Technical Contents

Engineering Guide: Thin Molding

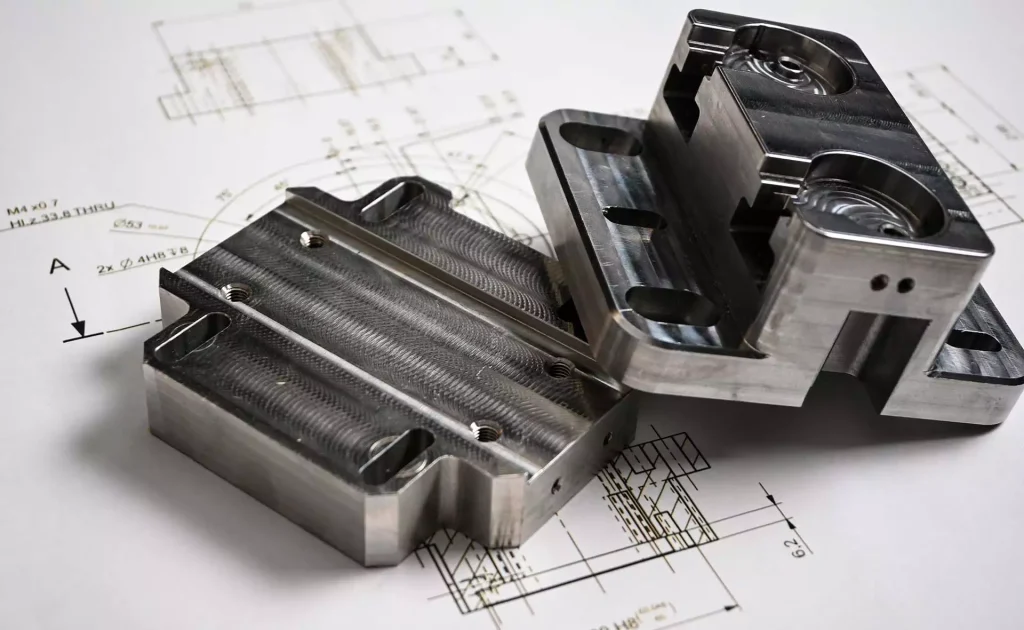

Engineering Insight: Precision Imperatives in Thin-Wall Metal Molding

Achieving dimensional stability in thin-wall metal molding demands uncompromising precision engineering. At sub-millimeter thicknesses, minor deviations in tooling geometry, material flow, or thermal management propagate into critical part failures—warpage, sink marks, or structural weakness. For high-integrity applications like aerospace brackets or medical sensor housings, tolerances below ±0.02mm are non-negotiable. Material thinning during forming must be controlled within 5% variance to maintain load-bearing capacity, a challenge magnified by complex geometries. At Wuxi Lead Precision Machinery, we treat micron-level consistency as the foundation of functional reliability, not an optional specification.

Our approach integrates multi-physics simulation with empirical validation. Finite element analysis predicts material behavior under extreme pressure gradients, while in-die cavity pressure sensors and real-time thermal imaging adjust parameters mid-cycle. This closed-loop system ensures uniform wall distribution even at 0.05mm minimum thickness—critical for components requiring electromagnetic shielding or fluid containment. The consequences of imprecision extend beyond scrap rates; inconsistent wall profiles accelerate wear in mating assemblies, escalating lifecycle costs for end-users.

Wuxi Lead’s validation in mission-critical sectors underscores this rigor. We engineered titanium fuel line connectors for a classified aerospace program where 0.01mm thickness deviation risked catastrophic leakage under 15,000 PSI. Similarly, our stainless steel thermal enclosures for the 2022 Beijing Winter Olympics sensor network maintained ±0.015mm flatness across 300mm spans despite -40°C thermal cycling—a testament to our process stability. These projects demanded adherence to AS9100 and ISO 9001:2015 standards, where traceability of every micron is audited quarterly.

