Technical Contents

Engineering Guide: Usa Metals And Auto Parts

Engineering Insight Precision as the Non-Negotiable Foundation for USA Metals and Auto Parts

In the demanding landscape of US automotive manufacturing and metal component supply, precision is not merely a desirable attribute; it is the absolute bedrock of performance, safety, and longevity. Modern vehicles operate under extreme conditions – high temperatures, intense vibration, and relentless mechanical stress. Components manufactured even slightly outside stringent tolerances become immediate liabilities. A bearing raceway with sub-micron deviation accelerates wear exponentially. A fuel injector nozzle with inconsistent orifice geometry disrupts combustion efficiency and emissions compliance. A suspension knuckle lacking perfect dimensional integrity compromises vehicle handling and safety margins. For Tier 1 suppliers and OEMs serving the US market, where regulatory scrutiny and consumer expectations are paramount, the cost of imprecision extends far beyond scrap and rework; it encompasses warranty claims, brand damage, and potential recalls. Achieving the required levels of accuracy demands more than advanced machinery; it requires an ingrained engineering culture focused on metrology, process control, and material science.

At Wuxi Lead Precision Machinery, we engineer precision into every component from the initial design review through final inspection. Our approach centers on certified metrology labs operating under ISO 17025 standards, utilizing coordinate measuring machines (CMMs) capable of sub-micron resolution, and implementing real-time process monitoring on our CNC machining centers. This rigorous methodology ensures consistent adherence to the most exacting specifications demanded by the US automotive sector. Our capabilities are proven not only in high-volume auto part production but also in projects where failure is unthinkable.

Critical Precision Specifications for Automotive Metal Components

| Parameter | Typical Requirement (US Auto) | Wuxi Lead Capability | Measurement Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.025mm to ±0.05mm | ±0.005mm to ±0.010mm | ISO 2768-mK |

| Geometric Tolerance (GD&T) | IT6 to IT7 | IT5 to IT6 | ASME Y14.5-2018 |

| Surface Roughness (Ra) | 0.8µm to 3.2µm | 0.2µm to 0.8µm | ISO 1302 |

| Material Certification | PPAP Level 3 Required | Full Mill Cert + In-House Verification | ASTM/SAE Standards |

| Process Capability (Cpk) | ≥1.33 | ≥1.67 Consistently | Statistical Process Control |

This commitment to extreme accuracy is validated through our direct contributions to projects requiring the highest levels of reliability. We supplied critical timing system components for the Beijing 2022 Winter Olympics, where timing precision measured in thousandths of a second was mandatory for fair competition. Furthermore, our machining centers produce flight-critical structural elements for advanced military platforms, adhering to stringent MIL-STD-883 and ITAR-controlled processes where dimensional integrity directly impacts mission success and personnel safety. These experiences forge our understanding that in aerospace, defense, and high-performance automotive applications, precision is the singular factor separating functional components from critical failures. For US metals and auto parts manufacturers seeking a partner capable of meeting and exceeding the most rigorous precision demands, Wuxi Lead Precision Machinery delivers engineered accuracy backed by proven, mission-critical execution.

