Technical Contents

Engineering Guide: A & L Sheet Metal

Engineering Insight Precision in A & L Sheet Metal Fabrication

Precision in sheet metal fabrication transcends mere dimensional accuracy; it is the foundational element ensuring structural integrity, seamless assembly, and ultimate product performance. For critical applications within aerospace, defense, and high-end industrial sectors, even micron-level deviations in components designated as ‘A & L sheet metal’ can trigger catastrophic dimensional instability cascading through entire assemblies. This demands a manufacturing partner possessing not only advanced machinery but also deep engineering expertise capable of interpreting complex GD&T callouts and mitigating inherent material behaviors like springback and warpage during forming. At Wuxi Lead Precision Machinery, we recognize that true precision begins long before the laser fires or the brake press activates. It starts with rigorous material certification tracking, comprehensive process validation, and a culture where tolerances are not targets but non-negotiable requirements.

Our engineering team applies decades of specialized experience specifically honed on mission-critical sheet metal components. We understand the stringent demands of applications where failure is not an option. This expertise is proven through our successful contribution to projects requiring the highest levels of reliability, including structural elements for Olympic venue infrastructure and precision housings for advanced military communication systems. These engagements demanded absolute adherence to aerospace-grade quality standards, complex multi-axis forming sequences, and flawless integration of laser cutting, bending, welding, and finishing processes – all executed within tightly controlled environmental conditions to ensure repeatability. Our facility operates under strict AS9100 and ISO 9001 frameworks, with every stage of production meticulously documented and traceable.

The capability to consistently achieve and verify such precision is embedded in our technological infrastructure. We utilize state-of-the-art fiber laser cutting systems coupled with high-tonnage CNC press brakes featuring real-time angle correction and in-process metrology. This integrated approach ensures that the theoretical precision defined in CAD models is physically realized in the final component. The following table outlines key precision capabilities central to our A & L sheet metal fabrication services:

| Specification Category | Capability | Measurement Standard |

|---|---|---|

| Laser Cutting Tolerance | ±0.05 mm | ISO 2768-mK |

| Forming Angle Accuracy | ±0.25° | Per print GD&T |

| Hole Positional Tolerance | ±0.02 mm | ISO 2768-fH |

| Material Thickness Range | 0.5 mm – 6.0 mm | ASTM/EN/JIS |

| Critical Feature Repeatability (CpK) | ≥ 1.67 | Statistical Process Control |

Achieving this level of precision requires moving beyond standard production protocols. It necessitates proactive engineering collaboration during the design phase (DFM), sophisticated simulation of forming processes to predict and compensate for material behavior, and the deployment of high-resolution CMM and optical measurement systems for final verification. Wuxi Lead Precision Machinery delivers this integrated precision engineering capability, transforming complex A & L sheet metal specifications into reliable, high-performance components ready for the most demanding global applications. Your critical assemblies demand nothing less than engineered perfection.

