity, cycle efficiency, and dimensional stability.

Following design approval, we move into the prototyping phase. This stage is critical for validating both the mold functionality and the final part quality. We fabricate prototype molds using high-grade tool steels such as P20, 718H, or H13, depending on production volume and material aggressiveness. CNC machining, wire EDM, and precision grinding ensure tolerances within ±0.002 mm. Each prototype part undergoes full dimensional inspection via CMM (Coordinate Measuring Machine) and surface finish analysis. Functional testing—including fit, assembly, and environmental exposure—is performed to confirm real-world performance. Feedback from this phase is used to fine-tune the mold before full-scale production.

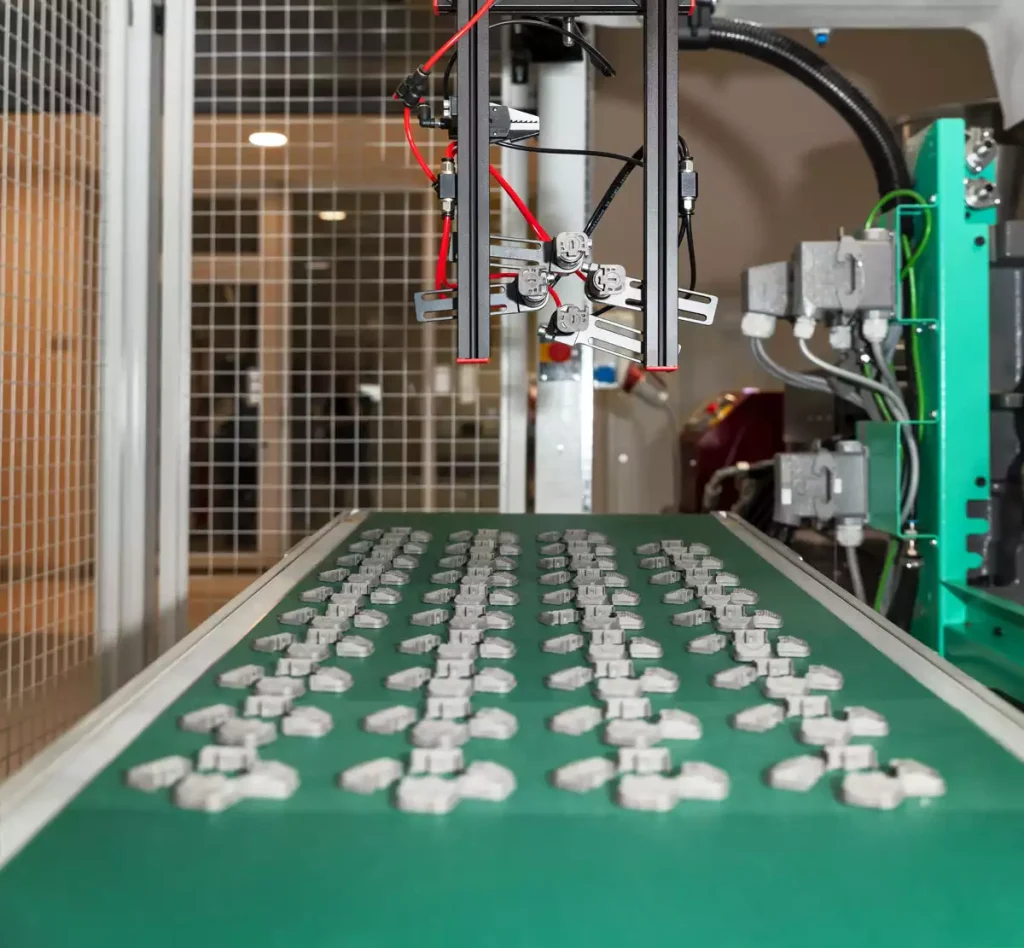

Mass production is executed on our automated, high-tonnage injection molding platforms, equipped with real-time monitoring systems. We employ closed-loop process control to regulate injection pressure, temperature, and cycle time, minimizing variability. In-process quality checks occur at defined intervals, with statistical process control (SPC) data logged for traceability. Our cleanroom-compliant facilities support production of high-precision components for automotive, medical, and industrial applications.

