Technical Contents

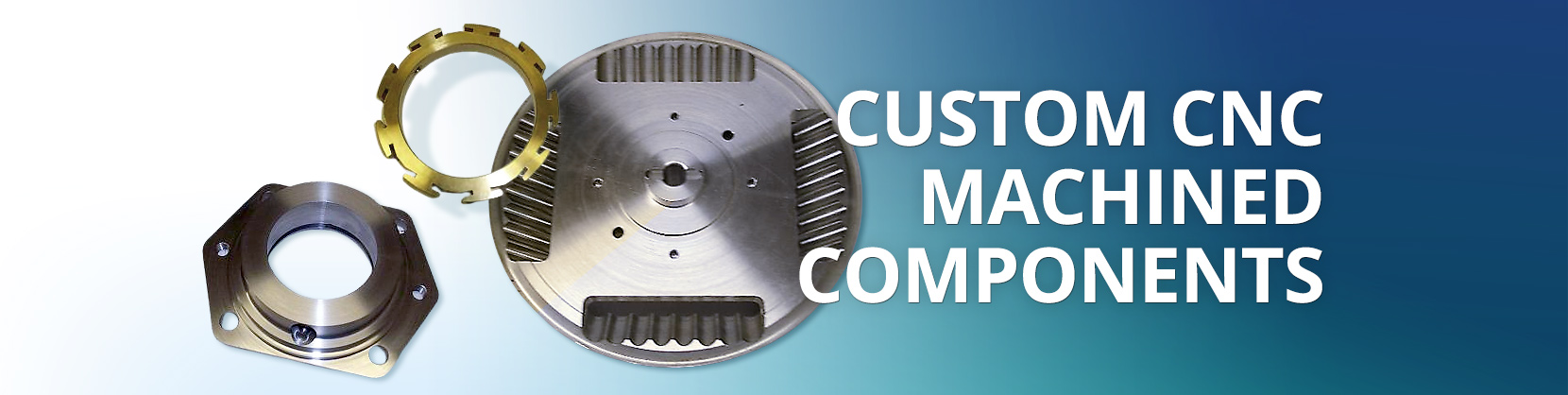

Engineering Guide: Casting Rubber Parts

Engineering Insight: Casting Rubber Parts with Precision

In the realm of custom metal manufacturing, the integration of rubber components through casting processes demands an exceptional level of precision, material science expertise, and engineering rigor. At Wuxi Lead Precision Machinery, we recognize that rubber casting is not merely a secondary operation—it is a critical engineering function that directly impacts the performance, durability, and reliability of the final assembly. Whether serving aerospace, defense, or high-performance industrial sectors, our approach to casting rubber parts is rooted in dimensional accuracy, material consistency, and process repeatability.

Precision in rubber casting begins with mold design. Even minor deviations in cavity geometry can result in part warpage, inconsistent wall thickness, or compromised sealing performance. Our engineering team employs advanced 3D modeling and finite element analysis (FEA) to simulate flow behavior, curing dynamics, and shrinkage characteristics of elastomeric materials. This predictive capability ensures that molds are optimized before production, minimizing trial iterations and accelerating time-to-market.

Material selection is equally critical. We work with a range of elastomers—including silicone, EPDM, nitrile, and fluorocarbon compounds—each chosen for specific thermal, chemical, and mechanical requirements. For military-grade applications, such as vibration dampers in armored vehicle suspensions, or Olympic-standard components like precision seals in aquatic timing systems, material performance under extreme conditions is non-negotiable. Our in-house material testing laboratory validates durometer, tensile strength, elongation, and compression set to ensure compliance with international standards.

Process control is the cornerstone of our casting methodology. Our automated dispensing systems deliver rubber compounds with ±0.5% volumetric accuracy, while temperature-controlled curing ovens ensure uniform cross-linking. This level of control eliminates common defects such as air entrapment, incomplete fills, or cure inconsistencies—issues that can lead to premature failure in mission-critical environments.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-integrity component manufacturing, with documented contributions to Olympic timing equipment and specialized defense systems. These projects demanded not only flawless functionality but also full traceability, from raw material batch numbers to final inspection reports. Our quality management system is ISO 9001:2015 certified, and we adhere to AS9100 standards for aerospace-related contracts.

