Technical Contents

Engineering Guide: C1018 Steel

Engineering Insight: c1018 Steel – The Role of Precision in High-Performance Manufacturing

In the realm of custom metal manufacturing, c1018 steel stands as a cornerstone material due to its balanced mechanical properties, weldability, and machinability. As a low-carbon steel, c1018 offers moderate strength with excellent ductility, making it ideal for applications requiring tight tolerances, consistent surface finishes, and reliable performance under dynamic loads. However, the true value of c1018 steel is not realized through its chemical composition alone—it is unlocked through precision engineering and expert process control.

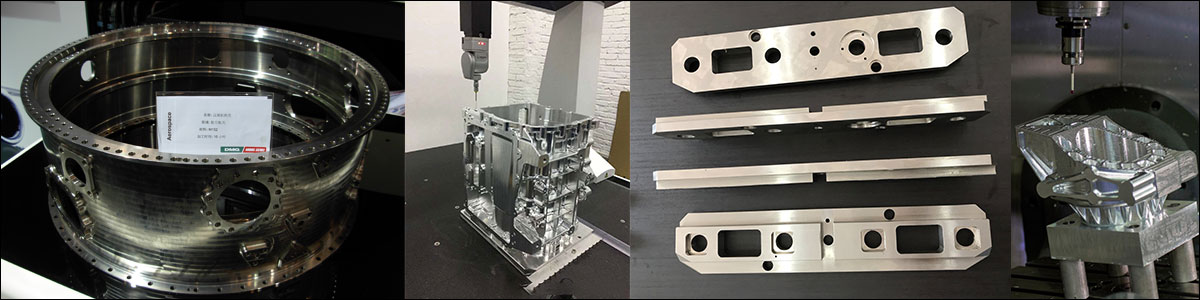

At Wuxi Lead Precision Machinery, we recognize that even the most predictable materials demand exacting standards. c1018 steel, while forgiving in many fabrication environments, behaves differently under varying thermal and mechanical conditions. Small deviations in machining parameters, heat treatment, or forming techniques can lead to dimensional instability, microstructural inconsistencies, or compromised fatigue resistance. This is especially critical in sectors such as aerospace, defense, and high-performance industrial equipment, where failure is not an option.

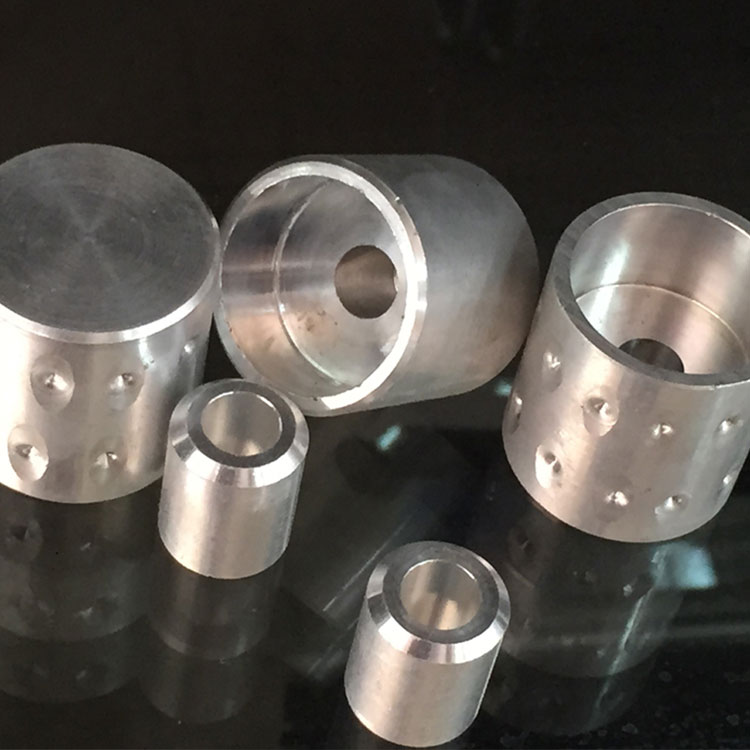

Our experience manufacturing precision components for Olympic-grade equipment and military-grade systems has reinforced the necessity of treating every c1018 steel part as a high-stakes engineering challenge. Whether producing shafts, spindles, or custom-forged housings, we implement closed-loop CNC machining, real-time metrology, and in-process inspection to ensure conformity to ±0.005 mm tolerances. Our facility utilizes advanced coordinate measuring machines (CMM) and optical comparators to validate geometry, surface integrity, and alignment—ensuring that each component performs as designed under real-world conditions.

