Technical Contents

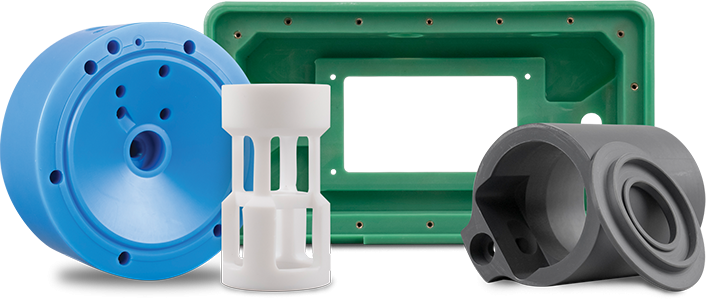

Engineering Guide: Common Injection Moulding Plastics

Engineering Insight: Common Injection Moulding Plastics and the Critical Role of Precision

In high-end manufacturing, the selection of injection moulding plastics is not merely a material decision—it is a strategic engineering imperative. At Wuxi Lead Precision Machinery, we understand that the performance, durability, and dimensional accuracy of a final component are deeply influenced by both the polymer chosen and the precision of the metal tooling used in its production. Our decades of experience in custom metal manufacturing, including precision-critical projects for Olympic-standard equipment and military-grade systems, have reinforced that tolerances in the micrometer range are not optional—they are foundational.

Common thermoplastics such as ABS, Polycarbonate (PC), Polyamide (Nylon), Polyoxymethylene (POM), and Polypropylene (PP) each offer distinct mechanical, thermal, and chemical properties. However, their successful application hinges on the consistency of the moulding process, which in turn depends on the accuracy and thermal stability of the mould itself. Even minor deviations in cavity geometry or cooling channel alignment can lead to warpage, sink marks, or inconsistent wall thickness—defects that are unacceptable in aerospace, medical, or defense applications.

For instance, Polycarbonate’s high impact resistance and optical clarity make it ideal for protective enclosures and lenses, but its sensitivity to shear stress demands uniform flow dynamics, achievable only through precisely machined runners and gates. Similarly, Nylon’s hygroscopic nature requires stable mould temperatures to prevent dimensional drift during cooling—a challenge met through precision-engineered cooling systems within the tool.

At Wuxi Lead, our approach integrates advanced CNC machining, multi-axis milling, and real-time metrology to ensure that every mould cavity replicates the CAD model within ±0.005 mm. This level of accuracy is not theoretical; it is proven through long-term partnerships where failure is not an option. Our work on components for Olympic timing systems demanded sub-0.01 mm repeatability across thousands of cycles—achieving zero defect rates under rigorous environmental testing. In military applications, our moulds have produced housings for communication devices operating in extreme temperatures and shock conditions, where material integrity and dimensional stability are mission-critical.

The table below outlines key properties of common injection moulding plastics and the corresponding precision requirements during tooling design and manufacturing.

| Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Shrinkage Rate (%) | Critical Tooling Consideration |

|---|---|---|---|---|

| ABS | 40–50 | 95–105 | 0.4–0.9 | Uniform wall thickness control; precise venting |

| PC | 55–75 | 135–140 | 0.6–0.8 | Balanced flow, low shear gating |

| Nylon 6 | 70–85 | 180–190 (annealed) | 0.7–1.5 | Moisture compensation; thermal stability |

| POM | 60–70 | 110–130 | 1.8–2.5 | High stiffness core/cavity; fast cooling |

| PP | 30–40 | 100–120 | 1.0–2.5 | Draft optimization; shrinkage prediction |

Precision in mould making is not a final step—it is embedded in every phase, from material selection to final inspection. At Wuxi Lead Precision Machinery, we bring proven expertise in high-tolerance metal fabrication to ensure that every plastic component meets the exacting standards of modern engineering.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Tooling for Injection Moulding Excellence

