Technical Contents

Engineering Guide: Surface Finishing 3D Printed Parts

Engineering Insight: Surface Finishing 3D Printed Parts

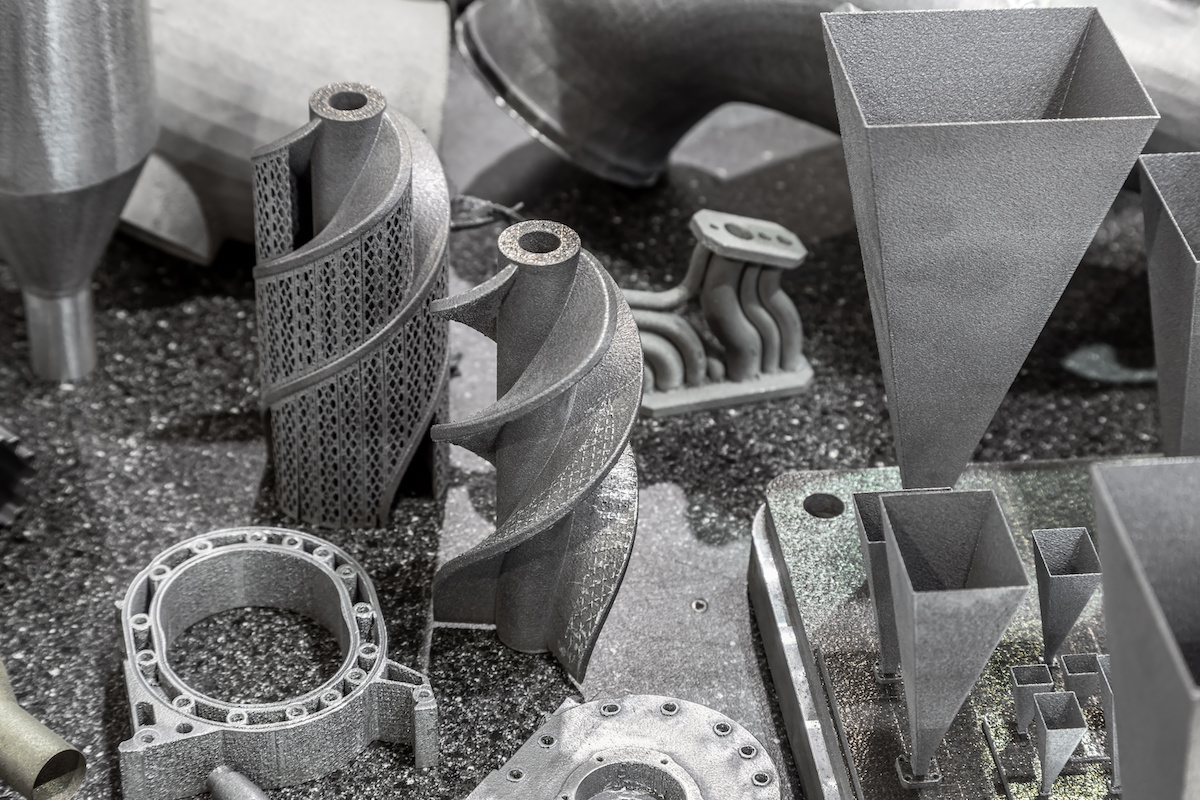

In the realm of advanced manufacturing, 3D printing has revolutionized prototyping and production by enabling complex geometries and rapid iteration. However, as additive manufacturing gains traction in mission-critical sectors such as aerospace, defense, and high-performance sports equipment, the demand for consistent, high-precision surface finishing has become paramount. At Wuxi Lead Precision Machinery, we recognize that the true value of a 3D printed component is not realized at the print stage—but in the final surface integrity and dimensional accuracy achieved through precision post-processing.