The following table outlines key specifications and capabilities for our rubber casting processes:

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.1 mm to ±0.05 mm (depending on geometry) |

| Material Types | Silicone, NBR, EPDM, FKM, Neoprene |

| Hardness Range (Shore A) | 30–90 |

| Part Weight Range | 5 g – 2.5 kg |

| Curing Methods | Heat cure, Room temperature cure |

| Production Volume | Prototype to High Volume (up to 500k units/year) |

| Secondary Operations | Insert molding, bonding, trimming, testing |

At Wuxi Lead, we treat every rubber casting project as an engineering challenge, not just a production task. Our goal is to deliver components that perform reliably under the most demanding conditions—backed by precision, proven experience, and uncompromising quality.

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Manufacturing for Rubber Casting

Wuxi Lead Precision Machinery specializes in producing high-integrity metal molds and tooling essential for demanding rubber casting applications. Our expertise lies not in manufacturing the rubber parts themselves, but in engineering the precision metal components—such as cores, cavities, inserts, and parting plates—that directly determine the dimensional accuracy, surface quality, and functional performance of the final cast rubber product. Achieving zero-defect rubber castings demands mold geometries held to exacting standards, where micron-level deviations in the metal tool translate directly to part rejection. We address this critical challenge through integrated advanced machining and metrology systems.

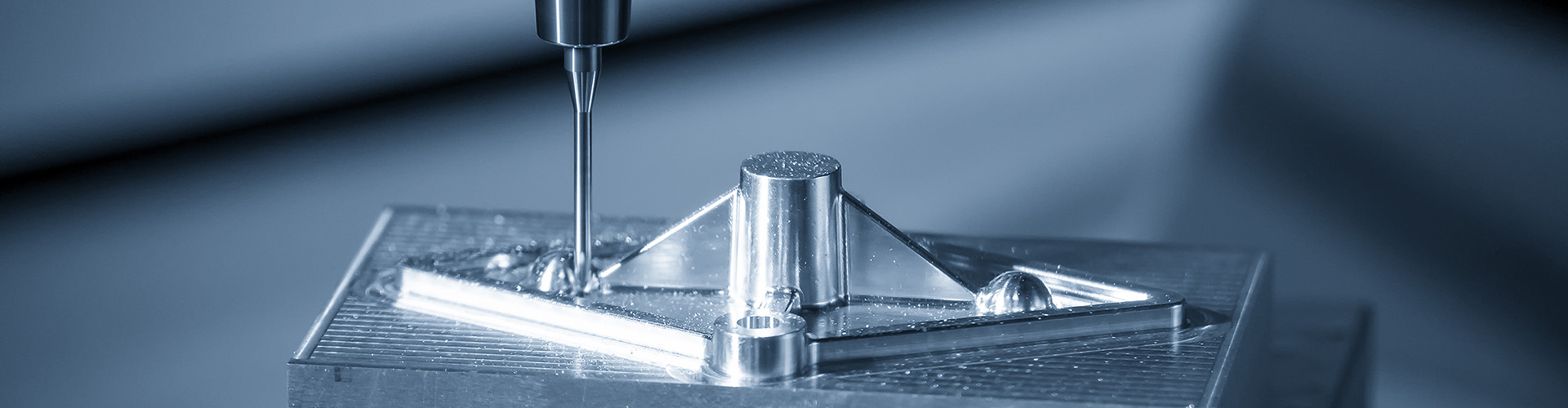

Our core capability centers on 5-axis simultaneous CNC machining, utilizing DMG MORI and MAZAK platforms with sub-micron positioning accuracy. This technology enables the complete machining of complex mold geometries—internal undercuts, organic sealing surfaces, and multi-angle venting channels—in a single setup. Eliminating manual repositioning prevents cumulative alignment errors that cause parting line mismatch, flash, or inconsistent wall thickness in rubber castings. High-speed machining with specialized toolpath strategies ensures optimal surface finishes on hardened tool steels (HRC 48-52), directly reducing rubber adhesion and post-cure finishing requirements. All machining operations are validated through in-process probing and thermal compensation systems to maintain stability across extended production runs.

Quality assurance is anchored by Zeiss CONTURA CMM systems operating in a climate-controlled metrology lab (20°C ±0.5°C). Every mold undergoes full 3D geometric inspection against CAD nominal data, with emphasis on critical rubber casting parameters: cavity dimensional integrity, parting line flatness, core pin positional accuracy, and draft angle consistency. Our inspection protocols extend beyond basic conformance; we analyze data to predict rubber shrinkage behavior and optimize mold compensation factors for specific elastomer compounds. Real-time SPC reporting provides traceable evidence of capability, ensuring molds perform consistently across thousands of casting cycles.

