Technical Contents

Engineering Guide: Acrylic Injection Molding

Engineering Insight: Precision in Acrylic Injection Molding

Acrylic injection molding demands an elevated level of engineering precision, far beyond standard thermoplastic processes. Polymethyl methacrylate (PMMA), commonly known as acrylic, presents unique challenges due to its sensitivity to shear stress, narrow processing window, and high optical clarity requirements. Even minor deviations in temperature, pressure, or cycle time can result in flow lines, internal stresses, or surface defects—defects that are unacceptable in high-performance applications such as aerospace, medical devices, and premium consumer electronics. At Wuxi Lead Precision Machinery, we approach acrylic injection molding not merely as a manufacturing process, but as a discipline of micron-level control and material science mastery.

Our engineering team leverages decades of experience in custom metal manufacturing to design and build molding systems that deliver repeatable, high-fidelity results. This expertise has been rigorously tested in mission-critical environments, including components used in Olympic-grade timing systems and military-grade optical housings. In these applications, optical clarity, dimensional stability, and long-term environmental resistance are non-negotiable. Our success in such demanding sectors underscores our ability to maintain tolerances within ±0.005 mm and surface finishes below Ra 0.025 µm—benchmarks that reflect the pinnacle of precision molding.

The foundation of this capability lies in our integrated approach to mold design, material handling, and process control. We utilize high-purity hardened tool steels with mirror-polished cavities, designed with balanced runner systems and optimized cooling channels to minimize thermal gradients. Our machines are equipped with closed-loop pressure and temperature controls, ensuring consistent melt homogeneity and injection profiles. Furthermore, we implement in-process monitoring systems that detect and correct anomalies in real time, preventing defects before they occur.

Material selection is equally critical. We work exclusively with medical- and optical-grade PMMA resins, sourced from certified suppliers, and apply strict drying protocols to eliminate moisture—typically conditioning material at 80°C for 4–6 hours to prevent hydrolysis during injection. Our process parameters are validated through Design of Experiments (DOE), ensuring optimal fill, pack, and hold phases for each unique geometry.

At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is engineered into every stage of production. Our track record in high-stakes industries is a testament to our unwavering commitment to excellence in acrylic injection molding.

| Parameter | Specification |

|---|---|

| Material Compatibility | Optical-grade PMMA, Modified Acrylics |

| Tolerance Range | ±0.005 mm |

| Surface Finish (Cavity) | Ra ≤ 0.025 µm (Mirror Polish) |

| Mold Material | H13, S136, or 420 Stainless Steel (Hardened) |

| Temperature Control | ±1°C Precision |

| Injection Pressure Range | 80–160 MPa (Adjustable) |

| Cycle Time Optimization | DOE-Validated Process Mapping |

| Quality Standards | ISO 9001, MIL-STD-810 (for military-grade parts) |

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Manufacturing for Acrylic Injection

