Technical Contents

Engineering Guide: Steel Fabrication Services

Engineering Insight: The Critical Role of Precision in Steel Fabrication Services

In the realm of industrial manufacturing, steel fabrication services form the backbone of countless high-performance applications, from aerospace and defense to large-scale infrastructure and precision machinery. At Wuxi Lead Precision Machinery, we understand that the integrity of any fabricated component begins with precision—both in design and execution. Precision in steel fabrication is not merely a measure of dimensional accuracy; it is a commitment to consistency, repeatability, and structural reliability under extreme conditions.

Steel, as a material, offers exceptional strength and durability, but its performance is only as reliable as the processes used to shape it. Even minor deviations in cutting, bending, or welding can lead to cascading failures in assembly or operation. This is especially critical in sectors where safety, load-bearing performance, and long-term endurance are non-negotiable. Our engineering team applies strict geometric dimensioning and tolerancing (GD&T) standards, ensuring every fabricated part conforms to exact specifications, regardless of complexity.

With over 15 years of specialized experience in sheet metal fabrication, Wuxi Lead Precision Machinery has delivered mission-critical components for projects demanding the highest levels of quality. Our work has supported infrastructure for Olympic venues, where structural precision directly impacts safety and longevity, as well as defense applications requiring MIL-STD compliance and rigorous traceability. These projects underscore our capability to meet exacting standards under tight deadlines and complex regulatory environments.

