Technical Contents

Engineering Guide: Cheap 3D Printing Services

Engineering Insight: The Critical Cost of Precision in Metal 3D Printing

The market demand for ostensibly “cheap 3D printing services” is understandable in today’s cost-conscious manufacturing landscape. However, for mission-critical custom metal components, prioritizing the lowest initial price often represents a profound false economy. True value in additive manufacturing is defined not by the quoted service fee, but by the unwavering precision, material integrity, and functional reliability delivered. In aerospace, defense, medical implant, and high-performance industrial applications, dimensional inaccuracies measured in microns or undetected material porosity can cascade into catastrophic system failure, regulatory rejection, or costly field recalls. The upfront savings of a budget service vanish when weighed against the immense downstream costs of rework, liability, and reputational damage.

Precision in metal 3D printing is non-negotiable. It demands rigorous control over the entire process chain: certified raw materials with traceable chemistry, meticulously calibrated laser parameters and environmental conditions within the build chamber, sophisticated in-situ monitoring, and stringent post-processing protocols including stress relieving, precision machining, and comprehensive non-destructive testing (NDT). This level of control requires significant investment in high-end machinery, metallurgical expertise, and quality management systems far beyond the scope of providers focused solely on minimal pricing. At Wuxi Lead Precision Machinery, our engineering philosophy is built on this understanding. Our work supporting Olympic infrastructure projects and classified military applications underscores the absolute necessity of zero-defect manufacturing. Components we produce for stadium structural elements or defense systems operate under extreme loads and environmental stresses where failure is inconceivable; achieving this demands precision that cheap services simply cannot replicate.

The technical disparity between budget offerings and precision-engineered metal AM is stark. Consider the critical specifications:

| Parameter | Typical Budget Service Offering | Wuxi Lead Precision Standard |

|---|---|---|

| Dimensional Accuracy | ±0.2% to ±0.5% (often higher) | ±0.05mm to ±0.1mm |

| Surface Roughness (As-Built) | Ra 15-25 µm | Ra 8-12 µm (controlled) |

| Material Density | 95-98% (porosity common) | >99.95% (near full density) |

| NDT Coverage | Often limited or absent | 100% (UT, X-Ray, Dye Pen) |

| Material Certification | Generic or incomplete | Full Mill Cert + In-House Validation |

This table illustrates why price alone is an inadequate metric. The tighter tolerances, superior surface integrity, guaranteed material density, and exhaustive testing inherent in precision manufacturing directly translate to component longevity, performance consistency, and regulatory compliance. Wuxi Lead Precision Machinery leverages its deep experience in high-stakes sectors to apply this same uncompromising standard to every custom metal part we produce. We understand that for our clients in demanding industries, the true cost of 3D printing is measured not at the order placement, but throughout the component’s operational life. When failure is not an option, precision is the only acceptable price. Partner with an engineering-led manufacturer where capability, not just cost, defines the solution.