Material traceability and process documentation are integral to our workflow. Every batch of c1018 steel is certified for chemical composition and mechanical properties, with full lot tracking from raw material to finished part. This level of control enables us to meet stringent regulatory requirements, including MIL-STD and ISO 9001:2015, while delivering repeatable quality across production runs.

The following table outlines the key mechanical and physical properties of c1018 steel under standardized conditions:

| Property | Value |

|---|---|

| Carbon Content | 0.15–0.20% |

| Tensile Strength (Ultimate) | 440–540 MPa |

| Yield Strength | 320–380 MPa |

| Elongation at Break | 15–20% (in 2 in) |

| Hardness (Brinell) | 120–140 HB |

| Density | 7.87 g/cm³ |

| Machinability Rating | 70% (relative to B1112) |

| Typical Applications | Shafts, pins, fasteners, gears |

Precision is not a secondary attribute—it is the foundation of reliability. At Wuxi Lead Precision Machinery, our mastery of c1018 steel is built on decades of refining processes, validating results, and delivering components where performance and consistency are non-negotiable. For mission-critical applications, the margin for error is zero. And so is our deviation from excellence.

Precision Specs & Tolerances

Technical Capabilities for C1018 Steel Precision Manufacturing

Wuxi Lead Precision Machinery delivers exceptional precision engineering for C1018 low-carbon steel components, leveraging advanced 5-axis CNC machining to overcome material-specific challenges. C1018’s excellent machinability and weldability make it ideal for high-volume production of pins, shafts, and structural hardware, yet its low hardenability demands meticulous process control to prevent thermal distortion and burring during high-speed cutting. Our facility utilizes DMG MORI and MAZAK 5-axis vertical machining centers with high-torque spindles and rigid tooling systems, enabling single-setup machining of complex geometries up to Ø850 mm x 1200 mm. This eliminates cumulative errors from multiple fixturing stages, critical for maintaining tight tolerances on intersecting features common in hydraulic manifolds or transmission components.

Our CNC programming integrates adaptive toolpath strategies specifically optimized for C1018’s chip formation characteristics, utilizing solid-carbide tooling with TiAlN coatings to minimize built-up edge and ensure surface integrity. All processes adhere to ISO 1302 surface finish standards, consistently achieving Ra 0.8 µm on critical sealing surfaces without secondary operations. To validate dimensional fidelity, every production lot undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA systems with 0.0001 mm resolution probes. Full first-article inspection reports (FAIR) include GD&T analysis per ASME Y14.5, with real-time SPC data monitoring for critical dimensions. Material traceability is maintained from mill certs through final inspection via our integrated ERP system, ensuring full compliance for aerospace (NADCAP) and medical device (ISO 13485) applications.

The following table details our standard and achievable tolerances for C1018 steel machining, reflecting our commitment to exceeding industry benchmarks:

| Dimension Type | Standard Tolerance (ISO 2768-mK) | Wuxi Lead Achieved Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.025 mm | CMM / High-Precision Micrometer |

| Angular Dimensions | ±0.5° | ±0.1° | Optical Comparator / CMM |

| Positional Tolerance | ±0.2 mm | ±0.05 mm | CMM with Iterative Alignment |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Portable Profilometer |

| Concentricity | Ø0.2 mm | Ø0.03 mm | CMM / Dial Indicator |

This capability framework ensures C1018 components meet stringent functional requirements while minimizing scrap rates. Our engineering team collaborates with clients during DFM analysis to optimize part geometry for efficient material utilization and cycle time reduction, typically achieving 20-35% faster throughput versus conventional 3-axis methods for complex parts. By combining 5-axis flexibility with metrology-grade validation, Wuxi Lead guarantees repeatability essential for mission-critical applications in fluid power, automation, and energy sectors. All capabilities are supported by in-house heat treatment coordination for stress-relieving C1018 components when required by design specifications.

