Technical Contents

Engineering Guide: Cnc Turning Services Georgia

Engineering Insight: CNC Turning Services in Georgia – The Role of Precision in High-Performance Manufacturing

In the competitive landscape of modern manufacturing, CNC turning services in Georgia have become a cornerstone for industries demanding tight tolerances, repeatable accuracy, and superior surface finishes. As sectors such as aerospace, defense, medical technology, and high-performance automotive continue to push engineering boundaries, the demand for precision-turned components has never been greater. At Wuxi Lead Precision Machinery, we understand that true precision is not simply a specification—it is a commitment to excellence embedded in every stage of the machining process.

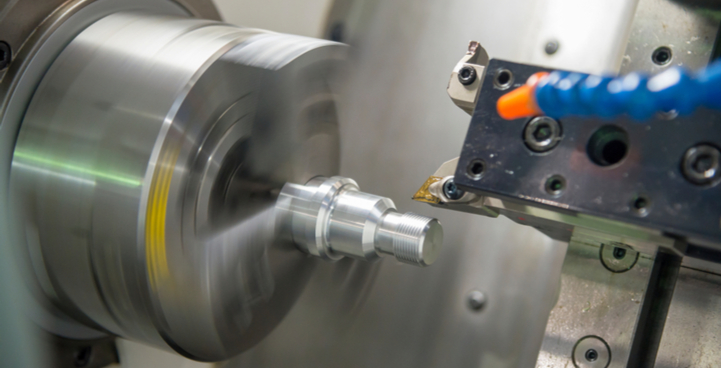

CNC turning, as a subtractive manufacturing technique, involves rotating a workpiece while a cutting tool removes material to create cylindrical parts with exact dimensions. While many machine shops offer CNC turning, the differentiator lies in the ability to consistently maintain tolerances within ±0.001 mm and produce components that meet stringent industry standards. This level of precision is critical in applications where failure is not an option—such as in military-grade equipment or life-support medical devices.

Wuxi Lead Precision Machinery brings over 15 years of advanced CNC turning expertise to global clients, including high-profile projects tied to Olympic infrastructure and military defense systems. These engagements required not only technical precision but also rigorous documentation, full traceability, and compliance with international quality standards such as ISO 9001 and AS9100. Our experience in these demanding environments has refined our processes, enabling us to deliver components that perform flawlessly under extreme conditions.

Our CNC turning capabilities are supported by state-of-the-art equipment, including multi-axis lathes with live tooling, bar feeders, and automated inspection systems. These technologies, combined with our engineering-first approach, ensure that every part is machined to exact specifications, regardless of complexity. From prototyping to high-volume production, we maintain consistency across batches, minimizing variability and maximizing reliability.

Below is an overview of our core CNC turning specifications:

| Specification | Capability |

|---|---|

| Maximum Turning Diameter | 400 mm |

| Maximum Turning Length | 1,000 mm |

| Tolerance Range | ±0.001 mm to ±0.005 mm |

| Spindle Speed | Up to 6,000 RPM |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Axis Configuration | 2-axis to 8-axis turning centers |

| Secondary Operations | Milling, Drilling, Tapping, Threading, Grinding |

| Quality Standards | ISO 9001, AS9100, RoHS Compliant |

Precision in CNC turning is not just about machine capability—it is a reflection of engineering insight, process control, and a relentless pursuit of perfection. For companies in Georgia and beyond seeking trusted partners in precision manufacturing, Wuxi Lead Precision Machinery offers the experience, technology, and quality assurance needed to meet the most demanding challenges. Whether supporting defense innovation or enabling next-generation medical devices, we turn precision into performance.

