In the realm of modern manufacturing, precision is paramount. CNC turning parts, with their intricate designs and flawless finishes, stand testament to this fact. These components, crafted with utmost accuracy, play a pivotal role in a myriad of applications, from automotive to aerospace, electronics to medical devices. As industries continue to evolve, the demand for high-quality CNC turned components has surged, especially from leading manufacturers in China, renowned for their precision engineering capabilities.

CNC Turning Parts: At its core, CNC turning is a subtractive manufacturing process that uses a rotating workpiece and a stationary cutting tool to shape and refine materials. The resulting CNC turning parts are not just components; they are masterpieces of precision, tailored to fit seamlessly into larger assemblies and systems.

The Role of Precision: In industries where even a micron’s deviation can lead to significant repercussions, the precision of CNC turned components is non-negotiable. It’s this precision that ensures the smooth functioning of machines, the safety of products, and the reliability of systems.

In the subsequent sections, we’ll delve deeper into the world of CNC turning parts, exploring their intricacies, the expertise of Wuxi Lead Precision Machinery in crafting them, and essential insights for international buyers.

Understanding CNC Turning Parts

CNC turning parts, often referred to as CNC turned components, are the result of a meticulous process that transforms raw materials into precision-engineered parts. These components are integral to a multitude of applications, ensuring the seamless operation of machinery and equipment.

- Basic Components and Their Functions:

- Lathe Bed: The foundation of the CNC machine, providing stability and ensuring precision.

- Chuck: Holds the workpiece in place, allowing for accurate turning and machining.

- Tool Turret: Houses various cutting tools, enabling the machine to perform multiple operations without manual intervention.

- Tailstock: Supports longer workpieces, ensuring they remain centered during the turning process.

- Control Panel: The brain of the CNC machine, where operators input commands and monitor the machining process.

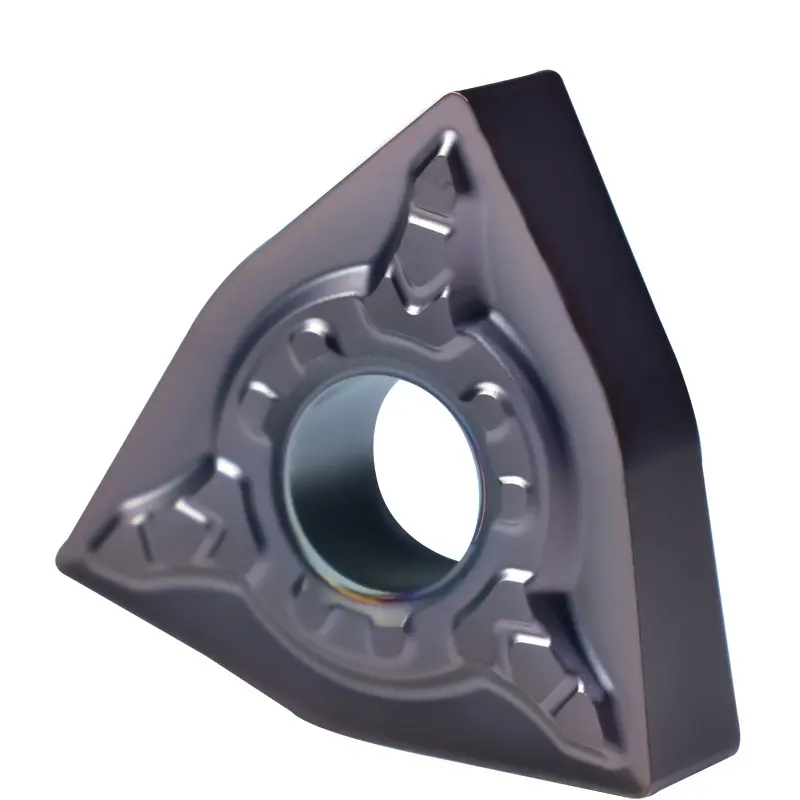

- The Intricacies of CNC Turned Components: CNC turning is not just about rotating a workpiece and cutting away excess material. It’s an art that demands expertise, understanding the nuances of the material, the cutting tool’s behavior, and the desired outcome’s specifications. The intricacies lie in selecting the right feed rate, ensuring optimal cooling, and choosing the appropriate cutting tool for each operation.

Wuxi Lead Precision Machinery: China’s Leading CNC Turned Parts Manufacturer

In the competitive landscape of CNC turned parts manufacturers, Wuxi Lead Precision Machinery stands out, not just as a supplier but as a partner committed to excellence.

- Company’s Expertise in CNC Turning and Precision Manufacturing: With years of experience under its belt, Wuxi Lead has mastered the art of CNC turning. Their team of seasoned professionals, equipped with state-of-the-art machinery, ensures that every component produced meets the highest standards of precision and quality.

- Commitment to Quality, Precision, and Swift Delivery: Wuxi Lead’s reputation is built on its unwavering commitment to quality. Every CNC turned component undergoes rigorous quality checks, ensuring they adhere to international standards. Moreover, with a robust logistics network, Wuxi Lead guarantees timely deliveries, catering to clients worldwide.

