Technical Contents

Engineering Guide: Cnc Milling Machine Services

Engineering Insight: The Critical Role of Precision in CNC Milling Machine Services

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. CNC milling machine services, as a cornerstone of modern precision engineering, demand micron-level accuracy, repeatability, and consistency across high-complexity components. At Wuxi Lead Precision Machinery, we recognize that the margin for error in mission-critical applications is effectively zero. This understanding drives our engineering philosophy and operational excellence in every CNC milling project we undertake.

Precision in CNC milling extends beyond dimensional accuracy. It encompasses surface finish integrity, geometric tolerancing, material stability, and the ability to maintain consistency across production batches. These factors are especially vital in industries such as aerospace, defense, and high-performance sporting equipment, where component failure is not an option. Our experience in manufacturing parts for Olympic-level athletic systems and military-grade hardware has honed our ability to meet and exceed the most stringent quality standards. These applications require not only compliance with ISO and AS9100 specifications but also a deep understanding of dynamic load conditions, thermal cycling, and long-term durability.

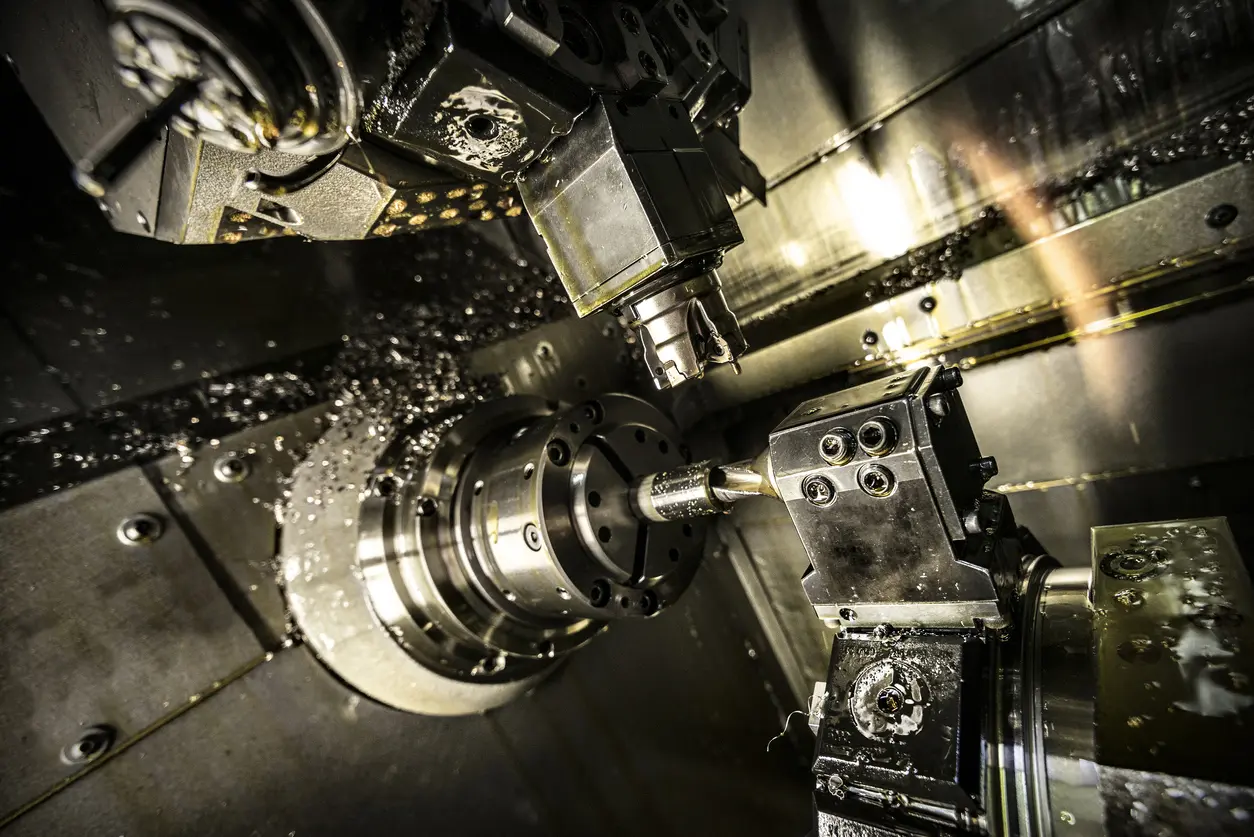

At the core of our precision capability is a fully integrated CNC machining ecosystem. Our facility houses state-of-the-art 3-axis, 4-axis, and 5-axis milling centers, each equipped with high-resolution probing systems, thermal compensation algorithms, and real-time tool wear monitoring. These technologies ensure that every cut is executed with maximum fidelity to the original CAD model. Our engineering team employs advanced CAM strategies—such as high-speed machining (HSM) and adaptive clearing—to optimize toolpaths, minimize cycle times, and preserve material integrity.

Material selection and process control are equally critical. We work with a broad spectrum of engineering-grade alloys and composites, including titanium, Inconel, aluminum 7075-T6, and PEEK, each requiring tailored cutting parameters and fixturing approaches. Our in-house metrology lab, anchored by a Zeiss coordinate measuring machine (CMM) and optical comparators, verifies conformance to tolerances as tight as ±0.002 mm.

The following table outlines the key technical specifications of our CNC milling capabilities:

| Specification | Performance Level |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 600 mm |

| Spindle Speed (Max) | 24,000 RPM |

| Tool-to-Part Tolerance | IT6 to IT7 (ISO 286) |

| Surface Roughness (Ra) | 0.4–1.6 μm (achievable) |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Inconel, PEEK, Delrin |