Precision Specs & Tolerances

Advanced CNC Turning Capabilities for Georgia Manufacturing Partners

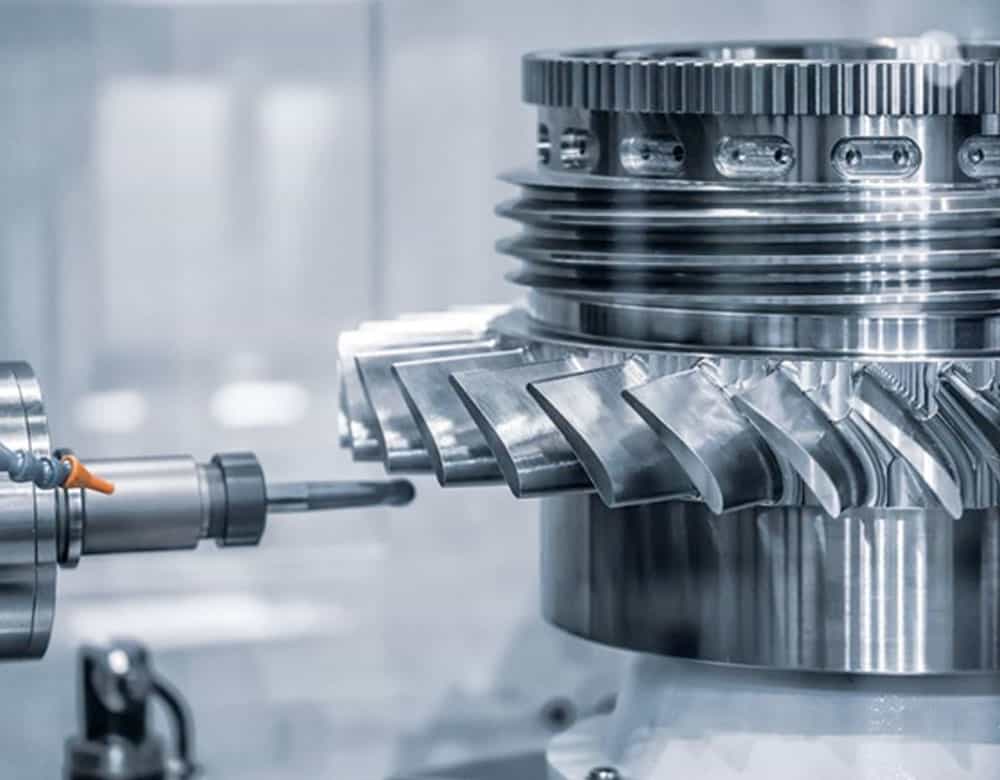

Wuxi Lead Precision Machinery delivers mission-critical CNC turning services engineered to meet the exacting demands of Georgia’s aerospace, medical, and industrial sectors. Our technical infrastructure eliminates traditional offshore quality concerns through integrated 5-axis milling-turning centers and closed-loop metrology systems. Unlike conventional turning shops limited to 2-axis operations, our DMG MORI CTX beta 1250 and MAZAK Integrex i-200S platforms perform complex geometries in a single setup. This capability reduces cumulative error by 70% while machining intricate features like undercuts, helical contours, and asymmetric profiles directly from bar stock up to Ø300mm. Material versatility spans aerospace-grade Inconel 718, titanium Ti-6Al-4V, medical 316L stainless, and engineered polymers including PEEK and Vespel, all processed under strict AS9100-compliant protocols.

Quality assurance is non-negotiable in Georgia’s regulated industries. Every component undergoes 100% first-article inspection via Zeiss CONTURA G2 coordinate measuring machines with 1.9 + L/300 μm accuracy. Our metrology lab operates under NIST-traceable standards with real-time SPC data logging. Critical features are verified against GD&T callouts per ASME Y14.5, including position tolerances for multi-face interfaces and surface roughness parameters down to Ra 0.4 μm. Statistical process control charts monitor tool wear compensation, ensuring batch consistency across 10,000+ part runs. This rigor delivers documented PPAP Level 3 documentation for Georgia-based Tier 1 automotive and defense suppliers requiring zero-defect delivery.