The following table details key tolerance capabilities for rubber casting mold components, reflecting our standard production envelope for tool steels and pre-hardened alloys. These values represent achievable results under controlled process conditions for features typical in hydraulic seals, automotive gaskets, and medical diaphragms.

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Capability | Impact on Rubber Casting |

|---|---|---|---|

| Cavity Dimensions | ±0.05 mm | ±0.01 mm | Ensures consistent part volume and sealing diameter |

| Parting Line Flatness | 0.03 mm | 0.005 mm | Eliminates flash and parting line mismatch |

| Core Pin Position | ±0.02 mm | ±0.005 mm | Maintains uniform wall thickness and concentricity |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Reduces rubber tearing and ejection force |

This combination of 5-axis machining precision and rigorous CMM validation delivers molds that consistently produce rubber castings meeting ISO 3302 and ASTM D2000 requirements. By controlling the metal tool’s geometry at the micron level, we directly enable our clients to achieve rubber part tolerances previously unattainable in high-volume production—reducing scrap rates, accelerating time-to-market, and ensuring reliability in critical sealing applications. Partner with Wuxi Lead to transform your rubber casting performance through uncompromised metal tooling integrity.

Material & Finish Options

Material Selection for High-Precision Cast Rubber Molds in Custom Metal Manufacturing

In the production of rubber components, the performance and longevity of molds directly influence part quality, production efficiency, and overall cost. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-precision tooling used in rubber casting applications. Selecting the appropriate mold material—aluminum, steel, or titanium—is critical to meeting specific production demands, including cycle life, thermal management, and dimensional stability.

Aluminum alloys are widely used for prototype and low-to-medium volume rubber casting due to their excellent thermal conductivity and machinability. The rapid heat dissipation of aluminum reduces cycle times, enhancing productivity in compression or transfer molding processes. Additionally, aluminum’s lightweight nature simplifies mold handling and installation. However, aluminum exhibits lower wear resistance compared to steel, making it less suitable for high-volume production runs. It is best deployed when tooling life requirements are under 10,000 cycles.

Steel, particularly tool steels such as H13 and P20, offers superior hardness, durability, and resistance to thermal fatigue. These properties make steel ideal for high-volume rubber casting operations where mold longevity and dimensional consistency are paramount. While steel molds have longer machining times and higher initial costs, their extended service life often results in lower cost-per-part over time. Steel is also more resistant to flash formation due to its rigidity under high molding pressures.

Titanium alloys are less common but offer unique advantages in specialized applications. With a high strength-to-density ratio and excellent corrosion resistance, titanium is suitable for aggressive environments or where weight reduction is critical. However, its high cost and challenging machinability limit its use to niche, high-performance sectors such as aerospace or medical device manufacturing.

Surface finishing, particularly anodizing, plays a crucial role in enhancing mold performance. Anodizing aluminum increases surface hardness and wear resistance while improving release properties—critical in rubber molding where adhesion can cause defects. Hard anodizing, in particular, creates a durable ceramic-like layer that significantly extends mold life and reduces maintenance. For steel molds, alternative finishes such as chrome plating or nitriding are typically preferred due to the limitations of anodizing on ferrous materials.

Below is a comparative overview of key material properties relevant to rubber casting mold applications.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Best Use Case | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 45–60 (anodized) | 120–180 | 1,000 – 10,000 | Prototyping, low-volume runs | Hard Anodizing, TiN Coating |

| Steel (H13) | 48–52 | 30–35 | 50,000 – 100,000+ | High-volume production | Chrome Plating, Nitriding |

| Titanium | 35–40 | 7–9 | 20,000 – 50,000 | Corrosive environments, aerospace | Anodizing, DLC Coating |

Material selection must align with production volume, part complexity, and environmental factors. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal combination of base material and surface treatment to ensure reliable, high-quality rubber casting performance.