| Quality Standards | ISO 9001, AS9100D, ISO 14001 |

Precision is not achieved by technology alone. It is the result of disciplined process engineering, continuous operator training, and a culture rooted in quality. At Wuxi Lead Precision Machinery, our legacy in high-stakes manufacturing environments has forged a standard of excellence that defines our CNC milling machine services. When performance cannot be compromised, our clients trust us to deliver precision that performs—every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced CNC milling solutions engineered to meet the stringent demands of aerospace, medical, energy, and high-technology sectors. Our core strength lies in integrating state-of-the-art multi-axis machining with rigorous, traceable quality assurance protocols, ensuring every component adheres to exacting specifications and functional requirements. This commitment to precision engineering forms the foundation of our service offering, enabling complex geometries and superior surface finishes unattainable through conventional methods.

Our primary machining platform centers on a modern fleet of high-torque, high-accuracy 5-axis CNC milling centers. These machines eliminate the need for multiple fixtures and secondary operations by enabling simultaneous movement across all five axes. This capability significantly reduces cumulative setup errors, improves part accuracy and consistency, and dramatically shortens lead times for intricate components such as impellers, turbine blades, complex housings, and medical implants. Advanced thermal compensation systems and rigid machine structures ensure dimensional stability throughout extended production runs, maintaining precision even under demanding machining conditions. Material versatility spans aluminum alloys, titanium, stainless steels, Inconel, and high-performance engineering plastics, processed with optimized toolpaths and cutting strategies.

Quality control is not a final step but an integrated process throughout production. Every critical dimension and feature undergoes verification using calibrated Coordinate Measuring Machines (CMMs) operated by certified metrology technicians. Our CMM fleet, featuring both bridge and gantry types with high-precision probes, provides comprehensive 3D measurement data traceable to international standards (ISO/IEC 17025). This data validates conformance to GD&T callouts, complex surface profiles, and critical positional tolerances, generating detailed inspection reports for full client transparency and audit compliance. Statistical Process Control (SPC) methodologies are actively employed to monitor process capability and drive continuous improvement.

