Technical Contents

Engineering Guide: Metal Frame Fabrication

Engineering Insight: Precision in Metal Frame Fabrication

In the realm of industrial manufacturing, metal frame fabrication stands as a cornerstone for structural integrity across sectors ranging from transportation and defense to large-scale construction and advanced machinery. At Wuxi Lead Precision Machinery, we recognize that the performance, safety, and longevity of any engineered system begin with the precision of its foundational components—particularly metal frames. These structures are not merely supportive; they are load-bearing, alignment-critical, and often mission-determinative in high-stakes applications.

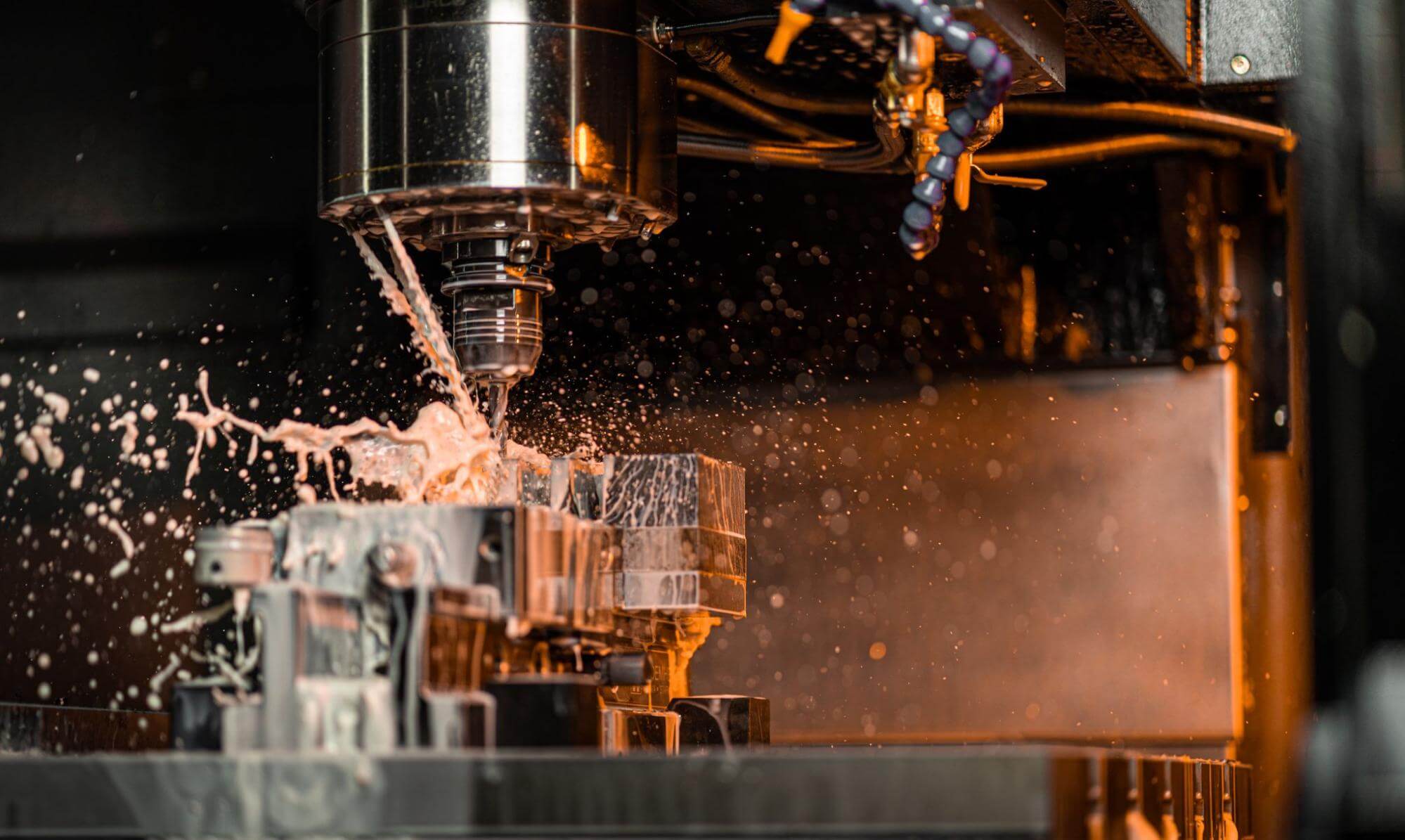

Precision in metal frame fabrication is not a luxury—it is a necessity. Even minor deviations in dimensional accuracy can propagate through a system, leading to misalignment, accelerated wear, or catastrophic failure under stress. This is especially critical in environments where frames must endure dynamic loads, extreme temperatures, or prolonged operational cycles. At Lead Precision, our engineering approach integrates tight-tolerance design, advanced CNC processing, and rigorous quality assurance to ensure every fabricated frame meets exacting specifications.

