Technical Contents

Engineering Guide: Urethane Casting Vs Injection Molding

Engineering Insight Precision in Urethane Casting vs Injection Molding

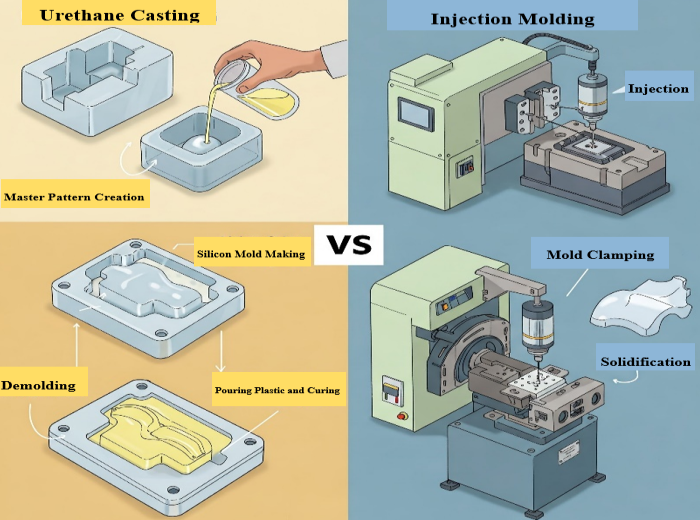

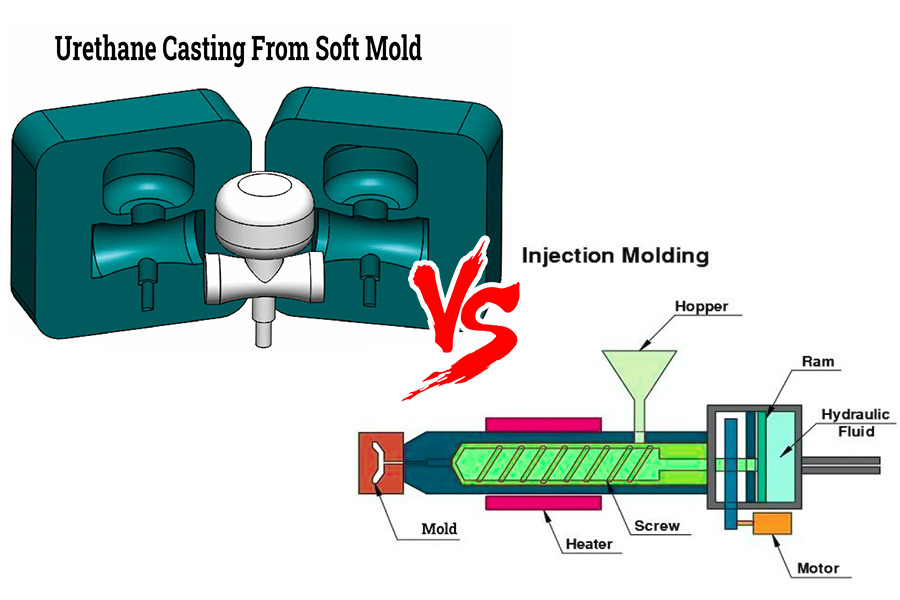

Precision is the non-negotiable cornerstone of high-performance manufacturing, directly impacting part functionality, longevity, and system integration. When evaluating urethane casting against injection molding for custom metal-adjacent applications, understanding how each process achieves dimensional accuracy is critical. Urethane casting excels in rapid prototyping and low-volume production of complex geometries using flexible silicone molds. However, material shrinkage during curing and mold degradation after 20–25 cycles inherently limit its repeatability. Tolerances typically stabilize around ±0.005 inches (0.13 mm), making it suitable for fit-check prototypes or elastomeric components where extreme precision is secondary to form validation.