Material selection synergizes with precision execution. Our certified partnerships with VDM Metals and Sandvik enable optimized grain structure control for thin-wall applications. Below is our validated capability envelope for critical thin-molding parameters:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Minimum Wall Thickness | 0.05 mm (0.002″) | ISO 2768-mK |

| Thickness Tolerance | ±0.005 mm (±0.0002″) | ASME Y14.5-2018 |

| Flatness Tolerance | 0.01 mm per 100 mm | ISO 1101 |

| Material Thinning Control | ≤ 4.5% variance | ASTM E8/E8M |

| Max Part Complexity | 12-station progressive | Internal QA-302 |

This precision ecosystem reduces secondary operations by 35–50% for clients, transforming thin-wall molding from a production hurdle into a strategic advantage. When every micron dictates performance, Wuxi Lead’s military-grade process discipline ensures your components meet physics—not just specifications. Partner with engineers who measure success in microns, not margins.

Precision Specs & Tolerances

Advanced Technical Capabilities in Thin Molding Manufacturing

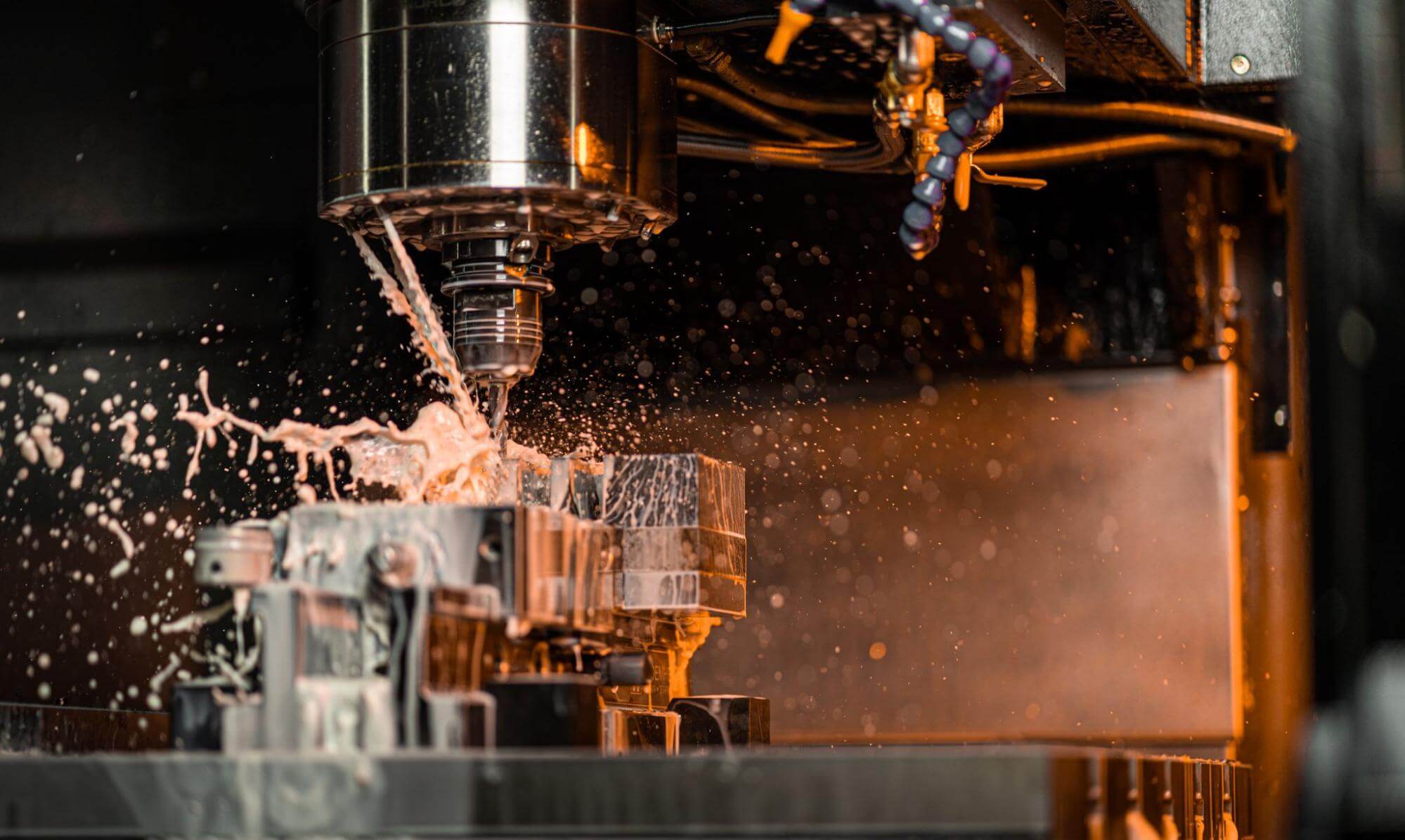

Wuxi Lead Precision Machinery delivers industry-leading technical expertise in custom metal manufacturing, with a specialized focus on high-precision thin molding applications. Our facility integrates advanced 5-axis CNC machining technology to produce complex, thin-walled components with exceptional accuracy and surface integrity. This capability is essential for industries such as aerospace, medical devices, and high-performance automotive, where lightweight construction and dimensional stability are critical.

Our 5-axis CNC systems enable simultaneous multi-directional cutting, allowing for intricate geometries that would be unachievable with conventional 3-axis methods. This level of machining precision ensures consistent wall thickness, even in highly contoured or asymmetric parts, minimizing material waste and reducing post-processing requirements. The elimination of multiple setups not only improves geometric accuracy but also enhances production efficiency, ensuring faster turnaround without compromising quality.