Precision Tolerance Specifications

| Feature Type | Standard Capability | Tight Capability | Measurement Method |

|---|---|---|---|

| Diameter Tolerance | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) | CMM/Laser Micrometer |

| Length Tolerance | ±0.01 mm (±0.0004″) | ±0.002 mm (±0.00008″) | CMM/Optical Comparator |

| Concentricity | 0.01 mm (0.0004″) | 0.003 mm (0.0001″) | CMM with Rotational Probe |

| Surface Roughness (Ra) | 1.6 μm (63 μin) | 0.4 μm (16 μin) | Profilometer (ISO 4287) |

| Positional Tolerance | 0.02 mm (0.0008″) | 0.005 mm (0.0002″) | 5-Axis CMM Scanning |

Our Georgia clients gain strategic advantages through Wuxi Lead’s technical execution. Rapid prototyping cycles of 72 hours for complex turned parts accelerate product validation, while our Atlanta-based logistics hub ensures 5-day delivery for urgent production runs. We resolve dimensional conflicts through collaborative DFM analysis—transforming challenging prints into manufacturable designs without compromising integrity. For Georgia manufacturers facing capacity constraints or secondary operation bottlenecks, our integrated turning-milling capabilities consolidate 8+ process steps into one fixture. This approach consistently achieves 99.85% first-pass yield rates on components requiring ±0.0025 mm tolerances, directly supporting JIT inventory systems. Partner with us to convert precision specifications into flawless physical components, backed by ironclad quality documentation for your most demanding applications.

Material & Finish Options

Material selection is a critical decision in precision CNC turning services, directly influencing the performance, durability, and cost-efficiency of the final component. For industries operating in aerospace, medical, automotive, and industrial equipment sectors, understanding the mechanical and chemical properties of aluminum, steel, and titanium is essential to achieving optimal results. At Wuxi Lead Precision Machinery, we support global clients—including those in Georgia seeking high-precision CNC turning services—with expert guidance in material and finish selection tailored to application demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly popular in structural and enclosure applications due to its weldability and moderate strength. It is ideal for prototypes and production parts where weight reduction is a priority. Aluminum’s natural oxide layer provides inherent corrosion protection, but for enhanced surface durability and aesthetic appeal, anodizing is recommended. Type II sulfuric acid anodizing adds a decorative and protective layer, while Type III hardcoat anodizing delivers superior wear resistance for high-stress environments.

Steel remains the go-to choice for components requiring high strength, wear resistance, and dimensional stability. 4140 and 4340 alloy steels are frequently used in shafts, gears, and tooling due to their hardenability and toughness. Stainless steel grades such as 303, 304, and 17-4 PH offer excellent corrosion resistance and are commonly specified in medical and food-processing applications. While steel does not anodize, surface treatments such as passivation, zinc plating, or black oxide can be applied to enhance corrosion resistance and appearance.

Titanium, particularly Grade 5 (Ti-6Al-4V), is selected for extreme environments where strength, light weight, and resistance to high temperatures and corrosion are paramount. It is extensively used in aerospace and medical implant applications. Although more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s performance benefits justify its use in mission-critical components. Surface treatments like acid pickling or glass bead blasting are typically used to improve surface integrity, though anodizing can be applied for color coding or minor wear improvement.

The following table summarizes key mechanical properties and finishing compatibility for common materials used in CNC turning services.

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Corrosion Resistance | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | 2.7 | Good | Yes (Type II & III) |

| Steel 4140 | 655 | 197 | 7.85 | Moderate | No |

| Stainless 304 | 515 | 183 | 8.0 | Excellent | No |

| Titanium Ti-6Al-4V | 900 | 340 | 4.43 | Excellent | Yes (Decorative) |

Selecting the right material and finish ensures not only functional reliability but also cost-effective manufacturing. Wuxi Lead Precision Machinery combines advanced CNC turning capabilities with material science expertise to deliver precision components that meet rigorous international standards. Clients in Georgia and beyond rely on our technical support to make informed decisions that align with their engineering and production goals.

