Technical Contents

Engineering Guide: Black Plastic Molding

Engineering Insight Black Plastic Molding Precision as Non Negotiable

The intersection of custom metal manufacturing and black plastic molding demands exceptional rigor. While Wuxi Lead Precision Machinery specializes in high-tolerance metal components and tooling systems, our deep expertise directly enables the success of demanding black plastic molding applications. This is critical because black polymers present unique engineering hurdles distinct from lighter colors. Their high pigment concentration absorbs significant radiant heat during processing, creating severe thermal gradients within the mold cavity. Without precision-engineered metal tooling – the core of our capability – these gradients lead to inconsistent cooling, internal stresses, warpage, surface defects like jetting or sink marks, and unacceptable color variation. Achieving true, uniform black without splay or mottling requires absolute control over mold temperature distribution and cavity geometry, impossible without sub-micron metal fabrication.

Precision in the metal mold base, cores, cavities, and cooling channels is not merely beneficial; it is the foundational requirement for viable black plastic parts. Standard tolerances fail under the thermal load. Minute deviations in parallelism or flatness cause flashing or parting line mismatches, especially problematic for black parts where even microscopic flashes are highly visible. Surface finish consistency across the entire cavity is paramount; variations become glaringly apparent under light due to the pigment’s opacity. Lead Precision’s mastery in CNC milling, grinding, and EDM ensures the metal tooling achieves the dimensional stability and thermal management needed. We control critical parameters to aerospace and defense standards, directly translating to molding success.

Our validation of this precision comes from the most unforgiving applications. We engineered and manufactured critical mold components for sensor housings used in a major international sporting event’s timing infrastructure, where black plastic parts required absolute dimensional stability under varying environmental conditions. Similarly, we produced intricate mold inserts for military communication device enclosures, meeting stringent MIL-STD requirements for EMI shielding and environmental resistance – specifications where black plastic molding precision directly impacts operational reliability. These projects demanded tolerances and material performance far exceeding commercial norms.

The table below outlines key precision parameters where our metal manufacturing expertise directly solves black plastic molding challenges:

| Critical Parameter | Standard Commercial Tolerance | Lead Precision Capability (Metal Tooling) | Impact on Black Plastic Molding |

|---|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm to ±0.002 mm | Eliminates warpage; ensures assembly fit |

| Cavity Surface Roughness | Ra 0.8 µm | Ra 0.05 µm to Ra 0.025 µm (Mirror) | Achieves uniform gloss; prevents visual defects |

| Warpage Control (Tooling) | ±0.10 mm | ±0.02 mm | Critical for flat black surfaces; avoids distortion |

| Color Consistency Support | Variable | Optimized Thermal Channels | Ensures uniform cooling; prevents mottling/splay |

| Thermal Stability (Tooling) | Moderate | High Thermal Conductivity Alloys | Manages pigment heat absorption; stabilizes cycles |

Wuxi Lead Precision Machinery’s value lies in transforming the inherent difficulty of black plastic molding into a controlled, repeatable process. Our decades of experience crafting mission-critical metal components for Olympic and military programs provide the exact precision engineering discipline required. We understand that the quality of the final black plastic part is irrevocably defined by the precision of the metal tooling that forms it. Partner with us to convert the challenges of black polymer processing into a competitive advantage through uncompromising metal manufacturing excellence.

Precision Specs & Tolerances

Advanced Technical Capabilities in Black Plastic Molding and Precision Metal Manufacturing