Material & Finish Options

Material Selection Guide: C1018 Steel, Aluminum, Titanium, and Anodizing Finishes

When selecting materials for precision manufacturing applications, understanding the mechanical properties, machinability, and finishing compatibility of each option is essential. At Wuxi Lead Precision Machinery, we specialize in custom metal components using high-performance materials such as C1018 steel, aluminum alloys, and titanium. Each material offers distinct advantages depending on the application’s strength, weight, corrosion resistance, and cost requirements.

C1018 steel is a low-carbon, general-purpose steel widely used in precision machining due to its excellent machinability and weldability. It contains approximately 0.18% carbon, providing a balanced combination of ductility and strength. This steel is ideal for parts requiring tight tolerances, such as pins, shafts, and fasteners, where moderate strength and ease of fabrication are priorities. While C1018 does not respond well to heat treatment due to its low carbon content, it can be case-hardened for improved surface durability. Its relatively low cost and availability make it a preferred choice for high-volume production runs in industrial machinery and automotive components.

Aluminum, particularly 6061 and 7075 alloys, is favored in applications demanding lightweight strength and corrosion resistance. With a high strength-to-weight ratio and excellent thermal conductivity, aluminum is widely used in aerospace, electronics, and transportation industries. It machines quickly with minimal tool wear and is highly compatible with finishing processes such as anodizing. Anodizing aluminum creates a durable, corrosion-resistant oxide layer that enhances wear resistance and allows for color coding or aesthetic customization. This finish is especially valuable in consumer-facing or outdoor applications.

Titanium stands out for its exceptional strength-to-density ratio and outstanding resistance to corrosion, particularly in harsh environments such as marine or chemical processing. While more challenging to machine due to its low thermal conductivity and tendency to gall, titanium is indispensable in aerospace, medical implants, and high-performance automotive systems. Its biocompatibility and resistance to fatigue make it a premium choice where long-term reliability outweighs initial cost.

Below is a comparative overview of key properties for these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| C1018 Steel | 440–540 | 7.85 | 75% | Low (requires coating) | Zinc plating, painting |

| Aluminum 6061 | 310 | 2.70 | 90% | High | Anodizing, powder coating |

| Titanium Grade 5 | 900 | 4.43 | 30% | Very High | Passivation, polishing |

At Wuxi Lead Precision Machinery, we support material selection with in-house engineering consultation, ensuring optimal performance and cost-efficiency for your custom components. Whether you require the economy of C1018 steel, the lightness of aluminum, or the resilience of titanium, our precision machining capabilities deliver consistent quality across all production volumes.

Manufacturing Process & QC

Precision Manufacturing Process for C1018 Steel Components

Wuxi Lead Precision Machinery executes a rigorously controlled manufacturing sequence for C1018 low-carbon steel components, engineered to deliver zero-defect outcomes for demanding industrial applications. This seamless workflow integrates material science expertise with advanced process control, ensuring dimensional accuracy and structural integrity from concept to final shipment.

The process commences with collaborative design engineering. Our team analyzes the component geometry, functional requirements, and C1018’s specific properties—including its excellent machinability, weldability, and moderate strength—to optimize the manufacturing strategy. Critical considerations include defining precise tolerances achievable with this material, selecting optimal heat treatment paths if required (noting C1018’s limited hardenability), and planning machining sequences to minimize internal stress and distortion. Material certification and traceability protocols are established at this stage, ensuring full compliance with ASTM A29/A29M standards.

Prototyping follows stringent design validation. Utilizing high-precision CNC milling and turning centers, we produce initial physical samples from certified C1018 bar stock. Every prototype undergoes comprehensive metrological verification against the CAD model using calibrated CMMs and surface finish testers. Dimensional reports, material test certifications, and first-article inspection documentation are provided for client approval. This phase identifies any potential manufacturability issues or design refinements needed before committing to full production, significantly mitigating downstream risk.

