Technical Contents

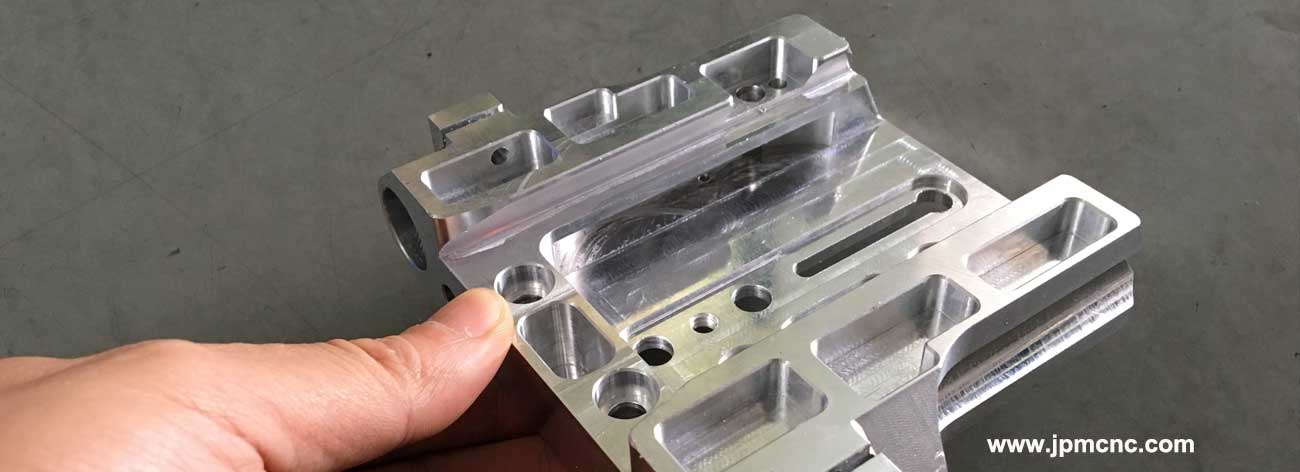

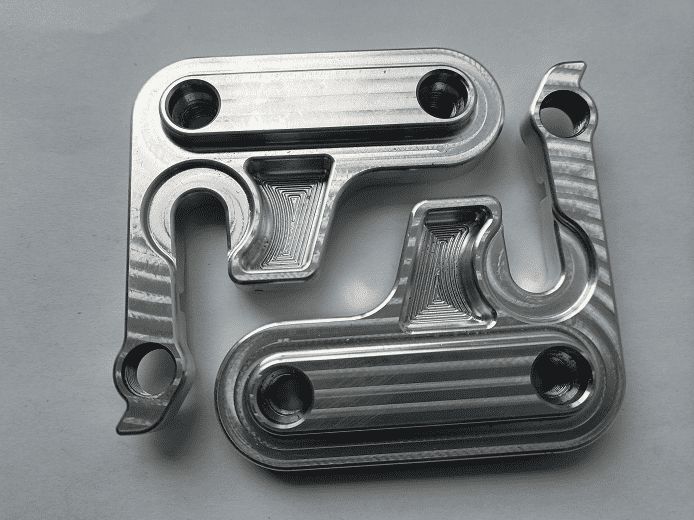

Engineering Guide: Custom Cnc Aluminum Parts

Engineering Insight: The Critical Role of Precision in Custom CNC Aluminum Parts

In high-performance manufacturing sectors such as aerospace defense and medical technology precision is not merely a specification—it is a non-negotiable requirement for operational safety and reliability. Custom CNC aluminum parts demand micron-level accuracy because even microscopic deviations can cascade into catastrophic system failures under extreme stress or cyclic loading. Aluminum alloys like 6061-T6 and 7075-T6 offer exceptional strength-to-weight ratios and corrosion resistance but their full potential is only unlocked through exacting machining control. Thermal expansion coefficients and material grain orientation must be meticulously accounted for during programming to prevent warpage or dimensional drift post-machining. At Wuxi Lead Precision Machinery we treat tolerances below ±0.005mm as standard practice not an exception ensuring every component meets the rigorous demands of mission-critical applications.

