Technical Contents

Engineering Guide: Aluminum Online

Engineering Insight: Precision as the Non-Negotiable Foundation in Aluminum Manufacturing

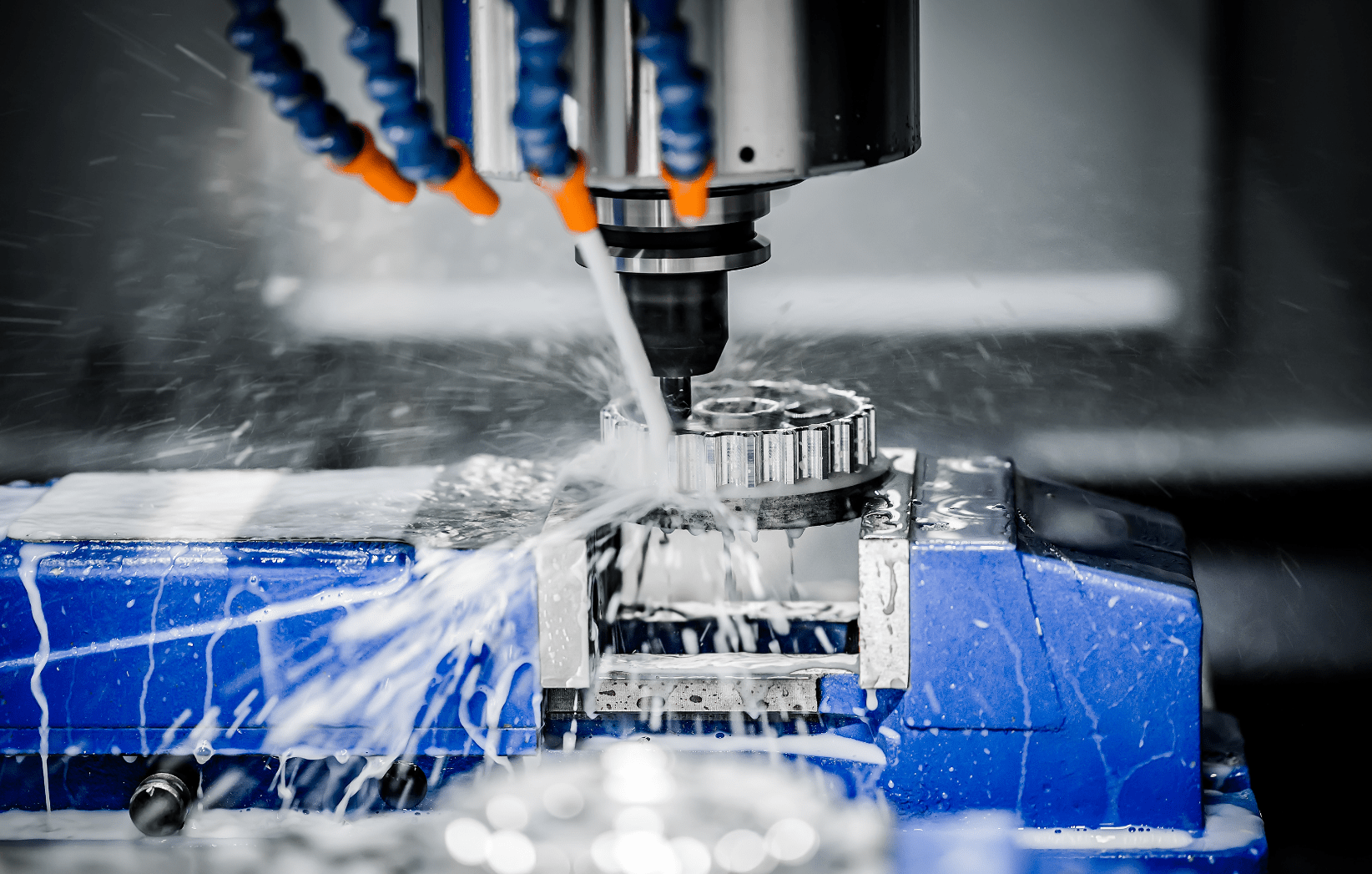

In the high-stakes realm of custom aluminum components, precision transcends mere specification – it is the absolute determinant of functional integrity, assembly success, and long-term performance. Tolerances measured in microns directly impact structural reliability, aerodynamic efficiency, thermal management, and the seamless integration of complex systems. For industries like aerospace, defense, and advanced medical equipment, where aluminum alloys dominate for their strength-to-weight ratio, even marginal deviations from nominal dimensions can cascade into catastrophic field failures, costly rework, or project delays. The inherent challenges of machining aluminum – including its thermal conductivity, tendency for built-up edge, and susceptibility to chatter-induced vibration – demand not just capable machinery, but a deeply ingrained engineering philosophy centered on process control and metrological rigor. At Wuxi Lead Precision Machinery, we recognize that true precision is not achieved through isolated high-end equipment alone, but through the meticulous orchestration of material science, thermal management, toolpath optimization, and real-time in-process verification.

Our commitment to uncompromising precision is forged in the fires of the most demanding applications. We have successfully delivered mission-critical aluminum components for Olympic infrastructure projects, where structural perfection under immense dynamic loads was non-negotiable. Similarly, our adherence to stringent military-grade specifications (including AS9100 and ITAR compliance) for defense contractors underscores our ability to consistently meet tolerances and material properties where failure is not an option. This experience translates directly to every client project, ensuring that the dimensional stability, surface finish, and geometric accuracy required for your high-performance aluminum parts are not just promised, but demonstrably achieved and rigorously validated.

Achieving micron-level consistency requires systematic control over every variable. Our integrated approach encompasses advanced 5-axis CNC machining centers operating within tightly controlled thermal environments, paired with sophisticated metrology suites featuring coordinate measuring machines (CMMs) and optical comparators. Material selection and pre-machining stress relief protocols are critical starting points. The table below outlines the core precision capabilities we bring to aluminum manufacturing:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (standard) to ±0.001 mm (critical features) | ISO 2768-mK, Custom |

| Geometric Tolerance (GD&T) | Positional: ±0.010 mm; Flatness: 0.005 mm/m | ASME Y14.5, ISO 1101 |

| Surface Roughness (Ra) | 0.4 µm (standard) to 0.1 µm (optical) | ISO 4287, ASME B46.1 |