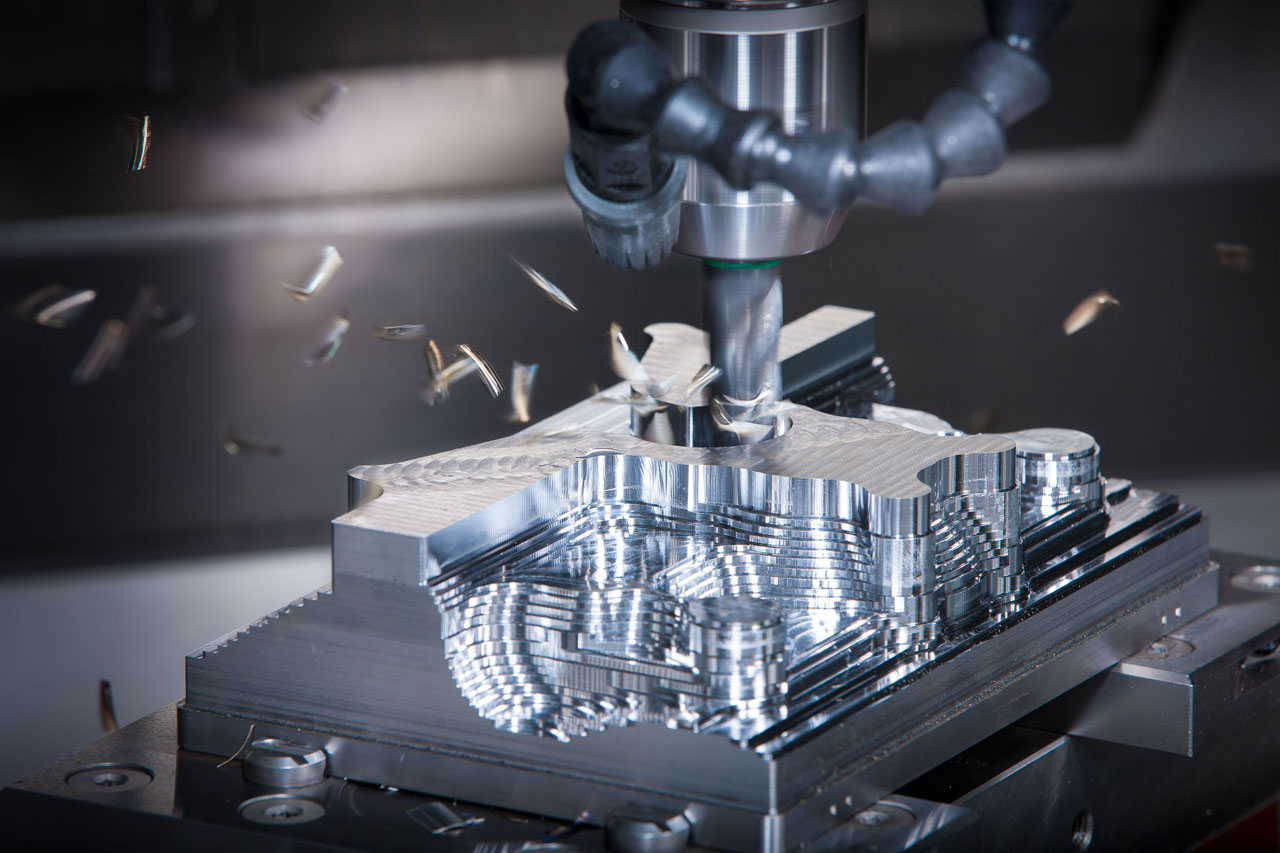

Wuxi Lead Precision Machinery delivers mission-critical mold solutions for demanding acrylic injection applications through integrated advanced manufacturing systems. Our facility leverages seven state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and MAZAK INTEGREX i-200S models, engineered specifically for complex mold base and cavity/core production. These systems enable single-setup machining of intricate geometries required for optical-grade acrylic components, eliminating cumulative errors from multi-axis repositioning. High-speed spindles (up to 24,000 RPM) and sub-micron linear encoders ensure consistent thermal stability during extended runs—critical for maintaining dimensional integrity in acrylic molds subjected to aggressive thermal cycling. We specialize in hardened P20, H13, and stainless steel mold construction with integrated conformal cooling channels, directly addressing acrylic’s sensitivity to uneven cooling rates that cause internal stress and optical distortion.