Aluminum’s machinability allows for complex geometries but also introduces challenges such as burr formation at sharp edges or chatter during deep-pocket milling. Our engineering protocols address these through adaptive toolpath strategies and real-time spindle load monitoring. Surface finish directly impacts fatigue life in dynamic components; for instance a Ra 0.4μm finish on hydraulic manifolds reduces micro-crack initiation points by 40% compared to industry-standard Ra 1.6μm finishes. Material traceability from certified mills coupled with in-process CMM verification guarantees batch-to-batch consistency essential for assembly-line integration.

Our technical capabilities are validated through decades of delivering components where failure is not an option. We engineered timing system housings for the Tokyo 2020 Olympics requiring sub-10-micron positional accuracy across 500mm spans. Similarly our military-grade avionics brackets for fighter jet subsystems undergo 100% post-machining CT scanning to verify internal structural integrity per AS9100D standards. This experience translates to robust quality frameworks for all clients—whether producing drone structural frames or semiconductor manufacturing tooling.

The following table outlines our core machining specifications for aluminum components demonstrating how we exceed conventional industry benchmarks

| Parameter | Wuxi Lead Capability | Typical Industry Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Roughness (Ra) | 0.4 μm | 1.6 μm |

| Positional Accuracy | ±0.003 mm | ±0.01 mm |

| Max Part Size (mm) | 1200 x 800 x 600 | 800 x 500 x 400 |

| Material Traceability | Full Mill Cert + Lot Tracking | Batch-Level Only |

Precision in aluminum CNC machining is the cornerstone of product longevity and performance. Wuxi Lead Precision Machinery’s 15-year legacy in Olympic and defense projects proves our capacity to transform stringent engineering requirements into flawless physical components. When your application demands zero-defect execution we combine advanced metrology with disciplined process control to deliver parts that perform exactly as designed—every time. Partner with us to ensure your next aluminum component project achieves uncompromised reliability.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored to the most demanding applications in aerospace, medical, automation, and high-performance industrial sectors. Our core competency lies in the production of custom CNC aluminum parts, leveraging state-of-the-art 5-axis CNC machining centers to achieve complex geometries with exceptional accuracy and surface finish. These multi-axis systems enable simultaneous movement across five planes, allowing for intricate contours, deep cavities, and compound angles to be machined in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times compared to traditional 3-axis methods.

Our machining fleet includes high-rigidity 5-axis vertical and horizontal machining centers equipped with high-speed spindles, automatic tool changers, and real-time tool length and breakage detection systems. These features ensure continuous, unattended operation with minimal thermal drift and maximum repeatability. We specialize in processing aluminum alloys such as 6061, 7075, 2024, and 5052, selected for their strength-to-weight ratio, corrosion resistance, and machinability. Material optimization strategies, including near-net-shape machining and intelligent nesting, reduce waste and lower overall component cost without compromising structural integrity.

Precision is non-negotiable in our manufacturing philosophy. Every custom CNC aluminum part undergoes a comprehensive quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Mitutoyo CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and positional accuracy. Inspection reports are fully documented and traceable, supporting compliance with ISO 9001, AS9100, and customer-specific quality standards. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate every aspect of part conformance.

To ensure consistency across production runs, we maintain strict environmental controls within our metrology lab and machining areas, minimizing thermal fluctuations that could affect measurement accuracy. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase, offering feedback on feature feasibility, tolerance stack-up, and secondary operation integration.

