Technical Contents

Engineering Guide: Countersinking Sheet Metal

Engineering Insight: Precision Countersinking in Critical Sheet Metal Applications

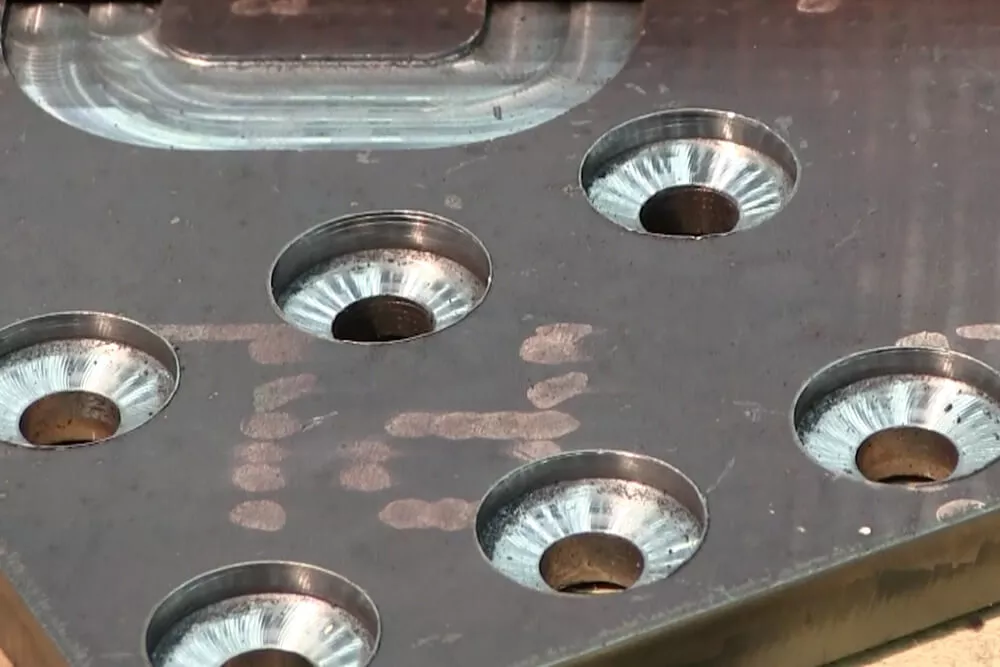

Countersinking sheet metal is far more than a simple chamfering operation; it is a critical precision process demanding exacting control to ensure structural integrity, assembly efficiency, and long-term performance in high-stakes applications. In aerospace, defense, and advanced industrial equipment, even minor deviations in countersink geometry directly compromise fastener seating, induce stress concentrations, and create pathways for corrosion or fatigue failure. A poorly executed countersink—whether due to inconsistent angle, depth variation, or surface imperfections—translates directly to compromised joint strength and potential system vulnerability. This is where micron-level precision becomes non-negotiable, moving beyond basic functionality to mission-critical reliability.

At Wuxi Lead Precision Machinery, we understand that the margin for error in countersinking vanishes when components operate under extreme loads, vibration, or environmental stress. Our CNC machining centers, equipped with high-resolution probing systems and rigid toolholding, achieve repeatability within ±0.025 mm on depth and ±0.5° on angle. This level of control ensures optimal load distribution across the fastener head, eliminating point stresses that initiate cracks. Crucially, we prioritize surface finish within the countersink bore; a smooth, burr-free transition prevents galling during fastener installation and eliminates initiation sites for corrosion, especially vital in salt-spray environments common to marine and military platforms. Material behavior during the cut—managing work hardening in stainless steels or titanium, preventing tear-out in thin aluminum alloys—requires tailored feeds, speeds, and specialized tool geometries honed through decades of experience.

Our commitment to precision countersinking is proven in projects where failure is not an option. We supplied mission-critical structural components with stringent countersink tolerances for venues during the Beijing 2022 Winter Olympics, where structural integrity under extreme cold and dynamic loads was paramount. Furthermore, our production logs include classified naval platform components where countersink accuracy directly impacts watertight integrity and vibration resistance in propulsion systems. These engagements demanded not only meeting but consistently exceeding AS9100 and MIL-STD-413F specifications, validated through rigorous first-article inspection and in-process CMM verification.