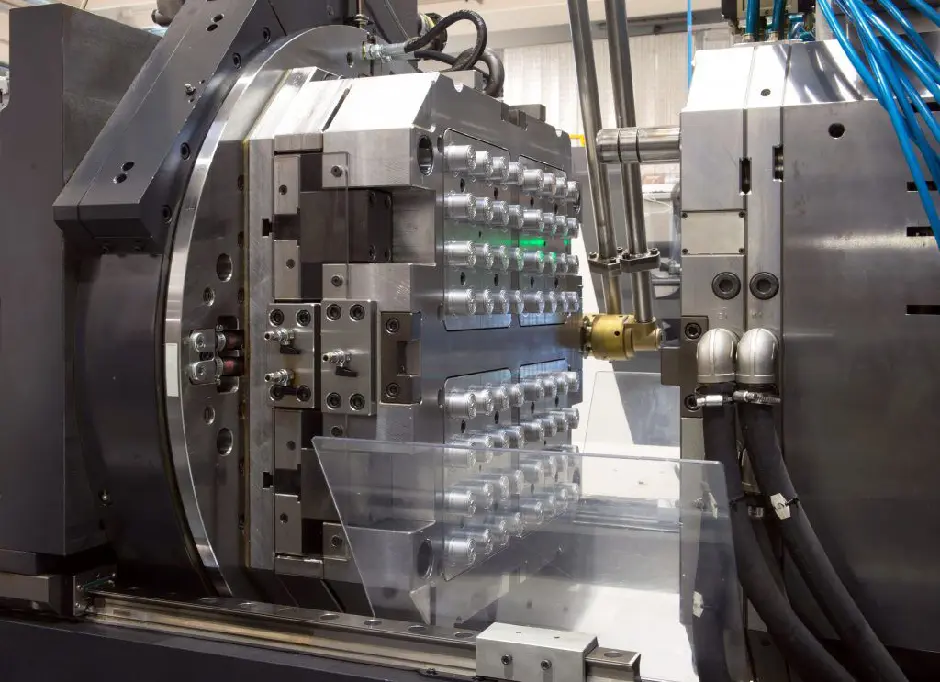

At Wuxi Lead Precision Machinery, our core expertise lies in manufacturing high-precision metal tooling and components critical to injection moulding success. While plastics form the end product, the dimensional accuracy, thermal stability, and surface integrity of the metal mould directly dictate part quality, cycle time, and production yield. We leverage advanced 5-axis CNC machining and rigorous metrology to deliver mould bases, cavities, cores, and inserts that meet the exacting demands of engineering-grade polymers like PEEK, PPS, and high-flow nylons.

Our 5-axis CNC machining centers, featuring Siemens or Fanuc controls, enable complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures, ensuring critical features—such as undercuts, conformal cooling channels, and micro-textured surfaces—achieve sub-micron repeatability. We specialize in hardened tool steels (e.g., H13, S136) and wear-resistant alloys, maintaining tight tolerances even during extended production runs. Integrated high-speed machining minimizes thermal distortion, preserving the dimensional stability required for thin-wall moulding and multi-cavity precision. Crucially, our processes account for polymer-specific factors: thermal expansion coefficients during mould design, gate vestige control, and venting precision to prevent flash or short shots in high-viscosity materials.

Quality validation is non-negotiable. Every component undergoes 100% inspection via Zeiss or Hexagon CMM systems, operating in temperature-controlled environments (20±0.5°C). Our metrology protocol exceeds ISO 10360 standards, utilizing calibrated probes and advanced software (e.g., CALYPSO) to verify form, position, and surface roughness. For mould alignment features and cavity/core interfaces, we validate perpendicularity and parallelism to ≤0.003 mm, ensuring zero mould shift during high-tonnage clamping. This granular inspection data is provided in comprehensive reports, enabling proactive adjustments before mould trials—reducing scrap rates and accelerating time-to-market.

The table below summarizes achievable tolerances for critical mould features, validated through our CMM-driven quality system:

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Cavity/Core Dimensions | ±0.005 mm | CMM (5-axis probing) |

| Ejector Pin Bores | H6/g6 (±0.002 mm) | CMM + air gaging |

| Alignment Bushings | ±0.002 mm | CMM with thermal compensation |

| Parting Line Flatness | ≤0.003 mm | CMM + optical flat |

| Cooling Channel Position | ±0.01 mm | CMM (3D trajectory scan) |

This precision foundation enables consistent replication of intricate plastic part geometries, from medical connectors requiring ±0.025 mm tolerances to automotive under-hood components demanding thermal resilience. By controlling metal tooling at the micron level, we directly mitigate common plastic defects: sink marks from uneven cooling, warpage from residual stress, and dimensional drift in hygroscopic resins. Partner with Wuxi Lead to transform polymer potential into production reality—where metal accuracy defines plastic perfection.

