Technical Contents

Engineering Guide: Metal Cutting Lathe

Engineering Insight: The Critical Role of Precision in Metal Cutting Lathes

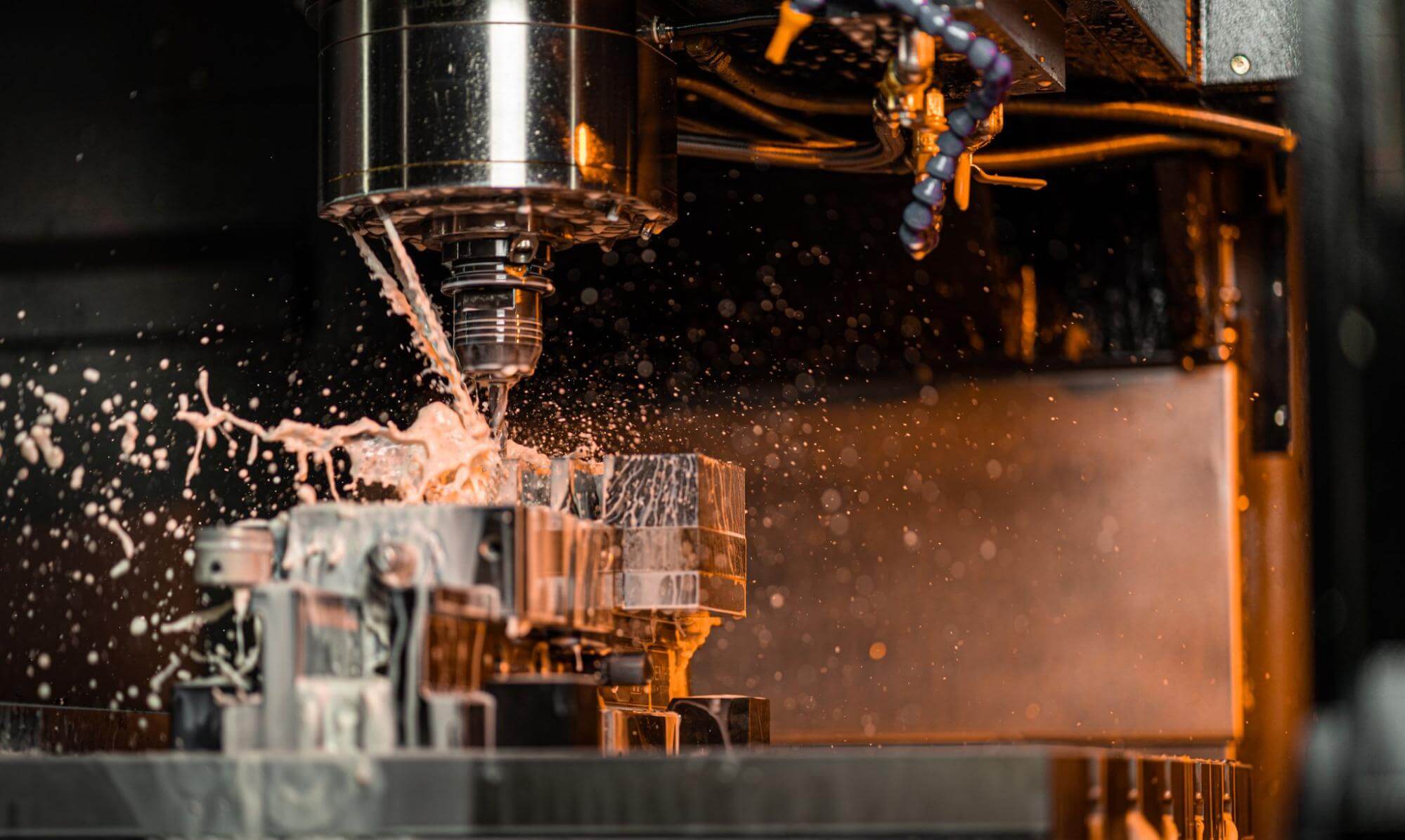

In the domain of high-performance manufacturing, the metal cutting lathe stands as a cornerstone of precision engineering. At Wuxi Lead Precision Machinery, we recognize that achieving micron-level accuracy is not merely a technical benchmark—it is a fundamental requirement for industries where failure is not an option. From aerospace components to military-grade systems and Olympic-caliber equipment, the performance of a metal cutting lathe directly influences the integrity, reliability, and functionality of the final product.