| In-Process Metrology | Real-time probing, thermal compensation | On-machine touch probes, laser systems |

| Final Inspection | Full CMM reporting, first article inspection (FAI) | AS9102, PPAP Level 3 |

The cost of imprecision in aluminum manufacturing extends far beyond scrap rates; it erodes system performance, compromises safety margins, and damages brand reputation. Partnering with a manufacturer possessing proven, battle-tested precision capabilities – validated by projects where global prestige and national security were at stake – mitigates this risk fundamentally. Wuxi Lead Precision Machinery provides the engineering depth, process discipline, and metrological authority to transform your most demanding aluminum designs into reality, with guaranteed dimensional fidelity. Discuss your specific precision challenges with our engineering team to secure the foundation your application demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of aerospace, medical, automotive, and industrial technology sectors. At the core of our technical capabilities is a state-of-the-art 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional accuracy and surface finish. Our multi-axis machining centers provide simultaneous motion across all five axes, allowing for intricate contouring, undercuts, and deep cavity work that would be unachievable with traditional 3-axis systems. This capability significantly reduces the need for multiple setups, minimizing cumulative error and improving part consistency.

All machining operations are supported by integrated CAD/CAM programming and toolpath simulation, ensuring optimal machining strategies and collision-free operation. Our engineering team works closely with clients during the design for manufacturability (DFM) phase to identify potential challenges and recommend adjustments that enhance performance while reducing lead times and costs. Materials commonly processed include aluminum alloys such as 6061, 7075, and 2024, as well as specialty alloys and engineered metals, all handled with material-specific cutting parameters to maintain integrity and dimensional stability.

Quality control is embedded throughout the production cycle. Every component undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, geometric tolerances, and surface profiles. The CMM system is fully programmable and capable of executing automated inspection routines, ensuring repeatability and compliance with ISO 10360 standards. Inspection reports are generated for every batch, providing full traceability and documentation for audit and certification purposes.

Our facility maintains a climate-controlled environment to minimize thermal variation during both machining and inspection, a critical factor in achieving and verifying tight tolerances. All operators and quality technicians are certified to international standards and participate in ongoing training to maintain proficiency in the latest machining and metrology techniques.