The following table details the core technical specifications and achievable tolerances under controlled production conditions, reflecting our standard high-precision capability baseline. Specific project tolerances are always defined collaboratively during engineering review.

| Feature | Specification | Capability |

|---|---|---|

| Axis Configuration | Simultaneous 5-Axis Milling | Complex contouring, undercuts, single-setup machining |

| Typical Work Envelope | X: 800-1200mm Y: 600-1000mm Z: 500-800mm | Accommodates medium to large precision components |

| Spindle Speed Range | 20 – 24,000 RPM | Optimized for high-speed finishing & hard milling |

| Positioning Accuracy | ISO 230-2: ≤ 0.005mm over 300mm | Ensures geometric integrity |

| Repeatability | ISO 230-2: ≤ 0.003mm over 300mm | Guarantees consistent batch quality |

| Linear Dimensional Tolerance | General Machining | ±0.010mm |

| Precision Machining | ±0.005mm | |

| Critical Features (CMM Verified) | ±0.002mm | |

| Geometric Tolerances | Flatness, Perpendicularity, etc. | 0.005mm per 100mm (Typical) |

| Surface Roughness (Ra) | Standard Finishing | 0.8 μm |

| High-Precision Finishing | 0.4 μm |

This combination of advanced 5-axis technology, meticulous process control, and uncompromising CMM-based verification ensures Wuxi Lead consistently delivers components that meet or exceed the most challenging precision requirements, providing our clients with reliable, high-value manufacturing solutions.

Material & Finish Options

Material selection is a critical factor in precision CNC milling, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity parts from aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding the characteristics of these materials enables engineers and procurement teams to make informed decisions aligned with functional requirements and environmental conditions.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061 and 7075 are commonly used, with 7075 offering higher strength for demanding structural applications. Aluminum’s natural corrosion resistance can be further enhanced through surface treatments like anodizing, which also allows for color coding and improved wear resistance.

Steel, particularly in alloy and stainless forms, delivers superior strength, hardness, and resistance to wear and deformation. Materials like 4140 alloy steel are ideal for high-stress mechanical components, while 304 and 316 stainless steels are preferred in medical, food processing, and marine environments due to their exceptional corrosion resistance. Although heavier than aluminum, steel provides unmatched durability under load and elevated temperatures, making it suitable for industrial tooling, shafts, and structural frameworks.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its outstanding strength-to-density ratio, biocompatibility, and resistance to high-temperature oxidation make it indispensable in aerospace, defense, and medical implant manufacturing. While more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s longevity in corrosive and high-stress environments justifies its use where reliability is paramount.

Surface finishing plays a complementary role in enhancing material performance. Anodizing, particularly for aluminum, is a controlled electrochemical process that thickens the natural oxide layer, significantly improving corrosion and abrasion resistance. Type II (sulfuric acid) anodizing is commonly used for general protection and aesthetic finish, while Type III (hard coat) anodizing provides a denser, thicker layer suitable for high-wear applications. Anodized surfaces also accept dyes, enabling visual identification without compromising integrity.

The following table summarizes key mechanical and machining properties of commonly used materials in CNC milling services:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Excellent | Enclosures, brackets | Anodizing, bead blasting |

| Aluminum 7075 | 570 | 2.8 | Good | Aerospace components | Hard anodizing, chemical film |

| Steel 4140 | 655 | 7.85 | Good | Shafts, tooling | Zinc plating, passivation |

| Stainless 316 | 580 | 8.0 | Moderate | Medical, marine parts | Electropolishing, passivation |

| Titanium Ti-6Al-4V | 950 | 4.43 | Fair | Aircraft, implants | Anodizing, laser marking |

At Wuxi Lead Precision Machinery, we combine expert material knowledge with advanced CNC milling capabilities to deliver components that meet exacting standards. Our engineering team supports clients in selecting the optimal material and finish combination to ensure performance, longevity, and cost-effectiveness across diverse industrial applications.

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

Our production process at Wuxi Lead Precision Machinery is engineered for uncompromising quality, transforming conceptual designs into flawless high-volume components. We integrate rigorous methodology across three critical phases, ensuring zero defects are not an aspiration but a guaranteed outcome for demanding aerospace, medical, and defense applications.