Precision in metal cutting is governed by a confluence of factors: spindle accuracy, thermal stability, toolpath repeatability, and dynamic rigidity. A deviation of even a few microns can result in part rejection, system failure, or compromised performance under extreme operational conditions. This is especially critical in sectors such as defense and high-end sports technology, where our CNC lathes have contributed to projects demanding the utmost consistency and precision. Our involvement in manufacturing components for Olympic training systems and military applications underscores our commitment to engineering excellence and zero-defect output.

At the heart of our metal cutting lathes is a design philosophy rooted in stability and control. We utilize high-rigidity cast iron beds with optimized ribbing structures to dampen vibrations and maintain geometric accuracy over extended operation cycles. Linear guideways with preloaded roller blocks ensure smooth motion and long-term positional fidelity. Additionally, our spindles are engineered for minimal runout and thermal growth, supported by precision bearings and active cooling systems that maintain performance under continuous load.

Our CNC control systems integrate advanced motion algorithms and real-time feedback loops, enabling adaptive cutting strategies that respond to material variances and tool wear. This level of intelligence ensures consistent surface finishes and dimensional accuracy across batch runs, a necessity for clients in medical device manufacturing, defense subcontracting, and precision instrumentation.

Wuxi Lead Precision Machinery brings over two decades of experience in delivering mission-critical machining solutions. Our engineering teams work closely with clients to tailor machine configurations that meet exacting tolerances and production demands. Whether machining titanium alloys for aerospace or hardened steels for defense systems, our lathes are built to perform under the most stringent requirements.

Below are key performance specifications representative of our high-end metal cutting lathe series:

| Specification | Value |

|---|---|

| Maximum Spindle Speed | 6,000 rpm |

| Spindle Taper | A2-8, ISO 40 |

| X-Axis Travel | 320 mm |

| Z-Axis Travel | 750 mm |

| Repeatability (X/Z) | ±0.003 mm |

| Positioning Accuracy | ±0.005 mm |

| Tool Magazine Capacity | 12 stations (optional 16) |

| Control System | Fanuc 31i or Siemens 840D |

| Rapid Traverse (X/Z) | 30 / 36 m/min |

| Maximum Turning Diameter | 520 mm |

Precision is not an add-on feature—it is engineered into every component, every process, and every machine we deliver. At Wuxi Lead Precision Machinery, we don’t just build lathes; we build trust through accuracy.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Cutting Lathe Operations

Wuxi Lead Precision Machinery delivers uncompromising precision in metal cutting lathe operations through advanced multi-axis CNC technology and rigorous quality validation. Our core strength lies in the deployment of state-of-the-art 5-axis CNC turning centers, enabling the simultaneous machining of complex geometries in a single setup. This eliminates cumulative errors from multiple fixturing stages, significantly enhancing part accuracy and repeatability while reducing lead times. These machines integrate high-torque spindles, sub-spindles for backworking, and live tooling capabilities, allowing us to execute intricate contours, deep grooves, off-center features, and complete part fabrication—including milling, drilling, and tapping—without secondary operations. Material versatility spans aerospace-grade titanium and Inconel, medical stainless steels, aluminum alloys, and hardened tool steels, all processed under strict thermal and vibration control protocols to maintain micron-level stability.

Quality assurance is non-negotiable in our process. Every critical dimension undergoes verification via Zeiss and Hexagon Coordinate Measuring Machines (CMM), operating within ISO 17025-accredited environmental conditions. Our CMM inspection suite utilizes calibrated probes and advanced metrology software to generate full GD&T reports, ensuring traceability to national standards. This data-driven approach validates geometric conformity, surface integrity, and functional performance against client blueprints, providing auditable proof of compliance for regulated industries. Process capability studies (Cp/Cpk) are routinely conducted on high-volume runs, guaranteeing sustained statistical control and minimizing scrap rates.

