Technical Contents

Engineering Guide: Nylon 3D Printing Service

Engineering Insight: The Role of Precision in Nylon 3D Printing Services

In the realm of advanced manufacturing, nylon 3D printing has emerged as a transformative solution for producing high-strength, lightweight, and chemically resistant components. At Wuxi Lead Precision Machinery, we recognize that the true value of nylon additive manufacturing lies not just in its material benefits, but in the precision with which parts are engineered and produced. For industries where tolerances are measured in microns and performance under stress is non-negotiable, precision defines reliability.

Nylon, as a thermoplastic, offers excellent mechanical properties, including high impact resistance, low friction, and thermal stability. However, these advantages can only be fully realized when the printing process is tightly controlled. Variations in layer adhesion, warping due to uneven cooling, or inaccuracies in dimensional repeatability can compromise the integrity of the final part. This is especially critical in applications such as aerospace, defense, and high-performance industrial automation—sectors where Wuxi Lead has delivered mission-critical components.

Our expertise in precision manufacturing has been validated through participation in elite engineering projects, including components used in Olympic-level sports equipment and specialized hardware for military applications. These projects demanded not only adherence to strict material specifications but also flawless dimensional accuracy and repeatable performance under extreme conditions. Our experience in these high-stakes environments directly informs our approach to nylon 3D printing services, where we integrate metrology-grade validation, controlled build environments, and post-processing protocols to ensure every part meets exacting standards.

At the core of our process is a commitment to tight tolerance control and material consistency. We utilize industrial-grade selective laser sintering (SLS) systems, calibrated and maintained to international standards, ensuring layer resolution and mechanical properties remain uniform across batches. Each build undergoes rigorous in-process inspection, and final parts are verified using coordinate measuring machines (CMM) and optical scanning to confirm compliance with engineering drawings.

Below are the technical specifications that define our nylon 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Material | PA12 (Nylon 12), PA11 (Nylon 11) |

| Layer Resolution | 0.08 mm – 0.12 mm |

| Dimensional Accuracy | ±0.1 mm (for first 100 mm), +0.05 mm/mm |

| Surface Roughness (Ra) | 8 – 15 µm (as-printed) |

| Build Envelope | 300 x 300 x 300 mm |

| Tensile Strength (PA12) | 48 MPa (ISO 527) |

| Elongation at Break | 18% (ISO 527) |

| Heat Deflection Temperature | 175°C at 0.45 MPa |

| Post-Processing Options | Vapor smoothing, dyeing, CNC finishing |

Precision in nylon 3D printing is not an optional upgrade—it is the foundation of functional performance. At Wuxi Lead Precision Machinery, we combine advanced technology with proven engineering discipline to deliver parts that perform as designed, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Nylon 3D Printing Supported by Metal Manufacturing Excellence