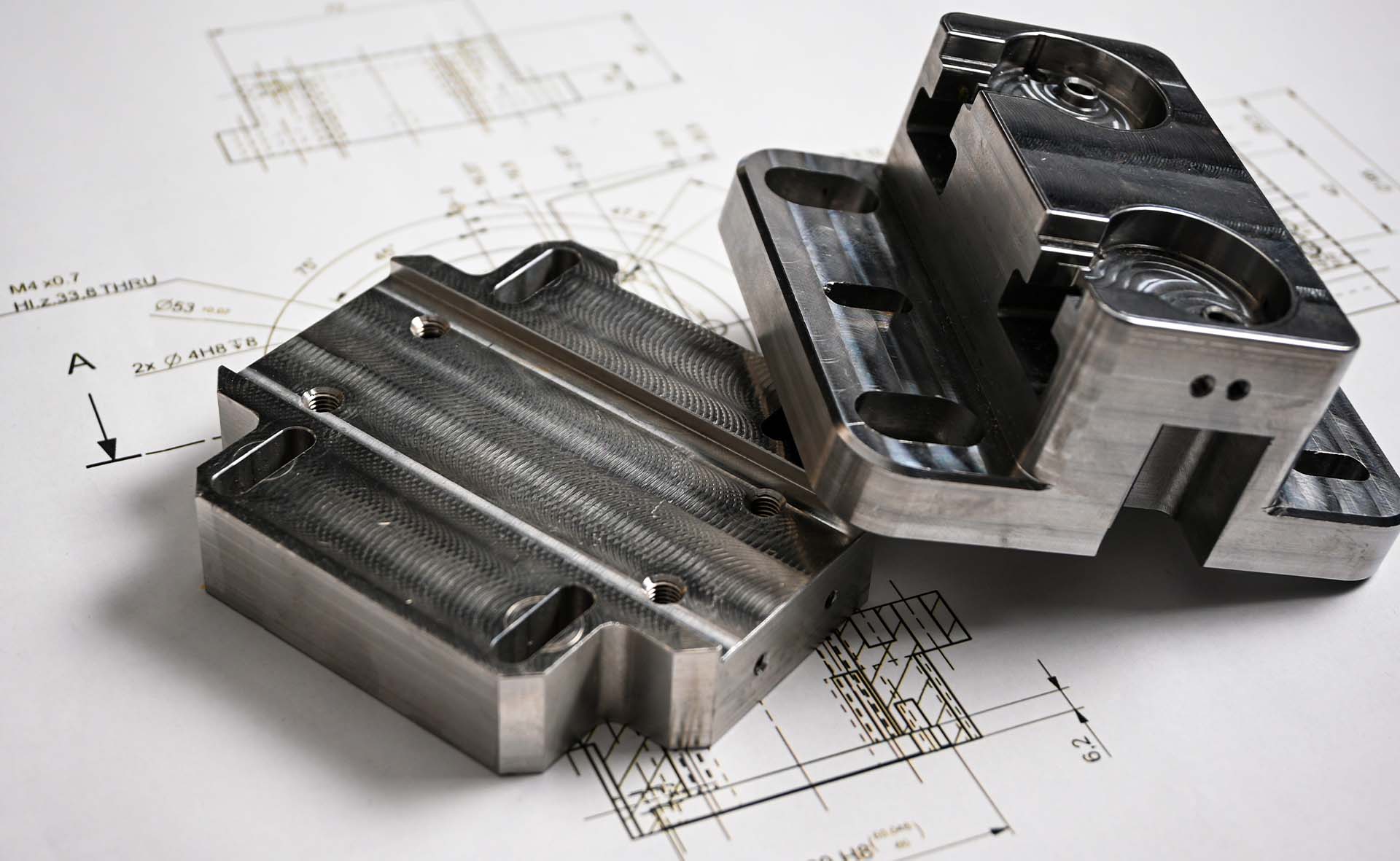

Rigorous quality control is non-negotiable in acrylic molding, where micron-level deviations manifest as flash, sink marks, or refractive inconsistencies. Every mold undergoes 100% CMM inspection using Zeiss CONTURA and Hexagon GLOBAL S systems with calibrated probe spheres traceable to NIST standards. Our inspection protocol includes full 3D surface deviation mapping against CAD nominal data, critical for optical surfaces requiring ≤0.5μm Ra finishes. In-process checks at 25%, 50%, and 75% machining stages prevent scrap escalation, while final validation includes thermal distortion simulation reports verifying performance at 180°C molding temperatures. This closed-loop methodology ensures molds consistently achieve ±0.005mm positional accuracy across multi-cavity layouts—essential for acrylic parts in medical devices and lighting where assembly tolerances are unforgiving.

The following table details our certified tolerance capabilities for acrylic injection molds:

| Feature | Standard Capability | Precision Capability |

|---|---|---|

| Cavity/ Core Dimensions | ±0.010 mm | ±0.005 mm |

| Shut-off Surfaces | ±0.008 mm | ±0.003 mm |

| Ejector Pin Alignment | ±0.012 mm | ±0.006 mm |

| Cooling Channel Position | ±0.020 mm | ±0.010 mm |

| Surface Finish (Ra) | 0.8 μm | 0.2 μm |

Our technical infrastructure bridges the gap between theoretical mold design and real-world acrylic production stability. By combining 5-axis micro-machining precision with metrology-grade validation, we eliminate the root causes of acrylic part rejection—warpage from uneven cooling, surface defects from poor venting, and dimensional drift during high-volume runs. Every mold ships with a comprehensive quality dossier including CMM heat maps, hardness test certificates, and conformal cooling flow analysis. This disciplined approach ensures your acrylic components meet the most stringent optical and mechanical specifications from first article through full production. Partner with Wuxi Lead to transform complex acrylic molding challenges into repeatable manufacturing success.

