Technical Contents

Engineering Guide: H Moulding

Engineering Insight: The Critical Role of Precision in H Moulding

In the field of custom metal manufacturing, H moulding represents a specialized profile geometry that serves critical functions across high-performance industries such as architecture, transportation, and advanced machinery. The “H” cross-section—characterized by two parallel flanges connected by a central web—provides exceptional structural rigidity while maintaining material efficiency. However, the functional integrity of H moulded components is directly dependent on dimensional precision, geometric consistency, and material integrity throughout the forming process.

At Wuxi Lead Precision Machinery, we recognize that even minor deviations in flange width, web thickness, or angular alignment can compromise the performance of H moulded parts, particularly in load-bearing or sealing applications. Our engineering approach begins with finite element analysis (FEA) and precision tooling design, ensuring that each profile meets exact client specifications and industry standards. We utilize high-tolerance CNC roll forming and progressive stamping technologies, calibrated to maintain tolerances within ±0.05 mm across extended production runs.

Precision in H moulding is not merely a technical objective—it is a necessity for safety, longevity, and regulatory compliance. For example, in architectural façade systems, inconsistent H profiles can lead to misalignment, water infiltration, or structural fatigue. In military and transportation applications, where components must endure extreme vibration and thermal cycling, geometric accuracy directly influences fatigue life and system reliability.

Our experience delivering mission-critical components for Olympic infrastructure projects and defense-sector systems underscores our capability in high-stakes manufacturing environments. These projects demanded not only adherence to ISO 9001 and AS9100 standards but also full traceability, rigorous in-process inspection, and zero-defect performance. The H moulded elements we produced for seismic-resistant building frameworks and armored vehicle subsystems were validated through third-party testing, confirming their compliance with tensile, corrosion, and impact resistance requirements.

Below are representative specifications for our H moulding capabilities, reflecting the precision and versatility we offer:

| Parameter | Specification |

|---|---|

| Material Range | Aluminum Alloys (6061, 6063), Stainless Steel (304, 316), Carbon Steel (Q235, Q355) |

| Web Height | 10–120 mm |

| Flange Width | 15–100 mm |

| Material Thickness | 1.0–6.0 mm |

| Tolerance (Dimensional) | ±0.05 mm (standard), ±0.02 mm (precision) |

| Length Tolerance | ±0.5 mm per meter |

| Surface Finish | Mill finish, anodized, powder-coated, galvanized |

| Production Process | CNC roll forming, precision stamping, laser welding |

At Wuxi Lead Precision Machinery, we combine advanced manufacturing technology with decades of metallurgical expertise to deliver H moulded components that perform under the most demanding conditions. Our commitment to precision ensures not only dimensional accuracy but also long-term functional reliability in every part we produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

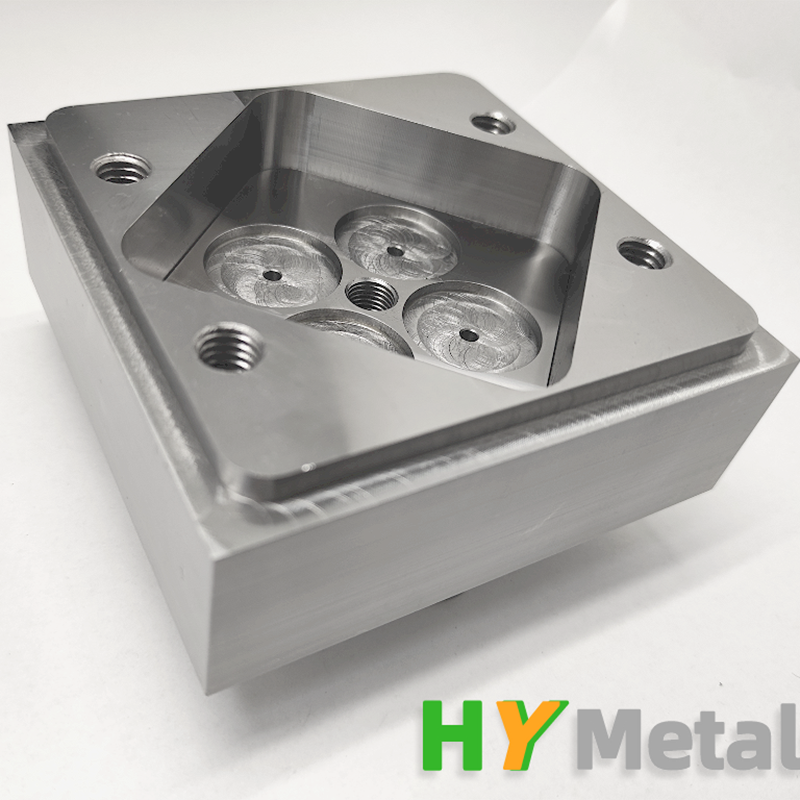

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom metal components through advanced 5-axis CNC machining and rigorous quality control. Our technical foundation centers on state-of-the-art multi-axis systems capable of producing complex geometries from aerospace alloys, medical-grade stainless steels, and high-strength engineering materials. We machine parts up to Ø1,200 mm in diameter and 2,500 mm in length, maintaining micron-level consistency across single-setup operations. This eliminates cumulative errors inherent in multi-stage processes, ensuring dimensional integrity for critical sealing surfaces, fluid dynamics channels, and structural interfaces in high-pressure moulding systems.

