Technical Contents

Engineering Guide: Hdpe Injection Molding

Engineering Insight: HDPE Injection Molding – The Role of Precision in High-Performance Manufacturing

In the realm of high-density polyethylene (HDPE) injection molding, precision is not merely a performance metric—it is a foundational requirement. HDPE, known for its excellent chemical resistance, impact strength, and low moisture absorption, is widely used across industries ranging from medical devices to aerospace and defense. However, the material’s favorable properties can only be fully realized when paired with a manufacturing process that maintains strict dimensional control, consistent wall thickness, and repeatable cycle accuracy. At Wuxi Lead Precision Machinery, we understand that in custom metal manufacturing for HDPE molding applications, the mold defines the product.

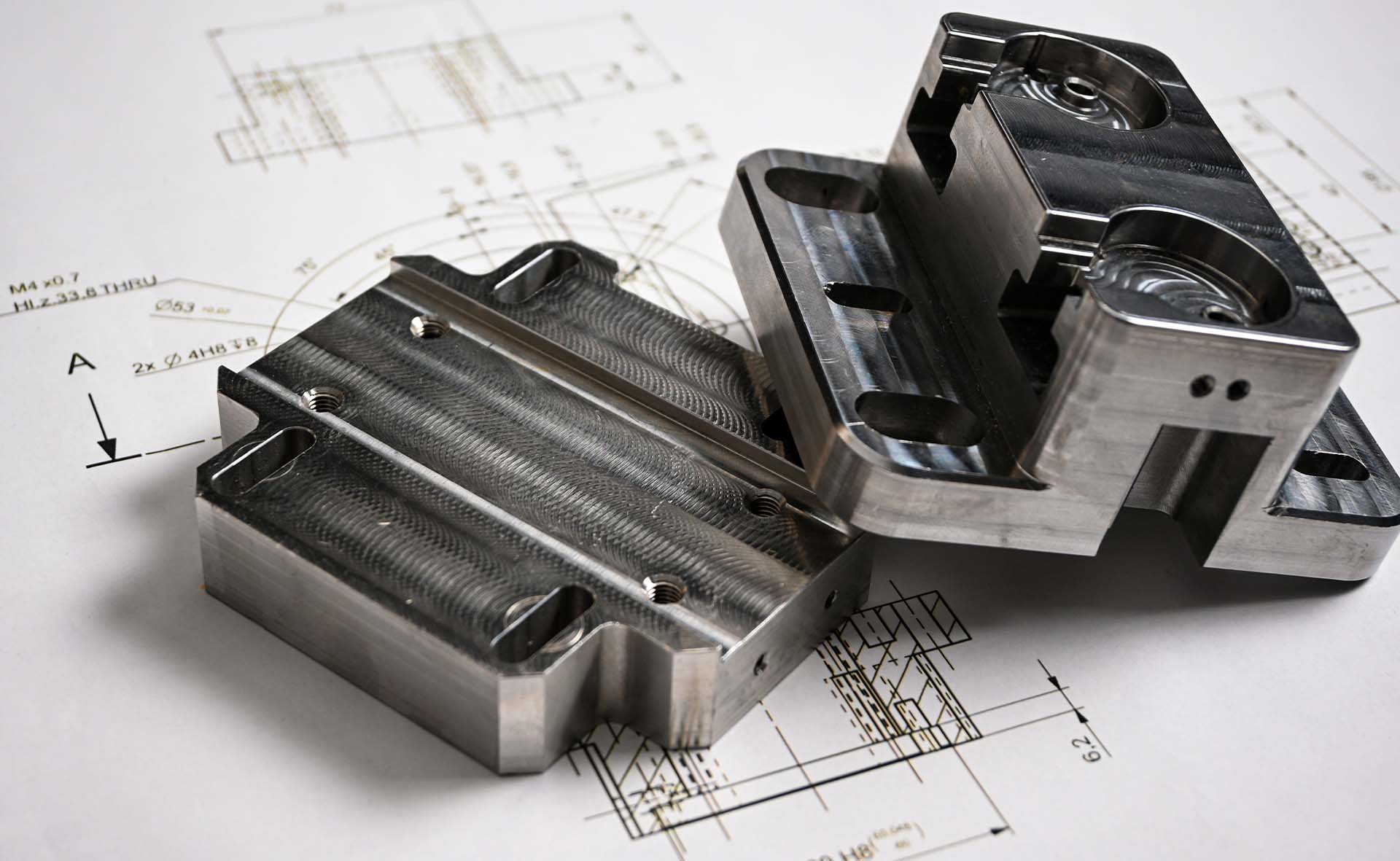

Our engineering team specializes in designing and fabricating high-precision steel and aluminum molds tailored to the thermal expansion characteristics and flow behavior of HDPE. Even minor deviations in cavity geometry or cooling channel placement can result in warping, sink marks, or inconsistent part weight—defects that are unacceptable in mission-critical applications. This is why we employ advanced CNC machining, EDM finishing, and 3D metrology to ensure tolerances within ±0.002 mm, far exceeding industry averages. Such precision ensures uniform filling, optimal packing, and minimal post-molding adjustment.

The demands of HDPE injection molding extend beyond the mold itself. Process stability, temperature uniformity, and clamping force consistency are equally vital. Our custom-built molding systems integrate real-time pressure and temperature monitoring, allowing for closed-loop process control that adapts to material batch variations. This level of control is especially critical when producing components for regulated sectors such as military hardware or Olympic-standard sports equipment—applications where Wuxi Lead has demonstrated proven expertise.