The journey begins with collaborative design refinement. Our engineering team conducts in-depth Design for Manufacturability (DFM) analysis, scrutinizing CAD models for geometric feasibility, optimal material utilization, and stress points. We proactively identify potential machining conflicts or tolerance stack-ups early, leveraging material science expertise to recommend alloys or composites best suited for the part’s functional lifecycle and environmental exposure. This phase eliminates theoretical flaws before metal is cut, establishing the foundation for defect prevention. Client sign-off on the validated manufacturing plan is mandatory prior to progression.

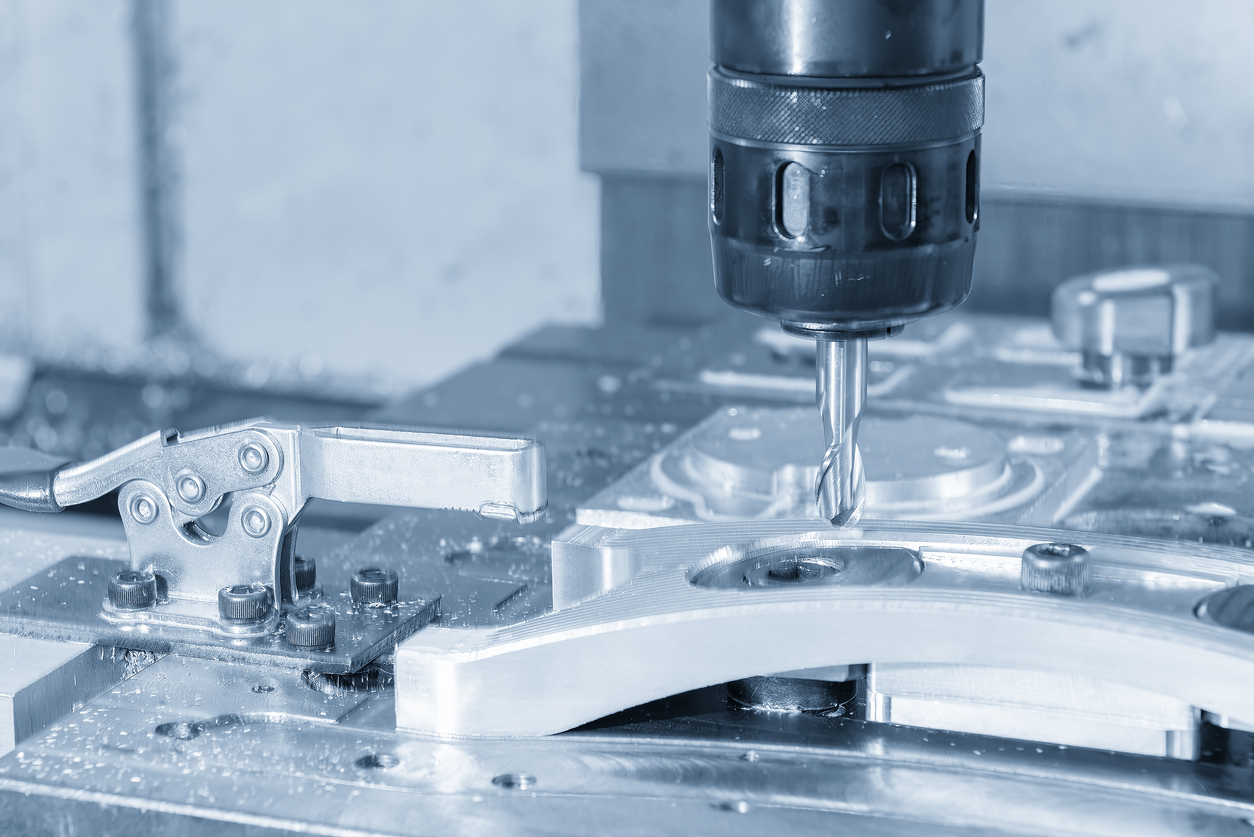

Prototyping transitions theory into tangible validation. Utilizing our high-precision 5-axis milling centers, we produce initial units under full production conditions. Each prototype undergoes exhaustive metrology: Coordinate Measuring Machine (CMM) scans verify geometric dimensioning and tolerancing (GD&T) compliance to micron-level accuracy, while surface roughness testers and material hardness checks confirm specifications. Functional testing simulates real-world loads and environments. This stage is not merely about creating a sample; it is critical process validation. Any deviation triggers immediate root cause analysis and process correction, ensuring the production protocol is perfected before scale-up. Client approval of prototype certification data is the gate to mass production.