Precision Specs & Tolerances

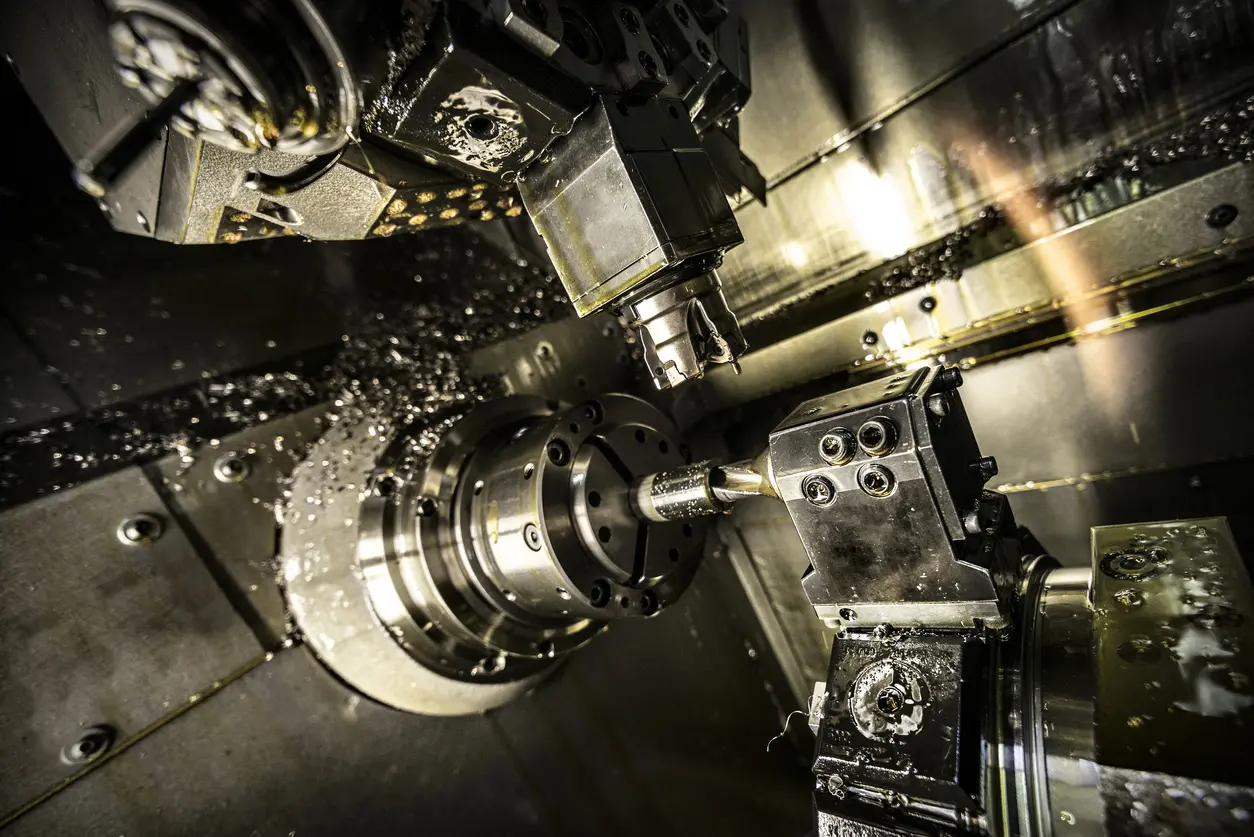

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries, including automotive, aerospace, and industrial automation. Our technical capabilities are engineered to meet the rigorous demands of precision-critical applications, particularly for clients in the USA metals and auto parts sector. At the core of our production workflow is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These machines support simultaneous multi-axis movement, allowing for intricate part features that would be unattainable with traditional 3-axis systems. This capability significantly reduces setup times, improves dimensional consistency, and ensures faster turnaround without compromising quality.

All machining operations are supported by a fully integrated digital manufacturing environment. We utilize advanced CAD/CAM software to simulate toolpaths, optimize cutting strategies, and ensure collision-free machining. This digital-first approach ensures that every component is manufactured to exact specifications, minimizing waste and maximizing repeatability. Materials commonly processed include aluminum alloys, stainless steel, titanium, and high-strength alloy steels—frequently used in automotive structural components, transmission systems, and performance-critical metal parts.

Quality control is embedded at every stage of production. Our dedicated metrology lab is equipped with high-precision Coordinate Measuring Machines (CMM) that perform comprehensive inspection routines on critical dimensions, geometric tolerances, and surface characteristics. Each part undergoes full first-article inspection (FAI) for new programs and periodic in-process checks during batch production. The CMM system generates detailed inspection reports compliant with ISO 9001 standards, providing full traceability and documentation for customer audits.

To ensure consistent output, we maintain strict environmental controls in the metrology lab and calibrate all measurement equipment annually to NIST-traceable standards. Our quality engineers are certified in GD&T (Geometric Dimensioning and Tolerancing), enabling precise interpretation of complex engineering drawings and ensuring that all parts meet or exceed customer specifications.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.025 mm | ±0.005 mm | Depending on part geometry and material |

| Geometric Tolerance (GD&T) | ±0.02 mm (Position, Flatness, etc.) | ±0.008 mm | Verified via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achievable with fine finishing passes |

| Hole Diameter Tolerance | H7 | H6 | Reamed or precision bored |

| Angular Tolerance | ±0.1° | ±0.05° | Verified with CMM and optical comparators |

| Maximum Work Envelope | 1200 x 800 x 600 mm | — | For 5-axis machining centers |

| Material Removal Rate (Typical) | Up to 1200 cm³/min | — | Varies by material and tooling |

Our combination of 5-axis CNC technology, rigorous CMM-based inspection, and adherence to international quality standards positions Wuxi Lead Precision Machinery as a trusted partner for high-end custom metal manufacturing in the global supply chain.