Throughout every phase, our zero-defect philosophy is enforced through a combination of predictive analytics, operator training, and multi-stage inspection protocols. Non-conforming parts are quarantined immediately, and root cause analysis is conducted to prevent recurrence.

The table below outlines key technical capabilities across our injection mold production process:

| Parameter | Specification |

|---|---|

| Mold Tolerance | ±0.002 mm |

| Part Tolerance | ±0.02 mm |

| Materials | P20, 718H, H13, S136, 420 Stainless Steel |

| Molding Machines | 50–2000 Ton Clamping Force |

| Surface Finish | SPI #A1, #A2, #B1, #B2, #C1, #C2 (Polished, Textured, EDM) |

| Lead Time (Prototype) | 15–25 Days |

| Lead Time (Production Mold) | 30–50 Days |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP, FAI, SPC |

By integrating engineering excellence with disciplined process control, Wuxi Lead Precision Machinery delivers injection mold services that ensure reliability, repeatability, and zero-defect performance at scale.

Why Choose Wuxi Lead Precision

Elevate Your Production with Precision Injection Molding Partnerships

Wuxi Lead Precision Machinery delivers mission-critical injection mold services for global manufacturers demanding uncompromising quality and reliability. As your strategic partner, we transform complex engineering requirements into high-performance molds that drive production efficiency, reduce lifecycle costs, and ensure consistent part integrity. Our ISO 9001-certified facility in Wuxi, China, combines 15+ years of specialized expertise with cutting-edge technology to solve the most demanding molding challenges across aerospace, medical, and automotive sectors. We operate beyond standard service expectations—integrating design validation, material science consultation, and rigorous quality assurance into every project phase. This holistic approach eliminates costly iterations, accelerates time-to-market, and guarantees molds engineered for 500,000+ cycles without performance drift.

Our technical capabilities are proven through measurable precision metrics. The table below outlines core specifications governing our mold fabrication process:

| Parameter | Capability Range | Industry Standard Reference |

|---|---|---|

| Tolerance Control | ±0.002 mm to ±0.005 mm | ISO 2768-mK |

| Mold Base Sizes | Up to 1,200 x 1,000 x 800 mm | DME Standard |

| Material Compatibility | P20, H13, S136, NAK80, Stainless | AISI/EN Standards |

| Lead Time (Prototype) | 25–35 days from approved drawings | Competitive Benchmark |

| Cavity Complexity | Up to 16 cavities with micro-features | In-House Validation Data |

Partnering with Lead Precision means aligning with a team that treats your production continuity as our core responsibility. We deploy multi-axis CNC machining centers with sub-micron repeatability, coordinate measuring machines (CMM) for 100% dimensional verification, and real-time process monitoring during mold trials. Unlike transactional suppliers, we conduct Failure Mode and Effects Analysis (FMEA) upfront to preempt defects—ensuring your first-article parts meet stringent regulatory and functional requirements. Our engineers collaborate directly with your R&D team to optimize gate design, cooling channels, and ejection systems, maximizing yield rates while minimizing material waste. This proactive engineering partnership reduces total cost of ownership by 18–22% compared to conventional mold sourcing, based on client case studies from Tier-1 automotive suppliers.

When substandard molds risk production halts or recall liabilities, precision is non-negotiable. Wuxi Lead Precision Machinery provides the technical authority and operational discipline to safeguard your manufacturing output. Contact our engineering team directly to initiate a capability review or request a confidential quotation. Specify your project scope, timeline, and critical tolerances to receive a tailored solution within 48 hours.

Advance your production integrity. Contact [email protected] to engineer your precision-molded future.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.