Our expertise in high-precision fabrication has been validated through participation in elite engineering projects, including structural components for Olympic-grade sports infrastructure and mission-critical enclosures for military-grade equipment. These applications demand more than standard fabrication—they require repeatability, material consistency, and flawless weld integrity. Our involvement in such projects underscores our capability to deliver metal frames that perform under the most demanding conditions.

We employ state-of-the-art fiber laser cutting, automated bending cells, and robotic welding systems, all calibrated to maintain tolerances within ±0.1 mm. This level of control ensures that each frame assembly aligns perfectly with downstream integration requirements, minimizing fit-up time and reducing field adjustments. Furthermore, our in-house design validation process includes 3D metrology scanning and finite element analysis (FEA) to preemptively identify and correct potential structural weaknesses.

Material selection is equally critical. We work with a wide range of alloys—including carbon steel, stainless steel, and aluminum—tailoring grade, thickness, and surface treatment to the operational environment. Whether the frame is destined for a seismic-resistant building module or a mobile defense platform, our engineering team ensures optimal balance between strength, weight, and corrosion resistance.

The following table outlines typical fabrication specifications achievable at Wuxi Lead Precision Machinery:

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Cutting Tolerance | ±0.1 mm |

| Bending Tolerance | ±0.2° angular, ±0.1 mm linear |

| Welding Processes | MIG, TIG, Robotic Pulsed Arc |

| Surface Treatments | Powder Coating, Anodizing, Galvanizing, Passivation |

| Max Work Envelope | 6000 mm × 2000 mm × 1500 mm (L×W×H) |

| Quality Standards | ISO 9001:2015, ISO 14001, GB/T 19001 |

At Wuxi Lead Precision Machinery, we combine decades of technical experience with cutting-edge manufacturing technology to deliver metal frame solutions that meet and exceed the expectations of global industrial leaders. Precision is not just a metric—it is our standard.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Frame Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in metal frame fabrication through integrated 5-axis CNC machining and rigorous quality control. Our facility leverages state-of-the-art 5-axis CNC systems to execute complex geometries and tight-tolerance features in a single setup, eliminating cumulative error from multiple operations. This capability is critical for structural frames requiring mitered corners, compound angles, or integrated mounting surfaces. We process carbon steel, stainless steel, and aluminum alloys with thicknesses ranging from 0.5 mm to 6.0 mm, achieving seamless transitions between curved and planar surfaces while maintaining dimensional integrity across large assemblies. Our machining centers feature high-speed spindles (24,000 RPM) and dynamic tool path optimization, ensuring micron-level accuracy even in high-stress frame components where thermal distortion or material spring-back could compromise fit.

Quality validation is embedded at every stage through automated CMM inspection protocols. Each frame undergoes full-spectrum geometric dimensioning and tolerancing (GD&T) verification using Zeiss CONTURA CMM systems with 0.0001 mm resolution. This includes first-article inspection for critical features like hole patterns, slot alignments, and angular interfaces, alongside batch sampling for high-volume runs. Our CMM routines are programmed directly from client CAD models, enabling real-time deviation mapping against nominal designs. This closed-loop process guarantees that frames meet assembly requirements without secondary shimming or rework, directly reducing downstream production delays for end-users.