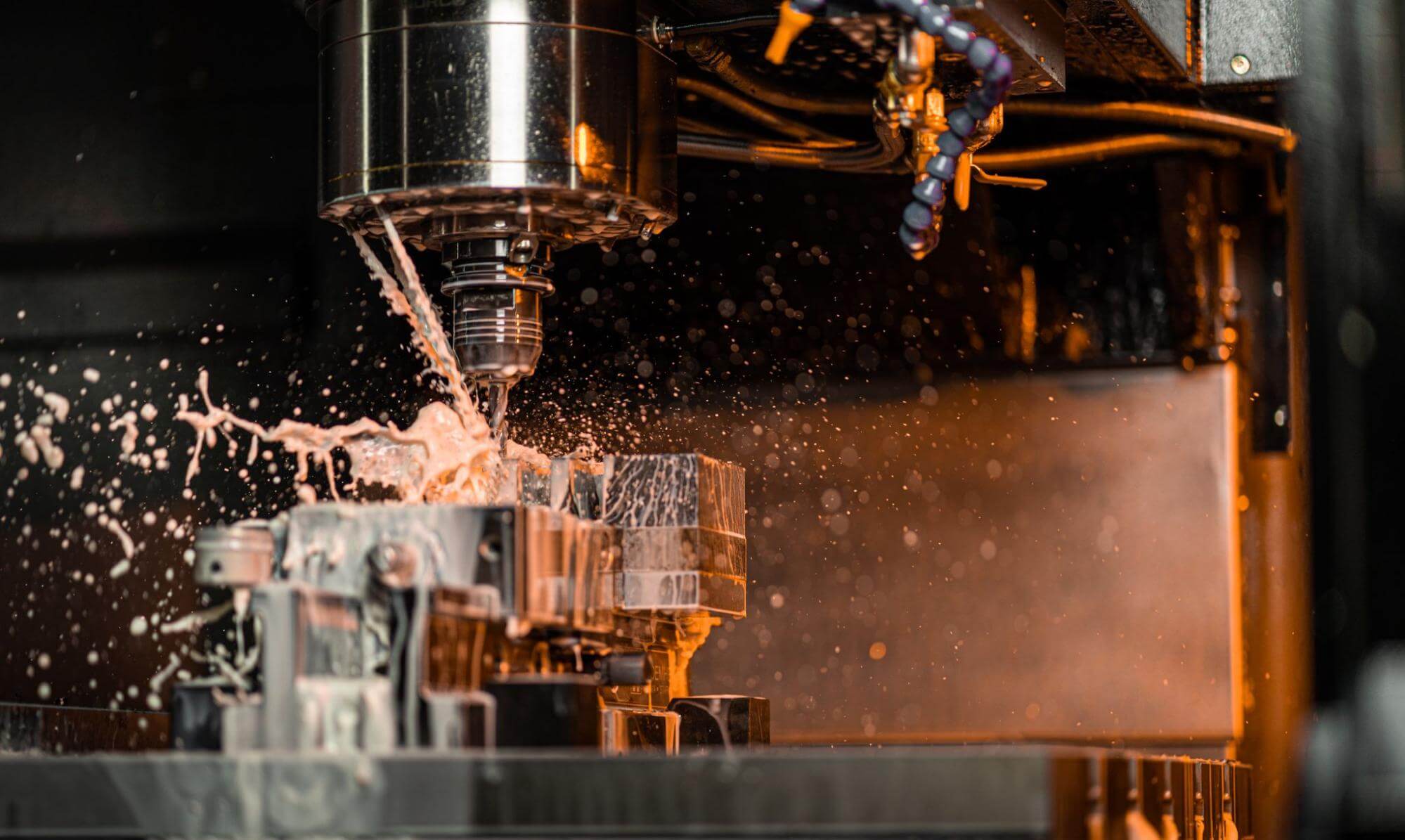

Our advanced manufacturing ecosystem integrates fiber laser cutting, CNC turret punching, automated bending cells, and robotic welding systems. This allows us to maintain tolerances down to ±0.05 mm in cutting and ±0.1° in angular forming—metrics that are essential for seamless integration in high-precision assemblies. Every stage of fabrication is monitored through in-process inspection and final quality validation using coordinate measuring machines (CMM) and laser scanning.

Material traceability, weld certification, and non-destructive testing (NDT) are standard protocols for critical applications. Whether working with mild steel, high-strength low-alloy (HSLA) steel, or stainless grades, our processes are engineered to preserve material properties while achieving exact form and function.

Below are key performance specifications achievable across our steel fabrication services:

| Parameter | Capability | Standard Tolerance |

|---|---|---|

| Laser Cutting Thickness | Up to 25 mm (mild steel) | ±0.05 mm |

| CNC Bending | Up to 4 m length, 12 mm thickness | ±0.1° angular accuracy |

| Punching Accuracy | ±0.08 mm | ISO 2768-m |

| Welding Processes | MIG, TIG, Spot, Robotic Welding | AWS D1.1 / MIL-W-46174 |

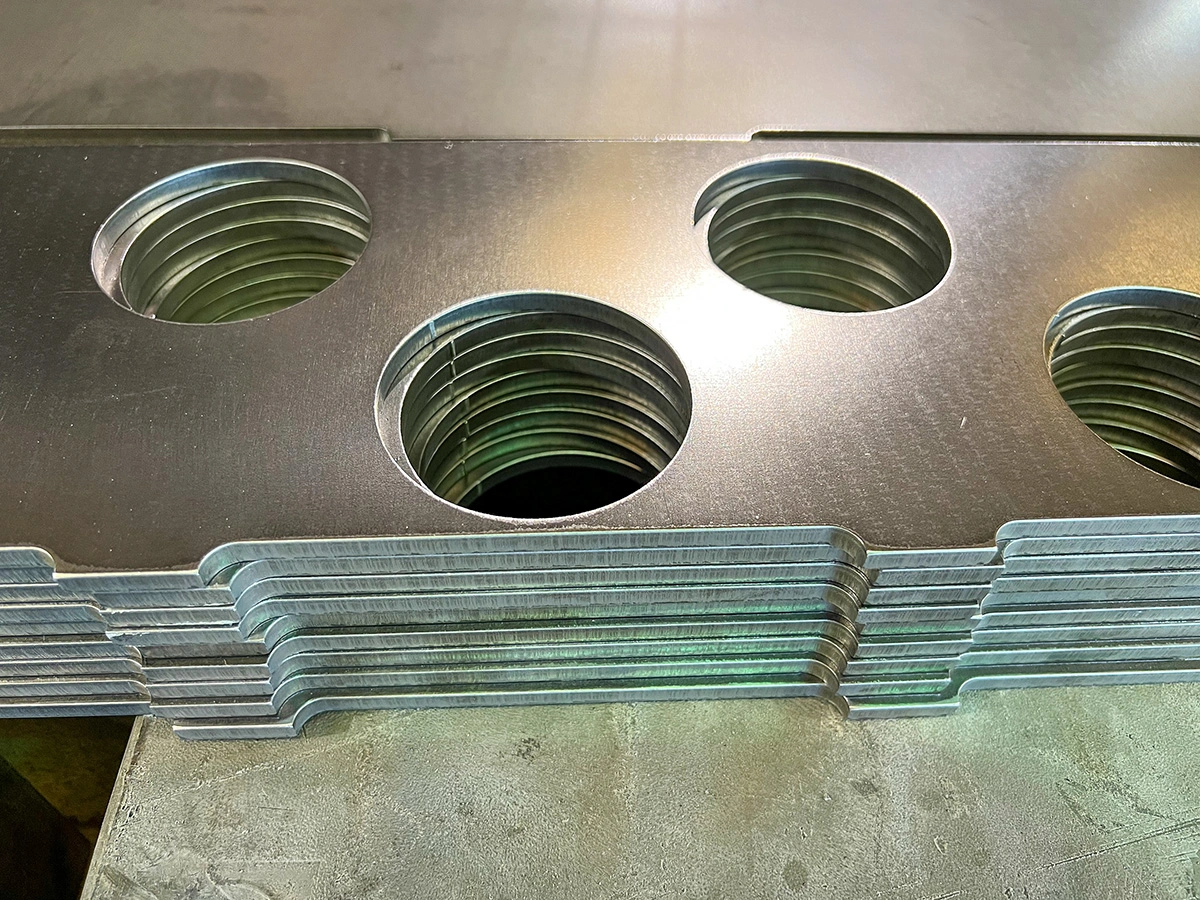

| Hole Positioning | CNC-controlled | ±0.1 mm |

| Surface Finish | Deburred, Passivated, Powder Coated | Ra ≤ 1.6 µm (machined) |

At Wuxi Lead Precision Machinery, precision is not an outcome—it is engineered into every process. Our proven track record in supporting Olympic-grade infrastructure and military-grade systems reflects our unwavering commitment to excellence in steel fabrication. For industries where failure is not an option, we deliver precision you can build upon.

Precision Specs & Tolerances

Technical Capabilities: Precision Steel Fabrication

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication services engineered for demanding industrial applications, with steel as our primary material focus. Our integrated manufacturing ecosystem combines cutting-edge multi-axis machining, high-power laser processing, and rigorous metrology to achieve exceptional geometric accuracy and repeatability on complex steel components. This capability is foundational for clients in aerospace, medical device, and energy sectors where dimensional integrity directly impacts system performance and safety.

Central to our precision workflow is a fleet of 5-axis CNC machining centers. These systems enable simultaneous multi-surface milling, drilling, and contouring of formed steel assemblies within a single setup. This eliminates cumulative error from re-fixturing, critical for maintaining tight positional tolerances across intricate geometries such as manifolds, housings, and structural brackets. High-speed spindles and rigid cast-iron frames ensure optimal surface finishes and burr-free edges on carbon steel, stainless steel, and specialty alloys up to 300mm in thickness.

Complementing our machining prowess, high-definition fiber laser cutting systems process steel sheet and plate up to 25mm thick with minimal heat-affected zones. Advanced nesting software maximizes material yield while maintaining cut quality. Precision press brakes with CNC-controlled backgauges execute complex bending sequences on steel components, consistently achieving tight angular tolerances across varied bend radii and flange lengths. Robotic welding cells further ensure consistent, high-integrity welds on assemblies requiring stringent metallurgical properties.

Quality verification is non-negotiable. Every critical dimension undergoes validation using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM). These systems provide traceable, sub-micron level measurement accuracy against 3D CAD models, generating comprehensive inspection reports with GD&T analysis. In-process checks at defined manufacturing stages prevent defect propagation, while final CMM certification guarantees compliance with the most stringent aerospace and medical standards. Material certifications and full inspection documentation are standard deliverables.

