Technical Contents

Engineering Guide: Republic Services Telford

Engineering Insight Precision as Operational Imperative for Republic Services Telford

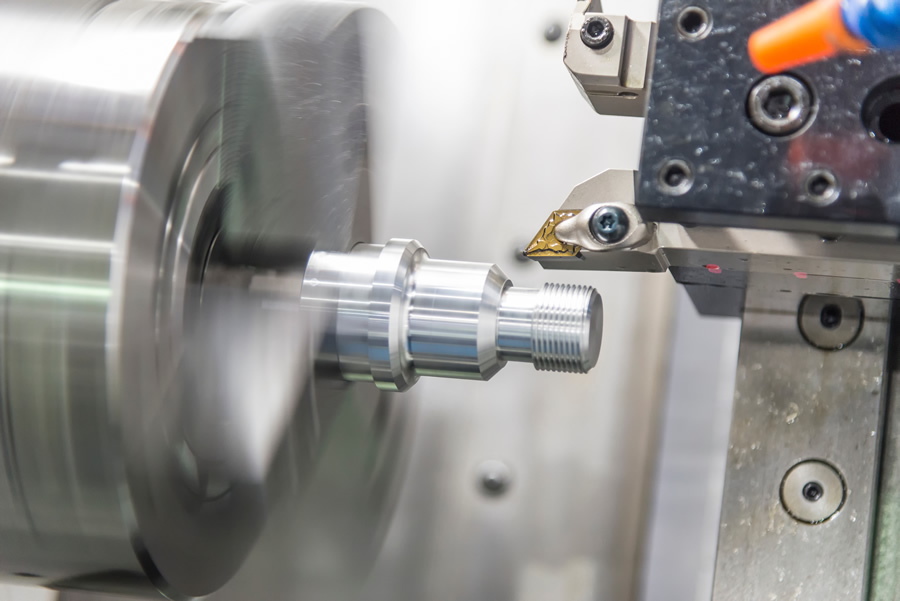

Precision engineering is not merely a technical specification in heavy-duty waste management infrastructure; it is the foundational requirement for sustained operational resilience and cost efficiency. For Republic Services Telford, whose facilities process high volumes under relentless mechanical stress and corrosive environments, component accuracy directly dictates system longevity and uptime. Sub-millimeter deviations in critical parts like compactor rams, shredder shafts, or sorting conveyor mechanisms initiate accelerated wear, misalignment, and catastrophic fatigue failures. These failures translate directly into unplanned downtime, costly emergency repairs, and compromised throughput – metrics that erode profitability in a competitive sector. The margin for error in continuous-operation machinery is effectively zero. Achieving true precision demands more than advanced CNC equipment; it requires an ingrained engineering culture focused on material science, thermal compensation, and rigorous in-process validation at every manufacturing stage.

Wuxi Lead Precision Machinery understands this operational reality intimately. Our engineering protocols are forged in environments where failure is non-negotiable. We have supplied mission-critical components for Olympic venue infrastructure, where structural integrity under peak load was paramount for public safety. Similarly, our military-grade manufacturing experience necessitates adherence to extreme dimensional stability and material performance standards under harsh conditions – standards directly transferable to the punishing realities of modern waste processing. This pedigree ensures every component we produce for clients like Republic Services Telford is engineered for decades of service, not just initial installation. Our process integrates multi-axis CNC machining with real-time metrology, utilizing hardened tooling and optimized cutting strategies to maintain tolerances unaffected by material batch variations or thermal drift during extended production runs.

The following specifications represent our baseline capability for demanding industrial applications, exceeding typical municipal equipment requirements:

| Capability Parameter | Specification Range | Relevance to Waste Management Equipment |

|---|---|---|

| Positioning Accuracy | ±0.003 mm | Ensures perfect alignment of heavy-load bearings and drive systems |

| Repeatability | ±0.002 mm | Guarantees consistent part interchangeability during maintenance |

| Surface Finish (Ra) | 0.4 µm to 3.2 µm achievable | Reduces friction and wear in high-cycle moving parts |

| Material Compatibility | Carbon Steels, Stainless (304/316), Cast Iron, Aluminum Alloys | Handles corrosive waste streams and high-impact loads |

| Max Work Envelope | 2000 x 1000 x 800 mm | Accommodates large structural frames and compactor assemblies |

| In-Process Metrology | On-machine probing with SPC | Prevents scrap batches; ensures first-article correctness |

For Republic Services Telford, partnering with a manufacturer possessing this level of precision discipline means more than receiving a part. It means receiving engineered reliability that minimizes total cost of ownership through extended component life, predictable maintenance cycles, and maximized facility uptime. Wuxi Lead Precision Machinery applies its Olympic and military-proven standards to every project, ensuring your critical infrastructure operates at peak efficiency, day after demanding day. Precision here is not an option; it is the operational bedrock.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for precision, consistency, and performance. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce highly complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and reducing setup times. This capability is particularly critical when manufacturing intricate components for industries such as aerospace, energy, medical, and high-performance automation, where tight tolerances and repeatable quality are non-negotiable.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and advanced control systems that support continuous, uninterrupted operation. This ensures optimal material removal rates while maintaining micron-level precision across diverse metals, including aluminum alloys, stainless steel, titanium, and specialty alloys. The integration of dynamic workholding and in-process probing further enhances part accuracy by compensating for thermal drift and tool wear in real time.

