Technical Contents

Engineering Guide: Rapid 3D Printing Service

Engineering Insight Precision in Rapid 3D Printing Services

In high-stakes metal manufacturing, rapid 3D printing transcends mere speed. True value emerges when accelerated production cycles converge with uncompromising dimensional accuracy and material integrity. For critical aerospace, defense, and advanced industrial applications, tolerances measured in tenths of a millimeter directly impact performance, safety, and regulatory compliance. At Wuxi Lead Precision Machinery, we recognize that rapid prototyping and low-volume production demand precision equivalent to traditional subtractive methods—not as an aspiration, but as a non-negotiable baseline. Speed without accuracy creates costly iterations, not solutions.

Our engineering approach integrates metrology-grade validation directly into the metal additive workflow. Every build undergoes rigorous in-process monitoring and post-build verification using calibrated coordinate measuring machines (CMM) and optical scanners traceable to national standards. This ensures geometric conformity and material properties meet stringent specifications from the first layer to the finished component. This discipline is forged through proven experience delivering mission-critical parts where failure is not an option. We supplied precision titanium structural nodes for the National Ski Jumping Centre at the Beijing 2022 Winter Olympics, components subjected to extreme thermal cycling and dynamic loads requiring sub-0.1mm deformation tolerance. Similarly, our certified production lines consistently meet the exacting dimensional and non-destructive testing (NDT) requirements for classified defense programs, where component integrity is paramount.

Rapid metal 3D printing achieves its highest utility when geometric complexity, material efficiency, and certified precision operate in unison. Below are key performance specifications achievable across our industrial-grade metal additive systems for common engineering alloys:

| Material | Standard Build Tolerance | Typical Surface Finish (As-Built) | Minimum Feature Size | Max Build Envelope (mm) |

|---|---|---|---|---|

| Titanium Ti-6Al-4V | ±0.05 mm | Ra 12.5 μm | 0.4 mm | 250 x 250 x 300 |

| Aluminum AlSi10Mg | ±0.07 mm | Ra 15.0 μm | 0.5 mm | 250 x 250 x 325 |

| Stainless Steel 17-4PH | ±0.06 mm | Ra 10.0 μm | 0.3 mm | 250 x 250 x 350 |

| Inconel 718 | ±0.08 mm | Ra 18.0 μm | 0.6 mm | 250 x 250 x 300 |

These specifications reflect our standard production capability under controlled environmental conditions with validated post-processing protocols. Achieving Olympic and military-grade reliability requires more than advanced hardware; it demands a culture where process validation, material science expertise, and continuous metrology define every build. For engineering teams facing compressed development timelines, partnering with a provider that treats precision as the core deliverable—not a secondary concern—eliminates the hidden costs of rework and accelerates time-to-value. When your application demands parts that perform as designed, from prototype to production, dimensional certainty is the foundation upon which speed delivers real advantage. Wuxi Lead Precision Machinery delivers rapid metal 3D printing where accuracy is never sacrificed for velocity.