Types and Applications of CNC Turning Parts

The versatility of CNC turning parts is evident in their widespread applications across various industries.

- Different Types of CNC Turned Components: From simple cylindrical shafts to complex geometric shapes, CNC turning can produce a diverse range of components. Be it bushings, pulleys, rods, or custom-designed parts, CNC turning caters to varied requirements.

- Industries and Sectors Relying on Precision CNC Turning:

- Automotive: For producing parts like axles, shafts, and bushings.

- Aerospace: Crafting components that demand high precision and reliability.

- Medical: Manufacturing surgical instruments and medical devices.

- Electronics: Crafting connectors, pins, and other intricate components.

The journey of understanding CNC turning parts is vast and intricate. As we delve deeper, we’ll explore the production process at Wuxi Lead, essential questions for international buyers, and insights into why Wuxi Lead is the preferred choice for many.

Production Process of CNC Turning Parts at Wuxi Lead

Crafting precision CNC turning parts is an intricate dance of technology, expertise, and attention to detail. Wuxi Lead Precision Machinery, with its advanced facilities and seasoned professionals, ensures that every part produced is a testament to excellence.

- Raw Material Selection: The foundation of any quality component lies in the raw materials. Wuxi Lead sources high-grade metals and alloys, ensuring the final product’s durability and performance.

- Machining and Turning: With the raw materials procured, the actual turning process begins. Advanced CNC machines, programmed with precision, shape the materials into the desired components. Every cut, every rotation is monitored to ensure accuracy.

- Finishing and Polishing: Post the turning process, the components undergo finishing operations. This could involve polishing, grinding, or even additional machining to achieve the desired surface finish and dimensional accuracy.

- Quality Control and Inspection: No component leaves the Wuxi Lead facility without undergoing rigorous quality checks. Advanced measuring instruments ensure that each part adheres to the specified tolerances and quality standards.

- Packaging and Dispatch: Once approved, the components are carefully packaged, ready for dispatch. Wuxi Lead’s efficient logistics ensures that clients receive their orders on time, every time.

Questions International Buyers Should Ask When Sourcing from Wuxi Lead

Sourcing precision components, especially from overseas, demands due diligence. Here are some pivotal questions for international buyers:

- What certifications does Wuxi Lead hold? Certifications can provide insights into a manufacturer’s commitment to quality and international standards.

- How does Wuxi Lead handle custom CNC turning requests? Understanding the customization process can help buyers align their requirements effectively.

- What are the lead times for bulk orders? This helps in planning and ensuring timely project completions.

- Can Wuxi Lead provide samples before finalizing a bulk order? Sampling can offer a tangible sense of the quality and precision Wuxi Lead brings to the table.

FAQ Tips for Purchasers of CNC Turning Parts

Navigating the intricate world of CNC turning parts can be a challenge. Here are some frequently asked questions to assist purchasers in their decision-making process:

1. What are the primary materials used in CNC turning parts at Wuxi Lead?

- Wuxi Lead primarily utilizes high-quality metals and alloys, such as stainless steel, aluminum, brass, and more, ensuring durability and optimal performance for the turned components.

2. How does CNC turning differ from CNC milling?

- While both are subtractive manufacturing processes, CNC turning involves a rotating workpiece with a stationary cutting tool, whereas CNC milling uses a stationary workpiece with a rotating cutting tool.

3. Can Wuxi Lead handle complex and intricate CNC turning designs?

- Absolutely! With advanced CNC machines and skilled professionals, Wuxi Lead can craft complex and custom designs with precision.

4. What is the typical tolerance level Wuxi Lead can achieve in CNC turning?

- Wuxi Lead is committed to precision, achieving tight tolerances that meet international standards. Specific tolerance levels can be discussed based on the component’s requirements.

5. How does Wuxi Lead ensure the quality of its CNC turned components?

- Every component undergoes rigorous quality checks using advanced measuring instruments, ensuring adherence to specified tolerances and quality standards.

6. Are there any minimum order quantities when ordering from Wuxi Lead?

- Wuxi Lead caters to a diverse clientele, from small-scale orders to bulk requirements. It’s advisable to discuss specific order quantities directly with the company.

7. How does Wuxi Lead manage lead times, especially for bulk orders?

- With state-of-the-art facilities and efficient processes, Wuxi Lead ensures swift turnarounds, even for bulk orders, while maintaining quality.

8. Can international clients visit Wuxi Lead’s facility for a firsthand look at the production process?

- Yes, Wuxi Lead welcomes potential clients to visit their facility, offering a transparent insight into their production processes and quality control measures.

9. What sets Wuxi Lead Precision Machinery apart from other CNC turned parts manufacturers in China?

- Wuxi Lead’s commitment to quality, advanced machinery, unparalleled expertise, and a client-centric approach make it a preferred choice for many international clients.

10. How does Wuxi Lead handle post-purchase support and potential issues with the components supplied?

- Wuxi Lead has a dedicated after-sales support team that promptly addresses any concerns, ensuring client satisfaction remains at the forefront.