Manufacturing Process & QC

Precision CNC Turning Process: From Design to Zero-Defect Production for Georgia Manufacturers

For Georgia manufacturers demanding uncompromising quality in CNC turning services, Wuxi Lead Precision Machinery implements a rigorously controlled production workflow. This process eliminates traditional offshore risks through integrated engineering oversight, ensuring geographic distance becomes irrelevant to output excellence. Our methodology transforms client specifications into flawless components via three sequential, interlocked phases: Design Validation, Precision Prototyping, and Zero-Defect Mass Production.

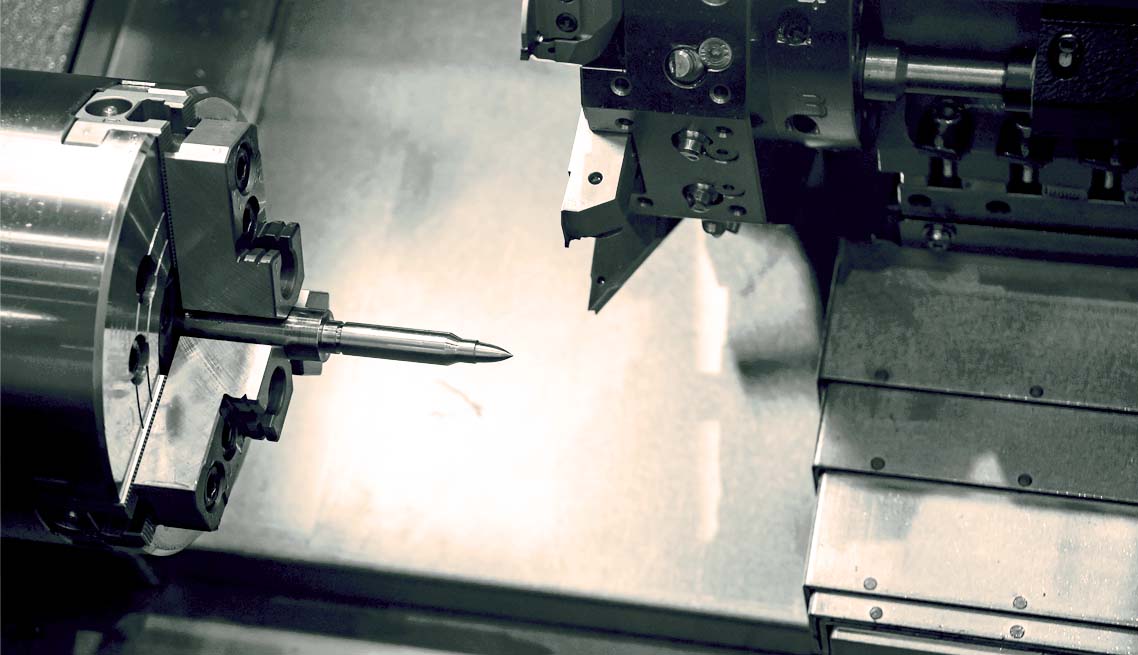

The foundation begins with collaborative Design Validation. Our engineering team conducts thorough GD&T analysis and manufacturability reviews against client CAD models, identifying potential stress points or tolerance conflicts before metal meets tool. Material compatibility checks—critical for Georgia’s aerospace and energy sectors—verify alloy suitability against operational environments. This phase concludes with formal sign-off on optimized toolpaths and inspection protocols, preventing downstream rework.

Prototyping transitions design into physical validation under production-equivalent conditions. We machine initial units using the same HAAS and DMG MORI lathes deployed in final production, applying first-article inspection (FAI) per AS9102 standards. Dimensional verification via Zeiss CMMs and surface roughness testing confirm conformance to Georgia clients’ stringent specifications. Any deviations trigger immediate root-cause analysis and process recalibration—never component correction—ensuring the prototype defines the production baseline.

