Technical Contents

Engineering Guide: Cnc Machin

Engineering Insight: The Non-Negotiable Imperative of Precision in CNC Machining

In high-stakes manufacturing sectors like aerospace, defense, and advanced medical technology, precision is not merely a desirable attribute; it is the absolute foundation of functionality, safety, and reliability. The margin for error measured in microns directly translates to system performance, longevity, and ultimately, human safety. Components operating under extreme stress, vacuum conditions, or requiring perfect fluid dynamics demand dimensional and geometric accuracy that pushes the boundaries of modern machining capability. Sub-micron deviations can cascade into catastrophic system failures, costly recalls, or compromised mission objectives. This uncompromising requirement elevates precision CNC machining from a production process to a critical engineering discipline where process control, material science, and metrology converge.

Achieving this level of fidelity requires far more than advanced machinery. It demands a holistic engineering approach integrating rigorous material selection protocols, thermally stable machining environments, meticulously calibrated tooling systems, and real-time in-process verification. At Wuxi Lead Precision Machinery, we engineer precision into every stage. Our multi-axis machining centers operate within controlled environments minimizing thermal drift, while our proprietary fixturing solutions eliminate workpiece distortion. Crucially, precision is validated not just post-process, but through integrated metrology and adaptive control systems that adjust parameters dynamically during cutting, ensuring tolerances are met consistently across entire production runs, not just on first articles.

Our commitment to micron-level accuracy is proven in mission-critical applications. We have successfully delivered components for Olympic timing systems demanding flawless synchronization and marine hardware for defense applications where reliability under extreme conditions is non-negotiable. This experience shapes our entire operational philosophy, ensuring every part meets the most stringent global standards.

The table below outlines the precision capabilities achievable through our integrated engineering and manufacturing system:

| Specification | Capability | Application Impact |

|---|---|---|

| Positional Accuracy | ±1.5 μm | Critical for multi-axis feature alignment in complex assemblies |

| Repeatability | ±0.8 μm | Ensures batch consistency for high-volume precision components |

| Surface Roughness (Ra) | 0.05 μm – 0.8 μm | Essential for fluid dynamics, sealing surfaces, and optical applications |

| Geometric Tolerances | IT Grade 3-4 | Meets aerospace and medical implant standards for form and fit |

| Material Range | Titanium, Inconel, Stainless Steels, Aluminum Alloys, Engineering Plastics | Supports diverse high-performance applications |

Precision in CNC machining is the tangible result of engineering rigor applied to process, people, and technology. It is the silent guarantee that a component will perform exactly as designed, under the most demanding circumstances. For industries where failure is not an option, partnering with a manufacturer possessing demonstrable expertise in achieving and verifying micron-level precision – proven in applications like Olympic infrastructure and military systems – is not just prudent engineering; it is a fundamental requirement for success. Wuxi Lead Precision Machinery delivers this assurance as standard.

Precision Specs & Tolerances

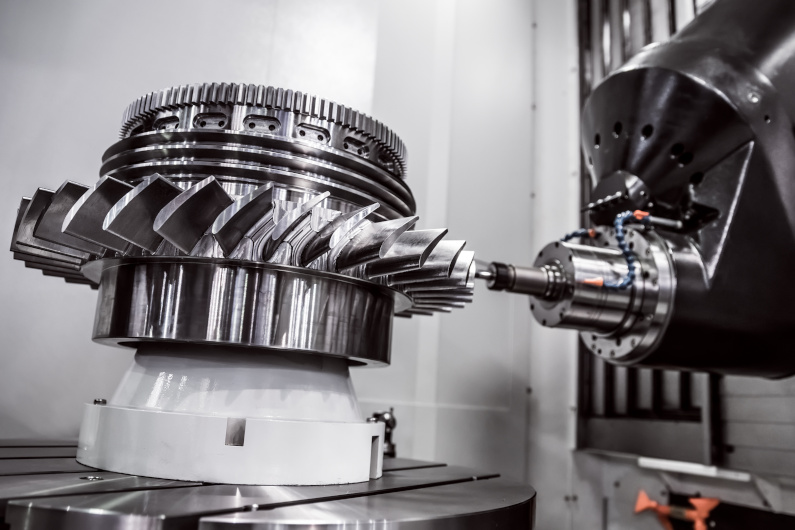

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered for the most demanding industries, including aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. Our multi-axis systems eliminate the need for multiple setups, reducing lead times and minimizing cumulative errors associated with repositioning. This capability allows us to machine intricate components from a single workholding setup, ensuring dimensional consistency and superior part integrity.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems that maintain cutting precision across extended production runs. We process a wide range of engineering materials, including aluminum alloys, stainless steel, titanium, Inconel, and engineering plastics, tailored to meet specific performance requirements. Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAM software to optimize toolpaths, reduce cycle times, and ensure repeatability.