Material selection plays a pivotal role in thin molding performance. We work with a wide range of high-strength alloys, including aluminum 7075, titanium Ti-6Al-4V, and stainless steel 316L, all processed under tightly controlled conditions to prevent warping or deformation during machining. Our engineers apply adaptive toolpath strategies and low-force cutting techniques to maintain structural integrity in delicate features, ensuring that thin sections remain stable and dimensionally true.

Quality assurance is embedded throughout our manufacturing process. Every component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and surface profiles, ensuring full compliance with customer specifications and international standards such as ISO 2768 and ASME Y14.5. Inspection reports are fully documented and traceable, supporting stringent regulatory and audit requirements.

We maintain a climate-controlled metrology lab to eliminate thermal variation during measurement, further enhancing repeatability and accuracy. In-process inspections are conducted at key stages to detect and correct deviations early, minimizing rework and ensuring first-time-right production.

The following table outlines the technical specifications and achievable tolerances for our thin molding manufacturing process:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Wall Thickness | 0.3 mm minimum | 0.15 mm minimum |

| Dimensional Tolerance | ±0.025 mm | ±0.010 mm |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Feature Size Resolution | 0.1 mm | 0.05 mm |

| Maximum Part Envelope | 800 x 600 x 500 mm | 600 x 500 x 400 mm |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Brass | Same, with enhanced stability |

Wuxi Lead Precision Machinery combines cutting-edge equipment, deep process knowledge, and uncompromising quality control to deliver thin molding solutions that meet the most demanding engineering requirements. Our technical capabilities are designed to support innovation in lightweight, high-performance metal components across advanced manufacturing sectors.