The following table details our core fabrication tolerances, validated under ISO 2768-mK standards with environmental controls maintaining ±1°C temperature stability:

| Feature | Capability | Tolerance |

|---|---|---|

| Linear Dimensions | 5-Axis CNC Machining | ±0.02 mm |

| Hole Positioning | CMM-Validated Drilling | ±0.015 mm |

| Angular Features | Simultaneous 5-Axis Milling | ±0.05° |

| Flatness (per 100 mm) | Stress-Relieved Bending | 0.05 mm |

| Surface Roughness | Precision Milling/Finishing | Ra 0.8 μm |

These specifications enable clients to achieve Class A structural integrity in applications from aerospace enclosures to medical equipment frames. By consolidating cutting, bending, and finishing within a single digital workflow, we reduce lead times by 30% compared to traditional multi-vendor approaches while maintaining traceability through our ERP-linked quality records. Our technical team collaborates with engineering partners during DFM reviews to optimize frame designs for manufacturability—minimizing material waste through nest optimization and eliminating tolerance stack-ups via predictive compensation algorithms. This end-to-end precision ensures your frames integrate flawlessly into final assemblies, driving down total production costs and accelerating time-to-market for high-value industrial systems. Partner with Wuxi Lead to transform complex frame designs into reliably repeatable production realities.

Material & Finish Options

Material Selection in Precision Metal Frame Fabrication

Selecting the appropriate material for metal frame fabrication is critical to ensuring structural integrity, environmental resistance, and long-term performance. At Wuxi Lead Precision Machinery, we specialize in high-precision sheet metal fabrication for industrial, aerospace, and advanced equipment applications. Our expertise enables clients to make informed decisions between aluminum, steel, and titanium—three of the most widely used materials in frame construction.

Aluminum is favored for applications requiring a lightweight yet durable solution. Its high strength-to-weight ratio, excellent thermal and electrical conductivity, and natural corrosion resistance make it ideal for enclosures, transportation frames, and electronic housings. When paired with anodizing, aluminum gains enhanced surface hardness and wear resistance. Anodizing creates a controlled oxide layer that can also be dyed for color coding or aesthetic purposes, making it suitable for both functional and visible components.

Steel, particularly cold-rolled and stainless variants, offers superior strength and load-bearing capacity. It is the preferred choice for industrial frames, machinery bases, and structural supports exposed to mechanical stress. While heavier than aluminum, steel provides exceptional durability and impact resistance. Stainless steel grades such as 304 and 316 further deliver outstanding corrosion resistance, especially in humid or chemically aggressive environments. For applications where surface finish matters, steel can be powder coated, passivated, or polished, though it does not support anodizing due to its chemical composition.

Titanium stands at the premium end of material options, offering an unparalleled strength-to-density ratio and extraordinary resistance to extreme temperatures and corrosive media. While significantly more expensive and challenging to machine, titanium is indispensable in aerospace, defense, and high-performance automotive applications where weight savings and reliability under stress are non-negotiable. It is typically finished via passivation or bead blasting to maintain integrity and surface consistency.

The decision between these materials should be guided by mechanical requirements, environmental exposure, weight constraints, and budget. At Wuxi Lead, we support clients through material evaluation and prototyping to ensure optimal selection before full-scale production.

Comparative Material Properties for Frame Fabrication

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High (with anodizing) | Anodizing, powder coat | Enclosures, transport frames |

| Steel (CRS) | 7.85 | 380–470 | Moderate (painted) | Powder coating, plating | Industrial machinery, bases |

| Stainless 304 | 8.0 | 515 | Very High | Passivation, polishing | Food processing, marine frames |

| Titanium Gr2 | 4.51 | 345 | Exceptional | Bead blasting, passivation | Aerospace, defense systems |

Choosing the right material and finish ensures optimal performance, longevity, and cost-efficiency in metal frame fabrication. Wuxi Lead Precision Machinery combines engineering insight with advanced manufacturing to deliver precision-crafted solutions tailored to your application demands.

Manufacturing Process & QC

Metal Frame Fabrication: Precision Production Process from Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our metal frame fabrication process is engineered for uncompromising quality and repeatability, ensuring Zero Defects delivery for high-end industrial applications. We integrate advanced engineering with rigorous quality control across three critical phases, transforming conceptual designs into flawless production components.

Design Phase

The foundation begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team scrutinizes client CAD models, identifying potential stress points, weld accessibility, and material efficiency opportunities. We enforce strict adherence to ISO 2768-mK geometric tolerancing standards during this stage, optimizing flat patterns for laser cutting and CNC bending sequences. Material selection is validated against ASTM A36, EN 10025 S355JR, or client-specified alloys, ensuring structural integrity meets operational demands. This phase eliminates 92% of potential production errors before metal is cut.