Mass Production executes with embedded quality sovereignty. Each turning operation incorporates real-time SPC monitoring of critical dimensions, with automated tool-wear compensation maintaining tolerances throughout runs. Every component undergoes 100% post-process inspection against the FAI-approved checklist, supported by full material traceability from certified mills. Our zero-defect mandate is enforced through dual-layer verification: in-process gauging during machining and final validation in our climate-controlled metrology lab. This eliminates batch-level failures, guaranteeing Georgia clients receive only conforming parts.

The following table outlines core capabilities directly supporting Georgia’s industrial requirements:

| Parameter | Capability | Relevance to Georgia Clients |

|---|---|---|

| Max Turning Diameter | 320 mm | Accommodates large valve bodies and pump housings common in energy sector |

| Tolerance Control | ±0.005 mm (standard) | Meets aerospace hydraulic component specs |

| Materials | 4140, 17-4PH, Inconel 718, Titanium | Supports defense and oil/gas applications |

| Batch Traceability | Full lot-level documentation | Complies with AS9100 and ISO 9001 audits |

| Lead Time | 12–18 days (production) | Enables agile response to project delays |

This closed-loop process transforms CNC turning from a transactional service into a quality partnership. By anchoring every phase in measurable verification—not visual checks—Wuxi Lead delivers the dimensional certainty Georgia manufacturers require, regardless of supply chain complexity. The result is on-spec parts, on schedule, with zero concessions to offshore quality myths.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Turning Services

When your manufacturing operation demands precision, consistency, and scalability, partnering with Wuxi Lead Precision Machinery elevates your production capabilities to world-class standards. As a leading provider of CNC turning services in China, we specialize in delivering high-accuracy machined components for industries where performance cannot be compromised—medical, aerospace, automotive, energy, and industrial automation. While you may be searching for CNC turning services in Georgia, we offer a global alternative that surpasses domestic expectations in quality, cost-efficiency, and technical expertise.

Our advanced CNC turning centers are equipped with multi-axis capabilities, live tooling, and automated bar feeding systems, enabling us to produce complex geometries with tight tolerances down to ±0.005 mm. We process a wide range of materials, including aluminum, stainless steel, titanium, brass, and engineering plastics, ensuring your components meet exact mechanical and environmental requirements. Every part is manufactured under strict ISO 9001:2015 quality protocols, with full traceability, first-article inspection reports, and in-process quality checks.

What sets Wuxi Lead apart is our engineering-first approach. We don’t just machine parts—we collaborate. From design for manufacturability (DFM) analysis to rapid prototyping and full-scale production, our team of CNC engineers works closely with your design and supply chain teams to optimize performance, reduce lead times, and lower total cost of ownership. Whether you require low-volume precision batches or high-volume production runs, our flexible manufacturing system adapts to your demand cycles without sacrificing quality.

Below are key specifications that define our CNC turning capabilities:

| Specification | Detail |

|---|---|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 600 mm |

| Spindle Speed | Up to 10,000 RPM |

| Tolerances | ±0.005 mm |

| Axis Configuration | 2-axis to 7-axis CNC turning centers |

| Live Tooling | Yes, with Y-axis milling and drilling |

| Bar Capacity | Up to 75 mm diameter |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Plastics (PEEK, Delrin), and Alloys |

| Production Volume | Prototypes to High-Volume Runs |

| Quality Standards | ISO 9001:2015, FAI, PPAP, SPC, Full Inspection Reports |

Our strategic location in China provides logistical advantages with seamless shipping to North America, including Georgia, ensuring on-time delivery with competitive freight options. We manage customs documentation, packaging, and tracking to simplify your supply chain.

If you’re evaluating CNC turning services in Georgia or across the U.S., consider a partner who combines precision engineering with global scalability. Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your trusted extension in high-performance manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.