The Process of Precision Sheet Metal Fabrication

Design & Prototyping: The initial stages of bringing a concept to life.

Precision sheet metal fabrication begins with a concept. Engineers and designers collaborate to transform an idea into a tangible design. This design is then converted into a digital prototype using advanced software tools. At Wuxi Lead Precision Machinery, the team employs the latest CAD/CAM software to ensure that the design is both functional and efficient. Prototyping allows for any potential issues to be identified and rectified before the manufacturing process begins, ensuring a smooth transition from concept to product.

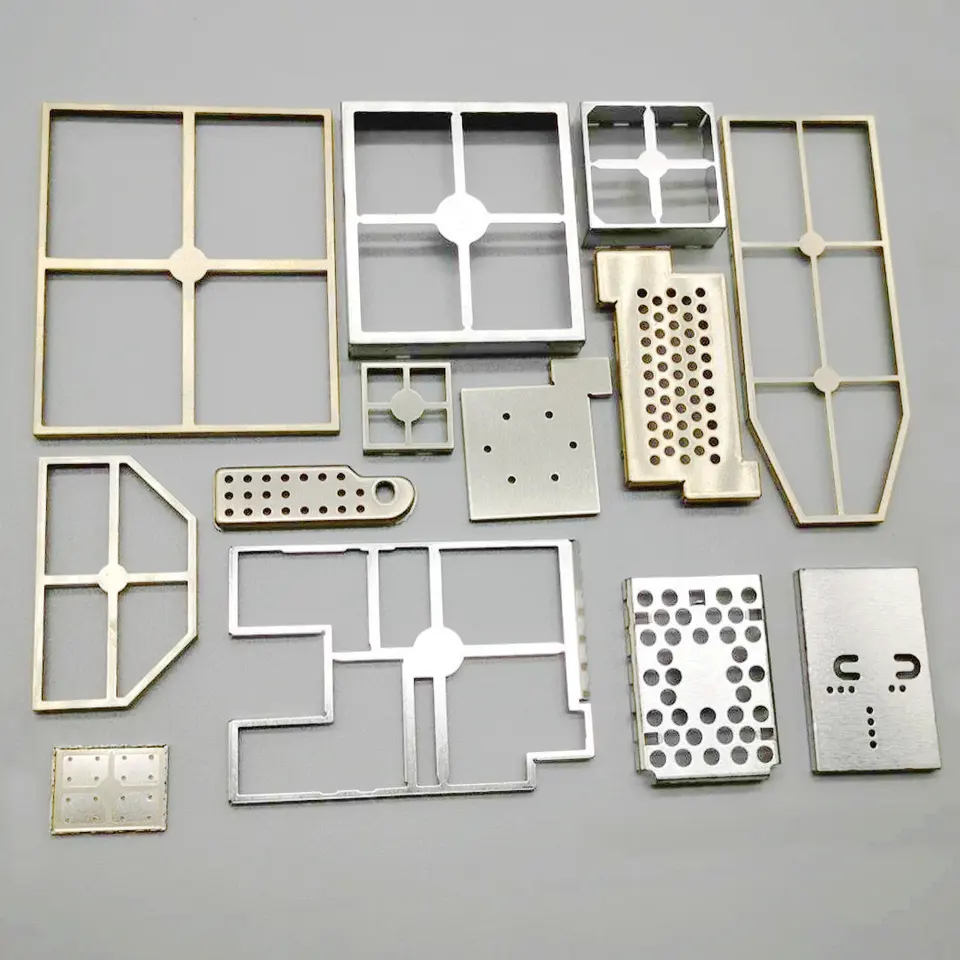

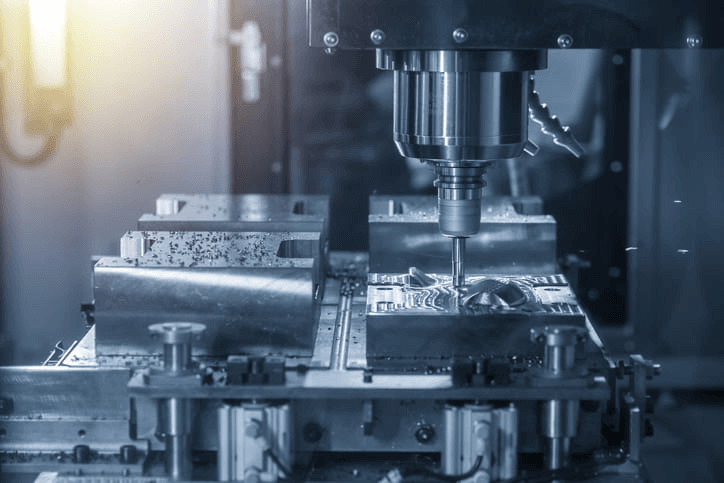

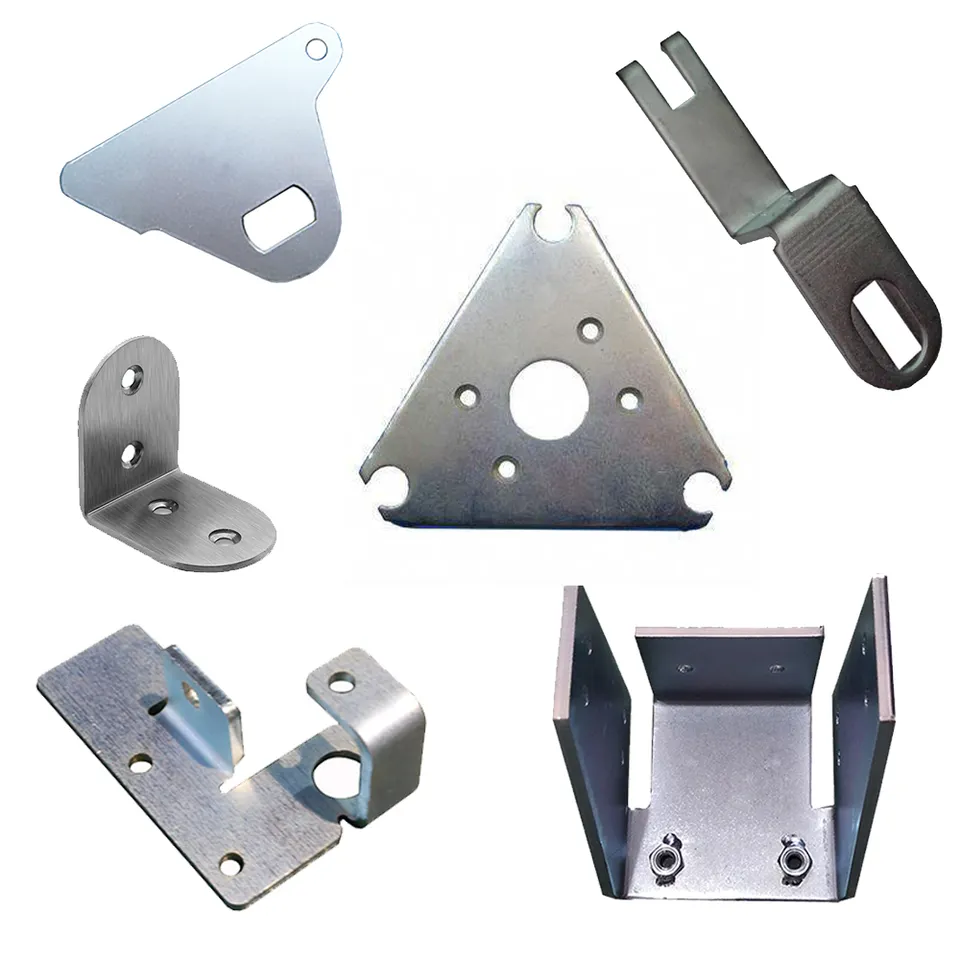

Cutting & Forming: Techniques like laser cutting, punching, and bending used in shaping the metal.

Once the design is finalized, the actual fabrication process begins. The first step is cutting the metal sheet to the desired shape. Laser cutting is a popular method due to its precision and efficiency. It uses a high-powered laser to cut the metal, resulting in clean edges and minimal waste. Punching, on the other hand, involves creating holes in the metal sheet. Bending is used to give the metal its desired shape. At Wuxi Lead, advanced machinery ensures that the cutting and forming processes are carried out with utmost precision, maintaining the integrity of the design.

Assembly & Welding: Joining multiple components to form a final product.

Once the individual components are ready, they are assembled to form the final product. This often involves welding, where two metal pieces are fused together using heat. Welding requires a high level of skill and expertise, as it determines the strength and durability of the final product. Wuxi Lead Precision Machinery boasts a team of skilled welders who ensure that each product is assembled with precision and care, ensuring longevity and reliability.