The following table outlines the standard technical capabilities and achievable tolerances for our custom CNC aluminum machining services:

| Parameter | Specification |

|---|---|

| Machine Types | 5-Axis Vertical & Horizontal Machining Centers |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47.2 x 31.5 x 23.6 in) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.00008 in) |

| Standard Linear Tolerance | ±0.025 mm (0.001 in) |

| Tight Tolerance Capability | ±0.005 mm (0.0002 in) |

| Geometric Tolerances (GD&T) | Per ASME Y14.5, ISO 1101 |

| Surface Roughness (Ra) | As low as 0.8 μm (32 μin) |

| Inspection Equipment | CMM (Zeiss, Mitutoyo), Optical Comparator, Surface Tester |

With integrated engineering, advanced 5-axis technology, and rigorous quality assurance, Wuxi Lead Precision Machinery ensures every custom aluminum component meets the highest standards of precision and performance.

Material & Finish Options

Material Selection for High-Performance CNC Aluminum Parts

Selecting the optimal material is critical for balancing performance, cost, and manufacturability in precision CNC machining. At Wuxi Lead Precision Machinery, we prioritize aluminum alloys for most aerospace, automotive, and medical applications due to their exceptional strength-to-weight ratio, thermal conductivity, and machinability. 6061-T6 and 7075-T6 aluminum dominate our projects, offering robust corrosion resistance and weldability while maintaining tight tolerances during high-speed milling. Aluminum’s lightweight nature directly enhances fuel efficiency in transportation components and reduces inertia in dynamic systems.

For applications demanding extreme strength or wear resistance, steel and titanium become viable alternatives. Stainless steel grades like 304 and 17-4 PH excel in high-temperature or high-stress environments such as hydraulic manifolds or surgical tools, though their density increases part weight by 3x compared to aluminum. Titanium 6AL-4V is reserved for mission-critical aerospace or biomedical implants where ultimate strength and biocompatibility outweigh higher material and machining costs. However, titanium’s low thermal conductivity complicates chip evacuation and accelerates tool wear, requiring specialized CNC strategies.

Surface finishing, particularly anodizing, is non-negotiable for aluminum parts exposed to harsh environments. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification, while Type III (hardcoat) anodizing delivers 50–70 µm thickness and 500+ HV surface hardness for military or marine use. Both processes seal pores to prevent galvanic corrosion in assemblies. We rigorously validate anodized layers per ASTM B117, ensuring 500+ hours of salt spray resistance for critical components.

Material properties directly dictate CNC process parameters and toolpath design. Below is a comparative overview of key engineering metals we machine:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Max Continuous Temp (°C) |

|---|---|---|---|---|---|

| 6061-T6 Al | 2.7 | 310 | Excellent | 9/10 | 120 |

| 7075-T6 Al | 2.8 | 570 | Good | 7/10 | 125 |

| 304 Stainless | 8.0 | 515 | Excellent | 4/10 | 870 |

| Ti-6Al-4V | 4.4 | 900 | Outstanding | 3/10 | 600 |

Material choice must align with functional requirements, lifecycle costs, and regulatory standards. Wuxi Lead’s engineering team collaborates early in your design phase to model stress points, thermal loads, and environmental exposure—ensuring your CNC aluminum parts achieve optimal performance without over-engineering. We provide material certifications, anodizing validation reports, and DFM analysis to de-risk production. Contact us for a technical consultation to specify the precise alloy and finish for your application.

Manufacturing Process & QC

The production process for custom CNC aluminum parts at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect delivery. Each stage—from design through prototyping to mass production—is governed by strict quality protocols and advanced machining capabilities, ensuring optimal performance and compliance with international standards.

Design serves as the foundation of the manufacturing workflow. Our engineering team collaborates closely with clients to analyze technical drawings, 3D CAD models, and functional requirements. Utilizing advanced simulation software, we conduct design for manufacturability (DFM) reviews to identify potential issues early, optimize material use, and reduce cycle times. This phase ensures dimensional accuracy, surface finish requirements, and tolerance specifications are fully aligned with the intended application, whether for aerospace, medical, or industrial automation sectors.