The following table details our standard and enhanced tolerance capabilities for critical machining parameters, reflecting our commitment to exceeding typical industry benchmarks:

| Parameter | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / High-Precision Micrometer |

| Concentricity | Ø0.020 mm | Ø0.008 mm | CMM / Dial Indicator (on fixture) |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Portable Profilometer |

| Angularity | ±0.02° | ±0.005° | CMM / Optical Comparator |

These tolerances are achievable across workpiece diameters from Ø3 mm to Ø420 mm and lengths up to 1,200 mm, contingent on material properties and feature complexity. Our engineering team collaborates proactively during the Design for Manufacturability (DFM) phase to optimize part geometry for maximum precision and cost efficiency. By integrating 5-axis turning with closed-loop CMM validation, Wuxi Lead ensures every component meets the stringent demands of aerospace, medical device, and energy sector applications—where failure is not an option. This capability translates directly to reduced assembly errors, extended component lifespan, and accelerated time-to-market for our global partners.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing part performance, durability, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in high-accuracy metal cutting lathes designed to handle a range of engineering-grade materials, with particular expertise in aluminum, steel, and titanium. Each material offers distinct mechanical properties and machining characteristics, making them suitable for specific industrial applications.

Aluminum is widely used in aerospace, automotive, and electronics due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is highly machinable, allowing for high-speed cutting and tight tolerances on our CNC lathes. However, its softness requires careful tool selection and cutting parameters to avoid built-up edge and dimensional inaccuracies. The most commonly machined aluminum alloys include 6061 and 7075, with the former offering good weldability and the latter superior strength.