Quality control is embedded at every stage of production. We employ a structured inspection protocol anchored by a Zeiss coordinate measuring machine (CMM), which provides metrology-grade verification of critical dimensions and geometric tolerances. The CMM system is integrated with CAD models for direct comparison, enabling full first-article inspection (FAI) reporting and statistical process control (SPC) analysis. In addition to CMM inspection, we utilize optical comparators, surface roughness testers, and digital micrometers to validate compliance with customer specifications.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across diverse part configurations. Below is a summary of our standard and precision tolerance capabilities.

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm |

| Hole Diameter | ±0.03 mm | ±0.012 mm |

| Positional Tolerance | ±0.05 mm | ±0.02 mm |

| Flatness | 0.05 mm | 0.01 mm |

| Perpendicularity | 0.05 mm | 0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

These tolerances are maintained across both prototype and high-volume production runs, supported by our ISO 9001-certified quality management system. All inspection data is documented and archived for full traceability, meeting the stringent documentation requirements of regulated industries.

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade quality assurance to deliver components that meet the highest standards of precision and reliability. Our technical capabilities are designed not only to meet specifications but to exceed expectations in performance, consistency, and delivery.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material choice directly impacts part performance, manufacturability, and total cost in high-precision CNC applications. At Wuxi Lead Precision Machinery, we prioritize materials that align with functional requirements while optimizing for our advanced 5-axis milling and turning capabilities. Aluminum, steel, and titanium dominate aerospace, medical, and energy sectors due to their unique properties, but each presents distinct machining challenges requiring specialized tooling, parameters, and thermal management strategies. Selecting the wrong grade or overlooking finish requirements can lead to dimensional instability, excessive tool wear, or premature part failure.

Aluminum alloys like 6061-T6 and 7075-T6 offer exceptional strength-to-weight ratios and thermal conductivity, making them ideal for aircraft components and heat sinks. However, their softness increases risks of galling and burring during high-speed machining. We mitigate this using sharp carbide tools, controlled feed rates, and cryogenic cooling to maintain tight tolerances (±0.005mm). Steel variants such as 304/316 stainless and 4140 provide superior strength and corrosion resistance for hydraulic manifolds or surgical instruments but accelerate tool wear due to work hardening. Our process employs rigid setups, positive rake cutters, and optimized coolant pressure to ensure surface integrity. Titanium Grade 5 (Ti-6Al-4V) excels in extreme environments but demands meticulous heat control; its low thermal conductivity causes localized heating that degrades tool life. We utilize high-pressure through-spindle coolant and reduced cutting speeds to prevent micro-welding and maintain dimensional accuracy.

Critical material properties must be evaluated against application demands. The following table summarizes key characteristics for common aerospace and medical grades:

| Material | Density (g/cm³) | Machinability Index | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 2.7 | 100 (Baseline) | 6061-T6, 7075-T6 | Enclosures, Heat Exchangers |

| Stainless Steel | 7.9 | 45-55 | 304, 316, 17-4PH | Surgical Tools, Valves |

| Titanium | 4.5 | 20-30 | Ti-6Al-4V (Gr5) | Aircraft Frames, Implants |

Surface finishes further define part functionality. Anodizing is critical for aluminum components exposed to corrosive or abrasive environments. Type II (sulfuric acid) anodizing provides durable corrosion resistance and dye receptivity for medical devices, while Type III (hardcoat) delivers extreme wear resistance for aerospace landing gear. We control anodizing thickness to ±5µm and pore sealing to meet ASTM B580 and AMS 2469 standards, ensuring consistent adhesion and electrical insulation. For steel, passivation or electropolishing prevents rust in fluid-handling systems, whereas titanium often requires abrasive blasting for biocompatible surface textures in implants.

