Technical Contents

Engineering Guide: Copper Parts

Engineering Insight: Precision Imperatives in Copper Part Manufacturing

Copper’s unparalleled thermal and electrical conductivity make it indispensable for aerospace, defense, and high-performance industrial applications. However, these same properties introduce critical precision challenges during machining. Thermal expansion during cutting can induce micro-deformations, while copper’s ductility risks burring and surface tearing if toolpaths or feeds/speeds lack exact calibration. Even micron-level deviations compromise part functionality—thermal management systems fail, electrical contacts overheat, and structural integrity degrades under cyclic loads. At Wuxi Lead Precision Machinery, we treat copper not merely as a material but as a precision engineering variable requiring holistic process control.

Our approach begins with material science integration. We select copper grades based on application-specific conductivity, strength, and machinability requirements, then pair them with optimized CNC parameters. Rigorous thermal management protocols—such as cryogenic cooling and adaptive spindle load monitoring—counteract heat-induced distortion. Simultaneously, diamond-coated tooling and sub-micron motion control ensure surface finishes that prevent particle shedding in vacuum or high-voltage environments. This discipline is non-negotiable; a 5-micron tolerance error in a satellite thermal spreader can trigger catastrophic overheating.

Wuxi Lead’s validation in mission-critical sectors underscores our precision mastery. We engineered copper waveguide components for Beijing Winter Olympic broadcast infrastructure, where signal integrity demanded ±0.005mm tolerances across 300mm lengths. Similarly, our military-grade copper heat exchangers for naval radar systems withstand 15g vibration loads while maintaining thermal transfer efficiency within 0.5% variance. These projects demanded not just machining skill but cross-functional rigor—from FEA-simulated stress analysis to in-process CMM verification at every machining phase.

The table below reflects achievable precision benchmarks for copper alloys under our controlled processes:

| Specification | Typical Capability | Military/Olympic Project Capability |

|---|---|---|

| Dimensional Tolerance | ±0.010 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Flatness | 0.015 mm/m | 0.005 mm/m |

| Material Grades | C11000, C10100, C18150 | C10200, C15000 (Beryllium-free) |

| Secondary Operations | Plating, Passivation, Stress Relieving | Mil-Spec Plating, Vacuum Brazing |

Precision in copper manufacturing transcends dimensional accuracy—it ensures system reliability when failure is not an option. Wuxi Lead’s fusion of material expertise, thermal dynamics mastery, and validated process control delivers copper components that perform flawlessly in the world’s most demanding environments. Partner with us to transform copper’s inherent advantages into engineered certainty.