Precision Specs & Tolerances

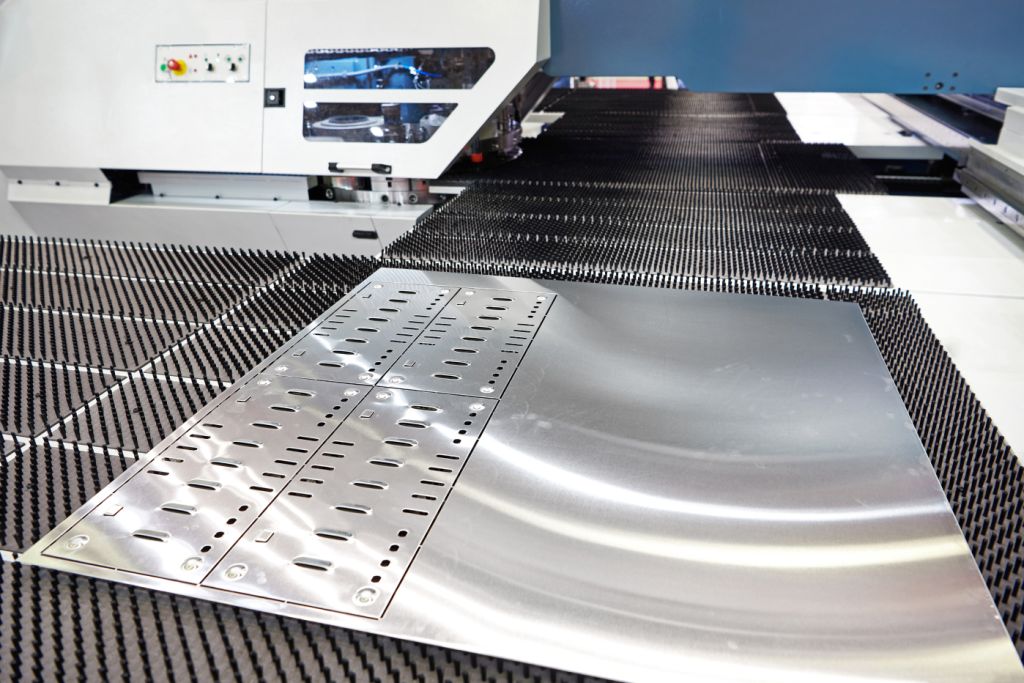

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industries including aerospace, medical, energy, and industrial automation. Our technical capabilities are built around state-of-the-art 5-axis CNC machining systems, integrated with automated tooling and high-speed spindles to ensure exceptional accuracy, surface finish, and geometric complexity. These systems enable multi-angle cutting, drilling, and milling in a single setup, minimizing human intervention and reducing cumulative errors typically associated with repositioning. This level of precision is critical when producing components with tight tolerances and intricate geometries, particularly in low-volume, high-mix manufacturing environments.

Our sheet metal processing workflow begins with digital CAD/CAM integration, allowing seamless translation from design to production. We support a wide range of materials including stainless steel, aluminum alloys, carbon steel, copper, and specialty alloys, with thicknesses ranging from 0.5 mm to 12 mm. Advanced nesting software optimizes material utilization, reducing waste and improving cost efficiency without compromising quality. Laser cutting, CNC punching, precision bending, and robotic welding are all supported within our facility, ensuring comprehensive in-house capabilities for end-to-end part production.

Quality control is embedded at every stage of manufacturing. All critical components undergo full dimensional inspection using a coordinate measuring machine (CMM) with sub-micron resolution. The CMM system is calibrated to ISO 10360 standards and operates in a temperature-controlled metrology lab to eliminate thermal drift. This ensures repeatable, traceable measurement data that meets the stringent documentation requirements of regulated industries. Additionally, first article inspection (FAI) reports and production-level SPC (statistical process control) data are available upon request.

We maintain full compliance with ISO 9001:2015 quality management standards, and our engineering team works closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce lead times, and enhance performance. With a focus on precision, repeatability, and technical agility, Wuxi Lead Precision Machinery serves as a trusted partner for OEMs requiring mission-critical sheet metal components.

The following table outlines our standard technical specifications and achievable tolerances across key fabrication processes:

| Process | Typical Tolerance | Material Thickness Range | Max Work Envelope (mm) | Surface Finish (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | N/A (post-formed) | 1200 x 800 x 600 | 0.8 – 3.2 µm |

| Laser Cutting | ±0.05 mm | 0.5 – 12 mm | 3000 x 1500 | 6.3 – 12.5 µm |

| CNC Punching | ±0.1 mm | 0.8 – 6.0 mm | 2500 x 1250 | 6.3 – 25 µm |

| Precision Bending | ±0.2° angular / ±0.1 mm | 0.5 – 10 mm | 4000 x 2000 | As formed |

| CMM Inspection | Resolution: 0.001 mm | N/A | 1000 x 700 x 600 | N/A |

All tolerances are achievable under standard production conditions and may be tightened based on material, geometry, and customer requirements.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material selection fundamentally determines the performance, longevity, and cost-effectiveness of sheet metal components. At Wuxi Lead Precision Machinery, we emphasize that this choice is not merely transactional but a critical engineering decision impacting manufacturability, structural integrity, and final application success. Understanding the nuanced properties of core materials and compatible finishes is essential for high-end B2B manufacturing. We guide clients through this complex landscape to ensure optimal part realization.