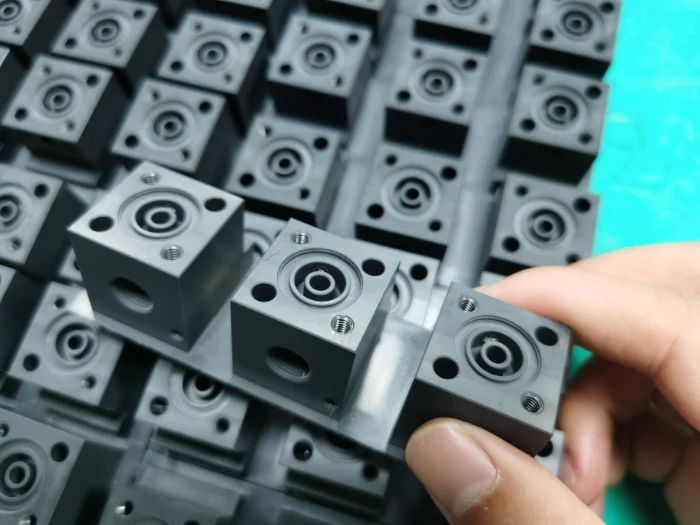

At Wuxi Lead Precision Machinery, our technical expertise in custom metal manufacturing extends seamlessly into high-precision black plastic molding, serving industries where material performance, dimensional accuracy, and aesthetic consistency are critical. Our integrated production environment combines state-of-the-art 5-axis CNC machining with advanced molding technologies, enabling us to deliver complex components in engineering-grade black plastics such as PEEK, PPS, PSU, and reinforced nylons. These materials are selected for their thermal stability, chemical resistance, and mechanical strength, making them ideal for aerospace, medical, semiconductor, and industrial automation applications.

Our 5-axis CNC machining centers provide unparalleled flexibility in shaping both metallic and plastic components. With simultaneous multi-axis movement, we achieve intricate geometries, tight internal features, and superior surface finishes that are unattainable with conventional 3-axis systems. This capability is particularly valuable in black plastic molding, where post-molding machining is often required to meet exacting specifications. Our machines operate with sub-micron repeatability, ensuring consistency across production batches while minimizing material waste and cycle time.

Quality control is embedded at every stage of production. All critical dimensions on black plastic molded parts are verified using Coordinate Measuring Machine (CMM) inspection, supported by non-contact optical scanning when appropriate. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 and IATF 16949 requirements. This rigorous inspection protocol guarantees that every component meets the specified geometric dimensioning and tolerancing (GD&T) criteria, even in thermally sensitive plastic substrates prone to slight post-molding deformation.

We maintain full in-house control over tooling design, mold fabrication, and process validation, allowing rapid prototyping and efficient transition to high-volume production. Our engineers utilize advanced mold flow simulation software to predict and mitigate potential defects such as sink marks, warpage, or voids—common challenges in black pigmented resins due to carbon black dispersion and thermal absorption characteristics.

The following table outlines our standard and precision machining tolerances for black plastic molded and CNC-finished components:

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 100 mm |

| Geometric Tolerances (GD&T) | ±0.03 mm | ±0.005 mm | Includes flatness, position, runout |

| Hole Diameter | ±0.04 mm | ±0.01 mm | Drilled or reamed |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machined surfaces |

| Angular Tolerance | ±0.1° | ±0.05° | Multi-face features |

| Molded Part Warpage | ≤ 0.15 mm per 50 mm | ≤ 0.08 mm per 50 mm | Verified post-annealing |

This combination of advanced equipment, rigorous quality assurance, and deep materials knowledge positions Wuxi Lead Precision Machinery as a trusted partner for high-end black plastic molding and precision metal manufacturing solutions.

Material & Finish Options

Material Selection for Black-Finishing Metal Components

Selecting the optimal base material is critical for achieving durable, high-performance black finishes in precision metal components. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, structural integrity, and compatibility with black surface treatments. While plastic molding serves distinct applications, this guide focuses exclusively on metal substrates for black-finished parts—where aluminum, steel, and titanium dominate aerospace, medical, and industrial sectors. Each material interacts uniquely with finishing processes, directly impacting corrosion resistance, wear performance, and aesthetic consistency.