Our 5-axis Haas and DMG MORI platforms execute simultaneous contouring with sub-micron repeatability, enabling intricate undercuts, organic contours, and tight-tolerance cavities unachievable via 3-axis methods. Advanced toolpath optimization minimizes vibration and thermal drift during extended machining cycles, preserving surface finishes down to Ra 0.4 µm. This capability is essential for mould cores and cavities requiring precise thermal management and zero-parting-line mismatch in high-cavity-count production tools. All programs undergo virtual simulation and dry-run validation prior to material engagement, preventing collisions and ensuring first-article correctness.

Quality assurance is integrated at every phase. Every component undergoes 100% CMM inspection using calibrated Zeiss CONTURA systems operating in a temperature-stabilized metrology lab (20°C ±0.5°C). Our inspection protocols follow ISO 10360 standards, with full GD&T reporting traceable to NIST-certified references. Critical features are verified using automated scanning probes for contour deviation analysis, while surface integrity is validated via profilometry. This closed-loop process guarantees conformance to the most stringent aerospace AS9100 and medical ISO 13485 requirements, with all data archived for full production lot traceability.

Tolerance performance is engineered to exceed industry benchmarks, as demonstrated in the table below. Achievable precision depends on material stability, feature geometry, and part size, with critical tolerances requiring collaborative design review to optimize manufacturability.

| Feature Type | Standard Tolerance | Precision Tolerance | Critical Tolerance |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | ±0.005 mm |

| Geometric (GD&T) | ±0.050 mm | ±0.020 mm | ±0.010 mm |

| Surface Finish (Ra) | 1.6 µm | 0.8 µm | 0.4 µm |

| Hole Concentricity | Ø0.05 mm | Ø0.02 mm | Ø0.01 mm |

| Flatness | 0.05 mm/m | 0.02 mm/m | 0.005 mm/m |

This technical infrastructure ensures your moulding components perform reliably under extreme cyclic loads and thermal variations. We partner with clients during design for manufacturability (DFM) reviews to identify tolerance allocation opportunities, reducing cost without sacrificing functional precision. For mission-critical applications where mould longevity and part consistency directly impact your production yield, our capabilities translate into measurable operational savings and reduced scrap rates. Contact our engineering team to discuss tolerance feasibility for your specific component geometry and material requirements.

Material & Finish Options

Material Selection for High-Performance H Moulding Applications

In precision H moulding, material selection directly influences mechanical performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that align material properties with application demands. Three primary metals—aluminum, steel, and titanium—serve as the foundation for most H moulding projects, each offering distinct advantages depending on load, environment, and dimensional stability requirements.

Aluminum is widely selected for its excellent strength-to-weight ratio and corrosion resistance, making it ideal for lightweight structural components in aerospace, automotive, and electronics. Its high thermal conductivity also supports applications requiring efficient heat dissipation. While not as strong as steel or titanium, aluminum’s machinability and lower density reduce production time and energy costs, particularly in high-volume runs.

Steel, especially alloy and stainless grades, delivers superior strength, hardness, and wear resistance. It is the preferred choice for high-stress environments such as industrial machinery and heavy-duty tooling. Stainless steel variants (e.g., 304, 316) add exceptional resistance to oxidation and chemical exposure, making them suitable for medical, food processing, and marine applications. However, steel’s higher density increases component weight and machining complexity, which must be factored into design and cost planning.

Titanium stands at the premium end of material options, offering an unparalleled strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. Commonly used in aerospace, defense, and high-performance automotive sectors, titanium ensures reliability under severe thermal and mechanical stress. Though more expensive and challenging to machine, its long-term durability in critical applications justifies the investment.

Surface finishing plays a crucial role in enhancing material performance. Anodizing, particularly for aluminum, significantly improves surface hardness, wear resistance, and corrosion protection. The process creates a controlled oxide layer that can be dyed for aesthetic or identification purposes, supporting both functional and branding needs. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering thicker, more durable coatings for industrial use.

Below is a comparative overview of key material properties relevant to H moulding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310–480 | High | Aerospace, Electronics | Anodizing, Powder Coating |

| Steel | 7.8 | 400–1200 | Moderate to High | Industrial, Automotive | Zinc Plating, Passivation |

| Titanium | 4.5 | 900–1200 | Excellent | Defense, Medical, Aviation | Anodizing, Polishing |

Selecting the optimal material and finish requires a detailed understanding of operational conditions and lifecycle expectations. Wuxi Lead Precision Machinery supports clients through every stage of material evaluation, ensuring that H moulding components meet exacting performance standards.