Precision Specs & Tolerances

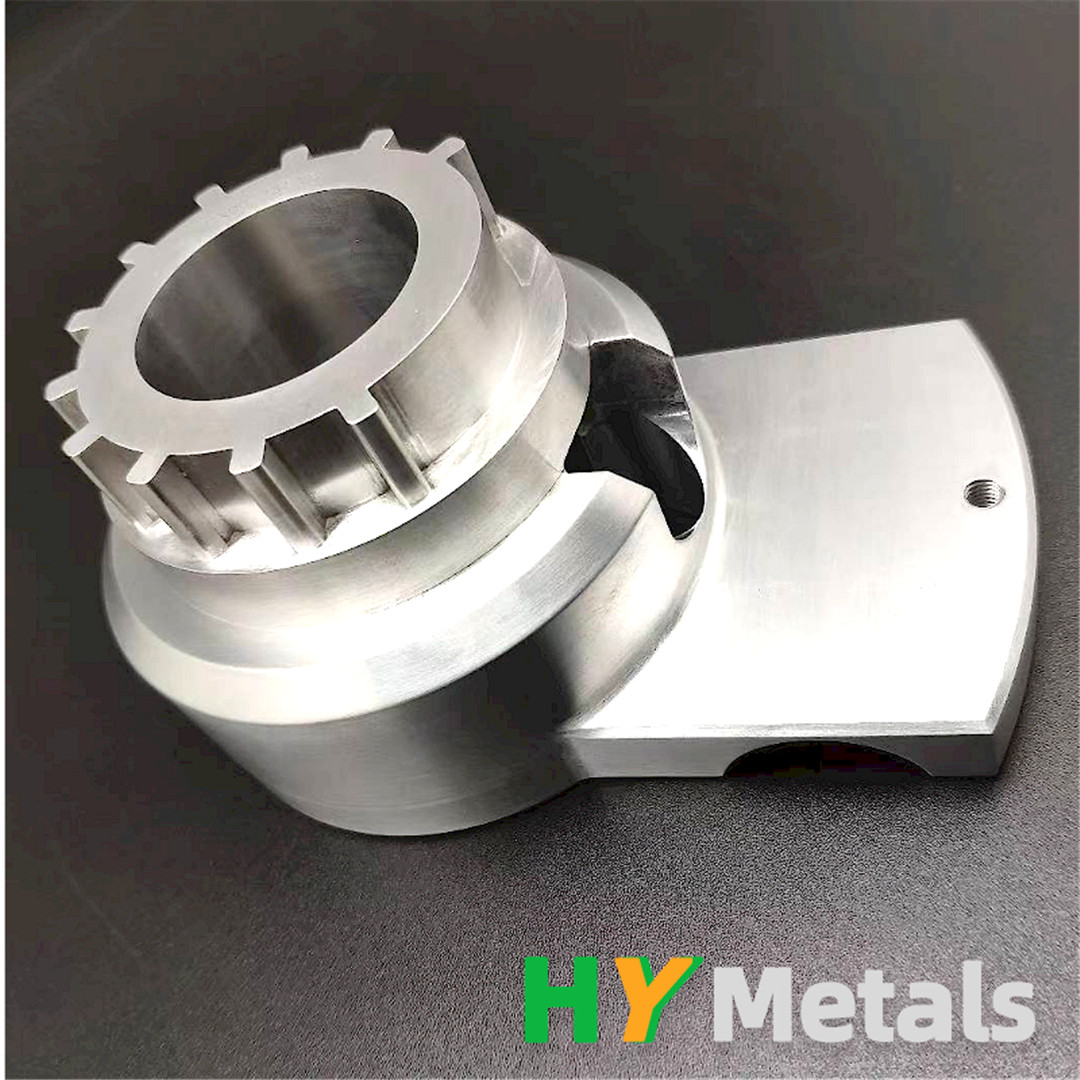

Wuxi Lead Precision Machinery delivers advanced rapid 3D printing services integrated with high-precision metal manufacturing to meet the demanding requirements of aerospace, medical, automotive, and industrial clients. Our technical capabilities combine additive manufacturing with secondary precision processes, ensuring parts not only achieve complex geometries but also meet stringent performance and quality standards. At the core of our production workflow is the integration of 5-axis CNC machining, which allows for the precise finishing of 3D printed metal components. This hybrid approach enables us to produce fully functional, end-use parts with superior surface integrity, dimensional accuracy, and mechanical properties.

Our rapid 3D printing service utilizes state-of-the-art metal additive technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS), supporting a wide range of engineering-grade alloys such as stainless steel, titanium, aluminum, and Inconel. These processes allow for rapid prototyping and low-volume production with minimal material waste and high design flexibility. However, additive manufacturing alone often leaves parts with surface roughness and minor dimensional deviations. To address this, every critical component undergoes post-processing on our 5-axis CNC machining centers. These multi-axis systems provide simultaneous movement across X, Y, Z, A, and B axes, enabling complex contouring, tight tolerance machining, and access to hard-to-reach features without the need for multiple setups. This ensures consistent part accuracy and repeatability, especially for components with intricate internal channels, undercuts, or organic geometries.

Quality assurance is embedded throughout our manufacturing process. All finished components are subject to comprehensive inspection using a Coordinate Measuring Machine (CMM), which verifies geometric dimensions and tolerances (GD&T) with micron-level precision. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 and AS9100 requirements. This rigorous inspection protocol guarantees that every part meets or exceeds customer specifications before shipment.