Precision Specs & Tolerances

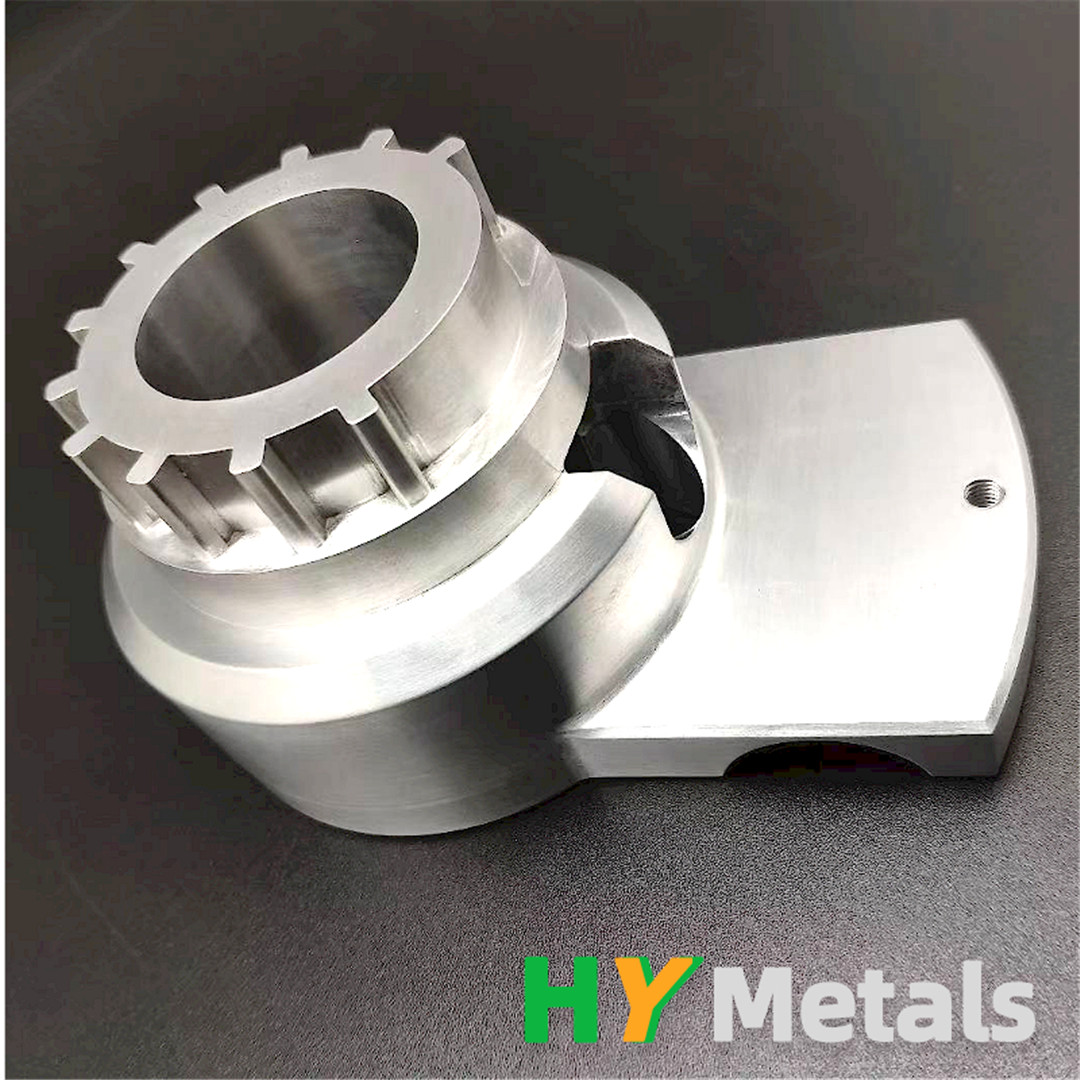

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions, engineered for precision, repeatability, and performance in demanding industrial applications. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with superior surface finish and dimensional accuracy. Our multi-axis machining centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems, ensuring optimal cutting performance across a wide range of engineering alloys, including titanium, aluminum, stainless steel, and Inconel.

The 5-axis architecture allows simultaneous movement across all five axes, minimizing setup changes and eliminating the risk of misalignment during multi-faceted operations. This capability is particularly critical for aerospace, medical, and energy sector components, where tight tolerances and intricate features are non-negotiable. Our programming team utilizes advanced CAM software to generate optimized toolpaths, reducing cycle times while maintaining micron-level precision. All machining processes are supported by rigorous in-process inspections and a climate-controlled production environment to mitigate thermal drift.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive post-production inspection using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), calibrated to international standards. The CMM provides full 3D geometric validation, including form, position, profile, and surface integrity, ensuring compliance with ISO 1101 and ASME Y14.5 specifications. Data from each inspection is documented in a full traceability report, available to clients as part of our quality submission package.

Our commitment to precision is quantified in the tolerances we consistently achieve across various feature types. These values reflect real-world production capability under controlled conditions and are maintained through continuous machine calibration and operator training.

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.010 | Up to 300 mm |

| Linear Dimensions (mm) | ±0.050 | ±0.025 | 300–600 mm |

| Hole Diameter | ±0.020 | ±0.010 | Reamed or precision bored |

| Positional Tolerance | ±0.025 | ±0.012 | Relative to datum |

| Profile Tolerance | ±0.030 | ±0.015 | Complex surfaces |

| Surface Finish (Ra) | 1.6 µm | 0.8 µm | As machined;可polished to 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.02° | Critical mating surfaces |

All tolerances are achievable on first-article and production runs, supported by statistical process control (SPC) methodologies. Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade verification to deliver custom metal components that meet the highest standards of engineering excellence.