The following table outlines the standard tolerance capabilities achievable across common feature types in aluminum components:

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Air Gauges, CMM |

| Positional Tolerance | ±0.020 mm | ±0.005 mm | CMM |

| Flatness | 0.02 mm/m | 0.005 mm/m | CMM, Surface Plate |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.01° | CMM, Optical Comparator |

These capabilities reflect Wuxi Lead Precision Machinery’s commitment to precision, consistency, and technical excellence in custom aluminum manufacturing. By combining advanced 5-axis CNC technology with metrology-grade inspection, we ensure every component meets the highest standards of quality and performance.

Material & Finish Options

Material Selection for Precision Engineered Components

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we guide clients through critical comparisons of aluminum, steel, and titanium, ensuring alignment with application demands. Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and consumer electronics due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and superior machinability. These properties significantly reduce component mass while maintaining structural integrity, directly impacting fuel efficiency and operational dynamics. Steel variants, especially 304 and 316 stainless grades, are indispensable where maximum strength, wear resistance, and durability in harsh environments are paramount. Applications range from heavy machinery components to medical instrumentation requiring stringent biocompatibility and sterilization tolerance. Titanium, primarily Grade 5 (Ti-6Al-4V), serves extreme conditions demanding unparalleled strength-to-weight performance combined with exceptional resistance to corrosion and high temperatures. Its use is critical in aerospace landing gear, marine components, and high-end medical implants, though its higher cost and machining complexity necessitate careful justification.

Material properties dictate not only base selection but also finishing requirements. Anodizing is the preeminent surface treatment for aluminum, enhancing wear resistance, corrosion protection, and providing an excellent base for adhesion or aesthetic coloring. We specialize in both Type II (Sulfuric Acid) for standard decorative and protective finishes, and Type III (Hard Anodizing) for demanding industrial applications requiring significantly increased surface hardness (up to 600 HV) and abrasion resistance. Precise control of electrolyte concentration, temperature, voltage, and sealing processes is non-negotiable to prevent common failures like micro-cracking, color inconsistency, or reduced fatigue strength. Wuxi Lead implements rigorous in-process metrology and post-treatment validation to guarantee anodized layer integrity meets exacting aerospace (AMS 2469, AMS 2471) and military specifications.

The following comparison highlights key characteristics to inform initial material screening:

| Property | Aluminum (6061-T6) | Steel (304 Stainless) | Titanium (Grade 5) |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Tensile Strength (MPa) | 310 | 515 | 900 |

| Corrosion Resistance | Good | Excellent | Exceptional |

| Typical Applications | Enclosures, brackets, UAV parts | Shafts, fasteners, surgical tools | Aircraft frames, marine hardware, implants |

Understanding the interplay between base material properties and finishing processes like anodizing is essential for component success. Wuxi Lead Precision Machinery leverages decades of CNC machining and surface treatment expertise to advise on the optimal material-finish combination, ensuring your components perform reliably under operational stress while meeting lifecycle cost targets. Partner with us for precision manufacturing where material science meets exacting execution.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every custom aluminum manufacturing project begins with a meticulously engineered design phase. This stage is critical to achieving zero defects and ensuring seamless transition into prototyping and mass production. Our engineering team collaborates directly with clients to analyze technical drawings, 3D CAD models, and functional requirements. Utilizing advanced simulation software—including finite element analysis (FEA) and computational fluid dynamics (CFD)—we validate structural integrity, thermal performance, and manufacturability before any material is cut. Design for manufacturability (DFM) reviews are conducted to optimize geometry, minimize waste, and enhance tool life, ensuring that every component is not only functional but also cost-efficient to produce at scale.

Prototyping: Validation Before Volume

Once the design is finalized, we move into the prototyping phase, where precision meets real-world testing. Using state-of-the-art CNC machining centers with ±0.005 mm accuracy, we produce functional prototypes in the actual aluminum alloy specified—typically 6061-T6, 7075-T6, or custom grades per application. These prototypes undergo rigorous in-house inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, material certifications, and first-article inspection (FAI) documentation are provided to the client for approval. This phase allows for design verification, fit-checking, and performance validation under operational conditions. Any necessary design refinements are implemented digitally and re-validated, ensuring full compliance before committing to full-scale production.