The following table outlines the standard tolerances achievable through our combined rapid 3D printing and 5-axis CNC finishing process:

| Feature | Standard Tolerance | Precision Capability (Optional) |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm |

| Hole Diameter | ±0.06 mm | ±0.03 mm |

| Positional Tolerance | ±0.05 mm | ±0.02 mm |

| Flatness | 0.05 mm | 0.02 mm |

| Surface Roughness (as-machined) | Ra 1.6 µm | Ra 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

By combining rapid 3D printing with high-precision 5-axis CNC machining and rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures that every custom metal part is manufactured to the highest industrial standards. This integrated capability allows us to deliver complex, mission-critical components with speed, accuracy, and full traceability.

Material & Finish Options

Material Selection for Industrial Metal Additive Manufacturing

Selecting optimal materials for rapid metal 3D printing requires balancing mechanical properties, environmental resistance, and post-processing capabilities. At Wuxi Lead Precision Machinery, we prioritize materials that deliver repeatability in high-stress applications while supporting secondary operations like precision CNC finishing. Aluminum alloys excel in weight-sensitive aerospace and automotive components where thermal conductivity and fatigue resistance are critical. Steel variants, particularly maraging and stainless grades, provide exceptional tensile strength and wear resistance for tooling, hydraulic systems, and structural parts operating under extreme loads. Titanium alloys dominate medical implants and defense applications due to their unmatched strength-to-weight ratio, biocompatibility, and corrosion resistance in saline or high-temperature environments.

Material performance must align with functional requirements. Below is a comparative specification table for common industrial alloys used in our laser powder bed fusion processes. All values reflect post-processed (stress-relieved and HIP-treated) properties per ASTM F3301 standards.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 480 | 280 | 8 | Moderate | Enclosures, heat exchangers |

| 17-4 PH Stainless | 7.75 | 1300 | 1150 | 12 | High (passivated) | Molds, valve components |

| Ti6Al4V (Grade 5) | 4.43 | 950 | 880 | 10 | Exceptional | Aircraft brackets, implants |

Surface finish selection directly impacts part longevity and performance. Anodizing remains the gold standard for aluminum components requiring enhanced wear resistance and electrical insulation. We implement Type II (sulfuric acid) anodizing for general-purpose corrosion protection with dye options for identification, and Type III (hardcoat) anodizing for critical wear surfaces like hydraulic pistons or drone landing gear. Hardcoat anodizing achieves 50–70 μm thickness with surface hardness exceeding 60 HRC, significantly extending service life in abrasive environments. For steel and titanium, we recommend alternative finishes: electropolishing for burr-free medical devices, or passivation per ASTM A967 for stainless steel to maximize oxide layer integrity. Titanium benefits from thermal oxidation treatments to boost surface hardness without dimensional change.

Wuxi Lead integrates material science with precision post-processing. Our engineers collaborate to match substrate properties with finish requirements—ensuring anodized layers adhere flawlessly to AlSi10Mg’s silicon-rich microstructure or that titanium’s oxygen diffusion zone complements its base fatigue strength. This holistic approach guarantees parts meet ISO 2768-mK tolerances while surviving mission-critical operational demands. Consult our technical team to validate material-finish pairings for your specific load, temperature, and regulatory constraints.

Manufacturing Process & QC

From Concept to Consistent Quality: The Wuxi Lead Precision Production Process

At Wuxi Lead Precision Machinery, our rapid 3D printing service is engineered for high-end industrial clients who demand precision, speed, and zero-defect outcomes in custom metal manufacturing. Our structured production workflow—spanning design validation, functional prototyping, and seamless transition to mass production—ensures every component meets exacting standards from first concept to final delivery.

The process begins with collaborative design engineering. Our team works directly with client CAD models, performing comprehensive design for additive manufacturing (DfAM) analysis. This step optimizes part geometry for structural integrity, material efficiency, and printability, reducing stress concentrations and minimizing post-processing needs. We assess wall thicknesses, overhangs, and support structures to ensure dimensional accuracy and surface quality, laying the foundation for defect-free production.