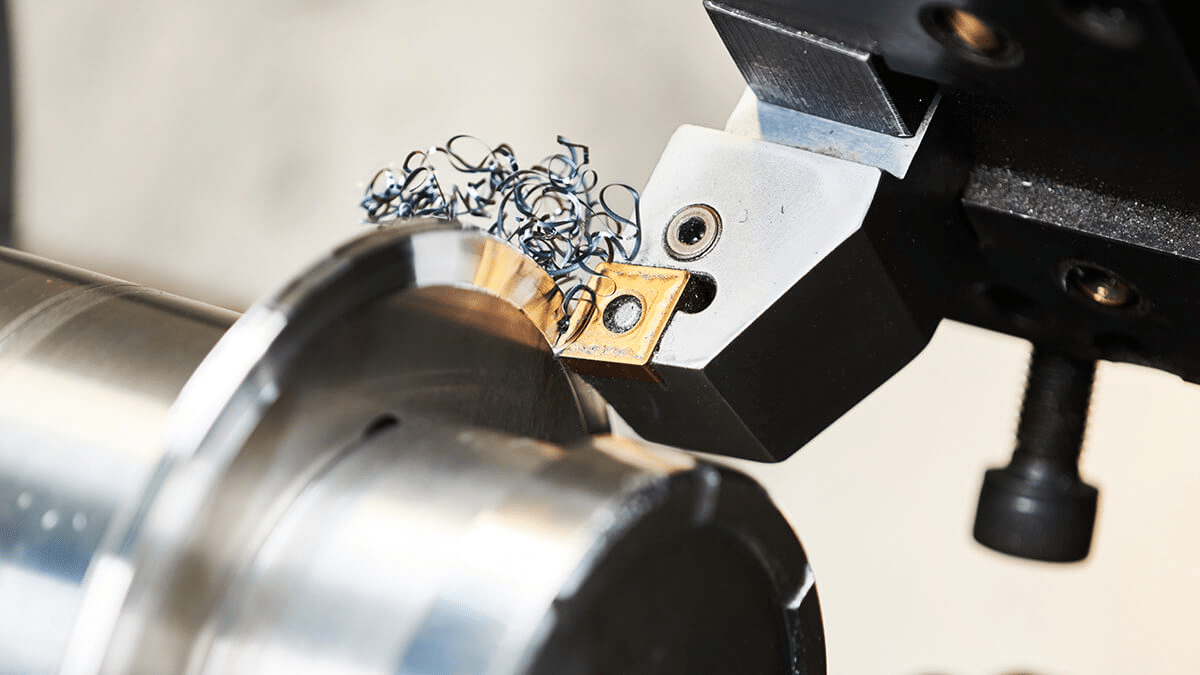

Steel, particularly alloy and stainless grades, is favored in heavy-duty industrial and medical applications where strength, wear resistance, and structural integrity are paramount. While more challenging to machine than aluminum due to higher hardness and work-hardening tendencies, steel delivers exceptional dimensional stability and surface finish quality when processed with precision toolpaths and rigid setups. Our CNC lathes are optimized for consistent steel machining, minimizing tool wear and vibration during prolonged operations.

Titanium stands at the high end of performance materials, known for its outstanding strength-to-density ratio and resistance to extreme environments. It is extensively used in aerospace, defense, and biomedical sectors. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools present significant machining challenges. Successful titanium turning requires lower cutting speeds, rigid machine setups, and specialized tooling to manage heat buildup and prevent galling. At Wuxi Lead, our lathes are engineered with high-torque spindles and advanced cooling systems to ensure precision when working with this demanding material.

Surface finishing plays a vital role in enhancing both functionality and appearance. Anodizing is the preferred post-processing method for aluminum components, providing a durable, corrosion-resistant oxide layer that can also be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior wear resistance for high-stress applications. While anodizing does not apply to steel or titanium, these materials benefit from alternative treatments such as passivation, plating, or polishing, depending on operational requirements.

The following table summarizes key material properties and machining considerations:

| Material | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating | Common Applications | Recommended Surface Treatment |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | Excellent | Aerospace, Automotive | Anodizing (Type II/III) |

| Steel 4140 | 655 | 197 | Moderate | Industrial Machinery | Passivation, Zinc Plating |

| Titanium Grade 5 | 900 | 334 | Poor | Aerospace, Medical Implants | Anodizing (Ti-specific), Polishing |

Selecting the right material and finish ensures optimal performance, longevity, and cost-efficiency in precision components. Wuxi Lead Precision Machinery supports clients in making informed decisions through technical consultation and advanced CNC turning capabilities tailored to each material’s demands.

Manufacturing Process & QC

Precision Metal Cutting Lathe Production: Design to Zero-Defect Mass Production

Achieving zero-defect performance in metal cutting lathe manufacturing demands a rigorously controlled process from initial concept through high-volume output. At Wuxi Lead Precision Machinery, we implement a closed-loop methodology ensuring every component meets micron-level tolerances demanded by aerospace, medical, and energy sectors. This begins with integrated design engineering where our team collaborates with clients to optimize part geometry for manufacturability. Using advanced CAD/CAM suites and finite element analysis, we simulate cutting forces, thermal dynamics, and vibration profiles to preemptively eliminate potential failure modes. Critical dimensions undergo geometric dimensioning and tolerancing (GD&T) validation against ASME Y14.5 standards, ensuring designs are inherently robust before physical work commences. Material selection is equally precise, with alloys verified through certified mill test reports and in-house spectrographic analysis to confirm composition and structural integrity.

Prototyping serves as the critical validation phase, transforming digital models into tangible test articles. Our five-axis milling and turning centers produce initial units under full production parameters, not simplified setups. Each prototype undergoes comprehensive metrology: coordinate measuring machines (CMM) verify dimensional accuracy against CAD models, while surface roughness testers and roundness gauges confirm finish and form specifications. Destructive testing on sacrificial samples validates material properties and internal integrity. Crucially, this phase includes process capability studies (Cp/Cpk) to statistically prove the machining sequence can consistently achieve tolerances tighter than client requirements. Any deviations trigger immediate design-for-manufacturing (DFM) revisions, with root cause analysis documented in our quality management system.