Mass production executes the validated process with military-grade discipline. Our shop floor operates under strict Statistical Process Control (SPC), with real-time monitoring of critical parameters like tool wear, spindle load, and thermal drift on every machine. Automated in-process gauging at defined intervals provides instant feedback, enabling micro-adjustments before non-conformances occur. Full traceability—tracking every component from raw material heat number through each machining operation to final inspection—is maintained per AS9100 standards. Final inspection employs 100% critical feature verification using calibrated CMMs and optical comparators, supported by comprehensive First Article Inspection (FAI) reports. This closed-loop system, combined with operator certification and autonomous quality checkpoints, guarantees zero defects reach the customer.

Key Process Specifications Across Production Stages

| Phase | Tolerance Capability | Primary Inspection Method | Material Verification | Traceability Level | Output Validation |

|---|---|---|---|---|---|

| Design | N/A | DFM Simulation & Analysis | Material Suitability | Project Documentation | Approved Plan |

| Prototyping | ±0.002 mm | CMM, Surface Roughness, Hardness | Chemical Composition | Full Batch | FAI Report |

| Mass Production | ±0.005 mm (Routine) | SPC, In-Process Gauging, CMM | Heat Treated Cert. | Per-Part Serial Trace | PPAP Level 3 |

Zero defects is non-negotiable. By embedding quality into every phase—from intelligent design collaboration through prototype stress-testing to SPC-driven mass production—we deliver components that perform reliably in the most critical applications, minimizing client risk and lifecycle costs. Wuxi Lead’s process is your assurance of precision, consistently achieved.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Machine Services

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in high-end manufacturing. As a leading provider of CNC milling machine services in China, we specialize in delivering custom-machined components that meet the most demanding engineering standards. Our advanced infrastructure, combined with decades of technical expertise, positions us as the ideal manufacturing partner for industries ranging from aerospace and medical devices to automation and energy systems.

Our commitment begins with precision and ends with performance. Every component we produce undergoes rigorous quality control, ensuring dimensional accuracy within ±0.002 mm and surface finishes as fine as Ra 0.4 μm. Our facility is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling centers, allowing us to handle complex geometries, tight tolerances, and high-mix production runs with equal efficiency. Whether you require rapid prototyping or high-volume production, our scalable processes ensure consistent output without compromising on quality.

We serve global clients who demand more than just machining—they require a true engineering partner. Our team of seasoned CNC engineers works closely with your design and R&D departments to optimize part manufacturability, reduce lead times, and lower total production costs. From material selection and tolerance analysis to final inspection and logistics, we manage every phase of production with transparency and precision.

Our facility is ISO 9001:2015 certified, and we utilize advanced metrology equipment including CMMs, optical comparators, and surface roughness testers to validate every batch. With in-house capabilities spanning CNC milling, turning, grinding, and secondary operations such as anodizing, plating, and heat treatment, we offer a complete turnkey solution.

Below are key specifications that define our CNC milling capabilities:

| Specification | Detail |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis |

| Maximum Work Envelope | 1200 × 600 × 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish | Ra 0.4 μm to Ra 3.2 μm (custom finishes available) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin, and other engineering alloys |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, SPC |

| Lead Times | Prototype: 5–7 days; Production: 10–20 days (varies by complexity) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. We bridge the gap between innovative design and flawless execution, ensuring your components perform exactly as intended.

Contact us today to discuss your next project. Email us at [email protected] and let our engineering team provide a detailed quote, material recommendations, and production timeline tailored to your requirements. At Lead Precision, we don’t just meet standards—we set them.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.