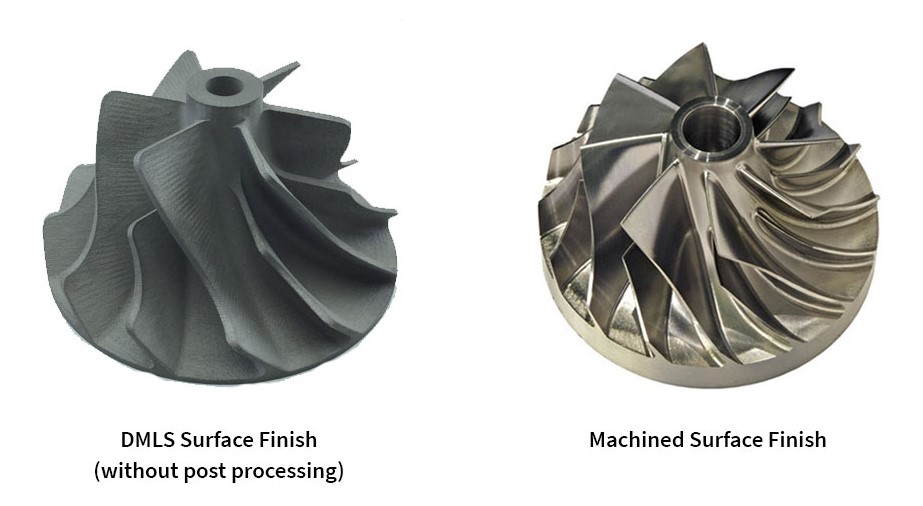

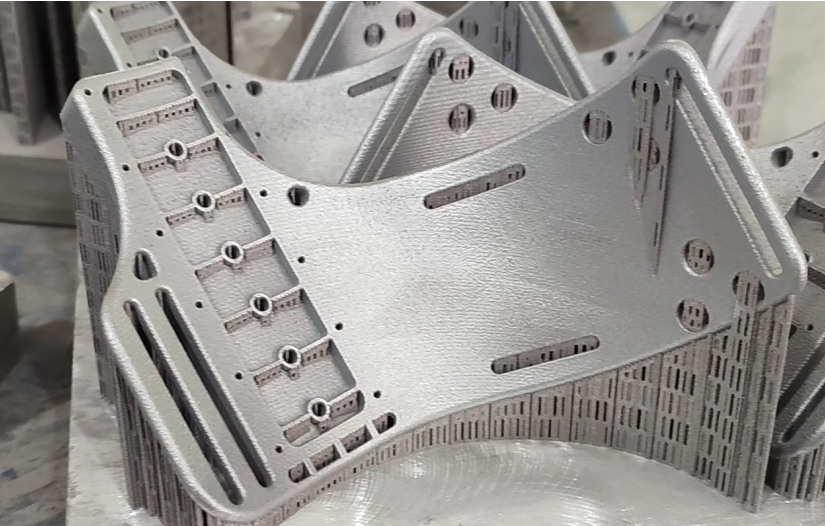

Additive manufacturing inherently produces parts with surface roughness due to layer-by-layer deposition. These microscopic inconsistencies can compromise mechanical performance, fatigue resistance, and aesthetic quality—especially in load-bearing or fluid-dynamic applications. For industries where failure is not an option, such as military systems or Olympic-grade equipment, surface finishing is not a cosmetic afterthought; it is an engineering necessity.

Our experience at Lead Precision extends to supporting components used in Olympic training apparatus and classified defense systems—applications where tolerances are measured in microns and reliability is non-negotiable. In these environments, we apply advanced finishing techniques including precision CNC machining, vibratory polishing, micro-abrasive blasting, and isotropic superfinishing. Each method is selected based on material type, part geometry, and functional requirements, ensuring optimal surface integrity without compromising design intent.

A critical factor in successful surface finishing is maintaining dimensional stability. Aggressive polishing or improper fixturing can introduce warping or material removal beyond acceptable limits. Our engineers utilize metrology-grade inspection tools—including coordinate measuring machines (CMM) and laser scanning—to validate surface quality and geometric accuracy before and after finishing. This closed-loop quality control ensures compliance with international standards such as ISO 2768 and ASME Y14.5.