Quality control is embedded at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with full 3D measurement capability. Our CMM system is calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 10360. This allows us to validate geometric tolerances, surface profiles, and positional accuracy with confidence. In addition to CMM inspection, we employ first-article inspection (FAI) and in-process checks to maintain consistency across production runs.

We understand that precision is not just about equipment—it’s about process integrity. Our engineering team works closely with clients to review design for manufacturability (DFM), optimize toolpaths, and select appropriate materials and finishes. This collaborative approach ensures that every component not only meets but exceeds technical expectations.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Value |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.010 mm |

| Geometric Tolerance (Flatness, Roundness) | ±0.008 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm (adjustable) |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Minimum Feature Size | 0.5 mm diameter |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| CMM Measurement Accuracy | ±1.5 + L/350 µm (L = length in mm) |

| Inspection Reporting | Full GD&T analysis with PDF and Excel output |

At Wuxi Lead Precision Machinery, we combine cutting-edge technology with rigorous quality assurance to deliver custom metal components that perform under the most demanding conditions. Our investment in 5-axis CNC machining and precision metrology ensures that every part we produce meets the highest standards of accuracy and reliability.

Material & Finish Options

Material Selection for Industrial Durability in Waste Management Applications

Selecting optimal materials is critical for waste management equipment operating in corrosive, high-impact environments. At Wuxi Lead Precision Machinery, we prioritize longevity and performance for Republic Services Telford’s demanding operational cycles. Below we detail key considerations for aluminum, steel, and titanium, alongside anodizing finishes to maximize component resilience.

Aluminum alloys, particularly 6061-T6, offer an exceptional strength-to-weight ratio ideal for moving parts like chute mechanisms and sensor housings. Its natural corrosion resistance withstands exposure to organic acids and moisture prevalent in waste streams. While lighter than steel, aluminum maintains structural integrity under vibration and thermal cycling. For Republic Services’ fleet efficiency, reduced component weight directly lowers fuel consumption without sacrificing durability.

Carbon and alloy steels such as 4140 provide unmatched tensile strength for high-stress structural components like loader arms and chassis reinforcements. These materials endure extreme mechanical loads and abrasion from compacted waste. We recommend heat-treated 4140 for critical wear zones due to its superior fatigue resistance. Note that steel requires protective finishes in waste handling applications; galvanizing or powder coating are common, though anodizing is not applicable to ferrous metals.

Titanium Grade 5 (Ti-6Al-4V) serves niche applications where extreme corrosion resistance and strength are non-negotiable, such as hydraulic fittings exposed to aggressive leachates. Its immunity to chloride-induced stress corrosion cracking justifies the premium cost for mission-critical parts. While titanium’s density is higher than aluminum, it remains 45% lighter than steel—ideal for weight-sensitive hydraulic systems requiring decades of service.

Anodizing significantly enhances aluminum’s surface properties for waste management use. Type II (sulfuric acid) anodizing creates a durable, non-conductive oxide layer resistant to chipping and chemical degradation. For Republic Services’ high-wear components like sorting system guides, we specify Type III (hardcoat) anodizing, which achieves 50–70 µm thickness with Rockwell hardness up to 70 HR15Y. This finish eliminates galling in moving assemblies and withstands 1,000+ hours of salt spray testing—critical for UK coastal operations. Crucially, anodizing does not alter dimensional tolerances, ensuring seamless integration with existing machinery.

Material performance metrics guide strategic selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance (vs. Waste Stream) | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (with anodizing) | Medium |

| Steel 4140 | 7.85 | 655 | Good (requires coating) | Low |

| Titanium Gr5 | 4.43 | 900 | Exceptional | High |

Wuxi Lead Precision Machinery tailors material and finish combinations to Republic Services Telford’s specific equipment lifecycle requirements. Our engineering team validates selections through accelerated corrosion testing and finite element analysis, ensuring each component meets 15+ year service expectations in real-world waste handling conditions. Contact us to optimize your next production run for maximum operational uptime.

Manufacturing Process & QC

From Concept to Consistency: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components that meet the most stringent industrial requirements. Our production process is engineered for precision, repeatability, and zero defects—ensuring every part aligns perfectly with client specifications. For partners like Republic Services Telford, where reliability and performance are non-negotiable, our three-phase workflow—Design, Prototyping, and Mass Production—forms the backbone of consistent, high-integrity output.

