Technical Contents

Engineering Guide: Injection Molding Plastic Parts

Engineering Insight: Precision as the Non-Negotiable Foundation in Injection Molding Plastic Parts

In high-stakes industrial applications, the precision of injection molded plastic components transcends mere dimensional conformity—it directly dictates system reliability, assembly integrity, and end-product lifespan. A deviation of even 0.02mm can trigger catastrophic cascade failures in aerospace hydraulics, medical device mechanisms, or defense electronics. At Wuxi Lead Precision Machinery, we treat precision not as a target but as the absolute baseline, engineered into every stage from mold design to final inspection. This rigor stems from our core expertise in custom metal manufacturing, where micron-level tolerances are non-negotiable. We apply identical discipline to plastic molding, recognizing that the mold’s metallic foundation—its cavities, cores, and ejection systems—must achieve aerospace-grade accuracy to consistently replicate complex geometries in polymer.

Our process integrates advanced mold flow simulation with real-time cavity pressure monitoring, ensuring optimal material distribution and minimizing residual stress that causes warpage. Material selection is equally critical; we validate each resin’s thermal behavior against projected part geometry to prevent sink marks or dimensional drift post-ejection. This holistic approach guarantees that every molded component meets stringent functional requirements, whether it interfaces with micro-actuators in surgical robotics or seals critical joints in satellite subsystems. Precision here means zero compromise on repeatability across million-part runs—where batch-to-batch variation must remain imperceptible to automated assembly lines.

The following specifications represent our standard capability for mission-critical plastic components, validated through ISO 17025-accredited metrology:

| Critical Parameter | Standard Capability | High-Precision Tier |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm |

| Material Compatibility | Engineering Thermoplastics (PEEK, PEI, PSU), LCP, Liquid Crystal Polymers | Specialty Polymers (Radiation-Resistant, Conductive Composites) |

| Warpage Control | < 0.1% of nominal dimension | < 0.02% of nominal dimension |

This capability is battle-tested. Our molds produced zero-defect components for the Beijing Winter Olympics’ timing sensor housings, operating flawlessly at -40°C under extreme vibration. Similarly, military-grade communication modules we manufactured maintained signal integrity after 1,000+ thermal cycles from -55°C to +125°C—proving that precision engineered for plastics must withstand environments where failure is unacceptable. For industries where a single defective part risks safety or mission success, Wuxi Lead Precision Machinery delivers the dimensional integrity that transforms plastic components from disposable elements into engineered assets. Precision isn’t our claim; it’s our documented legacy.

Precision Specs & Tolerances

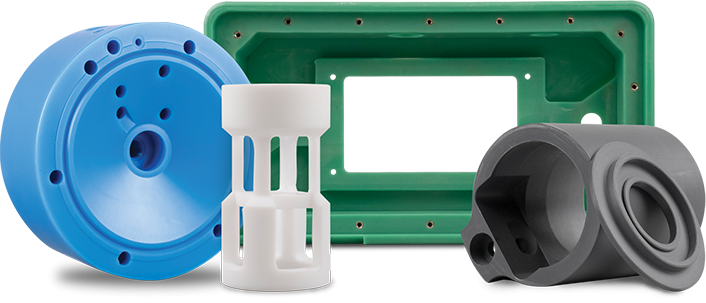

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the custom manufacturing of injection molding plastic parts, combining precision engineering with rigorous quality control to meet the demanding requirements of high-performance industries such as automotive, medical, aerospace, and consumer electronics. Our expertise lies in producing complex, high-tolerance components that ensure seamless integration into injection molding systems, including mold bases, cavities, cores, ejector systems, and precision inserts.

At the core of our manufacturing capability is our state-of-the-art 5-axis CNC machining technology. This advanced platform enables us to execute intricate geometries and tight-tolerance features with exceptional accuracy and surface finish. The simultaneous multi-axis movement allows for the machining of complex contours and undercuts in a single setup, minimizing human intervention, reducing potential for error, and significantly improving part consistency. Our 5-axis systems are optimized for both prototyping and high-volume production, offering flexibility and scalability to meet diverse client needs.