Material selection cannot be an afterthought. Early collaboration with our engineering team ensures optimal grade specification, machining strategy, and finish application—reducing lead times by 22% and scrap rates by 35% in recent client projects. Contact Wuxi Lead Precision Machinery to validate your material and finish requirements against real-world production constraints.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful production cycle begins with a meticulously engineered design phase. Our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models and technical drawings. This stage involves rigorous analysis of material properties, geometric tolerances, and functional performance under real-world conditions. Finite Element Analysis (FEA) and Design for Manufacturability (DFM) principles are applied to optimize part geometry, minimize stress concentrations, and ensure seamless manufacturability. All designs adhere to international standards including ISO 2768, ASME Y14.5, and GD&T specifications. This proactive approach eliminates potential flaws before physical production begins, reducing rework and accelerating time-to-market.

Prototyping: Validating Performance and Fit

Once the design is finalized, we proceed to precision prototyping using advanced 5-axis CNC machining centers. Prototypes are manufactured from the same high-grade materials intended for mass production—such as aerospace-grade aluminum, stainless steel, titanium, and engineering plastics—to ensure accurate validation of mechanical properties and dimensional stability. Each prototype undergoes comprehensive inspection via coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Functional testing, including fit checks, thermal cycling, and load simulations, confirms performance against operational requirements. Client feedback is integrated at this stage, allowing for iterative refinement with zero cost implications downstream. This validation gate ensures that only fully verified designs advance to full-scale production.