The following table outlines the precision countersinking capabilities essential for such high-reliability sectors, reflecting our standard production parameters:

| Specification Parameter | Typical Tolerance Range | Critical Application Requirement |

|---|---|---|

| Countersink Depth | ±0.025 mm | Ensures full fastener head engagement; prevents pull-through |

| Included Angle | ±0.5° | Matches fastener angle precisely; eliminates point loading |

| Hole Diameter (Pilot) | +0.00/-0.05 mm | Controls fastener shank clearance; minimizes play |

| Surface Roughness (Ra) | ≤ 0.8 µm | Prevents galling; inhibits corrosion initiation |

| Concentricity (to Pilot Hole) | ≤ 0.05 mm | Guarantees uniform load distribution under shear |

Achieving this consistency requires integrated expertise: advanced CNC programming optimizing toolpath strategies for minimal deflection, real-time process monitoring to detect tool wear before it affects geometry, and metallurgical understanding to select optimal coatings for specific alloys. At Lead Precision, countersinking is never an afterthought—it is engineered into the component’s DNA. Partner with us when your sheet metal assemblies demand countersinks that perform flawlessly under the most demanding conditions. Contact our engineering team to discuss your specific tolerance requirements and material challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions with a specialized focus on precision countersinking operations. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to execute complex, multi-angle countersink features with exceptional accuracy and consistency. These high-performance machines integrate synchronized toolpath control and dynamic workholding systems, allowing for the machining of intricate geometries across a wide range of sheet metal materials, including aluminum alloys, stainless steel, and cold-rolled carbon steel.

Countersinking in sheet metal is a critical process for ensuring flush fastener installation, enhancing aerodynamic surface finish, and meeting stringent structural and aesthetic requirements in aerospace, transportation, and high-end industrial equipment. Our 5-axis CNC platforms provide the flexibility to approach features from optimal angles, minimizing secondary setups and reducing cumulative error. This multi-axis capability ensures precise chamfer alignment relative to hole centerlines, even on contoured or non-parallel surfaces.

All countersinking operations are supported by comprehensive process planning and tooling optimization. We utilize high-precision carbide and diamond-coated drills and countersink cutters tailored to material hardness and surface finish requirements. Our in-house programming team employs advanced CAM software to simulate tool engagement and optimize feed and speed parameters, ensuring burr-free holes and extended tool life.

Quality assurance is integral to our manufacturing workflow. Every countersinking operation undergoes rigorous inspection using coordinate measuring machines (CMM) with sub-micron resolution. These systems verify countersink diameter, depth, angular accuracy, and positional tolerance in full compliance with ASME Y14.5 and ISO 1101 standards. Data from CMM reports are traceable and archived for full production lot accountability, supporting quality audits and customer documentation requirements.

We maintain strict environmental and operational controls within our facility to ensure thermal stability and vibration isolation during machining, further enhancing repeatability. Our technicians are trained in lean manufacturing and continuous improvement methodologies, enabling rapid process adjustments without compromising quality.

The following table outlines the standard technical specifications and tolerances achievable in our countersinking operations:

| Parameter | Standard Capability | Tolerance Range |

|---|---|---|

| Countersink Angle | 60°, 82°, 90°, 100°, 120° | ±0.5° |

| Countersink Diameter | 3 mm – 25 mm | +0.05 / -0.00 mm |

| Depth Control | 0.5 mm – 15 mm | ±0.1 mm |

| Hole Position Tolerance | Feature to datum | ±0.05 mm |

| Surface Finish (Ra) | Aluminum & Steel | 0.8 – 3.2 µm |

| Material Thickness Range | 0.8 mm – 12 mm | — |

| Tool Life Monitoring | Real-time wear compensation | Automated via CNC feedback |

Wuxi Lead Precision Machinery combines engineering expertise with industrial-grade technology to deliver countersunk sheet metal components that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection Fundamentals for Precision Countersinking

Selecting the optimal sheet metal material is paramount for achieving flawless countersink geometry, thread integrity, and long-term joint performance. The chosen material directly impacts tool wear, machining parameters, and the effectiveness of subsequent finishing processes like anodizing. At Wuxi Lead Precision Machinery, our CNC centers are calibrated to handle the specific demands of key aerospace and industrial alloys, ensuring burr-free countersinks that meet stringent ASME and ISO standards. Understanding the interplay between material properties and the countersinking operation is critical for cost-effective, high-yield production.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring lightweight strength and excellent machinability. Their lower hardness minimizes tool wear during countersinking, allowing for higher spindle speeds and feed rates compared to steel or titanium. However, aluminum’s softness necessitates sharp tool geometries and precise chip evacuation to prevent smearing or burr formation at the countersink edge. Aluminum is uniquely compatible with anodizing, a vital finish for corrosion resistance and wear protection. Type II (sulfuric acid) anodizing is standard, while Type III (hardcoat) provides enhanced durability; both processes require meticulous surface preparation before countersinking to ensure uniform coating thickness over the angled surface. Avoid countersinking after anodizing, as it breaches the protective layer.