The following table outlines our standard achievable tolerances for key steel fabrication processes. Note that specific project requirements may allow for tighter control based on part geometry, material grade, and feature complexity.

| Process | Dimensional Tolerance | Angular Tolerance | Notes |

|---|---|---|---|

| Laser Cutting (Steel) | ±0.10 mm | ±0.5° | Up to 20mm thickness |

| CNC Punching | ±0.15 mm | N/A | Hole positioning accuracy |

| Press Brake Bending | ±0.20 mm | ±0.5° | Per bend; cumulative depends on setup |

| 5-Axis CNC Milling | ±0.05 mm | ±0.1° | Critical features; full CMM verified |

| Welded Assembly | ±0.30 mm | ±1.0° | Post-stress relief; per drawing spec |

| General Machining | ISO 2768-m | ISO 2768-m | Default standard without specific callout |

Our technical infrastructure ensures steel fabrications meet the exacting demands of mission-critical applications. By embedding precision capabilities from digital design through final inspection, Wuxi Lead provides manufacturers with reliable, high-integrity components that perform consistently in the field. Partner with us for steel fabrication where tolerance adherence is not optional—it is engineered into every process step.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a foundational decision in sheet metal fabrication, directly influencing product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-precision fabrication of aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties suited to specific industrial applications. Understanding these materials enables engineers and procurement managers to make informed decisions aligned with functional requirements and environmental conditions.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, transportation, and electronics enclosures where lightweight construction and thermal management are critical. Grade 6061-T6 is commonly used for structural components due to its weldability and machinability, while 5052-H32 excels in marine and high-corrosion environments.

Steel remains the backbone of industrial fabrication, offering superior strength, affordability, and versatility. Mild steel (such as Q235 and Q345) is suitable for general fabrication, frames, and enclosures. For enhanced durability, stainless steel grades like 304 and 316 provide excellent resistance to oxidation and chemical exposure, making them ideal for food processing, medical devices, and outdoor applications. Our advanced laser cutting and forming capabilities ensure tight tolerances even in high-strength steel alloys.

Titanium, though more costly, delivers exceptional performance in extreme conditions. With a strength-to-density ratio surpassing both steel and aluminum, and outstanding resistance to corrosion—especially in saline or acidic environments—it is the material of choice for aerospace, defense, and high-performance automotive sectors. Grade 5 (Ti-6Al-4V) is most commonly used in critical load-bearing components due to its high fatigue resistance and biocompatibility.

Surface finishing further enhances material performance. Anodizing, particularly for aluminum, creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Our Type II (sulfuric acid) and Type III (hardcoat) anodizing processes meet MIL-A-8625 standards, providing thicknesses from 10 to 50 microns depending on application demands. This process not only improves wear resistance but also provides excellent adhesion for paint and primers.

Below is a comparative overview of key material properties relevant to sheet metal fabrication:

| Material | Typical Grades | Density (g/cm³) | Tensile Strength (MPa) | Common Applications | Key Advantages |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 290–320 | Aerospace, Electronics, Transport | Lightweight, Corrosion Resistant, Conductive |

| Mild Steel | Q235, Q345 | 7.85 | 370–500 | Industrial Frames, Enclosures | Cost-Effective, Weldable, Strong |

| Stainless Steel | 304, 316 | 7.9 | 515–620 | Medical, Food Processing, Marine | Hygienic, Corrosion Resistant |

| Titanium | Ti-6Al-4V (Grade 5) | 4.43 | 900–1000 | Aerospace, Defense, Automotive | High Strength-to-Weight, Extreme Durability |

At Wuxi Lead Precision Machinery, we support material selection with in-house metallurgical testing, prototyping, and finishing services to ensure optimal performance across your product lifecycle.

Manufacturing Process & QC

Precision Steel Fabrication: Integrated Workflow for Zero Defects

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered as a seamless, closed-loop system where Design, Prototyping, and Mass Production converge to deliver absolute quality. We eliminate defects at the source, not through final inspection, ensuring your components meet exacting specifications consistently. This integrated approach minimizes waste, accelerates time-to-market, and guarantees the structural integrity and dimensional accuracy critical for demanding industrial applications.

The foundation is our collaborative Design for Manufacturability (DFM) phase. Our engineering team works directly with your CAD models, conducting rigorous tolerance stack analysis and finite element analysis (FEA) simulations. We identify potential fabrication challenges—material stress points, weld accessibility, tooling conflicts—before a single sheet is cut. This proactive review optimizes part geometry for our advanced machinery, ensuring manufacturability while preserving your functional requirements. Approved designs transition directly into our digital manufacturing ecosystem, locking in validated parameters.