Injection molding, conversely, leverages hardened steel or aluminum tooling capable of maintaining micron-level consistency across hundreds of thousands of cycles. The high-pressure injection of molten thermoplastics or engineered resins into temperature-controlled cavities minimizes material variance, achieving tolerances as tight as ±0.0005 inches (0.013 mm). This precision is indispensable for mission-critical components in aerospace, medical devices, or automotive subsystems where cumulative tolerances affect safety and performance. Material selection further dictates achievable precision; injection molding accommodates glass-filled or carbon-fiber-reinforced polymers that resist warpage under thermal stress, while urethane casting is constrained to softer polyurethanes with higher thermal expansion coefficients.

The following table contrasts key precision and operational parameters:

| Parameter | Urethane Casting | Injection Molding |

|---|---|---|

| Typical Tolerance | ±0.005 in (0.13 mm) | ±0.0005–0.002 in (0.013–0.05 mm) |

| Tooling Material | Silicone rubber | Hardened steel or aluminum |

| Tooling Lifespan | 20–25 parts | 100,000+ parts |

| Material Constraints | Limited to polyurethanes | Engineering resins, composites |

| Volume Suitability | 1–50 parts | 1,000+ parts |

At Wuxi Lead Precision Machinery, we engineer solutions where precision is non-negotiable. Our CNC-machined tooling for injection molding consistently delivers aerospace-grade tolerances, validated through components deployed in Olympic timing systems requiring sub-0.001mm repeatability and military-grade sensor housings operating under extreme vibration. This expertise stems from 15 years of refining metrology protocols for clients where failure is not an option. While urethane casting serves niche low-volume needs, injection molding remains the definitive choice for production-intent parts demanding uncompromised accuracy.

Selecting the wrong process risks cascading failures: misaligned assemblies, accelerated wear, or field recalls. Partner with an engineering team that prioritizes precision at the tooling stage—not as an afterthought. Wuxi Lead integrates GD&T analysis, mold flow simulation, and in-process CMM verification to ensure every cavity meets your exacting standards, turning material science into measurable performance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of high-performance industries. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional precision and surface finish. These multi-axis platforms allow simultaneous movement across five planes, significantly enhancing machining accuracy and reducing setup times. This capability is particularly critical when producing components that require tight tolerances and intricate features—common in aerospace, medical, and industrial automation applications.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and process stability. By leveraging advanced CAM software and in-house programming expertise, we optimize toolpaths for maximum efficiency and minimal material waste. This level of control ensures that every component meets exact design specifications, whether in low-volume prototypes or high-volume production runs.

Quality assurance is fully integrated into our manufacturing workflow. Each part undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy. The CMM system captures thousands of data points across complex surfaces, ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our inspection reports are fully traceable and can be provided with every shipment, supporting regulatory compliance and customer validation processes.

We maintain strict environmental controls in our metrology lab to eliminate thermal distortion during inspection, further enhancing measurement reliability. All QC personnel are certified and follow ISO-compliant procedures, ensuring consistency across batches and long-term repeatability.

The following table outlines the standard machining tolerances achievable across common feature types using our 5-axis CNC systems and verified through CMM inspection:

| Feature Type | Standard Tolerance | Typical Surface Finish (Ra) | Material Compatibility |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | 0.8 – 3.2 µm | Aluminum, Steel, Stainless Steel, Titanium, Brass |

| Diameter (Internal/External) | ±0.005 mm | 0.8 – 1.6 µm | Aluminum, Steel, Stainless Steel, Titanium |

| Positional Tolerance | ±0.01 mm | — | All machinable metals |

| Flatness | 0.01 mm per 100 mm | 1.6 – 3.2 µm | Steel, Stainless Steel, Aluminum |

| Angular Features | ±0.05° | 1.6 – 3.2 µm | All machinable metals |

| Threaded Features | Class 6H/6g | — | Steel, Stainless Steel, Aluminum |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for clients requiring precision metal components where reliability, repeatability, and compliance are non-negotiable. Our combination of advanced equipment, rigorous quality control, and engineering expertise ensures that every project meets the highest standards of modern manufacturing.