Precision Specs & Tolerances

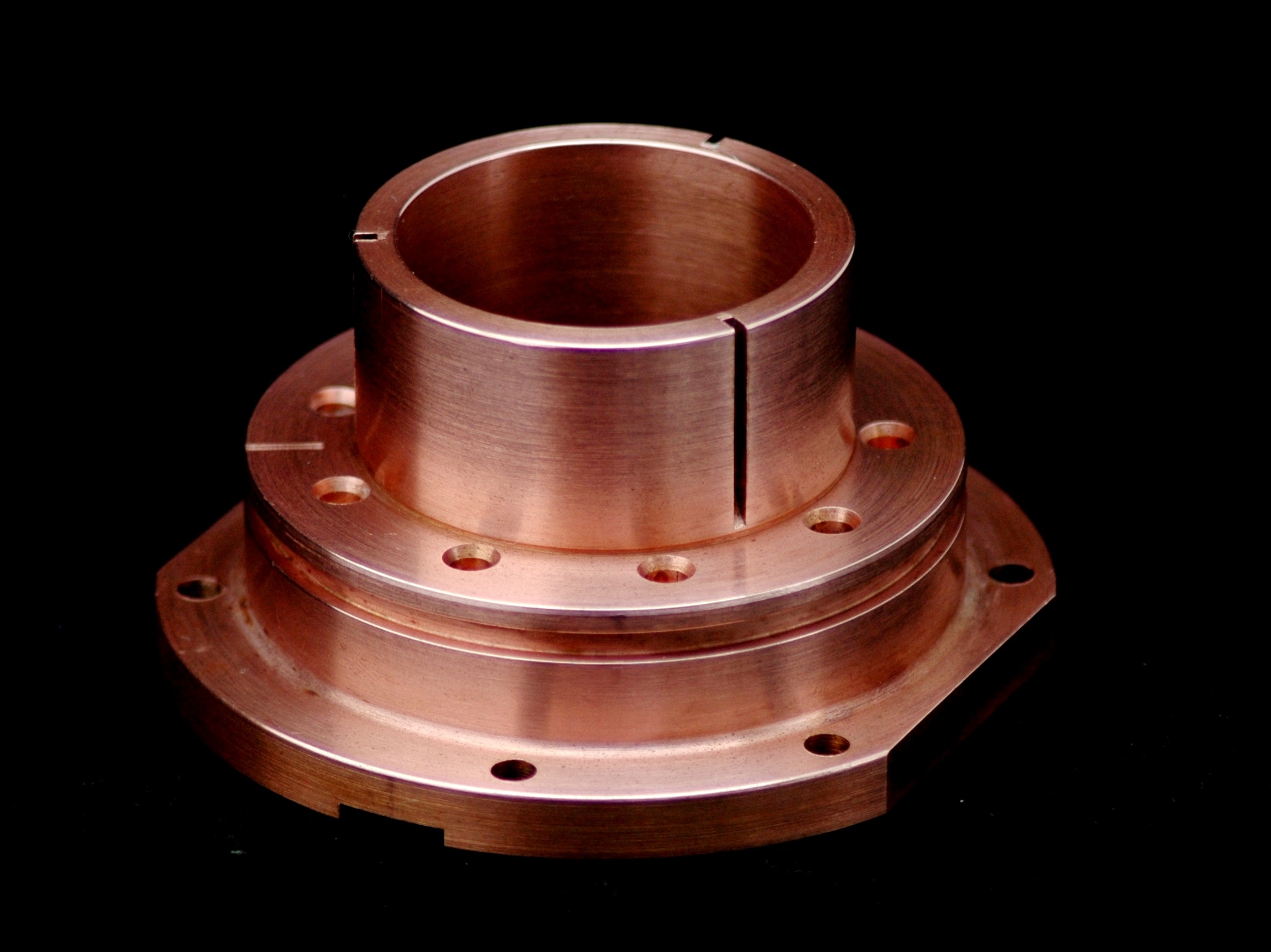

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance copper components, serving industries where thermal conductivity, electrical efficiency, and dimensional precision are critical. Our expertise in custom metal manufacturing is built on state-of-the-art 5-axis CNC machining technology, enabling us to produce complex copper parts with superior surface finish and tight tolerances. Copper, while highly conductive and corrosion-resistant, presents unique machining challenges due to its softness and tendency to work-harden. Our engineering team applies specialized toolpaths, cutting parameters, and fixturing strategies to ensure consistent part integrity and dimensional accuracy across both prototyping and high-volume production runs.

Our 5-axis CNC machining centers provide simultaneous multi-directional cutting, allowing for complete part geometry in a single setup. This reduces cumulative error, improves repeatability, and significantly shortens lead times. With the ability to machine intricate contours, undercuts, and internal features, we support demanding applications in power electronics, RF components, heat exchangers, and industrial automation. Each machine is maintained to OEM standards and operated by certified CNC programmers and machinists with extensive experience in non-ferrous materials.

Quality assurance is integral to our manufacturing process. Every copper component undergoes comprehensive inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring full compliance with customer specifications and international standards. Our CMM system captures thousands of data points across complex geometries, validating critical dimensions, positional tolerances, and form accuracy. Inspection reports are fully documented and available with each shipment, providing traceability and confidence in part performance.

We maintain strict environmental and process controls in our ISO-certified facility to minimize thermal drift and contamination, which is especially important when working with pure copper and high-copper alloys. Our quality management system supports AS9100 and ISO 9001 requirements, ensuring consistency across all production phases.

The following table outlines the standard precision capabilities for copper parts at Wuxi Lead Precision Machinery. Custom tolerances beyond these specifications can be achieved upon engineering review.

| Feature | Standard Capability | Notes |

|---|---|---|

| Positional Tolerance | ±0.005 mm | Per GD&T, verified via CMM |

| Linear Dimensional Tolerance | ±0.010 mm | Up to 300 mm length |

| Surface Finish (Ra) | 0.8 µm (typical) | As-machined;可达到 0.4 µm with polishing |

| Angular Tolerance | ±0.05° | Between features |

| Form Tolerance (Flatness) | 0.015 mm per 100 mm | Verified on surface plate and CMM |

| Feature Repeatability (CpK ≥ 1.33) | Within ±0.008 mm | Statistical process control applied |

| Maximum Part Size | 760 x 560 x 460 mm | 5-axis envelope |

| Minimum Wall Thickness (Copper) | 0.5 mm | Depends on geometry and alloy |

Wuxi Lead Precision Machinery combines precision engineering, advanced equipment, and rigorous quality control to deliver copper components that meet the highest performance standards in mission-critical applications.