Aluminum remains the industry standard for black-anodized components due to its exceptional electrochemical response. Anodizing forms a porous oxide layer that readily absorbs black dyes, yielding deep, uniform coloration while enhancing surface hardness. Steel variants like 303 or 17-4 PH require alternative approaches; electroless nickel plating with black topcoats or PVD coatings are typical, as steel cannot be anodized. Titanium achieves black finishes via PVD or plasma electrolytic oxidation (PEO), offering superior biocompatibility but at higher processing costs. Material choice must align with functional demands: aluminum suits lightweight enclosures and heat sinks, steel excels in high-stress mechanical parts, and titanium is indispensable for medical implants or extreme-environment aerospace components.

Critical Material & Finish Specifications

| Material | Primary Black Finish Process | Thickness Range (μm) | Salt Spray Resistance (hrs) | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | Type II Anodizing + Black Dye | 8–12 | 500–1,000 | Enclosures, brackets, optical mounts |

| Stainless Steel 316L | Electroless Nickel + Black E-Coat | 25–35 | 300–500 | Marine hardware, fluid systems |

| Titanium Grade 5 | PVD (TiN/TiCN) | 2–5 | 1,000+ | Surgical tools, aerospace fasteners |

Machinability during CNC processing directly influences finish quality. Aluminum’s softness allows high-speed milling with minimal tool wear, ensuring smooth surfaces ideal for dye penetration. Steel demands rigid setups and specialized tooling to prevent micro-chipping that disrupts coating adhesion. Titanium’s low thermal conductivity necessitates controlled feeds/speeds to avoid heat buildup, which can compromise subsequent PVD bonding. Crucially, all substrates require meticulous pre-treatment—deburring, alkaline cleaning, and etching—to eliminate contaminants that cause finish defects.

Wuxi Lead integrates material science with precision machining to eliminate finish failures. We validate each component’s material grade, surface roughness (Ra ≤ 0.8 μm pre-anodizing), and dimensional stability before finishing. For black-anodized aluminum, we enforce strict voltage control during anodizing to prevent “burning” and ensure dye uniformity. Steel parts undergo adhesion testing via ASTM D3359 cross-hatch analysis. Titanium PVD coatings are verified for thickness consistency using XRF spectrometry. This end-to-end control guarantees parts meet ISO 9001 and AS9100 standards for critical applications.

Material selection is not merely technical—it’s strategic. Choosing aluminum over steel for a drone chassis reduces weight by 60% while maintaining anodized black durability. Opting for titanium in corrosive environments eliminates long-term maintenance costs. Partner with Wuxi Lead to navigate these trade-offs: our engineers provide material-specific CNC programming and finish validation, ensuring your black-finished components perform flawlessly in service.

Manufacturing Process & QC

The production process for black plastic molding at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure precision, consistency, and zero defects. Rooted in advanced custom metal manufacturing expertise, our approach integrates engineering rigor with cutting-edge technology to deliver high-performance plastic components tailored to exact client specifications.

Design is the foundational phase, where engineering precision meets functional intent. Our team collaborates closely with clients to analyze application requirements, environmental conditions, and mechanical tolerances. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we develop optimized mold designs that account for material flow, thermal dynamics, and part ejection. Special attention is given to the selection of high-grade black engineering plastics—such as PBT, PPS, or black-filled polycarbonate—ensuring UV resistance, thermal stability, and long-term durability. Mold steel selection, typically NAK80 or H13 with mirror polishing and nitriding treatment, is finalized during this stage to support high-cycle production and surface finish consistency.

Prototyping follows design finalization, serving as a critical validation step before mass production. We employ rapid tooling techniques using CNC-machined pre-hardened steel molds to produce functional prototypes within 10–15 days. These prototypes undergo rigorous testing for dimensional accuracy, mechanical performance, and aesthetic finish. First Article Inspection (FAI) reports, including GD&T verification and material certification, are provided to confirm compliance. Any design adjustments are implemented digitally and re-validated through iterative prototyping until zero deviation is achieved.