Mass production leverages this validated foundation through embedded quality controls. Every lathe component is machined on our high-rigidity CNC turning centers equipped with real-time tool wear monitoring and in-process probing. Statistical process control (SPC) charts track critical dimensions at defined intervals, with automatic machine tool compensation adjusting for thermal drift or tool degradation. Full traceability is maintained via laser-etched part IDs linked to digital work orders, capturing all process parameters, inspection data, and operator certifications. Final inspection employs automated vision systems alongside manual verification by ASQ-certified technicians, with 100% of critical features measured against first-article approval (FAA) benchmarks. This integrated approach ensures zero-defect delivery, minimizing client scrap rates and assembly line disruptions.

Key Production Capabilities Enabling Zero Defects

| Parameter | Specification | Impact on Zero Defects |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Eliminates cumulative errors in multi-feature parts |

| Thermal Compensation | Real-time spindle & axis | Prevents dimensional drift during extended runs |

| In-Process Probing | On-machine touch-trigger | Catches deviations before part completion |

| SPC Monitoring Frequency | Per 10 parts (critical dims) | Ensures continuous process stability |

This disciplined progression—from physics-based design through statistically validated prototyping to tightly controlled mass production—forms the backbone of Wuxi Lead’s zero-defect commitment. We transform precision engineering into guaranteed operational reliability for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Metal Cutting Lathe Solutions

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and efficiency are non-negotiable in high-end manufacturing. As a leading innovator in CNC metal cutting lathe technology, we deliver advanced machining solutions engineered to meet the rigorous demands of aerospace, automotive, medical device manufacturing, and industrial equipment sectors. When you choose to partner with Lead Precision, you are not just acquiring machinery—you are gaining a long-term ally committed to your operational excellence.

Our metal cutting lathes are built on decades of engineering expertise, combining rigid construction, intelligent control systems, and cutting-edge automation to maximize throughput and part accuracy. Each machine is precision-calibrated and rigorously tested to ensure it performs under real-world production conditions. From complex contouring to high-speed finishing, our lathes deliver micron-level repeatability and extended tool life, reducing downtime and optimizing your cost per part.

We recognize that every manufacturing environment is unique. That’s why our engineering team works closely with clients to tailor solutions that align with your specific production goals. Whether you require a standard high-performance lathe or a fully customized turnkey system with integrated bar feeders, gantry loaders, or in-process inspection, Lead Precision delivers scalable solutions with seamless integration into existing workflows.

Our commitment extends beyond the sale. We provide comprehensive technical support, operator training, and preventive maintenance services to ensure your machines operate at peak performance throughout their lifecycle. With a responsive global service network and remote diagnostics capabilities, we minimize disruptions and keep your production lines running.

Choose a partner that combines Chinese manufacturing efficiency with German-level precision engineering standards. At Wuxi Lead Precision Machinery, innovation is not an add-on—it’s embedded in every spindle, every control, and every customer relationship.

Explore how our advanced metal cutting lathes can transform your production capabilities. Contact us today to speak with one of our CNC application specialists.

| Specification | Value |

|---|---|

| Spindle Speed | Up to 6,000 rpm |

| Bar Capacity | 20 – 65 mm (optional up to 80 mm) |

| Axis Configuration | 2-axis (X, Z), optional Y-axis and C-axis |

| Control System | Fanuc, Siemens, or Mitsubishi (customer-selectable) |

| Rapid Traverse (X/Z) | 30 / 30 m/min |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.001 mm |

| Tool Capacity | 8, 12, or 16 station turret |

| Machine Bed Material | High-grade Meehanite cast iron, vibration-damped |

| Automation Ready | Yes – compatible with bar feeders, gantry loaders, and robotic integration |

For technical inquiries, quotations, or to schedule a virtual demo, contact us at [email protected]. Let Lead Precision be your trusted partner in precision CNC machining.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.