Manufacturing Process & QC

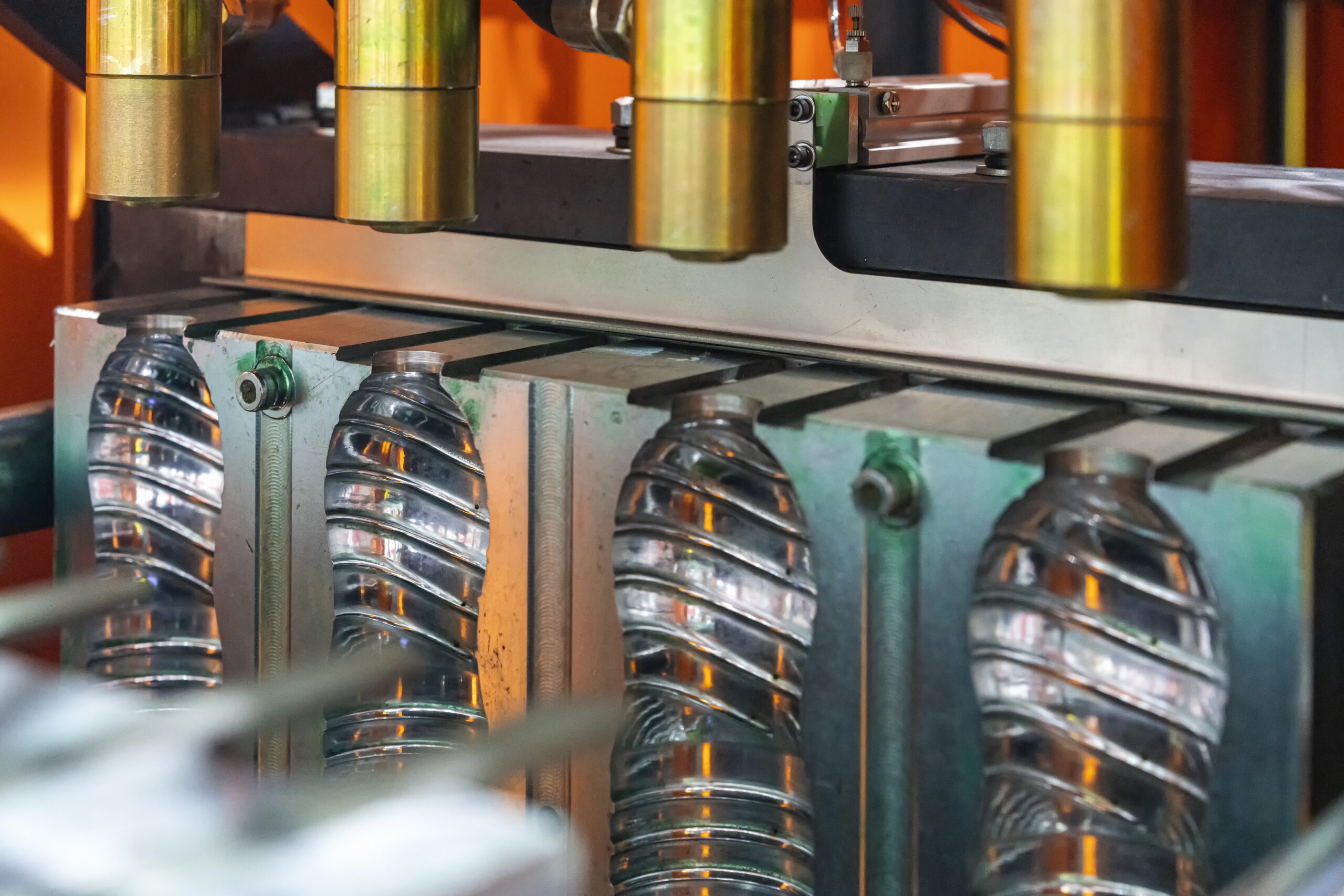

Precision Rubber Casting: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we transform complex rubber component requirements into flawless end products through a rigorously controlled three-phase process. Our expertise in custom metal manufacturing—specifically high-precision mold and tooling fabrication—ensures rubber casting meets exacting aerospace, medical, and industrial standards. Every stage prioritizes defect elimination, leveraging advanced metrology and process validation.

Design Phase: Engineering Precision at the Foundation

Design begins with collaborative analysis of your functional requirements, environmental exposure, and regulatory constraints. Our engineering team utilizes 3D CAD/CAM software integrated with finite element analysis (FEA) to simulate material flow, cure kinetics, and potential stress points. Critical attention focuses on mold geometry, gating systems, and venting to prevent voids, flash, or incomplete fills. Material selection—silicone, EPDM, NBR, or fluorocarbon—is validated against chemical resistance, temperature range, and durometer needs. This phase culminates in a digitally optimized mold design certified for manufacturability, ensuring the metal tooling we produce will deliver dimensional accuracy within microns.