Our involvement in projects supporting Olympic infrastructure and military-grade component manufacturing underscores our commitment to reliability under extreme conditions. These high-stakes environments require not only flawless part consistency but also full traceability, durability under cyclic stress, and long-term performance in harsh environments. Our molds are engineered for lifespans exceeding one million cycles, with surface finishes as fine as Ra 0.025 µm to support both functional and aesthetic requirements.

Below are key technical specifications that define our HDPE injection molding capabilities:

| Parameter | Specification |

|---|---|

| Mold Material | H13, S136, 2738HH, 718H (custom alloy options) |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.025 µm to Ra 0.8 µm (polished/textured) |

| Maximum Mold Size | 2000 mm × 1500 mm × 1000 mm |

| Clamping Force (System) | Up to 3000 tons |

| Cycle Repeatability | ±0.15 seconds |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| Expected Mold Life | 500,000 to 1,200,000 cycles |

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with cutting-edge manufacturing technology to deliver molds that meet the highest standards of performance and reliability. In HDPE injection molding, where material behavior and machine precision are in constant interplay, our engineering-first approach ensures that every component produced is a testament to accuracy, durability, and industrial excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for HDPE Injection Molding Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for HDPE injection molding applications through advanced manufacturing and rigorous quality control. Our technical foundation centers on multi-axis CNC machining, specifically engineered to produce complex, high-tolerance mold components that ensure optimal part consistency, extended tool life, and efficient production cycles for demanding HDPE materials. HDPE’s unique thermal behavior and viscosity profile necessitate molds with exceptional dimensional stability and thermal management—capabilities we achieve through integrated design-to-manufacturing workflows and metrology-driven processes.