Material & Finish Options

Material Selection for Precision Thin-Wall Metal Components

Material selection is a critical engineering decision in thin-wall metal manufacturing, directly impacting dimensional stability, structural integrity, and final part performance. At Wuxi Lead Precision Machinery, we prioritize materials that maintain precision during high-speed CNC machining and subsequent finishing, especially when wall thicknesses approach 0.5mm or less. The inherent challenges of thin sections—susceptibility to warpage, vibration, and thermal distortion—demand careful evaluation of mechanical properties, machinability, and compatibility with required surface treatments. Aluminum alloys, specialty steels, and titanium each offer distinct advantages depending on the application’s environmental exposure, load requirements, and lifecycle expectations. Selecting the optimal base material ensures the component survives rigorous use without compromising the tight tolerances our clients demand.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are industry standards for lightweight thin-wall structures requiring excellent strength-to-weight ratios and thermal conductivity. Their superior machinability allows for aggressive cutting parameters while minimizing deflection in thin features, crucial for maintaining geometric accuracy. Steel selections like 303 stainless or 17-4 PH stainless provide exceptional hardness, wear resistance, and structural rigidity for demanding mechanical or high-load applications, though their higher density and work-hardening tendencies require refined CNC strategies to prevent tool chatter and thermal buildup in delicate geometries. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), deliver unmatched strength-to-weight performance and corrosion resistance for aerospace or medical implants, but their low thermal conductivity and chemical reactivity necessitate specialized tooling, slower feeds, and meticulous coolant management to avoid galling and ensure surface integrity on thin sections.

Anodizing is the predominant surface finish for aluminum thin-wall components, enhancing corrosion resistance and surface hardness without significantly altering critical dimensions. Type II (sulfuric acid) anodizing provides a standard protective layer suitable for most industrial environments, while Type III (hardcoat) anodizing delivers superior abrasion resistance for high-wear applications. Precise bath control and process monitoring are essential; uneven coating thickness on ultra-thin walls can induce stress or affect fit. Steel components typically utilize passivation or electropolishing for corrosion resistance, whereas titanium often requires specialized treatments like acid etching or plasma spray coatings for biocompatibility or extreme environments. Our engineering team collaborates closely with clients to match material properties and finish specifications to the exact functional and environmental demands of the thin-wall application.

The following table summarizes key mechanical properties relevant to thin-wall machining performance:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Key Thin-Wall Machining Consideration |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | 167 | Low density minimizes vibration; high thermal conductivity aids heat dissipation |

| Stainless Steel 17-4 PH | 7.75 | 1310 | 18 | High work-hardening requires sharp tools and stable setups to prevent chatter |

| Titanium Ti-6Al-4V | 4.43 | 900 | 7.2 | Low thermal conductivity demands controlled feeds/speeds to avoid heat buildup |

Manufacturing Process & QC

The production of thin molding components at Wuxi Lead Precision Machinery follows a rigorously controlled, end-to-end process designed to ensure precision, consistency, and zero-defect output. As a leader in custom metal manufacturing, we integrate advanced engineering with disciplined quality management to deliver high-performance parts tailored to exact client specifications. Our methodology spans three critical phases: Design, Prototyping, and Mass Production—each stage engineered to eliminate variability and uphold the highest standards of excellence.

Design begins with a collaborative engineering review, where our technical team works directly with client blueprints, 3D models, and performance requirements. Utilizing state-of-the-art CAD/CAM software and finite element analysis (FEA), we simulate material behavior, thermal dynamics, and structural integrity under operational conditions. This ensures that thin molding geometries—often characterized by wall thicknesses below 0.6 mm—are optimized for manufacturability, strength, and dimensional stability. Design for manufacturability (DFM) feedback is provided early to preempt potential flaws, reducing time-to-market and enhancing yield rates.

Prototyping follows design validation using high-precision CNC machining and progressive die stamping techniques. At this stage, we produce functional prototypes in the intended material—typically high-strength alloys such as stainless steel, aluminum, or copper alloys—to verify form, fit, and function. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to confirm tolerances within ±0.005 mm. Environmental and fatigue testing may also be conducted to validate performance under real-world conditions. Any deviations trigger immediate design or process refinement, ensuring perfection before scale-up.