Prototyping: Validating Performance Before Scale

Rapid steel or aluminum prototype molds—machined via 5-axis CNC to mirror production tooling—are deployed for initial casting runs. This phase is non-negotiable for risk mitigation. We conduct rigorous first-article inspections using coordinate measuring machines (CMM) and optical comparators to verify conformity against GD&T specifications. Material cure profiles are fine-tuned through iterative testing, while physical properties (tensile strength, elongation, compression set) undergo third-party lab validation. Client feedback integrates into final adjustments, eliminating geometry or process flaws before committing to full-scale tooling. Only when all critical characteristics meet zero-defect criteria does the project advance.

Mass Production: Sustained Excellence Through Control

Production leverages hardened P20 or H13 steel molds, manufactured in-house with ±0.005 mm tolerances. Each casting cycle is governed by statistical process control (SPC), with real-time monitoring of temperature, pressure, and cure time. Fully automated material handling minimizes human error, while in-line vision systems inspect every part for surface defects. Batch traceability—linking raw material lots, machine parameters, and inspection data—is maintained via our MES platform. Final validation includes 100% dimensional checks on critical features and accelerated life testing per ASTM/ISO standards. This closed-loop system ensures consistent Cpk >1.67, guaranteeing zero-defect delivery across volumes from 1,000 to 500,000+ units.

Wuxi Lead Rubber Casting Specifications

| Parameter | Capability Range | Control Method |

|---|---|---|

| Material Types | Silicone, EPDM, NBR, FKM, HNBR | ISO 7619-1 Certified |

| Dimensional Tolerance | ±0.05 mm to ±0.25 mm (part size dependent) | CMM, Optical Comparator |

| Hardness Range | 30 to 90 Shore A | ASTM D2240 |

| Production Volume | 100 to 500,000+ units/batch | Automated SPC Monitoring |

| Lead Time (Production) | 15–25 days after proto approval | Integrated MES Scheduling |

| Certifications | ISO 9001, IATF 16949, RoHS/REACH | Full Traceability |

Wuxi Lead’s integration of precision metal tooling with disciplined rubber casting methodology ensures your components perform reliably in mission-critical applications. We engineer out variability at every phase—because in high-stakes manufacturing, zero defects isn’t a goal; it’s the baseline.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Casting Solutions in Rubber Part Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-integrity metal components designed to support complex rubber casting operations. As a trusted partner in custom metal manufacturing, we understand that the performance of rubber casting systems hinges on precision-engineered metal parts—components that must endure extreme pressures, thermal cycles, and continuous operational stress. Our engineering team collaborates directly with OEMs and industrial foundries to produce tailored solutions that optimize the efficiency, durability, and repeatability of rubber part casting processes.

Our expertise lies in the design and fabrication of mold bases, core plates, ejector systems, heating manifolds, and custom tooling assemblies—all built to meet the exact specifications required for high-volume rubber molding. Whether your application involves injection, compression, or transfer molding, our components ensure tight tolerances, superior thermal conductivity, and extended service life. We utilize advanced CNC machining centers, precision grinding, and strict quality control protocols to deliver metal parts that integrate seamlessly into your casting infrastructure.

We recognize that downtime and maintenance issues in rubber casting are often traced back to substandard or poorly matched metal tooling. That’s why every component we manufacture is validated for dimensional accuracy, material integrity, and functional fit. Our engineers work with you from concept through production, offering DFM analysis, rapid prototyping, and scalable manufacturing to accelerate your time to market.

Below are key technical specifications we support for casting rubber part tooling and related metal components:

| Specification | Capability |

|---|---|

| Material Options | P20, H13, 420SS, 1.2738, 1.2344, Aluminum 7075-T6 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 0.8 µm (polishing available to Ra 0.05 µm) |

| Max Machining Size | 1200 × 800 × 600 mm |

| Heat Treatment | Up to 52 HRC (quenching & tempering, nitriding) |

| Coating Options | TiN, CrN, DLC, Hard Chrome Plating |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing facility equipped with real-time process monitoring, in-house metallurgical testing, and a dedicated project management system. We serve global clients in automotive, medical device, industrial equipment, and aerospace sectors, where reliability in rubber casting is non-negotiable.

For your next rubber part casting project, trust a partner who combines engineering depth with manufacturing excellence. Contact us today at [email protected] to discuss your requirements, request a quote, or schedule a technical consultation. Let Lead Precision be the foundation of your casting success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.