Mass Production: Scalable Precision with Zero Defects

With client-approved prototypes, we initiate mass production under a fully controlled manufacturing system designed for zero defects. Our production floor integrates automated CNC machining cells, real-time process monitoring, and statistical process control (SPC) to maintain consistency across batches. Each aluminum component is traceable through serialized lot tracking, from raw material sourcing to final packaging. In-process inspections occur at defined intervals, and final quality audits include 100% visual checks and抽样 testing per AS9100 and ISO 9001 standards. Our lean manufacturing principles reduce cycle times while maintaining exceptional quality, enabling scalable output from hundreds to tens of thousands of units without compromise.

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum 6061-T6, 7075-T6, 2024-T4, 5052, Custom Alloys |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry) |

| Surface Finish | Ra 0.8 μm standard; down to Ra 0.2 μm with polishing |

| Max Work Envelope | 1200 x 800 x 600 mm (3-axis); 800 x 600 x 500 mm (5-axis) |

| Quality Standards | ISO 9001:2015, AS9100D, IATF 16949 (automotive) |

| Lead Time (Prototype) | 7–12 days after design approval |

| Lead Time (Mass Production) | 15–25 days depending on volume and complexity |

Through integrated design validation, precision prototyping, and defect-free mass production, Wuxi Lead Precision Machinery delivers high-performance aluminum components that meet the exacting demands of aerospace, medical, automotive, and industrial automation sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Manufacturing Advantage

In the demanding landscape of precision aluminum and metal component production, selecting a manufacturing partner transcends basic sourcing. It requires a strategic alliance grounded in engineering excellence, unwavering quality, and responsive collaboration. Wuxi Lead Precision Machinery stands as your definitive solution for complex, high-integrity parts where tolerance, repeatability, and material science are non-negotiable. We engineer partnerships, not just components, ensuring your design intent translates flawlessly into functional reality.

Our ISO 9001:2015 and AS9100D certified facility in Wuxi, China, operates at the pinnacle of CNC manufacturing capability. We integrate advanced multi-axis milling, turning, and wire EDM with rigorous in-process metrology, including CMM and optical comparators, to deliver parts meeting the strictest aerospace, medical, and industrial automation standards. Unlike commodity suppliers, we engage early in your design phase, offering DFM insights that optimize manufacturability, reduce lead times, and eliminate costly iterations. Our engineers speak your technical language, focusing on solving material behavior challenges—particularly critical in aluminum alloys where thermal dynamics and structural integrity dictate performance.

The following table details our core technical capabilities, reflecting the precision infrastructure backing your projects:

| Capability | Specification | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.001 mm (±0.00004″) | Critical for aerospace structural interfaces |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Ensures sealing integrity in hydraulic systems |

| Material Range | Aluminum 2024-T4 to 7075-T6; Titanium Gr5; Stainless 316L; Inconel 718 | Supports high-stress, corrosion-resistant applications |

| Max Work Envelope | 1200 x 800 x 650 mm (47 x 31 x 26″) | Accommodates complex structural assemblies |

| Throughput Efficiency | 95%+ OEE on qualified processes | Guarantees on-time delivery for volume runs |

This infrastructure is amplified by our commitment to transparency. Real-time production tracking, comprehensive First Article Inspection reports, and dedicated engineering support provide full visibility into your project’s progress. We understand that delays in prototyping or production directly impact your time-to-market; our rapid prototyping cell delivers functional aluminum test parts in 10–15 days without compromising quality. When your design demands micron-level precision in challenging geometries—such as thin-walled enclosures or integrated cooling channels—our process stability ensures zero-defect output batch after batch.

Partnering with Lead Precision means embedding manufacturing expertise into your supply chain resilience. We mitigate risks associated with offshore production through Western-managed quality systems and proactive communication protocols. Reduce your total cost of ownership by eliminating rework, minimizing inventory buffers, and accelerating validation cycles. Your next-generation aluminum component requires a partner who treats your specifications as engineering imperatives, not order fulfillments.

Initiate your strategic manufacturing partnership today. Contact our engineering team directly at [email protected] to discuss how our precision capabilities align with your project’s technical and commercial objectives. Provide your design files or requirements for a tailored feasibility assessment within 48 hours. Let Lead Precision become the engineered foundation of your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.