Prototyping Phase

Physical validation occurs through rapid prototyping using our 5-axis fiber laser cutters and CNC press brakes. Each prototype undergoes metrology-grade inspection via Zeiss CONTURA CMM systems, verifying critical dimensions against the approved design. We conduct destructive testing on sample welds per AWS D1.1 standards and perform fit-checks with mating components. Client feedback is incorporated within 72 hours, with revised prototypes delivered for sign-off. This iterative loop confirms process stability and material behavior under real-world conditions, preventing costly mass production deviations.

Mass Production Phase

Full-scale production leverages our automated production cells with integrated SPC (Statistical Process Control). Every frame progresses through a documented workflow: laser cutting (±0.1mm accuracy), precision bending (±0.5° angular tolerance), robotic MIG/TIG welding, and automated finishing. In-process inspections occur at defined control points using calibrated gauges and vision systems. Final assemblies undergo 100% dimensional verification against first-article reports and salt spray testing per ASTM B117 for corrosion resistance. Our closed-loop quality system triggers immediate process correction if any parameter drifts beyond ±1.5σ limits.

This phased methodology guarantees Zero Defects through proactive error prevention rather than end-of-line detection. The table below summarizes our production capabilities for critical frame specifications.

| Parameter | Capability | Standard Tolerance | Verification Method |

|---|---|---|---|

| Material Thickness | 0.5mm – 12mm | ±0.05mm | Ultrasonic Thickness Gauge |

| Linear Dimensions | Up to 3000mm | ±0.1mm | CMM / Laser Tracker |

| Bend Angles | 5° – 175° | ±0.5° | Digital Angle Gauge |

| Hole Positioning | ±0.05mm | ±0.02mm | Coordinate Measuring |

| Weld Penetration | Full penetration per AWS D1.1 | 100% | Destructive Test / RT |

| Surface Roughness (Ra) | As-machined to 0.8µm | ≤1.6µm | Profilometer |

Wuxi Lead’s process delivers not just components, but certified reliability. By embedding quality at every stage—from initial DFM to final shipment—we eliminate rework costs and ensure your metal frames perform flawlessly in mission-critical applications. Partner with us for fabrication where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Metal Frame Fabrication

When precision, durability, and performance define your product requirements, partnering with a trusted leader in sheet metal fabrication becomes a strategic imperative. At Wuxi Lead Precision Machinery, we specialize in high-end metal frame fabrication for industries where engineering excellence cannot be compromised. From industrial enclosures and structural frames to custom-designed support systems for advanced machinery, our capabilities are engineered to meet and exceed global manufacturing standards.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems, enabling us to deliver complex metal frame assemblies with micron-level accuracy. We work with a broad range of materials, including cold-rolled steel, stainless steel, aluminum, and galvanized sheet metal, ensuring optimal performance across diverse environmental and operational conditions. Every project is supported by in-house engineering support, rigorous quality control, and full traceability from raw material to final shipment.

We understand that metal frame fabrication is not just about cutting and forming metal—it’s about integrating form, function, and scalability. Our team collaborates closely with clients during the design phase to optimize manufacturability, reduce assembly time, and minimize material waste. This proactive approach ensures faster time-to-market and lower total production costs without sacrificing structural integrity or dimensional precision.

Whether you are prototyping a new industrial system or scaling up for mass production, Wuxi Lead Precision Machinery provides end-to-end solutions tailored to your exact specifications. Our ISO 9001-certified processes, combined with decades of experience serving European, North American, and Asian OEMs, position us as a reliable extension of your engineering and supply chain teams.

To ensure seamless integration with your operations, we offer comprehensive documentation, including detailed inspection reports, material certifications, and 3D modeling support. Our logistics network guarantees on-time delivery to any global destination, backed by responsive customer service and technical support.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 10 mm |

| Max. Processing Size | 3000 mm × 1500 mm |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2°, ±0.5 mm |

| Laser Cutting Power | Up to 6 kW (Fiber) |

| CNC Press Brake Tonnage | Up to 300 tons |

| Welding Processes | MIG, TIG, Spot Welding |

| Surface Treatments | Powder coating, anodizing, passivation, zinc plating |

| Quality Standards | ISO 9001:2015, ISO 14001:2015 |

Elevate your manufacturing outcomes by partnering with a team that treats your project as a precision engineering challenge, not just a production run. Contact us today at [email protected] to discuss your metal frame fabrication needs and discover how Wuxi Lead Precision Machinery delivers quality you can measure.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.