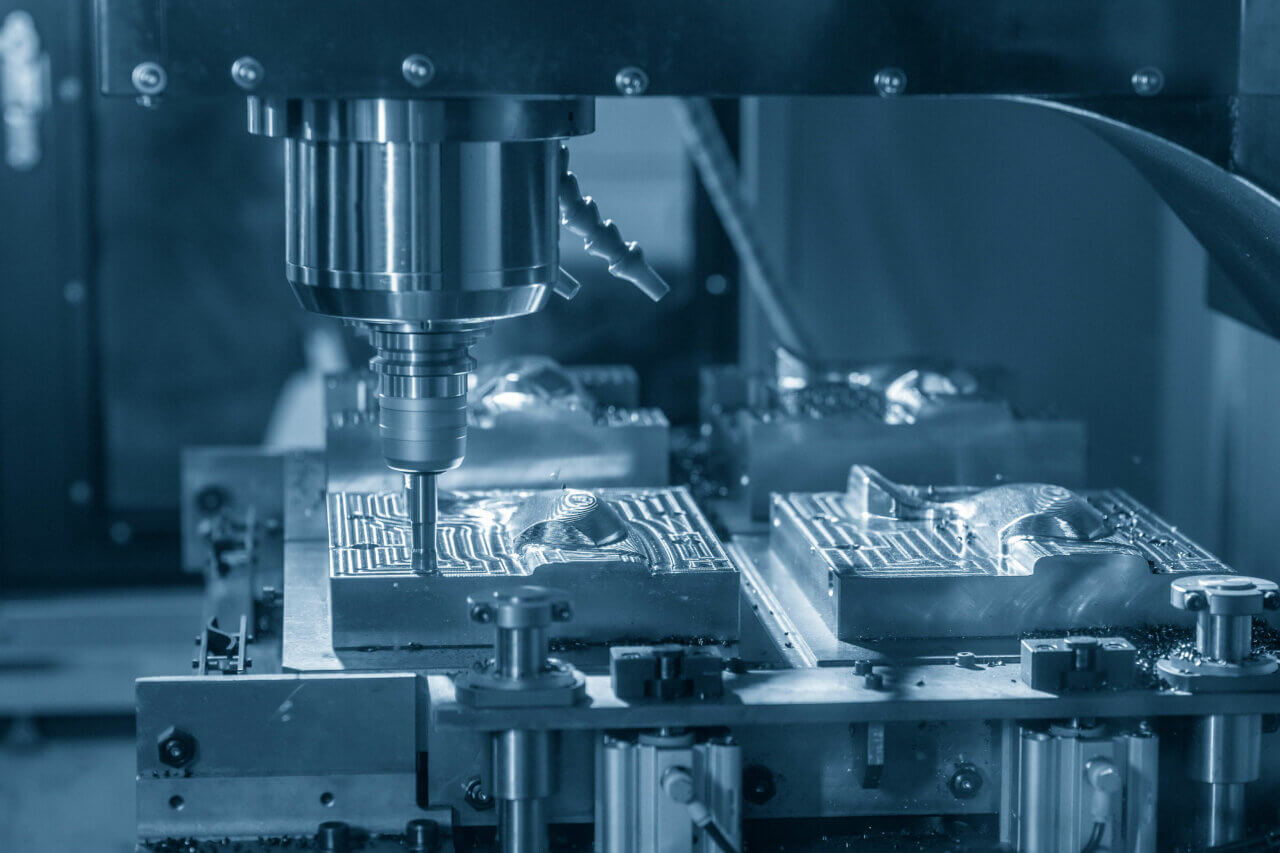

Mass Production: Scalable Precision with Zero Defects

Our mass production process is built on a foundation of automation, statistical process control (SPC), and 100% in-process inspection. Utilizing a fleet of high-speed CNC lathes, milling centers, and multi-axis machines, we maintain tight tolerances down to ±0.005 mm. Each production batch is monitored in real time using integrated sensors and automated measurement systems that detect deviations before they affect output quality. Our ISO 9001-certified quality management system enforces strict traceability, with every component assigned a unique production ID linked to material certificates, tooling logs, and inspection data. Final parts undergo full dimensional reporting and are packaged to prevent damage during global shipment.

Key Production Specifications

| Parameter | Capability | Standard Tolerance | Notes |

|---|---|---|---|

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics | Custom selection based on application | RoHS and REACH compliant |

| Tolerances | ±0.005 mm | ±0.01 mm typical | Tighter tolerances on request |

| Surface Finish | Ra 0.8 – 6.3 μm | Ra 1.6 μm standard | Polishing, anodizing, plating available |

| Max Part Size | 1200 x 800 x 600 mm | Custom fixturing for large components | 5-axis capability |

| Production Volume | 1 – 100,000+ units | Automated batch handling | Kanban and JIT delivery options |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers zero-defect components with unmatched consistency, enabling global manufacturers to rely on every part we produce.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Wuxi Lead Precision Machinery

In high-stakes precision manufacturing, selecting a CNC machining partner transcends transactional relationships. It demands a strategic ally with unwavering technical mastery, scalable capacity, and a proven commitment to your project’s success from prototype to high-volume production. Wuxi Lead Precision Machinery operates at this elevated standard, engineered to resolve the complex challenges faced by global innovators in aerospace, medical, energy, and advanced industrial sectors. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi, China, integrates cutting-edge technology with rigorous process discipline, ensuring every component meets the most stringent geometric and material specifications. We eliminate the risk of supply chain disruption through vertical integration, in-house metrology, and real-time quality validation—transforming precision from a promise into a measurable outcome.

Our technical infrastructure is built for uncompromising accuracy and efficiency. Below are core capabilities defining our operational excellence:

| Capability Category | Specification Details |

|---|---|

| Machine Types | 5-Axis Milling, Multi-Tasking Mill-Turn, High-Speed 3-Axis |

| Positional Accuracy | ±0.001 mm (linear), ±2 arc seconds (rotary) |

| Work Envelope Range | 300 x 200 x 200 mm to 1,200 x 800 x 600 mm |

| Material Expertise | Titanium, Inconel, Hastelloy, Medical-Grade Stainless, Aluminum Alloys |

| Surface Finish | Ra 0.2 µm to 1.6 µm (as machined), Micro-bore capabilities |

| Metrology Systems | CMM (Zeiss), OGP SmartScope, Surface Profilometers |

This technical foundation is amplified by our engineering-led approach. Our CNC programmers and process engineers collaborate directly with your team during Design for Manufacturability (DFM) reviews, identifying cost-saving optimizations without sacrificing performance. We deploy statistical process control (SPC) at critical stages, providing transparent data dashboards for real-time production visibility. Unlike commodity shops, we invest in continuous capability expansion—recent additions include Swiss-type lathes for micro-components and 5-axis wire EDM for complex geometries—ensuring we evolve alongside your innovation roadmap.

Partnering with Wuxi Lead means securing a manufacturer that operates as an extension of your engineering department. We prioritize seamless communication through dedicated project managers fluent in technical English, time-zone-aligned support, and secure digital collaboration platforms. Our facility’s strategic location within China’s industrial corridor ensures efficient logistics to global hubs while maintaining full traceability under U.S. ITAR and EU MDR frameworks where required. When tolerances are non-negotiable and deadlines are critical, our validated processes deliver consistency your end customers demand.

Initiate a precision partnership that drives measurable value. Contact our engineering sales team directly at Contact [email protected] to discuss your next project. Include your component drawings or specifications for a tailored capability assessment within 24 business hours. We will provide a comprehensive DFM analysis, competitive quotation, and production timeline—proving why global leaders trust Wuxi Lead for mission-critical CNC machining. Your pursuit of perfection requires a partner committed to achieving it. Let us demonstrate how.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.