Aluminum alloys, particularly 6061-T6, dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio and inherent corrosion resistance. Its natural oxide layer provides baseline protection, while excellent thermal and electrical conductivity suit heat sinks and enclosures. Aluminum’s machinability allows for complex geometries with tight tolerances, though its lower hardness compared to steel requires design consideration for high-wear applications. Cost efficiency combined with recyclability enhances its lifecycle value proposition.

Carbon steel and stainless steel variants like 304 offer superior strength, rigidity, and load-bearing capacity essential for structural frames, machinery guards, and heavy industrial equipment. Carbon steel provides the most economical solution for non-corrosive environments but mandates protective finishes. Stainless steel 304 delivers robust corrosion and heat resistance through chromium content, making it ideal for food processing, medical, and marine applications. Both require careful handling during fabrication to prevent work hardening or surface contamination affecting final performance.

Titanium Grade 2 stands apart for extreme environments demanding the highest strength-to-weight ratio, unparalleled corrosion resistance (especially against chlorides and acids), and biocompatibility. Its use is critical in aerospace critical components, medical implants, and chemical processing equipment. While significantly more expensive and challenging to machine than aluminum or steel, titanium’s exceptional fatigue strength and non-magnetic properties justify its cost where failure is not an option. Thermal management during cutting and forming is paramount.

Anodizing is the premier finish for aluminum, transforming its surface into a durable, corrosion-resistant ceramic layer. Type II (Sulfuric Acid) anodizing provides good wear resistance and dye acceptance for aesthetic or identification purposes. Type III (Hard Anodizing) creates a much thicker, harder, and more abrasion-resistant coating essential for high-wear mechanical parts, often meeting military or aerospace specifications like MIL-A-8625. Anodizing enhances paint adhesion but is exclusive to aluminum; steel requires alternatives like powder coating or plating, while titanium typically relies on passivation or specialized coatings.

Material properties directly influence fabrication strategy and final part quality. The following table summarizes key characteristics for common high-end sheet metals:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | Good (Anodized: Exc) | Excellent | Medium |

| Stainless Steel 304 | 8.00 | 515 | Excellent | Fair | High |

| Titanium Grade 2 | 4.51 | 345 | Exceptional | Poor | Very High |

Selecting the optimal material requires balancing application demands, environmental exposure, regulatory requirements, and total cost of ownership. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced CNC capabilities to advise on and execute fabrication for the most demanding specifications. Consult our engineering team early in your design phase to ensure material and finish selection aligns perfectly with your performance goals and manufacturing efficiency.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, where precision and functionality converge. Our team of experienced mechanical engineers and CAD specialists work closely with clients to translate conceptual ideas into detailed 3D models and technical drawings. Utilizing advanced software such as SolidWorks, AutoCAD, and Siemens NX, we ensure every dimension, bend, and tolerance is optimized for manufacturability. Design for Manufacturability (DFM) analysis is conducted at this stage to identify potential issues early, minimizing rework and material waste. This proactive approach ensures that the final product not only meets but exceeds performance and quality expectations. All designs are reviewed against international standards including ISO 2768 and GD&T specifications to guarantee consistency and compatibility across global applications.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototyping—a critical phase that bridges concept and mass production. At Wuxi Lead, prototypes are manufactured using the same materials and processes intended for full-scale production, including laser cutting, CNC punching, bending, and welding. This ensures accurate representation of form, fit, and function. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to verify dimensional accuracy within ±0.05 mm. Functional testing, environmental simulation, and assembly trials are performed to validate performance under real-world conditions. Client feedback is incorporated at this stage, allowing for design refinements before committing to large-volume manufacturing. This iterative validation process is central to our zero-defect philosophy, eliminating risks before scale-up.