Material & Finish Options

Material Selection for High-Performance Metal Components: Beyond Plastic Process Misconceptions

When evaluating manufacturing processes like urethane casting versus injection molding for end-use parts, a critical clarification is essential for metal component producers. Urethane casting exclusively processes liquid thermoset plastics, creating prototypes or low-volume plastic parts. Injection molding primarily handles thermoplastics, though Metal Injection Molding (MIM) exists for small, complex metal components. For custom metal manufacturing of structural or high-precision parts – the core expertise at Wuxi Lead Precision Machinery – CNC machining remains the dominant, high-fidelity production method. Material selection is therefore intrinsically linked to the machining process and final application requirements, not plastic-based casting techniques. Aluminum, steel, and titanium represent the primary high-performance alloys where our CNC capabilities deliver exceptional results.

Aluminum 6061-T6 offers an outstanding strength-to-weight ratio, excellent machinability, and good corrosion resistance, making it ideal for aerospace brackets, automotive housings, and fixture components. Its natural oxide layer provides baseline protection, but anodizing significantly enhances surface hardness, wear resistance, and aesthetic options. Steel alloys, particularly 304 and 17-4 PH stainless, are selected when superior strength, durability, and high-temperature performance are paramount, such as in hydraulic manifolds or medical instrument components. While steel cannot be anodized like aluminum, secondary finishes like passivation, electropolishing, or precision plating are standard. Titanium Grade 5 (Ti-6Al-4V) is the solution for extreme environments demanding exceptional strength-to-weight, unparalleled corrosion resistance in harsh chemicals or saltwater, and biocompatibility, common in aerospace landing gear and critical medical implants. Titanium can undergo specialized anodizing for color coding and minor surface enhancement, though its natural oxide layer is highly protective.

Surface finish selection directly impacts part performance and longevity. Anodizing is predominantly applied to aluminum, creating a hard, porous oxide layer that can be dyed and sealed. This process is not applicable to standard steel or titanium in the conventional sense; steel requires alternative corrosion control methods, while titanium anodizing serves different purposes. The inherent machined surface finish achievable via our precision CNC mills and lathes often meets stringent functional requirements, with options for polishing, bead blasting, or coating applied post-machining based on specific needs.

Our engineering team emphasizes that material choice must align with the part’s mechanical loads, environmental exposure, regulatory standards, and lifecycle costs. Below is a comparative overview of key properties for common machined alloys:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | Good (Anodized: Excellent) | Excellent (A1) | Excellent |

| Steel 304 | 515 | Very Good | Good (B) | Not Applicable |

| Titanium Grade 5 | 900 | Exceptional | Fair (C) | Specialized Process Only |

Selecting the optimal metal alloy and finish requires deep process understanding. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to guide clients through this critical decision, ensuring material properties and surface treatments perfectly match the application’s demands for performance, reliability, and cost-efficiency in high-end metal manufacturing. Consult our engineering team for a tailored material and process recommendation.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of any successful manufacturing project begins with meticulous design. For urethane casting and injection molding applications, our engineering team collaborates closely with clients to convert conceptual ideas into detailed 3D CAD models. This phase integrates material selection, part geometry, thermal behavior, and structural integrity analysis. Finite element analysis (FEA) and mold flow simulation ensure that both urethane casting and injection molding processes are optimized before physical prototyping begins. Design for manufacturability (DFM) reviews are conducted to eliminate potential defects such as warping, sink marks, or air entrapment, aligning the design with zero-defect objectives from day one.

Prototyping: Validating Performance and Tolerances

Once the digital model is finalized, we proceed to prototyping—critical for validating form, fit, and function. For low-volume or rapid iteration needs, urethane casting offers a cost-effective solution using silicone molds and polyurethane resins that replicate the appearance and mechanical properties of production-grade thermoplastics. This method is ideal for functional testing, market sampling, or pre-launch validation. For applications requiring higher thermal resistance, tighter tolerances, or long-term durability, injection molding prototypes are produced using aluminum or soft steel molds. These prototypes undergo rigorous inspection via coordinate measuring machines (CMM) and optical scanning to verify dimensional accuracy against CAD data. Every prototype is subjected to mechanical and environmental testing to simulate real-world conditions, ensuring reliability before scaling to mass production.