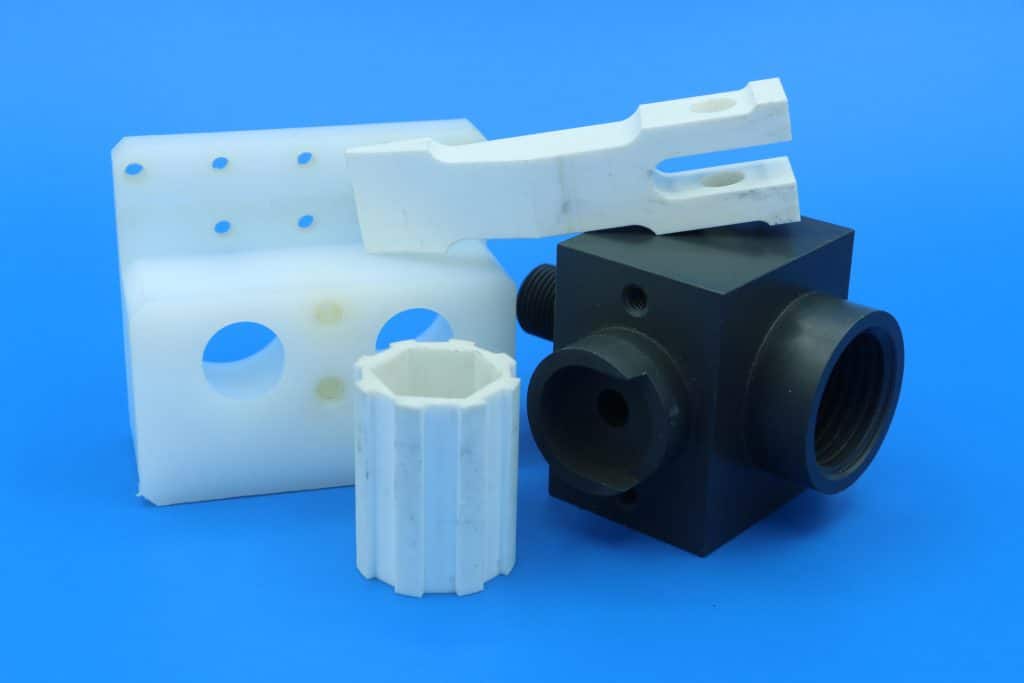

Material selection is a critical component of our process. We work with a broad range of engineering-grade plastics and reinforced polymers suitable for injection molding applications, including PEEK, PTFE, ULTEM, ABS, and polycarbonate. Each material is processed under controlled conditions to ensure dimensional stability, thermal resistance, and mechanical integrity. Our machining parameters are fine-tuned to accommodate the unique thermal expansion and machinability characteristics of each polymer, ensuring that final parts meet exact design specifications.

To guarantee the highest level of quality and repeatability, every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM systems provide full 3D metrology, enabling precise verification of geometric dimensions, positional tolerances, and surface profiles. Data from each inspection is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements.

The following table outlines the standard tolerances we achieve across key dimensional and geometric parameters:

| Parameter | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 100 mm; ±0.01 mm for >100 mm |

| Geometric Tolerances | ±0.008 mm | Includes flatness, parallelism, perpendicularity |

| Surface Roughness (Ra) | 0.4 – 1.6 µm | Adjustable based on application |

| Hole Diameter Tolerance | H7 fit | Custom fits available |

| Angular Tolerance | ±0.05° | For precision alignment features |

| Positional Tolerance | ±0.01 mm | Verified via CMM inspection |

Our technical capabilities are reinforced by a commitment to continuous improvement and engineering collaboration. By integrating precision 5-axis CNC machining with comprehensive CMM-based quality assurance, Wuxi Lead Precision Machinery ensures that each injection molding plastic part meets the highest standards of performance, reliability, and dimensional accuracy.