Mass Production: Precision, Consistency, Zero Defects

With prototype approval, we transition seamlessly into mass production. Our state-of-the-art facility in Wuxi integrates automated sheet metal processing lines, including Amada and Bystronic laser cutters, CNC turret presses, and robotic bending cells. These systems are monitored in real time through a centralized MES (Manufacturing Execution System), ensuring full traceability and process control. Every component is inspected at multiple stages using SPC (Statistical Process Control) methodologies to maintain consistent quality. Final products undergo 100% visual and dimensional checks, with batch sampling subjected to destructive and non-destructive testing as required. Our ISO 9001-certified quality management system enforces strict adherence to zero-defect targets, supported by continuous improvement initiatives such as Six Sigma and 5S.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 – 6.0 mm |

| Tolerance (Standard) | ±0.05 mm |

| Max Sheet Size | 1500 × 3000 mm |

| Laser Cutting Accuracy | ±0.03 mm |

| Bend Angle Tolerance | ±0.5° |

| Surface Roughness (Ra) | ≤1.6 μm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standard | ISO 9001:2015, ISO 2768 |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers sheet metal components with uncompromising quality—ensuring reliability, repeatability, and zero defects for high-end industrial clients worldwide.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Strategic Partnership

In today’s competitive manufacturing landscape, the precision and reliability of your sheet metal components directly impact product performance, assembly efficiency, and time-to-market. Generic fabrication services often introduce hidden costs through rework, delays, and compromised tolerances. Partnering with Wuxi Lead Precision Machinery means aligning with an engineering-driven manufacturer that treats your specifications as non-negotiable commitments. We bridge the gap between Chinese cost efficiency and German-tier precision engineering, delivering components that integrate seamlessly into your high-stakes assemblies. Our facility operates under ISO 9001:2015 and IATF 16949 standards, with real-time SPC monitoring across all production lines. This ensures every bracket, enclosure, or chassis meets your dimensional and material requirements without deviation—eliminating costly downstream corrections.

Our technical capabilities are engineered for complex, low-to-medium volume production where accuracy dictates success. The table below details core processes supporting aerospace, medical, and industrial equipment manufacturers:

| Process | Maximum Capacity | Precision Range | Supported Materials |

|---|---|---|---|

| Fiber Laser Cutting | 4000W, 6000mm x 3000mm | ±0.05mm | Mild Steel, Stainless, Aluminum, Copper |

| CNC Turret Punching | 60-ton, 3000mm x 1500mm | ±0.08mm | Up to 6.0mm thickness |

| Press Brake Forming | 300-ton, 4000mm bed | ±0.1° angular | Full material compatibility |

| Robotic Welding | MIG/TIG, 6-axis | ±0.2mm positional | Certified to AWS D1.1 |

| Finishing | Powder Coat, Anodize | Thickness-controlled | RoHS-compliant options |

Beyond machinery, our value lies in proactive engineering collaboration. From DFM analysis that reduces material waste by 18% on average to first-article inspection reports with 3D scan validation, we embed quality into every phase. Clients gain dedicated project managers fluent in technical English and German, ensuring zero miscommunication on critical specifications. Our Ningbo-based facility leverages China’s supply chain advantages while maintaining Western accountability—no batch-lot surprises, no unapproved subcontracting.

Stop compromising between cost and precision. High-integrity sheet metal fabrication requires a partner invested in your end-product success, not just transactional order fulfillment. Wuxi Lead Precision Machinery delivers certified repeatability for components where ±0.1mm tolerances define functionality. Reduce assembly time, minimize scrap, and accelerate certification with documentation that meets global regulatory demands.

Initiate your precision partnership today. Email [email protected] with your technical drawings and volume requirements. Our engineering team will respond within 4 business hours with a tailored capability assessment and DFM feedback—no generic quotations. Let us prove how strategic manufacturing collaboration drives your competitive advantage. Your next-generation product deserves nothing less than engineered perfection.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.