Mass Production: Consistency, Quality, and Zero Defects

Transitioning to high-volume manufacturing, injection molding becomes the preferred method due to its repeatability, speed, and material versatility. At Wuxi Lead, our fully automated injection molding cells operate under strict process controls, including real-time cavity pressure monitoring and robotic part handling to minimize human error. Each production run follows a documented quality plan with in-process inspections and statistical process control (SPC) to maintain tolerances and detect deviations early. Urethane casting, while not suited for high volumes, remains valuable for specialized low-volume runs where material flexibility or rapid turnaround is essential. Both processes are backed by our zero-defect philosophy, enforced through ISO 9001-certified workflows, 100% visual inspection, and batch traceability.

Process Comparison: Key Technical Specifications

| Parameter | Urethane Casting | Injection Molding |

|---|---|---|

| Typical Volume | 1 – 100 units | 1,000 – 100,000+ units |

| Lead Time (Setup) | 1 – 2 weeks | 4 – 8 weeks |

| Material Options | Polyurethanes (flexible to rigid) | Engineering thermoplastics (ABS, PC, Nylon, etc.) |

| Tolerance Accuracy | ±0.5% (up to ±0.25 mm) | ±0.05 mm (high precision) |

| Surface Finish | Smooth, paintable, textureable | Excellent, repeatable finishes |

| Tooling Cost | Low (silicone molds) | High (steel or aluminum molds) |

| Best For | Prototypes, low-volume parts | High-volume, end-use components |

By integrating advanced design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures that both urethane casting and injection molding deliver consistent, defect-free components tailored to exact customer requirements.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Your Optimal Production Pathway

Selecting between urethane casting and injection molding demands more than technical comparison; it requires strategic partnership with a manufacturer possessing deep material science expertise and agile production capabilities. At Wuxi Lead Precision Machinery, we move beyond simple process execution. We become your engineering extension, analyzing your specific part geometry, volume requirements, material properties, and timeline constraints to determine the optimal path to market. Whether you need rapid functional prototypes validated in days or high-volume production parts meeting stringent aerospace tolerances, our integrated facility eliminates the guesswork and supply chain fragmentation common with disparate vendors. We provide seamless transition from prototype to production, ensuring design integrity is maintained throughout your product lifecycle.

Our German-engineered CNC centers and certified cleanrooms support both processes with equal rigor. For urethane casting, we leverage advanced vacuum degassing and temperature-controlled ovens to achieve near-injection molding quality in polyurethanes, silicones, and epoxies – critical for medical devices or elastomeric seals. For injection molding, our all-electric and hybrid presses, coupled with in-house mold flow analysis, deliver micron-level precision in engineering thermoplastics like PEEK, PPSU, and glass-filled nylons demanded by automotive and industrial sectors. The decision matrix below clarifies core applications:

| Critical Factor | Urethane Casting | Injection Molding |

|---|---|---|

| Optimal Volume | 1 – 100 parts | 1,000+ parts |

| Lead Time (Tooling) | 1 – 3 days (silicone molds) | 4 – 8 weeks (steel/aluminum molds) |

| Part Tolerance | ±0.005 in (127 µm) | ±0.0005 in (12.7 µm) |

| Material Cost | Lower (per part, low volume) | Lower (per part, high volume) |

| Key Applications | Functional prototypes, bridge tooling, low-volume end-use | Mass production, complex geometries, high-wear components |

Choosing incorrectly risks wasted capital on premature tooling or delayed market entry due to inadequate prototyping. Wuxi Lead Precision mitigates this risk through our collaborative engineering review. Share your CAD files and requirements; our team conducts a no-cost manufacturability assessment within 24 hours. We identify potential molding issues, recommend material substitutions for enhanced performance, and provide transparent cost-per-part analysis across both processes. Our ISO 9001:2015 certified facility guarantees consistent quality, while our dedicated project managers ensure real-time communication – no time zone barriers, no language gaps.

Do not let process uncertainty stall your innovation cycle. Contact our engineering team directly at Contact [email protected]. Include your part specifications and target volume. We will respond within one business day with a detailed technical proposal outlining the optimal pathway, realistic timeline, and actionable next steps. Partner with a manufacturer that understands the critical balance between speed, cost, and precision in high-end metal and polymer component production. Your timeline starts now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.