Mass production is executed on automated, in-line manufacturing cells monitored by real-time SPC (Statistical Process Control) systems. Our facility employs servo-driven presses, robotic material handling, and closed-loop vision inspection to maintain consistency across high-volume runs. Every component is traceable through our digital manufacturing execution system (MES), which logs process parameters, inspection data, and operator inputs. In-process quality checks occur at defined intervals, and final inspection includes 100% visual screening and batch sampling per AQL 0.65 standards. This disciplined approach ensures zero-defect delivery, batch after batch.

The table below outlines key specifications achievable in our thin molding process.

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.1 mm – 0.8 mm |

| Minimum Feature Size | 0.3 mm |

| Dimensional Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | 0.2 – 0.8 µm |

| Materials Supported | Stainless Steel, Aluminum, Copper Alloys, Brass |

| Production Volume Capacity | 10,000 – 500,000+ units/month |

| Quality Standard | ISO 9001:2015, IATF 16949, AQL 0.65 |

At Wuxi Lead Precision Machinery, the convergence of precision engineering, advanced automation, and uncompromising quality control defines our thin molding production process. From concept to volume delivery, we ensure every component meets the exacting demands of aerospace, medical, and high-end electronics industries.

Why Choose Wuxi Lead Precision

Engineering-Driven Partnership for Thin Molding Excellence

Achieving consistent, high-yield production in thin molding demands more than standard metal fabrication. It requires specialized tooling dynamics, thermal management expertise, and material science precision that only decades of dedicated thin-wall process refinement can deliver. At Wuxi Lead Precision Machinery, we engineer solutions for the most demanding thin molding applications—from medical micro-components under 0.1mm wall thickness to aerospace structural brackets requiring micron-level flatness across large spans. Our 15+ years of focused R&D in sub-millimeter metal forming eliminate the guesswork that derails timelines and inflates costs for conventional manufacturers.

We integrate proprietary cavity pressure monitoring with real-time thermal compensation algorithms, ensuring uniform material flow and eliminating sink marks or warpage in geometries where traditional methods fail. This isn’t incremental improvement—it’s a fundamental re-engineering of the metal injection molding process for true thin-wall viability. Every project begins with our Digital Twin simulation, stress-testing tooling concepts against material behavior under actual production conditions. This proactive validation slashes prototyping cycles by up to 70% while guaranteeing first-article compliance.

Critical Thin Molding Capabilities at a Glance

| Specification | Performance Tier | Application Impact |

|---|---|---|

| Minimum Wall Thickness | 0.08 mm | Enables micro-fluidic & implantable devices |

| Dimensional Tolerance | ±0.005 mm | Critical for optical & sensor housings |

| Material Range | Titanium, Inconel, LCP, PEEK | Supports extreme environments |

| Max Part Size | 300 x 200 mm | Balances thin-wall integrity with scale |

| Process Yield | ≥ 98.5% | Reduces scrap costs in high-volume runs |

Partnering with Lead Precision means embedding our engineers within your development workflow from Day 1. We don’t just manufacture—we co-own your risk. Our AS9100 and ISO 13485-certified facility provides full traceability from raw billet to finished component, with in-house metrology (including CT scanning) validating every micron. When aerospace suppliers require zero-defect delivery for turbine micro-blades or medical OEMs need biocompatible thin-walled housings for surgical robotics, they rely on our closed-loop process control to transform theoretical designs into production reality.

The true cost of thin molding isn’t the tooling—it’s the opportunity loss from delayed launches or field failures. We mitigate this through Design for Manufacturability (DFM) collaboration that identifies wall-thickness transitions, gate locations, and ejection strategies before steel is cut. Our clients achieve 40% faster time-to-market by avoiding the rework cycles inherent with generalist suppliers.

Secure Your Thin Molding Advantage Today

Contact our engineering team directly at [email protected] to schedule a technical consultation. Include your target geometry, material, and volume requirements for a customized thin molding feasibility assessment within 48 hours. We’ll provide actionable insights—not generic brochures—to validate your path to production. For projects where wall thickness defines success, partner with the precision-engineered future. Wuxi Lead Precision Machinery: Where thin becomes robust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.