Material & Finish Options

Material Selection for Precision Metal Components: Beyond the 3D Printing Misconception

Wuxi Lead Precision Machinery frequently encounters requests for “cheap 3D printing services” in custom metal manufacturing. It is critical to clarify that high-integrity, production-grade metal components for industrial applications are predominantly manufactured using CNC machining, not metal 3D printing. While additive manufacturing has niche uses, CNC machining delivers superior dimensional accuracy, surface finish, material properties, and cost-efficiency for most metal parts at scale. True value lies in intelligent material and process selection, not chasing misleading low-cost labels. Selecting the optimal metal alloy directly impacts part performance, longevity, manufacturability, and total project cost.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are industry staples for lightweight structural components requiring good strength-to-weight ratio and excellent machinability. They are ideal for aerospace brackets, automotive housings, and consumer electronics enclosures. Aluminum responds exceptionally well to anodizing, creating a hard, corrosion-resistant, and electrically insulating surface layer available in various colors. Steel alloys, including 303, 304, and 17-4 PH stainless, provide high strength, wear resistance, and durability for demanding applications like hydraulic fittings, medical instruments, and industrial machinery shafts. While stainless steel offers inherent corrosion resistance, passivation is standard; anodizing is not applicable. Titanium Grade 5 (Ti-6Al-4V) is the choice for extreme environments demanding exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance, common in aerospace landing gear, medical implants, and marine components. Its challenging machinability requires specialized tooling and expertise but yields unparalleled performance where weight and durability are critical.

Anodizing is a vital electrochemical finish primarily for aluminum, significantly enhancing surface properties. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability. Type III (hardcoat) anodizing creates a much thicker, harder, and more abrasion-resistant layer essential for high-wear applications, though it limits color options. Proper pre-treatment and process control are non-negotiable for consistent, high-quality results that meet aerospace or medical standards.

Material selection must align with functional requirements, environmental exposure, regulatory needs, and production volume. Choosing incorrectly leads to premature failure, costly rework, or over-engineering. Our engineering team rigorously evaluates your application to recommend the optimal alloy and finish, ensuring performance and cost-effectiveness.

Key Metal Alloy Specifications for CNC Machining

| Material | Key Properties | Typical Applications | Machinability Rating (Relative) |

|---|---|---|---|

| Aluminum 6061-T6 | Good strength, excellent corrosion resistance, weldable, 310 MPa tensile strength | Brackets, enclosures, automotive parts | Excellent (9/10) |

| Stainless 304 | High corrosion resistance, non-magnetic, 515 MPa tensile strength | Valves, pumps, food processing equipment | Good (7/10) |

| Titanium Ti-6Al-4V | Exceptional strength-to-weight, biocompatible, 900 MPa tensile strength | Aerospace components, medical implants | Fair (5/10) |

| Steel 17-4 PH | High strength, good corrosion resistance, heat-treatable, 1000+ MPa tensile strength | Gears, shafts, aerospace fittings | Moderate (6/10) |

Partnering with an experienced precision manufacturer like Wuxi Lead ensures your material and finish choices translate into reliable, high-performance components delivered on time and within budget. We prioritize engineering integrity over misleading cost metrics.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, every successful manufacturing project begins with a rigorously engineered design phase. We collaborate closely with clients to transform conceptual ideas into detailed 3D CAD models, ensuring all functional, dimensional, and material requirements are met. Our engineering team employs advanced simulation software to conduct structural, thermal, and stress analysis, validating performance under real-world conditions. This proactive approach eliminates design flaws before physical production begins, reducing risk and accelerating time-to-market. Design for Manufacturability (DFM) principles are applied throughout, optimizing geometry, tolerances, and assembly methods to ensure seamless transition into prototyping and mass production.