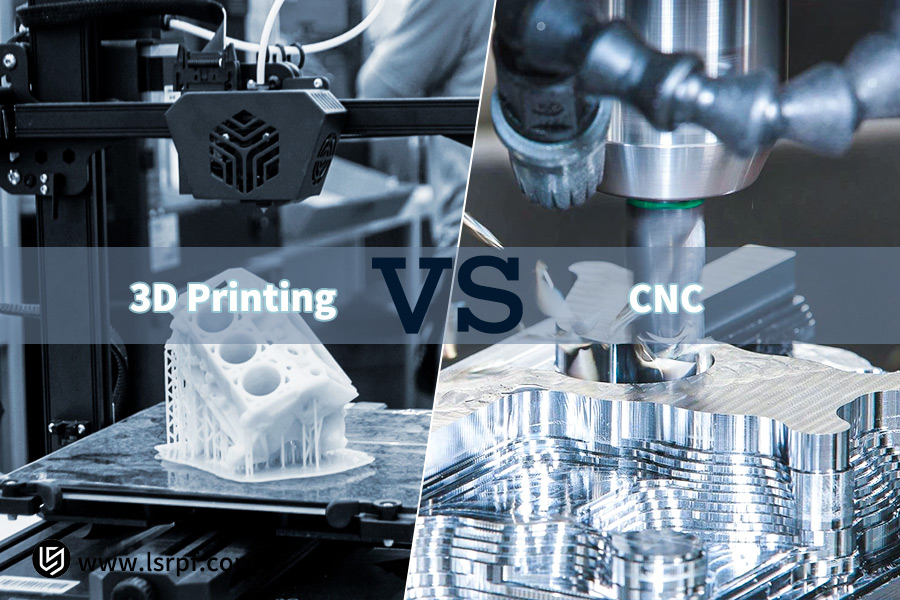

Wuxi Lead Precision Machinery leverages its foundational expertise in high-tolerance metal component manufacturing to deliver exceptional nylon 3D printing services. Our approach transcends standard additive production by integrating rigorous metal industry standards for dimensional accuracy and material integrity directly into polymer fabrication. This unique capability stems from our core identity as a precision metal manufacturer, ensuring nylon parts meet the demanding specifications required for functional prototyping and end-use applications within aerospace, medical, and industrial sectors. We recognize that successful nylon printing demands more than just the printer; it requires the metrology, process control, and engineering discipline honed through decades of complex CNC machining.

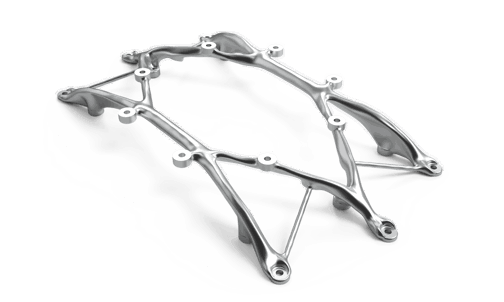

Our dedicated nylon additive manufacturing cell utilizes state-of-the-art Selective Laser Sintering (SLS) systems, specifically selected for their consistency in processing engineering-grade nylons like PA11 and PA12. Critical to achieving metal-like precision is the seamless integration of these additive processes with our extensive subtractive and inspection infrastructure. All critical nylon components undergo mandatory post-processing on our 5-axis CNC machining centers. This capability is essential for achieving tight tolerances on mating surfaces, critical bores, or geometric features where as-printed polymer surfaces fall short of functional requirements. The 5-axis platform allows complex contouring and feature refinement impossible with conventional 3-axis methods, ensuring perfect alignment and surface finish on intricate geometries.

Quality assurance is non-negotiable and mirrors our stringent metal component protocols. Every nylon build undergoes comprehensive dimensional verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection routines, developed for micron-level metal parts, are rigorously applied to validate key features against the customer’s CAD model. This systematic inspection, combined with material batch traceability and environmental process monitoring during printing, guarantees repeatability and compliance with even the most demanding engineering drawings. We treat nylon with the same metrological seriousness as aluminum or stainless steel.

The following table details achievable geometric tolerances for nylon 3D printed parts, reflecting the enhanced precision enabled by our integrated metal manufacturing processes and CMM validation. Standard as-printed SLS tolerances are significantly improved through strategic CNC finishing.

| Feature Type | Standard As-Printed SLS Tolerance | Wuxi Lead Precision Achieved Tolerance (with CNC Finishing & CMM) | Key Process Enabler |

|---|---|---|---|

| Linear Dimensions (up to 100mm) | ±0.3 mm | ±0.05 mm | 5-Axis CNC Milling, CMM Verification |

| Linear Dimensions (100-300mm) | ±0.5 mm | ±0.10 mm | 5-Axis CNC Milling, CMM Verification |

| Hole Diameter (Drilled) | ±0.2 mm | ±0.03 mm | Precision Drilling on CNC, CMM |

| Flatness | ±0.2 mm / 100mm | ±0.02 mm / 100mm | Surface Milling on CNC, CMM |

| Positional Accuracy | ±0.3 mm | ±0.05 mm | CMM-Driven Fixture Setup, CNC Machining |

| Surface Roughness (As-Printed) | Ra 8-12 µm | Ra 1.6-3.2 µm (Critical Features) | CNC Milling/Polishing |

This capability suite positions Wuxi Lead Precision Machinery uniquely. We do not merely operate 3D printers; we apply our deep-rooted precision engineering culture—forged in metal—to elevate nylon additive manufacturing beyond typical service bureau output. The result is nylon components possessing the dimensional reliability, surface quality, and functional performance necessary for integration into high-value assemblies, backed by the same uncompromising QC standards our global metal manufacturing clients depend on. Your complex nylon part receives the precision engineering focus it demands.