Material & Finish Options

Material Selection for High-Precision Injection Moulding Components

In the production of high-performance injection moulding tools and components, material selection is a critical engineering decision that directly influences tool life, dimensional stability, surface finish quality, and overall manufacturing efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of the injection moulding industry. Our expertise spans the use of aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume moulds due to their excellent machinability and thermal conductivity. These properties allow for faster cooling cycles and reduced lead times during tool development. While aluminum lacks the wear resistance of steel, its lightweight nature and ease of fabrication make it ideal for rapid iteration and short production runs. When enhanced with hard anodizing, aluminum components achieve improved surface hardness and corrosion resistance, extending service life in aggressive environments.

Steel remains the standard for high-volume injection moulding applications. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and thermal stability. These materials withstand thousands to millions of cycles without significant degradation, making them suitable for large-scale manufacturing. Steel moulds can be precision-machined to tight tolerances and further treated with surface coatings or polishing to achieve optical-grade finishes. For corrosive resins such as PVC or PET, stainless variants like 420 or S136 stainless steel are recommended to prevent pitting and maintain surface integrity.

Titanium, though less common, is gaining traction in specialized applications where extreme durability, high strength-to-density ratio, and resistance to thermal deformation are paramount. While significantly more expensive and challenging to machine, titanium offers exceptional performance in high-temperature environments and corrosive resin processing. Its use is typically reserved for critical, long-life components in aerospace or medical moulding applications.

Surface finishing plays an equally important role in mould performance. Anodizing, particularly hard anodizing, is a key process for aluminum components. This electrochemical treatment creates a durable, non-conductive oxide layer that enhances wear and corrosion resistance. The resulting surface can achieve hardness values up to 60 HRC, rivaling some tool steels. Anodized layers are also electrically insulating, which is beneficial in applications involving electrical discharge machining (EDM) or static-sensitive environments.

Below is a comparative overview of key material properties relevant to injection moulding component manufacturing.

| Material | Typical Grade | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Primary Use Case |

|---|---|---|---|---|---|

| Aluminum | 7075-T6 | 15–20 | 570 | 130 | Prototyping, low-volume production |

| Steel | P20 / H13 | 28–52 | 900–1,200 | 30–40 | High-volume, durable mould tools |

| Stainless Steel | S136 / 420 | 48–54 | 1,000–1,400 | 20–25 | Corrosion-resistant, high-polish tools |

| Titanium | Ti-6Al-4V | 36–40 | 900–1,100 | 7 | High-temp, aerospace, medical |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on application demands, production scale, and cost-efficiency targets. Our advanced CNC machining and surface treatment capabilities ensure that every component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision Injection Molding Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we engineer metal molds for high-integrity plastic components, demanding absolute precision from initial concept through mass production. Our Zero Defects methodology is embedded within a rigorously controlled three-stage workflow, ensuring every mold cavity delivers consistent, flawless parts for demanding industrial applications. Understanding the behavior of common thermoplastics is fundamental to this process, directly influencing mold steel selection, thermal management, and cavity geometry.

Design: Material Science Meets Engineering Precision

The foundation is a deep analysis of the target plastic’s properties. We collaborate closely with clients to define material specifications, considering flow characteristics, shrinkage rates, thermal stability, and end-use requirements. This data drives Finite Element Analysis (FEA) simulations, predicting melt flow, potential weld lines, sink marks, and internal stresses within the part before metal is cut. Critical mold features – gate location, cooling channel layout, venting strategy, and ejection systems – are optimized using this virtual prototyping. Material-specific tolerances are strictly applied to the mold’s core, cavity, and critical inserts, ensuring the steel geometry compensates for inherent plastic behavior. This phase eliminates theoretical defects at the source.

Prototyping: Validated Performance Under Real Conditions

A single-cavity prototype mold, crafted from hardened tool steel using our 5-axis CNC machining centers, undergoes rigorous validation. We process the actual production resin under precisely controlled parameters. Cavity pressure and temperature sensors provide real-time data, confirming simulation accuracy and identifying micro-defects invisible to the naked eye. Short shots, flash points, and dimensional deviations are measured against CAD models using CMMs. Crucially, we analyze how the plastic interacts with the metal mold surface under cycle. Any variance triggers immediate mold steel correction – not process adjustment – adhering to our principle that the mold must be perfect. This empirical validation ensures the final multi-cavity tool replicates only proven, defect-free performance.