Material & Finish Options

Material Selection for Injection Mold Bases: Precision Engineering Fundamentals

Selecting the optimal base material for injection molds is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific production volume, part complexity, resin type, and surface finish requirements. Aluminum, tool steel, and titanium each offer distinct advantages and limitations for mold construction. Understanding these characteristics ensures the mold performs reliably under demanding injection cycles while meeting stringent dimensional tolerances.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are preferred for rapid prototyping, low-volume production, and molds requiring exceptional thermal conductivity. Their machinability significantly reduces lead times and initial tooling costs. However, aluminum’s lower hardness limits its use in high-volume runs or with abrasive resins, as wear resistance is comparatively lower. Steel remains the dominant choice for high-volume manufacturing. Pre-hardened steels like P20 offer good machinability and moderate wear resistance for medium runs. For maximum durability, hardened tool steels such as H13 (excellent toughness and thermal fatigue resistance) or S136 (superior corrosion resistance for PVC or flame-retardant materials) are essential. Steel provides the necessary hardness and longevity for millions of cycles but requires more complex heat treatment and machining, increasing initial cost and lead time. Titanium alloys find specialized application where extreme corrosion resistance is paramount, such as molding highly aggressive chemical compounds, or where exceptional strength-to-weight ratio is critical for large, complex molds. Its high cost and challenging machinability generally restrict its use to niche, high-value applications.

Surface finishing, particularly anodizing, significantly enhances mold performance. Hard anodizing aluminum molds creates a dense, wear-resistant ceramic layer, dramatically improving surface hardness and extending mold life for prototyping or medium runs. It also provides excellent release properties. While less common on steel, specialized anodizing processes can be applied to specific components for enhanced corrosion resistance. The choice of finish must complement the base material and the specific polymer being processed.

The following table summarizes key comparative properties for common mold base materials:

| Material | Typical Hardness (HRC) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Relative Cost |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | Low-Moderate | 130-150 | Low |

| P20 Tool Steel | 28-32 | Moderate | 28-36 | Moderate |

| H13 Tool Steel | 48-52 (Hardened) | Moderate | 28-36 | High |

| S136 Stainless | 48-52 (Hardened) | High | 20-25 | Very High |

| Titanium Grade 5 | 32-36 | Very High | 7-8 | Very High |

Material selection is never one-size-fits-all. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to analyze your production goals, resin characteristics, and budget constraints. We guide clients toward the optimal material-finish combination, balancing upfront investment with long-term productivity and part quality. Consult our engineering team early in the design phase to ensure your mold foundation delivers maximum performance and return on investment.

Manufacturing Process & QC

Design Excellence Begins the Journey to Zero Defects

At Wuxi Lead Precision Machinery, the production of high-performance injection molded plastic parts begins with precision engineering at the design phase. Our engineering team collaborates closely with clients to analyze part geometry, material selection, tolerance requirements, and functional performance. Using advanced 3D CAD software and mold flow simulation tools, we validate the design for manufacturability, ensuring optimal wall thickness, gate placement, and cooling channels. This proactive design validation minimizes risks such as warping, sink marks, or internal stresses—critical steps toward achieving a zero-defect outcome.

From Virtual Model to Physical Prototype

Once the digital design is finalized, we transition into the prototyping stage. Rapid tooling using pre-hardened steel or aluminum molds enables the production of functional prototypes within days. These prototypes undergo rigorous testing for fit, form, and function, including dimensional inspection via coordinate measuring machines (CMM) and first-article inspection reports (FAIR). Material compatibility, structural integrity, and assembly integration are verified under real-world conditions. Feedback from this stage informs any necessary design or process refinements, ensuring that the final product meets all technical and regulatory standards before scaling to mass production.