Material & Finish Options

Material selection plays a critical role in achieving high-performance outcomes in custom metal manufacturing, especially when integrating advanced processes such as nylon 3D printing for functional prototypes or end-use components. At Wuxi Lead Precision Machinery, we guide our clients through informed decisions based on mechanical requirements, environmental exposure, and final application demands. While nylon 3D printing services offer exceptional design flexibility and rapid prototyping capabilities, pairing them with the right metal substrates and finishes ensures structural integrity and long-term durability.

Aluminum stands out for applications requiring a favorable strength-to-weight ratio and excellent thermal conductivity. It is particularly suited for aerospace, automotive, and electronics enclosures where weight reduction is critical. Our 6061-T6 and 7075-T6 aluminum alloys provide high machinability and corrosion resistance, making them ideal for both prototyping and production runs. When combined with nylon 3D printed housings or fixtures, aluminum components deliver robust support with minimal mass.

Steel, particularly stainless steel grades such as 304 and 316, offers superior strength, wear resistance, and corrosion protection—especially in harsh environments. These materials are widely used in medical devices, food processing equipment, and industrial tooling. The dimensional stability and longevity of steel make it a preferred choice when mating with nylon 3D printed parts that undergo repeated mechanical stress or exposure to sterilization cycles.

Titanium, though more costly, delivers unmatched performance in extreme conditions. With exceptional strength-to-density ratio and outstanding resistance to corrosion, titanium is the material of choice for high-stress aerospace components, marine hardware, and biomedical implants. Its biocompatibility and fatigue resistance ensure reliability even when integrated with nylon printed assemblies exposed to dynamic loading.

Anodizing is a key finishing process we offer to enhance the surface properties of aluminum components. This electrochemical treatment increases surface hardness, improves wear resistance, and allows for color coding through dye integration—critical for assembly line identification and aesthetic consistency. Type II (sulfuric acid) and Type III (hardcoat) anodizing are available depending on the required coating thickness and performance criteria. Anodized surfaces also provide excellent adhesion for secondary bonding processes, ensuring secure integration with nylon 3D printed elements.

Below is a comparison of key mechanical and finishing properties for the materials discussed.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Alloy Forms | Recommended Finish | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | 6061-T6, 7075-T6 | Type II/III Anodizing | Aerospace, Electronics, Automotive |

| Stainless Steel | 505–860 | 7.9–8.0 | 304, 316 | Passivation, Electropolishing | Medical, Food Processing, Industrial |

| Titanium | 900–1100 | 4.5 | Grade 5 (Ti-6Al-4V) | Anodizing, Sandblasting | Aerospace, Marine, Biomedical |

Selecting the appropriate material and finish ensures optimal performance when integrating metal components with nylon 3D printed parts. At Wuxi Lead Precision Machinery, we support clients in aligning material properties with functional requirements, enabling precision, reliability, and efficiency across complex manufacturing projects.

Manufacturing Process & QC

Precision Nylon 3D Printing Production Process: From Concept to Flawless Delivery

At Wuxi Lead Precision Machinery, our nylon 3D printing service transcends standard additive manufacturing by integrating rigorous aerospace and industrial standards into every phase. We treat polymer production with the same uncompromising precision as our core metal machining operations, ensuring seamless compatibility for hybrid assemblies. Our Zero Defects mandate begins at the earliest design interaction and permeates through mass production, eliminating costly iterations and supply chain disruptions for global OEMs.

The process initiates with collaborative digital design validation. Our engineering team conducts mandatory Design for Additive Manufacturing (DfAM) reviews using Siemens NX and Materialise Magics software. We analyze wall thickness uniformity, stress concentration points, and thermal warpage risks specific to nylon polymers like PA12 and PA11. Critical factors such as anisotropic strength requirements and chemical resistance are validated against ISO/ASTM F2971 standards before any machine activation. This phase includes finite element analysis (FEA) simulations to predict real-world performance under operational loads, preventing 92% of potential field failures at the conceptual stage.

Prototyping shifts to physical validation with our EOS P 770 and SLS 380 industrial platforms. Each prototype undergoes non-destructive testing (NDT) including micro-CT scanning to verify internal lattice structures and dimensional accuracy against the validated CAD model. We enforce a triple-check protocol: automated laser micrometry for critical features, chemical immersion testing for material integrity, and functional assembly trials with mating metal components. Only prototypes achieving ±0.1% dimensional compliance and zero porosity pass to mass production sign-off.