Prototyping is not merely a sample stage; it is a critical validation checkpoint. Using the exact production-grade materials and processes intended for volume, we produce functional prototypes under controlled conditions. Every bend, cut, and weld undergoes metrological verification against the original CAD data using calibrated CMMs and laser trackers. We subject prototypes to simulated operational loads and environmental tests where applicable. Only after confirming dimensional stability, assembly fit, and performance against all acceptance criteria does the design receive full production release. This phase catches latent issues invisible in simulation alone.

Mass Production leverages the validated process blueprint with unwavering discipline. Our automated production cells—featuring high-power fiber laser cutters, precision CNC press brakes with real-time angle feedback, and robotic welding cells—operate under strict Statistical Process Control (SPC). In-process inspections at critical control points monitor key characteristics continuously. Automated vision systems verify hole patterns and edge quality; in-line laser micrometers track bend angles. Material traceability is maintained from coil to finished part. The result is sustained capability to hold tight tolerances consistently, transforming validated prototypes into flawless high-volume output.

This integrated methodology, governed by ISO 9001:2015 and IATF 16949 standards, embeds quality into every action. By resolving conflicts early in design, proving feasibility through rigorous prototyping, and controlling production with advanced process monitoring, Wuxi Lead achieves true zero-defect manufacturing. You receive components that perform reliably, reduce assembly line disruptions, and uphold your reputation for excellence.

Wuxi Lead Precision Sheet Metal Capabilities Summary

| Process | Capability Range | Standard Tolerance | Key Material Compatibility |

|---|---|---|---|

| Laser Cutting | 0.5mm – 25mm Thickness | ±0.1mm | Mild Steel, Stainless, Aluminum |

| CNC Bending | 0.5mm – 6mm Thickness | ±0.2° / ±0.1mm | Mild Steel, Stainless, Aluminum |

| Robotic Welding | MIG/TIG; Up to 8mm Thickness | ±0.5mm (Position) | Mild Steel, Stainless, Aluminum |

| Surface Finishing | Powder Coating, Anodizing, Passivation | Per ASTM/ISO Specs | All Processed Materials |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Steel Fabrication Services

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a leading provider of high-end sheet metal fabrication services in China, we specialize in transforming complex engineering requirements into real-world industrial solutions. Our clients span aerospace, energy, automation, and advanced manufacturing sectors, where tolerance, repeatability, and material integrity are non-negotiable. When you choose to partner with Lead Precision, you gain more than a supplier—you gain a committed engineering ally.

Our state-of-the-art facility in Wuxi integrates advanced CNC technology with decades of hands-on metalworking expertise. From laser cutting and precision bending to robotic welding and custom finishing, every process is optimized for consistency and scalability. We work with a broad range of materials, including carbon steel, stainless steel, aluminum, and specialty alloys, ensuring your components meet both functional and environmental demands. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing systems adapt to your timeline without compromising quality.

What sets us apart is our end-to-end control over the fabrication process. Our in-house engineering team collaborates closely with clients during design for manufacturability (DFM) analysis, helping to optimize parts for cost, strength, and assembly efficiency. This proactive approach reduces lead times, minimizes waste, and ensures first-time-right outcomes. Every component undergoes rigorous inspection using coordinate measuring machines (CMM) and non-destructive testing methods, guaranteeing compliance with ISO 9001 standards and your exact specifications.

We understand that global supply chains demand more than technical excellence—they require trust, transparency, and responsiveness. That’s why we maintain open communication at every stage, providing real-time updates, detailed quality reports, and logistics coordination tailored to your operational needs. Our export experience spans North America, Europe, and Asia, with packaging and shipping protocols designed to protect sensitive components during transit.

Consider the technical capabilities that define our service offering:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Max. Laser Cutting Area | 3000 mm × 1500 mm |

| CNC Bending Tonnage | Up to 300 tons |

| Tolerance Accuracy | ±0.05 mm |

| Welding Processes | MIG, TIG, Spot, Robotic |

| Surface Finishes | Powder coating, anodizing, passivation, polishing |

| Certifications | ISO 9001:2015, ISO 14001 |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your project as our own. We are committed to engineering excellence, on-time delivery, and continuous improvement.

For inquiries, technical collaboration, or a detailed quote, contact us today at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.