Material & Finish Options

Material Selection in Acrylic Injection Molding: Precision Components for High-Performance Tools

In the field of acrylic injection molding, the performance and longevity of molds depend critically on the materials used for their construction. While acrylic is the molded polymer, the mold itself must be fabricated from high-strength metals capable of withstanding repeated thermal cycling, mechanical stress, and corrosive byproducts. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection molds, utilizing aluminum, steel, and titanium—each selected based on production volume, part complexity, and environmental conditions.

Aluminum is widely used for prototype molds and low- to medium-volume production runs. Its excellent thermal conductivity allows for faster cooling cycles, improving throughput during trial runs. Additionally, aluminum is easier to machine, reducing lead times and tooling costs. However, its lower hardness makes it less suitable for long production cycles or abrasive additives in acrylic resins.

Steel, particularly tool steels such as P20, H13, and 420 stainless, remains the standard for high-volume acrylic injection molding. These alloys offer superior hardness, wear resistance, and dimensional stability under sustained use. Hardened steel molds can endure millions of cycles with minimal degradation, making them ideal for commercial-scale manufacturing. Stainless variants also provide enhanced resistance to corrosion from moisture and chemical residues in certain acrylic formulations.

Titanium is reserved for specialized applications where extreme durability and corrosion resistance are paramount. Though more expensive and challenging to machine, titanium molds offer exceptional strength-to-density ratios and thermal stability. They are particularly beneficial in molding high-temperature acrylics or in environments where oxidation and chemical exposure are concerns.

Surface finish plays a critical role in part quality and mold maintenance. Anodizing is a key finishing process, especially for aluminum molds. This electrochemical treatment forms a durable, non-conductive oxide layer that enhances surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing is commonly applied for general-purpose molds, while Type III (hardcoat anodizing) is used when maximum durability is required. Anodized surfaces also allow for precise texture replication, critical for aesthetic acrylic parts.

For steel and titanium molds, alternative surface treatments such as nitriding, chrome plating, or PVD coatings are typically preferred, though anodizing remains a strategic option for aluminum-based systems due to its compatibility and cost efficiency.

Below is a comparative overview of mold material properties relevant to acrylic injection molding.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum (7075) | 40–45 | 130 | Moderate | Prototypes, low-volume runs | Yes (Type II/III) |

| Steel (P20) | 28–32 | 28–36 | Low | Medium to high-volume production | No |

| Steel (H13) | 44–52 | 30–35 | Moderate | High-stress, high-temp molding | No |

| Steel (420 SS) | 50–55 | 25–30 | High | Corrosive environments | No |

| Titanium (Grade 5) | 35–40 | 6–7 | Excellent | Specialized, high-durability | Limited (specialized) |

Selecting the right mold material and finish ensures optimal cycle life, part quality, and return on investment. At Wuxi Lead Precision Machinery, we guide clients through these decisions with engineering precision and manufacturing excellence.

Manufacturing Process & QC

Acrylic Injection Molding: Precision Process for Zero-Defect Production

At Wuxi Lead Precision Machinery, we engineer the critical metal tooling enabling flawless acrylic injection molding. While we specialize in custom metal manufacturing for molds and dies—not plastic processing—our precision engineering directly dictates the success of your acrylic part production. Achieving zero defects in acrylic molding demands rigorous control starting with the mold itself. Our integrated process ensures every phase delivers uncompromising quality.

The journey begins with collaborative Design for Manufacturability (DFM). Our engineers meticulously analyze your acrylic part geometry, material properties, and functional requirements. We focus on optimizing gate locations, cooling channel layouts, and ejection systems specifically for acrylic’s sensitivity to shear stress and thermal gradients. This phase identifies potential sinks, warpage, or flow lines early, preventing costly revisions later. We simulate mold filling and cooling using advanced CAE software, verifying pressure distribution and solidification behavior to ensure dimensional stability and optical clarity critical for acrylic applications.

Prototyping transitions the validated design into tangible reality. We manufacture a high-fidelity prototype mold using production-intent materials and processes. This allows rigorous physical validation under actual molding conditions. We measure critical dimensions, assess surface finish quality against optical standards, and verify cycle times. Any micro-defects—such as knit lines, vacuum voids, or residual stress marks—are identified and traced back to mold design or process parameters. Iterations occur here, not in mass production, ensuring the final mold design is perfected for zero-defect output.