Prototyping: Validating Performance with Zero Defects

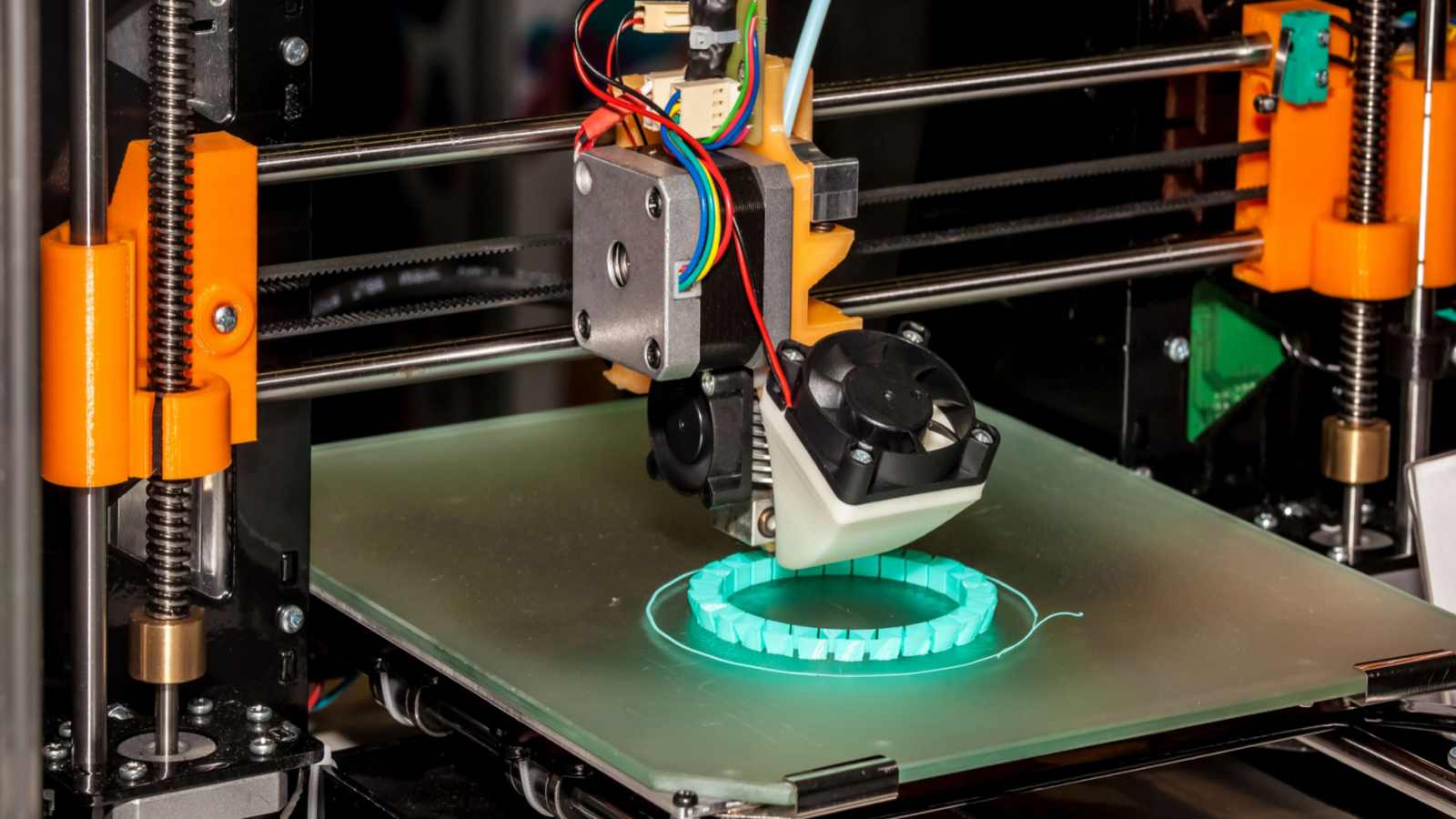

Once the design is finalized, we move into the prototyping stage using high-precision additive manufacturing and CNC machining techniques. Our metal 3D printing services utilize state-of-the-art technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), enabling rapid fabrication of complex, high-integrity metal parts in materials including titanium, stainless steel, aluminum, and Inconel. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical scanning, and metallurgical analysis to verify dimensional accuracy, surface integrity, and material properties. This validation phase ensures that form, fit, and function align exactly with design intent. Any necessary refinements are incorporated digitally before approval for full-scale production, guaranteeing a zero-defect pathway forward.