Mass Production: Sustained Excellence Through Closed-Loop Control

Full-scale production commences only after prototype validation confirms Zero Defects capability. Our multi-cavity molds, built with premium P20, H13, or stainless steels, integrate advanced process monitoring. Real-time cavity pressure curves, melt temperature stability, and clamp force profiles are continuously compared against the validated prototype baseline. Statistical Process Control (SPC) charts track critical part dimensions, triggering automatic machine shutdown at the first sign of drift. Every mold undergoes scheduled maintenance based on actual cycle counts, not time, with wear points meticulously inspected and refurbished using our in-house EDM and polishing capabilities. This closed-loop system guarantees that the millionth part meets the same exacting standard as the first.

Material selection directly impacts mold longevity and part quality. Key plastic properties influencing our precision mold design include:

| Plastic Material | Typical Shrinkage Rate (%) | Melt Temperature Range (°C) | Key Processing Challenge |

|---|---|---|---|

| ABS | 0.4 – 0.9 | 210 – 250 | Moisture sensitivity; warpage control |

| Polypropylene (PP) | 1.0 – 2.5 | 200 – 300 | High shrinkage; weld line strength |

| Polycarbonate (PC) | 0.6 – 0.8 | 260 – 310 | High viscosity; moisture drying critical |

| Nylon 6/6 | 0.7 – 1.5 | 260 – 290 | Hygroscopic; variable shrinkage |

| Polyethylene (HDPE) | 1.5 – 4.0 | 220 – 260 | Very high shrinkage;翘曲 control |

This integrated approach – where material science, precision metal manufacturing, and real-time process analytics converge – is how Wuxi Lead delivers injection molds that consistently produce zero-defect plastic components, cycle after cycle, for the world’s most exacting manufacturers.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Moulding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components engineered to meet the exacting demands of modern injection moulding applications. Our expertise extends beyond standard manufacturing—we integrate advanced CNC machining, tooling design, and material science to produce moulds and components that enhance performance, durability, and production efficiency. As a trusted partner in the global manufacturing ecosystem, we understand the critical role that material selection plays in achieving optimal part quality and process reliability.

Injection moulding success begins with the right combination of material properties and precision-engineered tooling. Our engineering team collaborates closely with clients to analyze application requirements, cycle times, thermal stability, and mechanical loads, ensuring that every component we produce aligns with your production goals. Whether you are working with commodity resins or high-performance polymers, our manufacturing solutions are designed to support consistent, repeatable results at scale.

We recognize that material compatibility with mould surfaces, cooling efficiency, and wear resistance directly impact tool life and part quality. That is why our custom metal components are manufactured using premium-grade alloys and treated with advanced surface technologies to resist corrosion, abrasion, and thermal fatigue. By integrating precision engineering with deep materials knowledge, we help you reduce downtime, minimize maintenance, and achieve tighter tolerances across high-volume production runs.

Below is a reference table outlining key properties of common injection moulding plastics we routinely support in tooling and component design:

| Plastic Material | Tensile Strength (MPa) | Heat Deflection Temp (°C) | Shrinkage Rate (%) | Typical Applications |

|---|---|---|---|---|

| ABS | 40–50 | 95–105 | 0.4–0.7 | Consumer electronics, automotive trims |

| Polycarbonate (PC) | 55–75 | 130–140 | 0.6–0.8 | Safety shields, optical lenses |

| Polypropylene (PP) | 30–40 | 100–120 | 1.0–2.5 | Packaging, medical devices |

| Polyethylene (PE) | 20–30 | 70–90 | 1.5–4.0 | Containers, industrial fittings |

| Nylon (PA6/PA66) | 70–85 | 180–220 | 0.7–1.5 | Gears, structural components |

| POM (Acetal) | 60–70 | 110–140 | 1.8–2.5 | Precision gears, fasteners |

| PEEK | 90–100 | 260–300 | 0.8–1.5 | Aerospace, medical implants |

These material characteristics directly influence mould design, cooling channel layout, and ejection systems—all areas where our engineering team adds measurable value. We utilize simulation software and real-time process data to optimize tool geometry and surface finish, ensuring compatibility with your selected resin.

For manufacturers seeking a strategic partner in precision metal components for injection moulding, Wuxi Lead Precision Machinery offers unmatched technical depth and global delivery capability. Contact us today at [email protected] to discuss your next project with our engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.