Mass production begins only after full client approval, leveraging fully automated, high-tonnage electric injection molding machines with closed-loop process control. Each molding cycle is monitored in real time for pressure, temperature, and shot consistency using integrated sensors and statistical process control (SPC) systems. The black plastic material is dried and fed through a climate-controlled handling system to prevent contamination and moisture absorption, which can lead to surface defects. Post-molding, parts are inspected using optical measurement systems and automated vision inspection to detect cosmetic flaws or dimensional drift. Every batch is traceable through our ERP system, with full documentation of process parameters and quality checks.

Our zero-defect philosophy is enforced through a combination of preventive maintenance, operator training, and a robust Quality Management System compliant with ISO 9001:2015. Continuous improvement is driven by real-time data analytics and client feedback loops.

| Parameter | Specification |

|---|---|

| Material Options | PBT, PPS, PC, ABS (black pigment, UV stabilized) |

| Mold Steel | NAK80, H13, 2738HH |

| Surface Finish | SPI-A1, VDI 14–22 (polished, texture, matte) |

| Tolerance (Dimensional) | ±0.02 mm (depending on part size) |

| Production Capacity | Up to 500,000 units/month |

| Quality Standards | ISO 9001:2015, IATF 16949 (on request) |

| Lead Time (Prototype) | 10–15 days |

| Lead Time (Mass Production) | 25–35 days after sample approval |

This end-to-end process ensures that every black plastic component meets the highest standards of performance, aesthetics, and reliability required in automotive, medical, and industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Black Plastic Molding Excellence

Achieving flawless black plastic components demands more than standard molding expertise. The unique challenges of pigment dispersion, thermal stability, and surface finish consistency in dark polymers require precision-engineered tooling and deep material science understanding. At Wuxi Lead Precision Machinery, we bridge the gap between complex design intent and production reality through our mastery of custom metal manufacturing for high-performance molds. Our CNC-engineered mold bases and cavities eliminate warpage, sink marks, and cosmetic defects inherent in black plastic applications, ensuring dimensional accuracy and repeatability down to ±0.002 mm.

We recognize that black plastics amplify even microscopic imperfections in mold surfaces. This is why every mold we produce starts with proprietary hardened P20 or H13 tool steel, meticulously stress-relieved and polished to SPI-A1 standards. Our 5-axis CNC milling centers achieve mirror finishes critical for matte or high-gloss black aesthetics, while integrated cooling channels prevent thermal degradation during extended production runs. Unlike generic mold suppliers, we optimize steel selection and heat treatment specifically for the polymer’s viscosity and thermal profile—whether you’re processing ABS, PC, or engineering-grade nylons with carbon black.

The foundation of our black molding success lies in metallurgical precision. Below are the core specifications our molds deliver as standard for demanding black plastic applications:

| Critical Parameter | Lead Precision Standard | Industry Typical |

|---|---|---|

| Mold Steel Hardness | 38-42 HRC (H13) | 30-34 HRC |

| Cavity Surface Finish | Ra 0.025 µm (SPI-A1) | Ra 0.1 µm |

| Dimensional Tolerance | ±0.002 mm | ±0.01 mm |

| Cooling Uniformity | ±1.5°C across cavity | ±5°C |

| Parting Line Precision | 0.001 mm | 0.005 mm |

Partnering with us means gaining a technical extension of your engineering team. We conduct rigorous Design for Manufacturing (DFM) analysis upfront, identifying potential flow issues or ejection challenges unique to opaque materials. Our in-house metallurgy lab validates steel integrity, while real-time process monitoring during mold trials ensures zero defects before full-scale production. Clients across automotive sensor housings, medical device enclosures, and consumer electronics consistently achieve 99.8% first-pass yield rates with our molds—eliminating costly rework and scrap common in black plastic manufacturing.

Do not compromise on the foundation of your black plastic components. Contact our engineering team today to discuss your specific material, volume, and surface finish requirements. We will provide a comprehensive mold feasibility assessment and timeline within 48 hours. Send your CAD files and specifications to [email protected] for immediate technical review. Let Wuxi Lead Precision Machinery transform your black plastic molding challenges into competitive advantage through precision metal craftsmanship. Your next high-yield production run starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.