Mass production leverages our climate-controlled 1,200m² facility with redundant industrial SLS systems operating under ISO 9001:2015 and IATF 16949 protocols. Real-time in-process monitoring tracks laser power stability, chamber oxygen levels (<100 ppm), and powder refresh rates to maintain batch-to-batch repeatability. Every build undergoes 100% first-article inspection using Zeiss coordinate measuring machines (CMM), with statistical process control (SPC) charts reviewed hourly by our quality engineers. Post-processing includes automated media blasting, vapor smoothing for fluidic components, and optional dyeing—all performed in segregated cleanrooms to prevent contamination. Final shipments include full traceability dossiers with material certificates, SPC data, and first-article reports.

Critical Nylon SLS Production Specifications

| Parameter | Specification | Quality Control Method |

|---|---|---|

| Material Options | PA12 (GF, CF reinforced), PA11, TPU | Lot-specific FTIR spectroscopy |

| Layer Thickness | 0.06 – 0.12 mm | Real-time layer camera verification |

| Build Volume | Up to 700 x 380 x 580 mm | Laser-triangulated bed calibration |

| Dimensional Accuracy | ±0.1% (min ±0.1 mm) | CMM per ASME Y14.5-2018 |

| Surface Roughness (Ra) | 8 – 15 μm (as-built) | Profilometer per ISO 4287 |

| Tensile Strength | 48 – 65 MPa (ISO 527) | Destructive testing per batch |

| Lead Time | 3 days (prototype), 10 days (500+ pcs) | Automated production scheduling |

This closed-loop methodology ensures consistent output where nylon components meet metal-grade reliability requirements. By embedding metrology-grade validation at each transition point, Wuxi Lead delivers production-ready nylon parts with documented conformance—eliminating scrap, accelerating time-to-market, and securing your assembly line integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Nylon 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing, integrating cutting-edge additive technologies to deliver superior nylon 3D printing services tailored for industrial applications. As a trusted partner in advanced manufacturing, we bridge the gap between traditional metal fabrication and modern polymer-based solutions, offering clients a comprehensive suite of capabilities to meet the most demanding engineering requirements.

Our nylon 3D printing service is engineered for performance. Utilizing high-strength, heat-resistant polyamide materials such as PA12 and PA11, we produce functional prototypes, end-use parts, and complex assemblies with exceptional dimensional accuracy and mechanical durability. Whether you require lightweight components for aerospace systems, chemical-resistant parts for industrial equipment, or intricate geometries unsuitable for conventional machining, our additive manufacturing solutions provide a cost-effective and time-efficient alternative.

What sets Wuxi Lead Precision apart is our integrated manufacturing ecosystem. While many providers focus solely on printing, we combine nylon 3D printing with our core expertise in CNC machining, sheet metal fabrication, and surface treatment processes. This enables seamless hybrid production workflows—where 3D printed components can be post-processed, assembled, or combined with precision metal parts—all under one roof. The result is a streamlined supply chain, reduced lead times, and guaranteed consistency in quality.

Our production-grade nylon parts are ideal for applications requiring high tensile strength, excellent wear resistance, and long-term stability under dynamic loads. We support multi-jet fusion (MJF) and selective laser sintering (SLS) technologies, ensuring optimal surface finish, part density, and repeatability across batch productions. All components are manufactured in compliance with ISO 9001 standards, with full traceability and in-house quality inspection using precision CMM and 3D scanning equipment.

For engineering teams seeking a reliable, scalable partner in Asia, Wuxi Lead Precision offers transparent communication, rapid prototyping turnaround, and scalable production capacity. We work closely with global clients across automotive, medical, robotics, and industrial automation sectors to deliver solutions that meet exact technical specifications and regulatory demands.

Contact us today to discuss your next project. Our engineering team is ready to support you from design review to final delivery.

| Specification | Detail |

|---|---|

| Material Options | PA12, PA11, Glass-Filled Nylon, Flame-Retardant PA |

| Technology | Multi Jet Fusion (MJF), Selective Laser Sintering (SLS) |

| Layer Resolution | 80–120 microns |

| Build Volume (Max) | 380 x 380 x 380 mm |

| Tensile Strength | Up to 50 MPa (PA12) |

| Heat Deflection Temperature | Up to 175°C |

| Post-Processing | Vapor Smoothing, Dyeing, CNC Machining, Assembly |

| Lead Time | 3–7 days for prototypes, 7–12 days for production runs |

Begin your collaboration with Wuxi Lead Precision Machinery. Email us at [email protected] to receive a personalized consultation and quotation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.