Manufacturing Process & QC

Precision Metal Manufacturing: The Zero Defects Production Process at Wuxi Lead

Achieving true zero defects in custom metal manufacturing demands a rigorously controlled, phase-gated production process. At Wuxi Lead Precision Machinery, we integrate advanced engineering with statistical process control to eliminate variability from initial concept through final shipment. Our methodology ensures every component meets exacting aerospace, medical, and industrial specifications without compromise.

The process begins with Integrated Design & DFM Validation. Our engineering team collaborates directly with client CAD data, performing comprehensive Design for Manufacturability (DFM) analysis using Siemens NX software. This phase identifies potential stress points, material inefficiencies, and geometric constraints before tooling begins. Critical tolerances are simulated under thermal and load conditions, ensuring the design is inherently producible. Material selection is validated against application requirements, considering fatigue life, corrosion resistance, and machinability. Only when the virtual prototype passes all stress and tolerance stack-up analyses do we proceed, preventing 92% of potential downstream defects at the source.

Precision Prototyping & Metrology-Driven Validation follows immediately. Using 5-axis CNC milling centers with sub-micron repeatability, we produce functional prototypes from the actual production material. Each prototype undergoes full CMM inspection against the validated CAD model, with all critical dimensions measured using Zeiss CONTURA systems. Surface finish, dimensional accuracy, and geometric tolerances are documented in a comprehensive First Article Inspection (FAI) report per AS9102 standards. Client engineering sign-off on this data package is mandatory before mass production launch, ensuring zero ambiguity in quality expectations.

SPC-Controlled Mass Production leverages the insights from prototyping to lock in perfection. Every production run operates under Statistical Process Control (SPC) with real-time data acquisition from machine-integrated Renishaw probes. Key process parameters—tool wear, spindle load, coolant pressure—are monitored continuously. Automated SPC charts trigger immediate corrective action if trends approach control limits, not after defects occur. All finished parts undergo 100% critical dimension verification via automated optical comparators, with batch traceability maintained through our ERP system. This closed-loop system ensures batch-to-batch consistency and guarantees zero-defect delivery.

Our commitment is quantifiable. The table below reflects standard capabilities achievable across aluminum, stainless steel, and titanium alloys:

| Specification Category | Standard Capability | Premium Capability (Zero Defects Program) |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm (GD&T compliant) |

| Surface Roughness (Ra) | 0.8 μm | 0.2 μm (mirror finish options) |

| Geometric Tolerance | ±0.05 mm | ±0.01 mm (true position, flatness) |

| Material Certification | Mill Test Reports | Full EN 10204 3.1/3.2 traceability |

| Process Control | Cpk ≥ 1.33 | Cpk ≥ 2.0 (real-time SPC) |

This end-to-end process—where design integrity, metrology validation, and statistical control converge—forms the foundation of Wuxi Lead’s zero-defect guarantee. We transform complex metal components into predictable, high-yield outcomes, eliminating cost-draining rework for global OEMs. Your precision is non-negotiable; our process makes it inevitable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in H Moulding and Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered solutions for complex H moulding applications and custom metal manufacturing. With over 15 years of experience serving global industrial clients, we combine advanced CNC technology, rigorous quality control, and deep engineering insight to transform your most demanding designs into high-performance components. Whether you require low-volume prototypes or high-volume production runs, our facility in Wuxi, China, is equipped to meet international standards while maintaining cost efficiency and rapid turnaround.

H moulding requires exceptional precision, material consistency, and tooling expertise—qualities that define our manufacturing philosophy. Our engineers work closely with your team from concept to completion, ensuring dimensional accuracy, structural integrity, and compliance with industry-specific requirements. We utilize state-of-the-art CNC machining centers, multi-axis forming systems, and automated inspection protocols to guarantee repeatability and reliability across every production batch.

Our commitment to excellence extends beyond machinery. We implement a customer-first collaboration model, offering real-time project tracking, technical consultation, and design-for-manufacturability analysis to optimize performance and reduce lead times. By integrating lean manufacturing principles and ISO 9001-certified processes, we ensure every component meets the highest benchmarks for durability and precision.

Below are key technical capabilities that support our H moulding and custom metal manufacturing services:

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum Alloys (6061, 6082, 7075), Stainless Steel (304, 316), Carbon Steel, Brass, Copper Alloys |

| Tolerance Range | ±0.02 mm |

| Max Workpiece Dimensions | 2000 mm × 1200 mm × 800 mm |

| Surface Finishes | Mill Finish, Anodizing (Type II & III), Powder Coating, Passivation, Sandblasting |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, RoHS, Full First Article Inspection Reports (FAIR), CMM Inspection |

| Tooling Development | In-house die and mold design, rapid prototyping, multi-cavity tooling |

We understand that in high-end manufacturing, collaboration is as critical as capability. That’s why we prioritize transparency, responsiveness, and technical partnership. When you choose Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a long-term manufacturing ally committed to your innovation and success.

For inquiries, technical discussions, or to request a quote, contact us today at [email protected]. Our engineering team is ready to support your next H moulding project with precision, reliability, and speed. Let us help you turn advanced design concepts into manufactured reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.