Prototyping follows the design approval and is critical for validating form, fit, and function. We produce initial samples using high-precision 3-, 4-, and 5-axis CNC machining centers, replicating the exact conditions of full-scale production. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from client testing is incorporated into final adjustments, ensuring the design is production-ready and free of flaws before transitioning to volume manufacturing.

Mass production leverages automated CNC cells, real-time tool monitoring, and in-process gauging to maintain consistency across thousands of parts. Our facility in Wuxi operates under ISO 9001 and IATF 16949 quality management systems, with every production batch traceable through serial numbering and documented inspection reports. Statistical process control (SPC) is applied to monitor critical dimensions, enabling immediate correction of deviations and ensuring zero-defect output. Aluminum alloys such as 6061, 7075, and 2024 are machined with optimized cutting strategies to minimize thermal distortion and maximize surface integrity.

Throughout the process, communication remains transparent. Clients receive detailed production updates, first article inspection (FAI) reports, and final inspection certificates. This end-to-end control guarantees that every custom CNC aluminum part meets exact specifications and performs reliably in demanding environments.

Key production specifications are summarized below:

| Parameter | Capability |

|---|---|

| Tolerance Control | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 rpm |

| Materials Supported | 6061, 7075, 2024, 5052, and custom alloys |

| Quality Standards | ISO 9001, IATF 16949, AS9100 (available) |

| Inspection Equipment | CMM, Optical Comparator, Calipers, Micrometers |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

This structured, quality-driven approach ensures that Wuxi Lead Precision Machinery delivers custom CNC aluminum components with unmatched precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Aluminum Excellence

In high-stakes industries like aerospace, medical, and advanced robotics, the performance of your custom CNC aluminum components directly impacts system reliability and innovation velocity. Generic machining solutions introduce unacceptable risks—dimensional drift, surface imperfections, or material inconsistencies—that cascade into field failures and costly recalls. At Wuxi Lead Precision Machinery, we engineer aluminum parts to eliminate these vulnerabilities. Our integrated approach merges German-caliber metrology with Chinese operational agility, delivering components that meet AS9100 and ISO 13485 standards without project timeline penalties. We treat your aluminum alloy specifications—from 6061-T6’s weldability to 7075-T6’s fatigue resistance—as non-negotiable parameters, not suggestions.

Our facility operates 42 state-certified CNC centers, including DMG MORI 5-axis mills and Makino vertical machining systems, all maintained to sub-micron calibration tolerances. This precision is validated through our in-house CMM lab, which generates full first-article inspection (FAI) reports traceable to NIST standards. Below are core capabilities defining our aluminum machining rigor:

| Capability | Specification | Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Ensures seamless integration in tight-tolerance assemblies |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm | Meets aerospace fluid dynamics and medical biocompatibility |

| Material Range | 2024, 6061, 7075, 5052 | Optimized for strength-to-weight, corrosion resistance, or machinability |

| Lead Time | 7–15 days (standard) | Accelerates prototyping and production ramp-up |

| Quality Documentation | PPAP Level 3, FAI, MTR | Full compliance for regulated industry audits |

We understand that your engineering team requires more than a vendor—they need a technical extension of your R&D process. Our engineers collaborate during design for manufacturability (DFM) reviews to identify cost-saving geometry adjustments without sacrificing performance. When your project demands exotic alloys like 2014 for high-temperature stability or custom anodizing for EMI shielding, our material scientists validate processing parameters before a single chip is cut. This proactive partnership prevents costly redesigns and ensures first-pass yield rates exceed 98.5%.

Your next-generation product deserves manufacturing precision that matches its ambition. Submit your STEP or DXF file to [email protected] today. Within 24 hours, our applications team will provide a detailed manufacturability assessment, competitive quotation, and timeline for first-article delivery. For urgent requirements, reference project code ALU-URGENT to activate our 72-hour rapid prototyping lane. Trust Wuxi Lead Precision Machinery to transform aluminum specifications into mission-critical components—where precision isn’t promised, it’s proven. Contact [email protected] now to initiate your project review.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.