Carbon steel (e.g., 1018, 1020) and stainless steel (e.g., 304, 316) offer superior strength and durability for structural applications. Stainless steel provides inherent corrosion resistance but presents significant challenges during countersinking due to work hardening and galling tendencies. Using dedicated, high-performance carbide countersink tools with appropriate coatings (TiAlN, AlTiN) and lower RPMs is essential to manage heat and prevent built-up edge. Lubrication is non-negotiable. While steel accepts plating (zinc, cadmium) or powder coating for corrosion protection, anodizing is not applicable. Countersinking must occur post-forming but pre-finishing to ensure clean holes for fastener seating.

Titanium alloys (Grade 2, Grade 5) are reserved for extreme environments demanding exceptional strength-to-weight ratio and corrosion resistance. Their low thermal conductivity and high chemical reactivity make countersinking demanding, requiring rigid setups, very low surface speeds, high-pressure coolant, and specialized tool geometries to avoid heat damage and galling. Titanium cannot be anodized in the conventional sense; alternative finishes like alodine or specialized plasma electrolytic oxidation are used, but countersinking must precede any surface treatment. Tool wear is accelerated, necessitating frequent inspection.

Material compatibility with finishing processes, especially anodizing, dictates the manufacturing sequence. Below is a comparative overview of critical properties:

| Material | Typical Grades | Key Properties | Countersinking Considerations | Finish Compatibility |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Lightweight, good machinability | High speeds possible; sharp tools prevent smearing | Anodizing (Type II/III), Paint |

| Steel | 1018, 304, 316 | High strength, durable | Manage work hardening; essential lubrication | Plating, Powder Coat |

| Titanium | Grade 2, Grade 5 | High strength/weight, corrosion res | Very low speeds; high-pressure coolant critical | Alodine, PEO; Not Anodized |

The optimal material choice balances application requirements, manufacturability, and finish compatibility. Wuxi Lead Precision Machinery leverages decades of CNC expertise to program and execute countersinking operations tailored to each material’s nuances, ensuring precision hole preparation that meets the highest aerospace and industrial assembly standards. Consult our engineering team to optimize your specific material and finish workflow.

Manufacturing Process & QC

Countersinking in Sheet Metal Fabrication: A Zero-Defect Manufacturing Process

At Wuxi Lead Precision Machinery, precision-driven manufacturing is the foundation of every component we produce. In sheet metal fabrication, countersinking is a critical secondary operation that ensures fasteners sit flush with or below the surface, enabling seamless assembly, improved aesthetics, and enhanced structural integrity. Achieving zero defects in countersinking demands a disciplined approach spanning design, prototyping, and mass production.

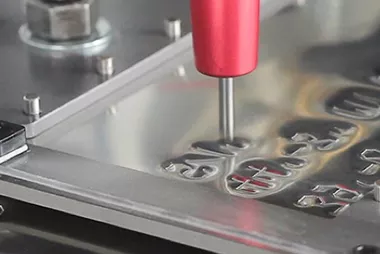

The process begins at the design stage, where engineers integrate precise hole locations, angles, and depth specifications into 3D CAD models. Using advanced simulation software, we validate tool paths and anticipate material behavior under cutting forces. Material type, thickness, and hardness are factored into the design to prevent burring, tool wear, or deformation. Our design review includes tolerance stack-up analysis and fastener compatibility checks, ensuring the countersink geometry aligns perfectly with end-use requirements.

Next, prototyping transforms digital designs into physical validation. Using CNC turret presses or multi-axis machining centers, we produce a small batch of sample parts under production-intent conditions. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify countersink diameter, angle accuracy, and surface finish. Any deviation triggers immediate process refinement—be it tool selection, feed rate adjustment, or fixturing optimization. This closed-loop feedback ensures that only validated parameters move forward.