Below is a summary of typical surface finish specifications achievable through our integrated finishing processes:

| Process | Material Compatibility | Typical Ra (μm) | Dimensional Tolerance (mm) | Application Examples |

|---|---|---|---|---|

| CNC Machining | Titanium, Stainless Steel, Aluminum | 0.4 – 1.6 | ±0.005 | Aerospace fittings, Weapon mounts |

| Vibratory Polishing | All metals | 0.2 – 0.8 | ±0.02 (form retention) | Medical enclosures, Fluid manifolds |

| Micro-Abrasive Blasting | Inconel, Tool Steels | 1.0 – 3.2 | ±0.01 | Turbine blades, Nozzles |

| Isotropic Superfinishing | High-strength alloys | 0.05 – 0.1 | ±0.003 | High-cycle fatigue components |

At Wuxi Lead Precision Machinery, we combine decades of metalworking expertise with cutting-edge technology to deliver surface finishes that meet the highest standards of performance and reliability. When additive manufacturing meets precision engineering, the result is not just a printed part—but a mission-ready component.

Precision Specs & Tolerances

Technical Capabilities for Precision Surface Finishing of 3D Printed Parts

At Wuxi Lead Precision Machinery, we specialize in transforming as-built 3D printed metal and polymer components into mission-critical finished parts through advanced subtractive post-processing. Our integrated approach addresses the inherent surface roughness, dimensional variance, and geometric limitations of additive manufacturing, ensuring parts meet stringent aerospace, medical, and industrial application requirements. The cornerstone of this capability is our fleet of state-of-the-art 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems provide the simultaneous multi-directional tool access essential for finishing complex organic geometries common in 3D printed designs without requiring multiple fixturing setups. This eliminates cumulative alignment errors and preserves critical feature relationships, achieving seamless transitions between additively manufactured near-net-shape forms and final precision surfaces.

Material compatibility is paramount in post-processing. Our CNC systems are optimized for the full spectrum of 3D printable alloys, including titanium Ti-6Al-4V, Inconel 718, aluminum AlSi10Mg, and stainless steels, as well as high-performance polymers. We utilize specialized toolpath strategies and cutting parameters tailored to each material’s thermal and mechanical properties, preventing delamination, recast layer formation, or subsurface damage that can compromise part integrity. This precision machining capability extends beyond basic contouring to include micro-milling for fine surface textures, precision hole boring to exact diameters, and critical edge conditioning—all while maintaining the structural advantages of the original additive build.

Rigorous quality control is embedded at every stage. All finished surfaces undergo comprehensive verification using Zeiss CONTURA and GLOBAL S-Coordinate Measuring Machines (CMM). Our inspection protocols validate not only dimensional accuracy against the nominal CAD model but also surface texture parameters (Ra, Rz) and geometric tolerances critical for sealing, mating, or fatigue performance. This data-driven QC ensures traceability and provides clients with certified reports for regulatory compliance. The table below details achievable tolerances for surface-finished 3D printed components:

| Feature | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, Optical Comparator |

| Geometric Tolerances (GD&T) | ±0.08 mm | ±0.02 mm | CMM (ISO 1101 compliant) |

| Surface Roughness (Ra) | 1.6 – 3.2 μm | 0.4 – 0.8 μm | Profilometer (ISO 4287) |

| Hole Diameter | ±0.03 mm | ±0.005 mm | CMM, Air Gaging |

| Positional Accuracy | ±0.05 mm | ±0.015 mm | CMM (Full 3D Analysis) |

Our process delivers dimensional stability, functional surface integrity, and certified conformance that additive manufacturing alone cannot achieve. By combining 5-axis CNC precision with metrology-grade validation, Wuxi Lead transforms 3D printed prototypes and production parts into reliable, high-performance components ready for demanding operational environments. This capability represents the critical bridge between innovative design freedom and real-world engineering performance.

Material & Finish Options

Material Selection for Surface Finishing of 3D Printed Metal Parts

Selecting the appropriate base material is critical when planning surface finishing processes for 3D printed metal components. At Wuxi Lead Precision Machinery, we specialize in post-processing techniques that enhance both the functional performance and aesthetic quality of additively manufactured parts. Among the most widely used materials in high-performance applications are aluminum, steel, and titanium. Each offers distinct mechanical properties and responds differently to surface treatments such as anodizing, making informed selection essential.