Material & Finish Options

Material Selection for High-Performance Copper Components: A Precision Engineering Guide

Selecting the optimal base material is fundamental when engineering critical copper parts for demanding applications. While copper itself offers unparalleled electrical and thermal conductivity, specific project requirements often necessitate evaluating alternative metals or copper alloys. Wuxi Lead Precision Machinery leverages decades of CNC expertise to guide clients through this critical decision, ensuring the chosen material aligns precisely with functional, environmental, and economic constraints. Understanding the inherent properties of copper versus common alternatives like aluminum, steel, and titanium is essential for achieving peak component performance and longevity.

Copper remains the benchmark for electrical conductivity and heat dissipation, making it indispensable for busbars, connectors, heat exchangers, and RF shielding. However, pure copper exhibits lower mechanical strength and hardness compared to structural metals, potentially limiting use in high-stress mechanical assemblies. Its susceptibility to certain corrosive environments may also require protective finishes. Aluminum provides significant weight savings and good corrosion resistance but sacrifices substantial conductivity and strength relative to copper. Steel delivers exceptional strength and wear resistance but is non-conductive and prone to rust without protection. Titanium offers an outstanding strength-to-weight ratio and supreme corrosion resistance, particularly in marine or chemical settings, yet it is significantly more expensive and challenging to machine than copper, with very low conductivity.

The comparative specifications below highlight key material properties relevant to precision copper part manufacturing:

| Material | Electrical Conductivity (% IACS) | Typical Tensile Strength (MPa) | Corrosion Resistance (General) | Machinability Rating |

|---|---|---|---|---|

| Copper (C11000) | 100 | 210-250 | Good (varies by environment) | Excellent (Free-Machining Alloys) |

| Aluminum (6061-T6) | ~35 | 310 | Very Good | Excellent |

| Steel (304 Stainless) | Negligible | 515 | Good (Passivated) | Fair to Good |

| Titanium (Grade 5) | ~3 | 900 | Exceptional | Poor |

Application context dictates the ideal choice. Prioritize copper or high-copper alloys for electrical paths, thermal management, or RF applications where conductivity is non-negotiable. Choose aluminum when weight reduction is critical and moderate conductivity suffices. Opt for stainless steel in structural components requiring high strength, wear resistance, and moderate corrosion resistance where conductivity is irrelevant. Reserve titanium for extreme environments demanding maximum strength-to-weight and corrosion resistance, accepting higher cost and machining complexity.

Surface finishing significantly impacts final part performance and appearance. Anodizing is a critical process exclusively for aluminum, enhancing its corrosion resistance, wear properties, and providing electrical insulation – it is not applicable to copper, steel, or titanium. Copper components typically utilize electroplating (nickel, tin, silver, gold) for enhanced corrosion resistance, solderability, or specific electrical properties, or chemical passivation for basic protection. Wuxi Lead Precision Machinery possesses advanced in-house and partner capabilities for all relevant finishing processes, ensuring finishes meet stringent aerospace, medical, and industrial specifications without compromising the tight tolerances achieved through our precision CNC machining. Consult our engineering team early in the design phase to optimize material and finish selection for your specific copper part application.

Manufacturing Process & QC

From Concept to Copper Excellence: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we specialize in the production of high-performance copper components for industries where thermal conductivity, electrical efficiency, and dimensional accuracy are non-negotiable. Our end-to-end manufacturing process is engineered for precision, consistency, and zero-defect delivery. From initial design to full-scale production, every stage is optimized to meet the most demanding specifications.

The process begins with collaborative design engineering. Our team works closely with clients to analyze application requirements, material behavior, and manufacturability. Using advanced CAD/CAM software and finite element analysis (FEA), we simulate thermal, electrical, and mechanical performance to refine geometries before any material is cut. This phase ensures that the final component not only fits but performs under real-world conditions.