Mass Production leverages the perfected tool with integrated process control. Our molds incorporate features like conformal cooling channels for uniform thermal management and cavity pressure sensors for real-time process monitoring. Every production cycle is governed by precise, locked parameters for melt temperature, injection speed, packing pressure, and cooling time—tailored to the specific acrylic grade. Automated in-line inspection systems, including vision systems for surface defects and critical dimension checks, provide immediate feedback. Statistical Process Control (SPC) data is continuously analyzed, enabling proactive adjustments before deviations occur. This closed-loop system, built upon our precision metal foundation, guarantees consistent part conformance to micron-level tolerances and optical requirements.

The performance of the mold is paramount. Below are key specifications we engineer into every acrylic injection mold to enable zero-defect production.

| Specification Parameter | Target Value for Acrylic Molding | Critical Impact |

|---|---|---|

| Mold Base Material | High-grade P20 or H13 Pre-hardened | Ensures structural rigidity and thermal stability during high-cycle production |

| Cavity Steel Grade | S136H or NAK80 (Mirror Polish) | Provides exceptional corrosion resistance and ultra-smooth surface finish (SPI-A1) |

| Linear Tolerance Class | ISO 2768-mK (±0.002mm typical) | Guarantees dimensional accuracy critical for optical clarity and assembly |

| Surface Roughness (Cavity) | Ra ≤ 0.025 µm (SPI-A1) | Eliminates surface defects like orange peel, essential for light transmission |

| Critical Feature Control | In-mold pressure & temperature sensors | Enables real-time process correction to prevent internal stresses and warpage |

This disciplined progression—from intelligent design through validated prototyping to tightly controlled mass production—forms the backbone of our zero-defect commitment. Wuxi Lead Precision Machinery delivers the metal foundation where precision meets perfection in acrylic molding.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Acrylic Injection Molding

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the demanding requirements of modern industrial applications. Our expertise extends into the advanced domain of acrylic injection molding, where material integrity, dimensional accuracy, and surface finish are non-negotiable. As a trusted partner to global OEMs, medical device manufacturers, and consumer electronics innovators, we bring engineering rigor, state-of-the-art equipment, and decades of process mastery to every project.

Acrylic injection molding presents unique challenges due to the material’s sensitivity to temperature, shear stress, and moisture content. Standard molding practices often result in internal stress, warpage, or optical defects—compromising both functionality and aesthetics. At Lead Precision, we address these challenges with purpose-built molding systems, climate-controlled production environments, and a deep understanding of polymer rheology. Our engineers work closely with clients from design inception through production ramp-up, ensuring mold flow analysis, gate positioning, and cooling channel design are optimized specifically for acrylic resins such as PMMA.

We operate a fully integrated manufacturing ecosystem in Wuxi, China, equipped with high-clamp electric and hybrid injection molding machines capable of micro-precision dosing and repeatable cycle control. Our in-house tooling division fabricates hardened steel and pre-hardened molds with mirror-polished cavities, essential for achieving optical clarity and Class 1 surface finishes. All processes are governed by ISO 9001-certified quality systems, with real-time monitoring and 100% inspection protocols for critical dimensions and visual defects.

Our clients choose Lead Precision not only for technical capability but for partnership-driven collaboration. We offer full project transparency, rapid prototyping, and scalable production runs—from low-volume pilot batches to high-volume manufacturing. Whether you require small, complex optical components or large, thin-walled enclosures, our team ensures your acrylic parts meet the highest standards of performance and consistency.

Below are key technical specifications for our acrylic injection molding capabilities:

| Parameter | Specification |

|---|---|

| Molding Machine Range | 50 to 1,200 tons clamping force |

| Shot Weight Accuracy | ±0.01 g |

| Material Compatibility | PMMA (acrylic), modified acrylics, co-molding with PC or ABS |

| Mold Tolerance | ±0.002 mm |

| Part Dimensional Tolerance | ±0.025 mm (typical) |

| Surface Finish | SPI-A1 (mirror polish), textured options |

| Production Environment | Climate-controlled, low-humidity drying |

| Quality Standards | ISO 9001:2015, full traceability, SPC monitoring |

When precision matters, partner with a manufacturer that understands the science and art of acrylic injection molding. Contact us today at [email protected] to discuss your next project with our engineering team. Let Wuxi Lead Precision Machinery be your strategic partner in delivering excellence—on time, to spec, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.