The process begins with Design, where our engineering team collaborates closely with client technical data, CAD models, and functional requirements. Using advanced simulation software, we conduct structural, thermal, and tolerance analyses to optimize geometry and material selection. This phase includes Design for Manufacturability (DFM) reviews to eliminate potential production risks before any material is cut. Our engineers ensure that every design is not only functional but also scalable for high-volume output without compromising quality.

Next is Prototyping, a critical validation step. We fabricate initial units using the same CNC machining, sheet metal forming, and welding processes intended for full-scale production. These prototypes undergo rigorous in-house testing, including dimensional inspection via CMM (Coordinate Measuring Machine), material hardness verification, and fit-checks with mating components. Feedback from Republic Services Telford is integrated swiftly, allowing for rapid iteration. This phase confirms design integrity and process readiness, reducing downstream variability.

Once approved, we transition to Mass Production, executed in our ISO 9001-certified facility. Our automated production lines are monitored in real time using IoT-enabled CNC systems that detect tool wear, thermal drift, and positional deviations. Every component passes through multiple inline inspection stages, with statistical process control (SPC) ensuring consistency across batches. We maintain full traceability—from raw material lot numbers to operator logs and inspection reports—enabling full accountability and rapid root-cause analysis if needed.

Our zero-defect philosophy is enforced through a combination of automation, human expertise, and closed-loop quality control. At Wuxi Lead, we do not simply manufacture parts—we guarantee performance.

Production Specifications Overview

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on geometry) |

| Material Compatibility | Stainless Steel, Aluminum, Carbon Steel, Brass, Titanium |

| Max Workpiece Size | 2000 mm × 1200 mm × 800 mm |

| Surface Finish Options | As-machined, Anodized, Powder Coated, Passivated |

| Production Capacity | Up to 50,000 units/month (scalable) |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, XRF Analyzer |

| Lead Time (Prototype) | 7–14 days (based on complexity) |

| Lead Time (Mass Production) | 4–6 weeks (including QA and packaging) |

All processes are documented and auditable, ensuring compliance with international standards and client-specific quality mandates.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Manufacturing Excellence

Republic Services Telford operates in demanding industrial environments where equipment reliability and precision directly impact operational continuity and safety. At Wuxi Lead Precision Machinery, we engineer custom metal components that withstand the rigors of waste processing, recycling infrastructure, and heavy machinery applications. Our partnership transcends conventional manufacturing; we integrate deeply with your engineering and procurement teams to transform complex specifications into mission-critical parts. With 15 years of specialized experience serving global industrial leaders, we prioritize your uptime, regulatory compliance, and total cost of ownership from initial design consultation through to just-in-time delivery.

Our advanced CNC capabilities—encompassing 5-axis milling, turning, and multi-tasking centers—ensure geometric complexity and micron-level accuracy for components such as shredder rotors, conveyor systems, and hydraulic manifolds. We deploy rigorous in-process metrology using Zeiss CMMs and optical comparators, guaranteeing that every part meets or exceeds ASME Y14.5 and ISO 2768 standards. This technical discipline is paired with proactive supply chain management, mitigating material volatility risks through strategic partnerships with certified global steel and alloy suppliers. The result is consistent delivery of components that reduce wear, minimize unplanned downtime, and extend asset lifecycles in high-stress operational settings.

Key technical specifications underpinning our partnership value include:

| Specification | Capability | Relevance to Republic Services Telford Operations |

|---|---|---|

| Material Expertise | Carbon steel, stainless (304/316), abrasion-resistant alloys (AR400/500) | Ensures durability against corrosive waste streams and abrasive materials |

| Dimensional Tolerances | ±0.005mm (linear), ±0.002° (angular) | Critical for seamless integration into high-torque drive systems and precision assemblies |

| Certifications | ISO 9001:2015, ISO 14001, NADCAP (pending) | Validates compliance with environmental safety and quality frameworks |

| Lead Times | 15-25 days for prototyping; 30-45 days for production | Supports agile response to maintenance schedules and project timelines |

| Project Management | Dedicated APQP/PPAP coordination, real-time digital tracking | Eliminates communication gaps and ensures traceability from RFQ to shipment |

Choosing Wuxi Lead Precision means aligning with a partner who treats your operational challenges as our engineering mandate. We invest in understanding the unique stressors within Telford’s facility—whether thermal cycling in sorting systems or impact loads in compaction units—to refine material selection and finishing processes. Our technical team collaborates during design-for-manufacturability reviews, identifying cost-saving optimizations without sacrificing performance. This proactive engineering partnership reduces total project risk while accelerating time-to-value for your capital equipment investments.

Initiate a precision manufacturing partnership built on technical integrity and operational accountability. Contact our engineering sales team at [email protected] to schedule a confidential capability review. Include your component specifications or operational challenges, and we will respond within 24 hours with a tailored solution proposal—including feasibility analysis, timeline mapping, and a no-obligation cost breakdown. Republic Services Telford deserves manufacturing partners who deliver certainty in uncertainty. Let us prove why global industrial leaders trust Wuxi Lead Precision Machinery as their strategic metal fabrication ally.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.