Next, we move to precision prototyping. Utilizing CNC milling, turning, and EDM (Electrical Discharge Machining), we produce functional prototypes in the exact grade of copper—typically C11000 (electrolytic tough pitch) or C10100 (oxygen-free electronic copper)—intended for final production. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We validate dimensions, tolerances, and surface integrity, ensuring alignment with ISO 2768 and customer-specific standards. Feedback from this stage is integrated into the final production program, eliminating risks before scale-up.

Once approved, the project transitions to zero-defect mass production. Our automated CNC production lines operate under strict SPC (Statistical Process Control) protocols, with real-time monitoring of tool wear, cutting parameters, and environmental conditions. Each copper part is machined with micron-level accuracy, supported by in-process gauging and 100% visual inspection via high-resolution imaging systems. We employ non-destructive testing (NDT) methods such as ultrasonic testing for critical applications to detect subsurface anomalies.

Throughout the production cycle, traceability is maintained via a digital quality log for each batch, including material certificates, inspection reports, and process parameters. Our facility is ISO 9001 and IATF 16949 certified, ensuring compliance with global quality benchmarks.

Copper Manufacturing Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Material Grades | C11000, C10100, C10200, C12200 |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry) |

| Surface Roughness (Ra) | 0.2 µm to 1.6 µm |

| Maximum Part Size | 500 mm × 400 mm × 300 mm |

| Minimum Feature Size | 0.3 mm (milled), 0.1 mm (EDM) |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 2768, ISO 9001, IATF 16949, RoHS |

| Secondary Operations | Deburring, cleaning, plating, laser marking |

At Wuxi Lead, copper is more than a material—it’s a performance enabler. Our integrated process ensures every component meets the highest standards of precision, reliability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Copper Components

Copper’s exceptional thermal conductivity, electrical performance, and machinability make it indispensable for aerospace, medical, and semiconductor applications. Yet its softness and thermal sensitivity demand specialized expertise to avoid deformation, burring, or dimensional drift during precision manufacturing. At Wuxi Lead Precision Machinery, we transform these challenges into competitive advantages through proprietary CNC processes engineered exclusively for high-integrity copper alloys. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring every component meets the uncompromising tolerances required in critical systems. When your project hinges on flawless copper performance, partnering with Lead Precision means securing a supplier that treats your specifications as non-negotiable engineering mandates—not mere suggestions.

Our dedicated copper production cell integrates multi-axis Swiss lathes, high-speed milling centers, and non-contact metrology systems calibrated for copper’s unique behavior. We mitigate thermal expansion through cryogenic tooling and adaptive feed-rate algorithms, achieving repeatability unattainable with conventional methods. The table below outlines our validated capabilities for complex copper geometries:

| Parameter | Capability | Application Impact |

|---|---|---|

| Alloy Range | C10100, C11000, C17200, C18150 | Optimized for conductivity vs. strength |

| Tolerance Control | ±0.0002″ (5µm) linear | Ensures seal integrity in vacuum systems |

| Surface Finish | Ra 0.4µm to 3.2µm (as-machined) | Critical for electrical contact reliability |

| Feature Complexity | 7-axis simultaneous interpolation | Enables monolithic fluid manifolds |

| Lead Time | 14 days for first-article approval | Accelerates prototyping cycles |

This precision is backed by our zero-defect culture. Every copper batch undergoes traceable material certification, in-process thermal monitoring, and final validation via CMM and spectral analysis. We document full process signatures for your audit trails—because in regulated industries, compliance isn’t optional. Our engineering team collaborates from DFM review through production, identifying cost-saving opportunities without sacrificing performance. For instance, we recently reduced a medical connector client’s scrap rate by 68% by redesigning coolant paths to prevent micro-galling in pure copper contacts.

Initiate your copper component project by forwarding CAD files and requirements to [email protected]. Include target volumes, critical dimensions, and application environment details. Our technical sales engineers will respond within 4 business hours with a feasibility assessment and process plan—not a generic quotation. For urgent RFQs, reference “COPPER-URGENT” in the subject line to trigger expedited review. Wuxi Lead Precision Machinery operates 24/7 in Jiangsu Province with direct shipping lanes to global hubs, ensuring on-time delivery without compromising quality. Trust your copper components to engineers who speak the language of conductivity, yield strength, and micron-level accountability. Precision-engineered copper solutions start here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.