Mass Production: Scalable Precision with Full Traceability

With prototype validation complete, we transition to high-volume manufacturing using a hybrid approach that integrates CNC machining, precision stamping, and automated 3D printing cells. Our production floor is equipped with IoT-enabled machines that provide real-time monitoring of critical parameters such as temperature, tool wear, and dimensional drift. This data-driven environment allows for immediate corrective action, maintaining strict adherence to quality standards. Each component is serialized and tracked through our quality management system, ensuring full traceability from raw material to finished part. In-process inspections and final QA audits are conducted at defined intervals, with all results documented per ISO 9001 and IATF 16949 standards.

Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Inconel (718, 625), Tool Steel |

| Tolerances | ±0.02 mm for 3D printed parts; ±0.005 mm for CNC machined components |

| Layer Thickness (AM) | 20–50 μm |

| Build Volume (SLM) | Up to 500 x 500 x 400 mm |

| Surface Roughness (Ra) | 4–12 μm (as-built); <1.6 μm (post-processed) |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (depending on volume) |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAI documentation |

Through this integrated process—design, prototyping, and mass production—Wuxi Lead ensures every metal component meets the highest standards of precision, reliability, and consistency, delivering true zero-defect manufacturing for demanding industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Metal Additive Manufacturing Beyond Compromise

The pursuit of inexpensive metal 3D printing often leads to critical failures: inconsistent microstructures, dimensional inaccuracies, and parts that fracture under operational stress. At Wuxi Lead Precision Machinery, we reject the false economy of “cheap” metal additive services. Our industrial-grade metal AM solutions prioritize repeatability, material integrity, and engineering validation—ensuring your components perform reliably in aerospace, medical, and energy applications where failure is not an option. We transform complex geometries into mission-critical assets through rigorous process control and metallurgical expertise, eliminating the hidden costs of rework, delays, and compromised safety.

Our integrated manufacturing ecosystem combines EOS and SLM industrial printers with in-house CNC finishing, heat treatment, and non-destructive testing. Every build undergoes real-time melt pool monitoring and post-process metrology to guarantee dimensional stability within ±0.05 mm and surface finishes as fine as Ra 1.6 μm. Unlike commoditized services, we collaborate from design inception—optimizing topology, support structures, and material selection to reduce weight without sacrificing strength. This holistic approach delivers certified parts that meet ASTM F75, F136, and AMS 7000 standards, turning ambitious designs into field-ready components.

Technical Capabilities at a Glance

| Parameter | Specification | Industry Impact |

|——————–|—————————————-|————————————-|

| Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg | Corrosion resistance, high-temp stability |

| Build Volume | 500 x 500 x 500 mm | Large-scale industrial components |

| Accuracy | ±0.05 mm (as-built), ±0.02 mm (CNC post-processed) | Precision fit for critical assemblies |

| Post-Processing | HIP, Stress Relief, CNC Milling, Polishing | Eliminates internal defects, ensures fatigue life |

| Certifications | ISO 9001, AS9100, NADCAP | Compliance for regulated sectors |

Partnering with Lead Precision means accessing a dedicated engineering team that treats your project as a technical partnership—not a transaction. We begin with a free design-for-additive (DfAM) review to identify cost-saving opportunities without compromising performance. Our Ningbo facility operates 24/7 with live build tracking, providing transparency from powder management to final inspection. When your application demands zero-defect reliability, our closed-loop quality system delivers traceability from electron beam to end-use installation.

Stop accepting the limitations of budget metal printing. Contact our engineering team today to request a project assessment and discover how our precision metal AM services reduce your total cost of ownership. Email [email protected] with your CAD file and requirements—we respond within 4 business hours with actionable feedback. Let us prove why global leaders in turbine manufacturing and surgical robotics trust Lead Precision for parts that perform when it matters most. Your breakthrough design deserves manufacturing excellence, not compromises. Reach out now to engineer the future together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.