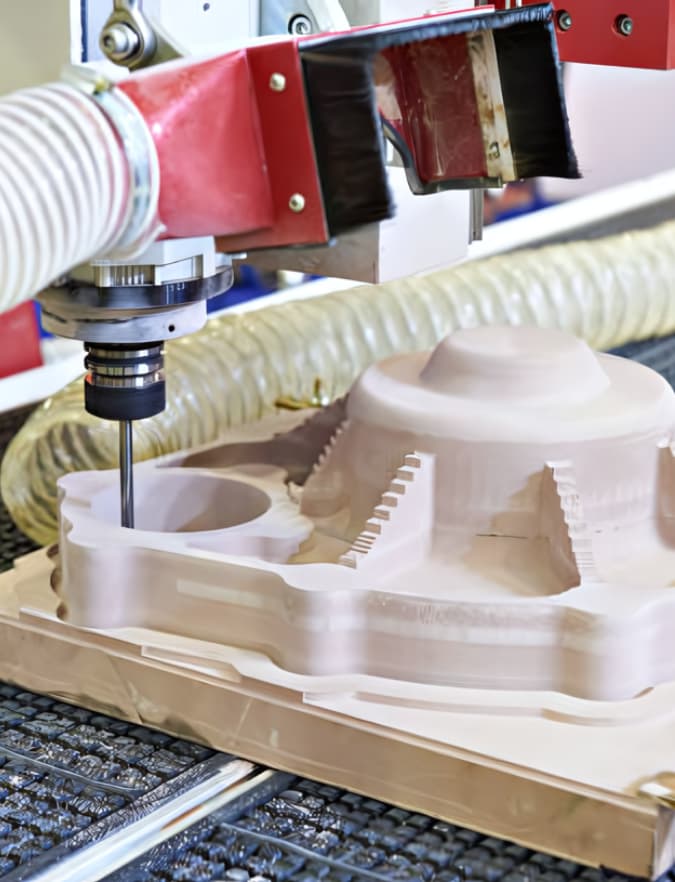

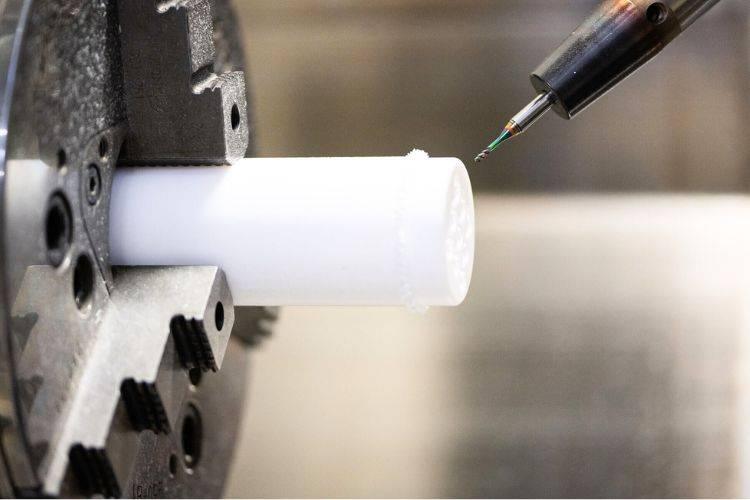

Our 5-axis CNC machining centers form the core of this capability. These systems enable the fabrication of intricate mold cavities, cores, and sliders with undercuts and organic geometries in a single setup, eliminating cumulative alignment errors inherent in multi-step processes. This precision directly translates to reduced knit lines, minimized flash, and uniform wall thickness in final HDPE parts—critical for pressure-rated containers, medical components, and automotive fluid systems. Advanced toolpath strategies ensure surface finishes as fine as Ra 0.4 µm, reducing post-machining labor and enhancing part ejection reliability. Crucially, our 5-axis capability allows for the precise integration of conformal cooling channels within mold cores. These channels follow the part contour, enabling rapid, uniform heat extraction during HDPE solidification. This reduces cycle times by up to 25% while minimizing warpage and internal stresses, directly improving part quality and production economics.

Thermal stability is paramount for HDPE molds due to the material’s sensitivity to temperature gradients. We utilize stress-relieved P20, H13, and stainless steel alloys, machined under controlled thermal conditions to prevent distortion. Every critical feature undergoes validation via Coordinate Measuring Machine (CMM) inspection, with full 3D reporting against CAD models. Our Zeiss CONTURA CMMs achieve measurement uncertainties of ±2.5 µm + L/300 µm, verifying geometric dimensioning and tolerancing (GD&T) compliance for features like core pin locations, vent depths, and cooling channel alignment. This metrology-backed approach ensures molds perform predictably across thousands of cycles, even under the high clamping forces and thermal cycling typical of HDPE processing.

The following table details our standard and precision machining tolerance capabilities for mold components, validated through CMM inspection and adhering to ISO 2768-mK standards where applicable. These tolerances are consistently achieved across materials including tool steels, aluminum, and copper alloys used in HDPE molding applications.

| Feature Type | Standard Capability | Precision Capability | Measurement Standard |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | ISO 2768-mK / ASME Y14.5 |

| Angular Dimensions | ±0.05° | ±0.01° | ISO 1101 |

| Flatness | 0.010 mm/m | 0.003 mm/m | ISO 128-24 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | ISO 4287 |

| Positional Tolerance | ±0.008 mm | ±0.002 mm | ASME Y14.5 GD&T |

Notes: Precision capabilities apply to features ≤ 300 mm; require stress-relieved materials and thermal stabilization. All measurements conducted in ISO Class 7 metrology lab at 20±0.5°C. Tolerances validated per ISO 10360-2 for CMM performance.