Aluminum alloys, particularly AlSi10Mg, are favored in aerospace and automotive industries due to their excellent strength-to-weight ratio and thermal conductivity. These parts are commonly produced via selective laser melting (SLM) and are ideal candidates for anodizing. Anodizing aluminum creates a durable, corrosion-resistant oxide layer that can be dyed in various colors, offering both protection and visual appeal. However, the porous surface typical of as-printed aluminum requires precision machining or polishing prior to anodizing to ensure uniform coating adhesion and appearance.

Stainless steel, especially grades 316L and 17-4 PH, delivers high tensile strength, wear resistance, and excellent performance in corrosive environments. While anodizing is not applicable to steel, alternative surface finishes such as electropolishing, passivation, and powder coating are frequently employed. Electropolishing removes surface irregularities and enhances corrosion resistance by enriching the chromium oxide layer. For applications requiring a decorative or protective finish, media blasting followed by coating provides a refined surface suitable for demanding industrial use.

Titanium and its alloy Ti6Al4V are renowned for exceptional strength, biocompatibility, and resistance to extreme temperatures and corrosion. Commonly used in medical implants and aerospace components, titanium parts benefit from surface treatments that improve fatigue life and wear resistance. Though titanium can undergo a form of anodizing, it is primarily used for aesthetic coloration rather than corrosion protection due to the metal’s naturally stable oxide layer. For functional enhancements, techniques such as thermal oxidation or nitriding are recommended.

Understanding the interaction between material and finish ensures optimal performance and longevity of 3D printed parts. Below is a comparative overview of key properties and compatible finishing methods.

| Material | Common Grades | Tensile Strength (MPa) | Corrosion Resistance | Compatible Surface Finishes |

|---|---|---|---|---|

| Aluminum | AlSi10Mg | 400–500 | Moderate | Anodizing, Polishing, Painting |

| Stainless Steel | 316L, 17-4 PH | 550–1300 | High | Electropolishing, Passivation, Powder Coating |

| Titanium | Ti6Al4V | 900–1100 | Very High | Anodizing (color), Thermal Oxidation, Nitriding |

At Wuxi Lead Precision Machinery, we support clients in matching material selection with appropriate post-processing strategies to meet exacting industry standards. Proper integration of material and finish not only improves part functionality but also ensures consistency, reliability, and compliance in high-end manufacturing applications.

Manufacturing Process & QC

Precision Surface Finishing for Additive Manufactured Metal Components

Achieving flawless surface integrity on 3D printed metal parts is non-negotiable for demanding aerospace, medical, and energy applications. At Wuxi Lead Precision Machinery, we integrate surface finishing as a core engineering consideration from the earliest design phase, ensuring seamless transition from prototype to zero-defect mass production. Our process eliminates the common pitfalls of post-processing as an afterthought, directly addressing inherent challenges like surface porosity, stair-stepping, and residual stress from additive layer fusion.

Design initiates our zero-defect protocol. Our engineers collaborate with clients to optimize part geometry specifically for post-processing requirements. This includes strategic placement of support structures to minimize witness marks, defining critical surfaces requiring stringent Ra tolerances, and incorporating necessary stock allowances for subsequent machining or polishing. Early simulation of thermal stresses during finishing prevents distortion in final components. Prototyping validates this integrated approach. We produce functional prototypes using the exact target production alloy and AM parameters, then subject them to the full suite of proposed finishing techniques. Rigorous metrology, including CMM and profilometry, verifies dimensional stability, surface roughness, and fatigue performance against client specifications before committing to tooling. This phase is critical for refining process parameters and eliminating potential failure modes.