Finishing: Processes like painting, powder coating, and plating to enhance the product’s appearance and durability.

The final step in the fabrication process is finishing. This involves giving the product its final appearance and ensuring its durability. Painting provides a protective layer against corrosion and enhances the product’s aesthetic appeal. Powder coating is another popular finishing technique, known for its durability and resistance to chipping. Plating involves coating the metal with a thin layer of another metal, like chrome or gold, to enhance its appearance and protect it from corrosion. Wuxi Lead offers a range of finishing options, allowing clients to choose the one that best suits their needs.

With the detailed insight into the precision sheet metal fabrication process, clients can make informed decisions and appreciate the intricacies involved in bringing their concepts to life. Wuxi Lead Precision Machinery’s commitment to quality and precision ensures that each product is crafted to perfection, meeting the highest industry standards.

FAQ Tips about Precision Sheet Metal Fabrication

- What materials can be used in precision sheet metal fabrication at Wuxi Lead?

- We work with a variety of metals, including stainless steel, aluminum, brass, and more, depending on the client’s requirements.

- How long does the fabrication process typically take?

- The timeline varies based on the complexity of the design and the volume of the order. However, we always strive to meet the deadlines set by our clients.

- Do you offer bulk order discounts?

- Yes, we offer discounts for bulk orders. Please contact our sales team for more details.

- Can I visit the Wuxi Lead facility to see the production process?

- Absolutely! We welcome clients to visit our facility and witness our production processes firsthand.

- How do you ensure the quality of your products?

- We have stringent quality control measures in place, from the initial design phase to the final product. Each product undergoes rigorous testing to ensure it meets our quality standards.

- Do you ship internationally?

- Yes, we cater to clients globally and can arrange for international shipping.

- What finishing options do you offer?

- We offer a range of finishing options, including painting, powder coating, and plating, among others.

- Can I provide my own design for fabrication?

- Yes, we work closely with clients to bring their designs to life. You can provide your design, and our team will assist in the fabrication process.

- How do I get a quote for my project?

- You can contact our sales team with your requirements, and they will provide a detailed quote based on your specifications.

- What sets Wuxi Lead Precision Machinery apart from other manufacturers?

- Our commitment to quality, state-of-the-art technology, experienced team, and customer-centric approach set us apart in the industry.

- How do you handle complex and intricate designs?

- With our advanced machinery and skilled team, we can handle intricate designs with precision. Our team collaborates closely with clients to understand their requirements and ensure the design is executed flawlessly.

- Are there any minimum order requirements?

- While we handle bulk orders efficiently, we also cater to smaller orders. The minimum order requirement can vary based on the specifics of the project. It’s best to discuss this directly with our sales team.

- How do you ensure timely delivery of orders?

- We have a streamlined production process and a dedicated logistics team that ensures timely delivery of orders. Regular updates are provided to clients about the status of their order.

- What safety measures are in place during the fabrication process?

- Safety is paramount at Wuxi Lead. We adhere to strict safety protocols, and our facility is equipped with safety equipment to ensure the well-being of our staff.

- Can Wuxi Lead assist with the installation of the fabricated products?

- Yes, we offer installation support and guidance for the products we fabricate. Our team can provide detailed instructions or on-site assistance, depending on the client’s needs.

- How is the pricing determined for precision sheet metal products?

- Pricing is determined based on the complexity of the design, materials used, volume of the order, and any additional services required. We ensure transparency in our pricing, with no hidden costs.

- Do you offer any warranties or guarantees on your products?

- Yes, all our products come with a warranty. The specifics of the warranty can vary based on the product and will be detailed in the contract.

- How do I get started with my precision sheet metal project at Wuxi Lead?

- Simply reach out to our sales team with your requirements. They will guide you through the entire process, from design to delivery.

- What industries do you primarily serve?

- We cater to a wide range of industries, including automotive, aerospace, electronics, construction, and more.

- Why should I choose precision sheet metal over other materials?

- Precision sheet metal offers durability, versatility, and can be customized to meet specific requirements. It’s cost-effective and suitable for both large-scale and small-scale projects.

Choosing Wuxi Lead Precision Machinery for your precision sheet metal needs ensures a partnership with a company that values quality, precision, and customer satisfaction above all else. With our expertise and commitment, your project is in capable hands.