Precision in mold manufacturing is non-negotiable for HDPE success. At Wuxi Lead, our 5-axis machining, thermal management expertise, and CMM-verified quality control converge to deliver molds that maximize productivity, minimize waste, and ensure repeatability—transforming HDPE design intent into flawless production reality. Partner with us to convert complex requirements into measurable manufacturing outcomes.

Material & Finish Options

Material Selection for HDPE Injection Molding Tooling

In HDPE injection molding, the choice of tooling material is critical to ensuring long-term durability, dimensional stability, and cost efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance molds, leveraging advanced metallurgy and precision engineering to meet the demanding thermal and mechanical requirements of HDPE processing. The most commonly used materials for mold construction are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and surface finish requirements.

Aluminum alloys, such as 7075-T6 and 6061-T6, are favored for low- to medium-volume production runs due to their excellent machinability and thermal conductivity. These properties allow for faster cycle times and reduced energy consumption during molding. Aluminum molds are also significantly lighter, facilitating easier handling and installation. However, aluminum’s lower hardness makes it more susceptible to wear and abrasion, limiting its use in high-volume applications or with abrasive additives in HDPE formulations.

For high-volume production, tool steel—particularly P20, H13, and S136—is the preferred choice. These steels offer superior hardness, wear resistance, and thermal stability. P20 steel is commonly used for molds requiring moderate polish and durability, while H13 excels in applications involving high thermal cycling due to its excellent toughness and resistance to thermal fatigue. Stainless tool steels like S136 provide exceptional corrosion resistance, making them ideal for molding HDPE grades with high moisture content or chemical additives. Steel molds have a significantly longer service life but require more time and cost to manufacture.

Titanium and its alloys, though less common, are emerging in specialized applications where extreme wear resistance, high strength-to-density ratio, and corrosion resistance are paramount. While titanium molds are expensive and challenging to machine, they offer unparalleled longevity in aggressive molding environments and are particularly suitable for precision components in medical or aerospace industries.

Surface finishing plays a crucial role in part quality and mold maintenance. Anodizing is a widely used post-processing technique, especially for aluminum molds. This electrochemical process enhances surface hardness, improves wear resistance, and provides a non-conductive, corrosion-resistant layer. Hard anodizing (Type III) can increase surface hardness up to 60 HRC, making aluminum molds more competitive in medium-duty applications. For steel molds, alternatives such as nitriding, chrome plating, or PVD coatings are typically employed to achieve similar performance enhancements.

Below is a comparative overview of key material properties for HDPE injection molding tooling:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | Low | Prototypes, low-volume runs |

| P20 Steel | 28–32 | 30 | Moderate | Medium-volume production |

| H13 Steel | 48–52 | 35 | Moderate | High-thermal cycling molds |

| S136 Steel | 50–54 | 25 | High | Corrosion-prone environments |

| Titanium Ti-6Al-4V | 36–41 | 7 | Very High | High-wear, precision components |

Selecting the right material and finish ensures optimal mold performance, reduced downtime, and consistent part quality in HDPE injection molding operations.

Manufacturing Process & QC

HDPE Injection Molding: Precision Execution from Concept to Zero-Defect Production

Achieving flawless HDPE injection molded components demands a rigorously controlled process chain, where superior metal tooling forms the indispensable foundation. At Wuxi Lead Precision Machinery, our integrated approach ensures dimensional accuracy, material integrity, and absolute consistency, transforming client specifications into defect-free reality. This begins with meticulous design collaboration, where our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis. We evaluate wall thickness transitions, gate placement, and ejection strategies specific to HDPE’s crystalline structure and thermal behavior, utilizing advanced mold flow simulation to predict and eliminate potential sinks, warpage, or knit lines before metal is cut. This phase is critical for mitigating inherent HDPE challenges like post-molding shrinkage and ensuring optimal material flow within the cavity.

Prototyping serves as the vital validation stage, moving beyond theoretical simulation. Using the same high-precision hardened steel molds crafted by our CNC specialists, we produce functional prototypes under production-intent conditions. This allows rigorous physical testing of mechanical properties, dimensional conformity, and assembly fit. Any micro-adjustments identified—such as fine-tuning cooling channel layouts or venting—are implemented immediately on the tooling. This iterative step, conducted with the same metrology equipment used in full production, confirms the design’s manufacturability and eliminates costly surprises later. It transforms theoretical DFM insights into proven process parameters.