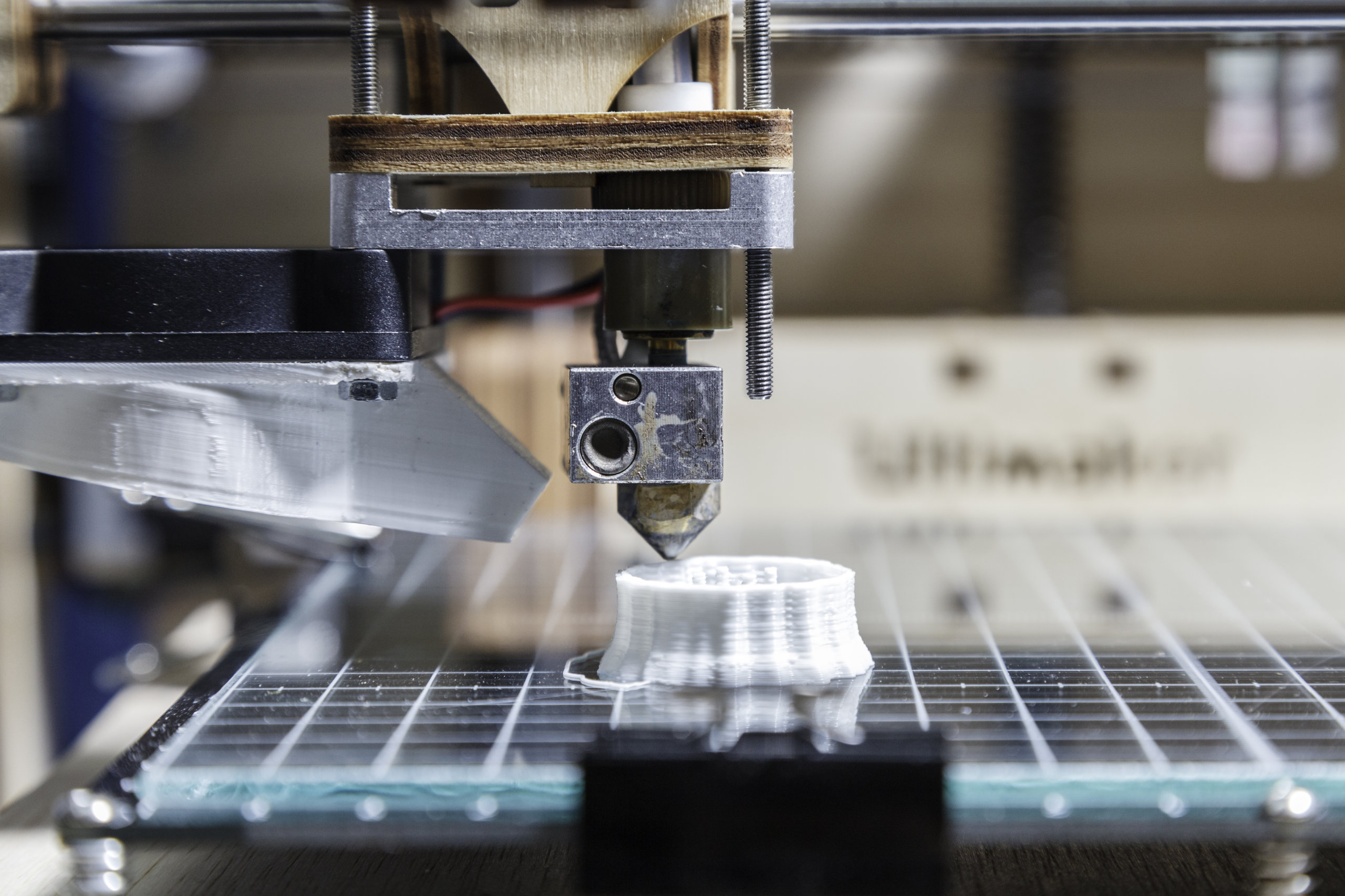

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art metal additive systems. Utilizing laser powder bed fusion (LPBF) technology, we produce fully dense, high-strength metal prototypes in materials such as 316L stainless steel, Inconel 718, Ti-6Al-4V, and AlSi10Mg. These prototypes are not merely visual models—they are functionally validated under real-world conditions, enabling performance testing, fit checks, and design iteration within days, not weeks. Each prototype undergoes rigorous metrology, including CMM and 3D scanning, to verify conformance to specifications.