Mass production leverages the validated process window with unwavering consistency. Our automated finishing cells, featuring multi-axis CNC grinding, precision vibratory finishing, and isotropic micro-machining, operate under strict SPC controls. Every batch undergoes 100% in-process inspection at defined control points, with real-time data fed back to adjust parameters. Material removal rates, media composition, and dwell times are precisely managed to maintain geometric accuracy while achieving the target surface. Final parts undergo comprehensive validation per ASTM F1800 or ISO 4287 standards, including visual, dimensional, and surface roughness checks, ensuring absolute conformance before shipment. This closed-loop system, rooted in design intent and proven in prototyping, guarantees repeatability and zero-defect delivery at scale.

The following table outlines key surface finishing processes we deploy for critical AM metal components, highlighting their precision capabilities and application suitability.

| Process | Material Suitability | Typical Ra (μm) | Dimensional Impact | Best For Applications |

|---|---|---|---|---|

| Precision CNC Grinding | All Metals (Ti, SS, Inconel) | 0.2 – 0.8 | ±0.005 mm | Critical sealing surfaces, bearing journals |

| Isotropic Micro Machining | Titanium, Cobalt-Chrome | 0.05 – 0.2 | ±0.002 mm | Medical implants, fluid dynamics surfaces |

| Automated Vibratory Finishing | Aluminum, Stainless Steel | 0.4 – 1.6 | ±0.02 mm | Cosmetic surfaces, non-critical features |

| Electrochemical Polishing | Stainless Steel, Nickel Alloys | 0.05 – 0.1 | Minimal | Ultra-clean surfaces, corrosion resistance |

Wuxi Lead’s end-to-end ownership of the design-to-production continuum transforms surface finishing from a bottleneck into a value-added, defect-proofed capability. We deliver not just parts, but guaranteed surface performance meeting the most stringent global industry requirements.

Why Choose Wuxi Lead Precision

When it comes to advanced manufacturing, the difference between a good component and a superior one lies in the details—especially in surface finishing. At Wuxi Lead Precision Machinery, we specialize in transforming 3D printed metal parts into high-performance, production-ready components through precision surface finishing techniques. As a trusted partner in custom metal manufacturing, we combine engineering expertise with state-of-the-art equipment to deliver finishes that meet the most demanding industrial standards.

Our facility in Wuxi, China, is equipped to handle post-processing requirements for complex additively manufactured parts across aerospace, medical, automotive, and energy sectors. Whether your project requires deburring, polishing, grinding, or specialized coatings, our team applies tailored methodologies to enhance surface integrity, fatigue resistance, and dimensional accuracy. We understand that each 3D printed component presents unique challenges due to layering artifacts, internal geometries, and material anisotropy—our solutions are designed to address these with precision and consistency.

Partnering with Wuxi Lead Precision Machinery means gaining access to a fully integrated finishing workflow backed by rigorous quality control. Our technicians use advanced metrology tools, including coordinate measuring machines (CMM) and surface profilometers, to validate every finish against your specifications. We support both small-batch prototyping and high-volume production, ensuring scalability without compromise.

Below are key capabilities and specifications we offer in surface finishing for 3D printed metal parts:

| Parameter | Specification |

|---|---|

| Supported Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel (625, 718), Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Surface Roughness Achievable | As low as Ra 0.1 µm (polished), typical post-processing range Ra 0.8–3.2 µm |

| Finishing Methods | Vibratory finishing, centrifugal barrel finishing, micro-milling, electrochemical polishing, sandblasting, tumbling |

| Dimensional Accuracy | ±0.005 mm (with post-process inspection and compensation) |

| Batch Capacity | Up to 50 kg per cycle (varies by geometry and method) |

| Quality Standards | ISO 9001:2015 certified, full traceability, first-article inspection reports, PPAP support |

| Lead Time | 5–10 working days (standard), expedited options available |

We work closely with design and engineering teams to optimize finishing strategies early in the development cycle, reducing rework and accelerating time to market. Our goal is not just to meet your specifications—but to exceed them through continuous improvement and technical collaboration.

For expert surface finishing of your 3D printed metal components, contact us today. Let Wuxi Lead Precision Machinery be your strategic partner in achieving flawless, functional, and repeatable results.

Email us at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.