Mass production leverages the validated tooling and parameters within a tightly controlled environment. Our automated molding cells operate under strict Statistical Process Control (SPC), continuously monitoring critical variables like melt temperature, injection pressure, and cooling time. Real-time data feeds into our quality management system, triggering automatic adjustments to maintain stability. Every cycle is audited against the zero-defect standard through automated vision inspection and periodic CMM verification, ensuring parts consistently meet tolerances down to ±0.02mm. Material handling adheres to strict HDPE drying protocols to prevent hydrolysis-induced defects. This systematic execution, rooted in precision metal tooling and process discipline, guarantees that every component leaving our facility meets the highest industrial standards.

The table below outlines key process parameters and their control strategy across phases, demonstrating our commitment to repeatability:

| Parameter | Design Target (Simulation) | Prototype Validation | Mass Production Control |

|---|---|---|---|

| Melt Temperature | 200-230°C | Confirmed ±3°C | Real-time SPC ±2°C |

| Injection Pressure | Optimized via simulation | Validated flow front | Closed-loop control |

| Cooling Time | Calculated for shrinkage | Verified flatness | Dynamic adjustment |

| Dimensional Tolerance | Predicted variation | CMM verified (±0.05mm) | Automated inspection (±0.02mm) |

| Cycle Time | Estimated | Measured & optimized | Stabilized ±0.5 seconds |

Zero defects are not an aspiration but the engineered outcome of this seamless integration—where precision metal tooling, validated process science, and relentless monitoring converge. Wuxi Lead delivers production certainty for mission-critical HDPE components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced HDPE Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered solutions for demanding industrial applications. As a trusted leader in precision metal manufacturing based in China, we bring decades of engineering excellence to the field of HDPE injection molding. Our advanced machinery and deep material expertise ensure that your production goals are met with unmatched consistency, durability, and efficiency.

HDPE (High-Density Polyethylene) presents unique challenges in injection molding due to its high shrinkage rate, sensitivity to cooling parameters, and stringent requirements for dimensional stability. Standard molding equipment often falls short in maintaining the tight tolerances and surface finish demanded by industries such as automotive, medical devices, and industrial containers. That’s where Lead Precision stands apart. Our custom-built molding systems are engineered with precision-machined steel and aluminum components, optimized for thermal control, wear resistance, and long-term reliability in high-cycle environments.

We understand that every client has distinct production needs. Whether you’re developing complex multi-cavity molds, high-clamp-force applications, or specialized ejection systems, our engineering team works closely with you from concept to commissioning. We integrate advanced simulation tools and real-time monitoring systems to optimize mold flow, cooling efficiency, and cycle times—ensuring maximum output with minimal waste.

Our commitment to quality is reflected in every stage of manufacturing. All components are produced in-house using CNC machining centers with micron-level accuracy, followed by rigorous inspection using CMM and optical measurement systems. This vertical integration allows us to maintain full control over tolerances, material selection, and delivery timelines—critical advantages when scaling production or entering regulated markets.

Below are key technical specifications of our HDPE injection molding systems tailored for industrial clients:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 800 kN – 6,500 kN |

| Screw Diameter | 45 mm – 90 mm |

| Injection Pressure | Up to 220 MPa |

| Maximum Shot Weight (HDPE) | 1,800 g |

| Mold Thickness Range | 250 mm – 800 mm |

| Machine Control System | Siemens S7 with HMI touchscreen interface |

| Cooling Channel Optimization | CFD-verified design for uniform temperature |

| Repeatability (Shot Weight) | ±0.3% |

| Material Compatibility | HDPE, PP, LLDPE, recycled polyolefins |

| Compliance Standards | CE, ISO 9001, ISO 14001 |

Partnering with Wuxi Lead Precision Machinery means gaining a long-term engineering ally dedicated to your operational success. We don’t just supply equipment—we deliver performance-driven solutions backed by technical support, training, and global service coverage.

For detailed consultation or to request a custom quote for your HDPE injection molding project, contact us today at [email protected]. Let Lead Precision power the next generation of your manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.