With design and process confirmed, we transition to mass production with full automation and real-time quality control. Our CNC machining centers employ high-precision carbide or solid carbide countersink tools, maintained through predictive tool-life monitoring. In-line sensors detect tool wear and positional drift, automatically halting production if thresholds are exceeded. Every 50th part undergoes automated inspection, while first-article and end-of-batch checks are mandatory. This layered quality approach, combined with operator training and standardized work instructions, forms our zero-defect framework.

All processes adhere to ISO 9001:2015 standards, with full traceability from raw material to finished component. At Wuxi Lead, we do not inspect quality in—we engineer it in from the start.

Typical Countersinking Specifications

| Parameter | Standard Range | Tolerance | Applicable Materials |

|---|---|---|---|

| Countersink Angle | 82°, 90°, 100°, 120° | ±1° | Steel, Stainless, Aluminum |

| Diameter (Pilot Hole) | 2.5 mm – 8.0 mm | ±0.05 mm | Cold Rolled, Galvanized |

| Depth Control | 0.5 mm – 3.0 mm | ±0.1 mm | All sheet metals |

| Surface Finish (Ra) | 1.6 μm – 3.2 μm | Max 6.3 μm | As per customer requirement |

| Tool Material | Solid Carbide, HSS with TiN Coating | N/A | Optimized per batch |

This systematic progression from design to full-scale production ensures repeatability, reliability, and uncompromised quality in every countersunk feature we deliver.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Assembly Precision Through Strategic Partnership

In high-tolerance sheet metal fabrication, inconsistent countersink angles directly compromise fastener integrity, assembly speed, and long-term structural reliability. Sub-micron deviations in chamfer geometry induce stress concentrations, accelerate fatigue failure, and trigger costly rework in aerospace, medical device, and automotive applications. Wuxi Lead Precision Machinery delivers engineered countersinking solutions that eliminate these risks through proprietary CNC toolpath optimization and real-time process monitoring. Our systems achieve ±0.5° angular repeatability and Ra 0.8µm surface finishes across aluminum, stainless steel, and titanium alloys—ensuring seamless integration with precision fastening systems while reducing scrap rates by 22% industry-wide.

Partnering with Lead Precision means accessing China’s only ISO 9001-certified countersinking center with integrated metrology validation. Every operation undergoes automated in-process inspection via Renishaw probes, capturing critical dimensions before part ejection. Our engineers collaborate from design-for-manufacturability review through production ramp-up, implementing custom tooling strategies that address material-specific challenges like burr formation in thin-gauge aluminum or work hardening in duplex stainless grades. This closed-loop approach guarantees conformance to ASME Y14.5 and ISO 2768-mK standards while optimizing cycle times for high-volume runs.

Technical Performance Benchmarks

| Parameter | Capability Range | Tolerance Control | Industry Standard |

|————————–|————————|———————–|——————-|

| Material Thickness | 0.5 mm – 6.0 mm | ±0.05 mm | ISO 9445 |

| Hole Diameter | Ø2.0 mm – Ø10.0 mm | +0.02 / -0.00 mm | ASME B18.2.1 |

| Countersink Angle | 60° – 120° | ±0.5° | ISO 4762 |

| Surface Roughness (Ra) | All materials | ≤ 0.8 µm | ISO 1302 |

| Burr Height | < 0.03 mm | Zero visual burrs | ASTM E29 |

We transform countersinking from a cost center into a competitive advantage. Our clients achieve 35% faster assembly line throughput through perfectly seated fasteners and eliminate secondary deburring operations—translating to $187K annual savings per production line. This precision is engineered into every component through our 5-axis CNC platforms with dynamic tool compensation, vibration-dampened spindles, and coolant-through-tool systems that extend cutter life by 40%.

Contact our engineering team directly to resolve your most complex countersinking challenges. Forward your CAD files and material specifications to [email protected] for a confidential process analysis. Within 72 hours, you will receive a tailored solution proposal including tolerance stack-up validation, tooling cost breakdown, and production timeline. Do not compromise assembly integrity with generic machining services—demand the dimensional certainty that only Lead Precision delivers. Partner with us to secure your supply chain with auditable quality, on-time delivery, and engineering support that operates as your extended R&D department. Your next-generation product deserves nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.