Upon client approval, we transition directly into scalable mass production. Our digital manufacturing platform allows for batch production with full traceability and consistent process parameters. Each build is monitored in real time using in-situ sensors and layer-wise imaging to detect anomalies, ensuring every part meets the same standard as the approved prototype. Post-processing—including stress relieving, support removal, heat treatment, and precision machining—is performed in-house under controlled conditions, maintaining tight tolerances and surface finishes.

Quality is embedded at every stage. Our ISO 9001-certified processes, combined with a zero-defect philosophy, mean that every component is inspected, documented, and validated. We implement statistical process control (SPC) and first-article inspection (FAI) protocols to guarantee repeatability across production runs, regardless of volume.

This integrated approach—design precision, rapid iteration, and defect-free scaling—makes Wuxi Lead the preferred partner for aerospace, medical, and high-performance industrial clients who cannot afford compromise.

Rapid 3D Printing Service Specifications

| Parameter | Specification |

|---|---|

| Technology | Laser Powder Bed Fusion (LPBF) |

| Materials | 316L, Inconel 718, Ti-6Al-4V, AlSi10Mg, Tool Steel |

| Build Volume | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 10–15 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing |

| Quality Standards | ISO 9001, FAI, SPC, 100% dimensional inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Additive Manufacturing

In high-stakes industrial sectors where component failure is not an option, your rapid 3D printing service must deliver more than speed. It requires metallurgical integrity, repeatable precision, and seamless integration into your production ecosystem. Wuxi Lead Precision Machinery transcends basic prototyping to provide certified, production-ready metal additive manufacturing solutions engineered for aerospace, medical device, and energy applications. We eliminate the traditional trade-off between accelerated development cycles and uncompromised part performance. Our integrated approach combines German-engineered EOS and SLM systems with in-house metallurgical analysis and AS9100-certified quality control, ensuring every printed component meets stringent aerospace and medical standards from the first layer to final inspection. This is not rapid prototyping—it is rapid production with zero tolerance for deviation.

Our technical capabilities are built for demanding industrial realities. The table below details core specifications for our metal additive service:

| Parameter | Capability | Industrial Relevance |

|---|---|---|

| Supported Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr, Maraging Steel | Full biocompatibility and high-temp alloys |

| Build Volume | Up to Ø250 x 325 mm (EOS M400-4) | Complex assemblies in single build |

| Dimensional Accuracy | ±0.05 mm per 100 mm | Eliminates secondary machining for critical features |

| Surface Roughness (as-built) | Ra 8-12 μm | Optimized for functional testing |

| Post-Processing | HIP, stress relief, precision CMM | Ensures fatigue resistance and certification |

| Lead Time (Production) | 7-10 days for qualified parts | Accelerates time-to-market without QA risk |

Partnering with Lead Precision means embedding manufacturing expertise directly into your engineering workflow. Our application engineers collaborate from initial design review through to serial production, optimizing topology, support structures, and thermal management to prevent porosity and distortion. Unlike commodity 3D printing services, we provide full material traceability, SLM process parameter validation, and metallurgical reports meeting AMS 7000 standards. This depth of technical partnership mitigates supply chain risk while ensuring your printed components perform identically to traditionally manufactured counterparts—critical for FAA Part 145 or ISO 13485 compliance. Our Wuxi facility operates under ISO 9001 and IATF 16949 frameworks, with real-time production monitoring accessible via secure client portal.

The future of metal manufacturing demands partners who treat additive not as a novelty but as a precision engineering discipline. When your project requires parts that withstand 1,000°C combustion environments or human implantation, compromise is unacceptable. Initiate your production-critical project with engineers who speak your technical language and deliver certified results. Contact our additive manufacturing team directly at [email protected] to submit your CAD files and receive a process-specific feasibility assessment within 24 hours. Let us demonstrate how Lead Precision transforms rapid 3D printing from a prototyping tool into your most reliable production asset. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.