Mass production deployment leverages our automated, high-volume CNC infrastructure under a Zero Defects Quality Management System. Each production run begins with 100% material verification. Machining parameters are precisely calibrated for C1018’s characteristics, utilizing specialized tooling and coolants to maintain surface integrity and dimensional stability. Real-time Statistical Process Control (SPC) monitors critical dimensions at defined intervals, with automatic tool wear compensation and process adjustments triggered by control chart deviations. Every component undergoes 100% visual inspection and selective dimensional verification per AQL standards. Final parts receive thorough deburring, cleaning, and protective coating as specified, accompanied by full material and process traceability documentation.

This integrated approach, combining deep material understanding with closed-loop process control, guarantees consistent production of C1018 steel components meeting the most exacting industrial specifications. Our AS9100-certified facility ensures reliability for aerospace, automotive, and industrial machinery sectors.

C1018 Steel Key Specifications for Manufacturing

| Property | Typical Value | Relevance to Manufacturing Process |

|---|---|---|

| Carbon Content | 0.15-0.20% | Determines weldability and hardenability limits |

| Tensile Strength | 440-550 MPa | Impacts cutting forces and tool selection |

| Yield Strength | ≥ 325 MPa | Critical for structural component design validation |

| Hardness (Brinell) | 121-149 HB | Guides machining speed/feed parameters |

| Machinability Rating | 70% (160 BHN Basis) | Enables high-speed precision machining |

| Typical Applications | Shafts, Pins, Fasteners, Bushings | Dictates surface finish and tolerance requirements |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in c1018 Steel Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components using high-quality c1018 steel, tailored to meet the exacting demands of global industries. As a trusted partner in custom metal manufacturing, we combine advanced CNC machining capabilities, rigorous quality control, and deep metallurgical expertise to transform raw c1018 steel into mission-critical parts for automotive, industrial equipment, construction, and precision instrumentation sectors. Our facility in Wuxi, China, operates under ISO 9001 standards, ensuring every component meets international tolerances, repeatability, and performance benchmarks.

c1018 steel is a low-carbon, general-purpose alloy known for its excellent machinability, weldability, and surface finish—making it ideal for shafts, pins, fasteners, and structural components. At Lead Precision, we go beyond standard processing. Our team optimizes every stage of production, from material sourcing and cold drawing to precision turning, milling, and heat treatment, ensuring dimensional accuracy down to ±0.005 mm. Whether you require small-batch prototypes or high-volume production runs, our agile manufacturing ecosystem adapts to your timeline, quality requirements, and technical specifications.

We understand that in high-end manufacturing, consistency is non-negotiable. That’s why every lot of c1018 steel we process undergoes comprehensive material certification and mechanical testing. Our in-house metrology lab employs CMMs, optical comparators, and hardness testers to validate conformity to ASTM A29 and other international standards. This end-to-end traceability ensures that your components perform reliably under real-world conditions.

Below are the key mechanical and physical properties of c1018 steel as processed in our facility:

| Property | Value |

|---|---|

| Carbon Content | 0.15–0.20% |

| Tensile Strength (Ultimate) | 440–540 MPa |

| Yield Strength | ≥370 MPa |

| Elongation at Break | 15% (in 2″) |

| Hardness (Brinell) | 120–140 HB |

| Density | 7.87 g/cm³ |

| Machinability Rating | 75% (relative to B1112) |

| Surface Finish (Typical) | Ra 0.8–1.6 μm |

| Common Forms Processed | Bar stock, cold-finished, turned blanks |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to technical excellence, on-time delivery, and long-term collaboration. We work closely with engineering teams worldwide to refine designs for manufacturability, reduce lead times, and lower total production costs—without compromising integrity.

For expert manufacturing solutions in c1018 steel, contact us today at [email protected]. Let Lead Precision become your trusted extension in precision metalwork.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.