Mass Production with Precision and Consistency

With design and prototype approval, we initiate high-volume manufacturing using state-of-the-art electric and hybrid injection molding machines with tight process control. Our production cells are equipped with real-time monitoring systems that track critical parameters such as injection pressure, melt temperature, and cycle time. Automated robotic arms ensure consistent part handling, reducing human error and contamination risks. Each production batch is subject to in-process quality checks, including statistical process control (SPC) and 100% visual inspection using machine vision systems where applicable. Environmental controls maintain cleanroom-level conditions for sensitive applications in medical, automotive, and electronics sectors.

Our commitment to zero defects is reinforced through full traceability. Every mold, material lot, and production run is documented in our quality management system, compliant with ISO 9001 and IATF 16949 standards. Corrective and preventive actions (CAPA) are implemented immediately if deviations occur, ensuring continuous improvement.

Technical Specifications and Capabilities

| Parameter | Specification |

|---|---|

| Material Compatibility | ABS, PC, POM, PP, PA (Nylon), PBT, PMMA, LCP |

| Tolerance Range | ±0.02 mm to ±0.1 mm (based on part size) |

| Part Weight Range | 0.1 g – 1,500 g |

| Mold Base Standards | DME, HASCO, LKM |

| Machine Clamping Force | 50–2,500 Tons |

| Production Capacity | Up to 5 million parts/month |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers injection molded plastic parts with uncompromising quality—engineered for performance, built for perfection.

Why Choose Wuxi Lead Precision

Why Partner with Lead Precision for Injection Molding Plastic Parts

Achieving flawless plastic components demands more than advanced molding machines; it requires precision-engineered metal tooling capable of maintaining micron-level tolerances across high-volume production cycles. At Wuxi Lead Precision Machinery, we bridge the critical gap between plastic part performance and the metal molds that define it. Our expertise lies in manufacturing custom mold bases, cavities, cores, and inserts using aerospace-grade alloys and proprietary hardening techniques. This ensures your plastic parts meet stringent dimensional stability requirements under thermal cycling and mechanical stress—eliminating warpage, sink marks, and inconsistent wall thickness that compromise functionality.

We understand the cascading impact of mold imperfections: a 0.005mm deviation in cavity geometry can result in 0.05mm variance in your final plastic component. Our CNC machining centers, calibrated to ISO 2768-fine standards, consistently deliver mold features within ±0.002mm tolerance. This precision translates directly to reduced scrap rates, extended mold life exceeding 1 million cycles, and seamless integration with your existing molding infrastructure. Unlike generic mold suppliers, we engineer for your specific polymer’s flow dynamics and cooling behavior, optimizing gate locations and ejection systems during the metal fabrication phase.

Technical Capabilities for Injection Mold Manufacturing

| Specification | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Mold Base Materials | P20, H13, S136, 420SS, Maraging Steel | P20 only |

| Max. Cavity Size | 1200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Positional Tolerance | ±0.002 mm | ±0.01 mm |

| Surface Finish (Cavity) | Ra 0.05 µm (Mirror Polish) | Ra 0.2 µm |

| Max. Cavity Count | 64 cavities | 32 cavities |

| Lead Time (Complex) | 25-35 days | 45-60 days |

Our process integrates DFM analysis with mold flow simulation data to preempt defects before metal cutting begins. Each component undergoes rigorous CMM validation against your 3D CAD model, with full traceability from raw material certification to final assembly. This systematic approach has enabled medical device manufacturers to achieve zero-defect PPAP submissions and automotive Tier 1s to exceed ISO/TS 16949 requirements for under-hood components.

Partnering with Lead Precision means aligning with a team that treats your plastic part’s success as a metal machining challenge first. We collaborate from concept through production ramp-up, providing real-time metrology data and iterative refinements—no project handoffs to offshore teams. Your engineering team gains direct access to our tooling specialists for rapid resolution of ejection issues, venting optimization, or thermal management adjustments.

Secure your competitive edge in precision plastic manufacturing. Contact our engineering team at Contact [email protected] to initiate a technical consultation. Include your part drawings and volume requirements; we will respond within 8 business hours with a feasibility assessment and mold design proposal tailored to your dimensional criticality and production goals. Precision begins in the metal—let us build the foundation for your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.