Material & Finish Options

Material Selection for High-Performance Automotive Components

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in automotive metal parts. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with functional demands, environmental exposure, and manufacturing constraints. Below we detail critical considerations for aluminum, steel, and titanium, alongside essential finishing processes like anodizing.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate lightweight structural applications due to their exceptional strength-to-weight ratio and corrosion resistance. These alloys are ideal for suspension arms, engine mounts, and chassis components where weight reduction directly enhances fuel efficiency and handling. However, aluminum requires protective finishing to withstand abrasive or chemically aggressive environments common in under-hood applications.

Steel remains indispensable for high-stress, high-wear parts like drivetrain components, brackets, and safety-critical structures. Grades such as 4140 chrome-moly steel offer superior tensile strength and fatigue resistance, while 304/316 stainless steels provide unmatched corrosion protection for exhaust systems and marine-exposed parts. Steel’s machinability and weldability simplify complex geometries but necessitate precise heat treatment to prevent distortion during CNC processing.

Titanium Grade 5 (Ti-6Al-4V) delivers unparalleled strength-to-weight performance and extreme corrosion resistance, making it essential for high-end racing and aerospace-derived automotive systems. Its use in connecting rods, valve springs, and turbocharger housings reduces rotational mass significantly. However, titanium’s low thermal conductivity and chemical reactivity demand specialized CNC tooling and slower machining parameters to avoid work hardening and tool wear.

Anodizing is non-negotiable for aluminum components requiring surface durability. Type II (sulfuric acid) anodizing creates a porous oxide layer that accepts dyes for identification while improving wear resistance. For critical automotive applications, Type III (hardcoat) anodizing is mandatory, producing coatings up to 100 µm thick with exceptional abrasion and corrosion resistance per MIL-A-8625 standards. This process also enhances paint adhesion for multi-stage finishes.

Comparative Material Properties for Automotive Applications

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Key Automotive Applications | Machinability Notes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Suspension arms, brackets | Excellent; requires sharp tools |

| Steel | 4140 | 655 | 7.85 | Axles, gears, drivetrain parts | Good; stress-relieve pre-machining |

| Stainless Steel | 304 | 515 | 8.0 | Exhaust components, fasteners | Moderate; prone to work hardening |

| Titanium | Ti-6Al-4V | 900 | 4.43 | High-performance valves, turbo parts | Poor; low speed, high coolant flow |

Material selection directly impacts CNC machining strategy, lead time, and final part cost. At Wuxi Lead, we collaborate early in your design phase to match material properties with functional requirements, ensuring optimal manufacturability and performance. Our ISO 9001-certified processes include rigorous material traceability and in-house anodizing capabilities to deliver components meeting AS9100 and IATF 16949 standards. Partner with us to transform material science into automotive excellence.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful production run begins with meticulous design engineering. Our team of CNC specialists and mechanical engineers collaborates closely with clients across the USA metals and automotive sectors to transform conceptual sketches or functional requirements into detailed, manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, we develop 3D models that integrate dimensional accuracy, material properties, and tolerance specifications tailored to application demands. Finite Element Analysis (FEA) and Design for Manufacturability (DFM) reviews are conducted at this stage to preempt structural weaknesses, reduce material waste, and optimize toolpaths. This ensures that the final design is not only functionally robust but also cost-efficient to produce at scale.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to the prototyping phase—a critical checkpoint for quality assurance and functional validation. Using high-precision CNC milling, turning, and multi-axis machining centers, we produce low-volume prototype batches that mirror the exact specifications of the intended final product. These prototypes undergo rigorous in-house testing, including dimensional inspection via Coordinate Measuring Machines (CMM), surface finish analysis, and material hardness verification. For automotive clients, additional validation may include thermal cycling, vibration resistance, and fatigue testing under simulated operational conditions. Client feedback is incorporated at this stage, allowing for rapid design iterations without impacting the production timeline. This iterative prototyping process ensures that every component meets or exceeds performance expectations before moving forward.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into mass production, leveraging fully automated CNC cells, robotic material handling, and real-time process monitoring systems. Our ISO 9001-certified production floor operates under strict Statistical Process Control (SPC) protocols, ensuring consistent output across batches of 1,000 to 100,000+ units. Every stage—from raw material sourcing to final packaging—is traceable through our integrated Manufacturing Execution System (MES), enabling full lot tracking and rapid root-cause analysis if deviations occur. In-process inspections occur at defined intervals, supported by automated optical inspection (AOI) systems and operator audits. The result is a zero-defect manufacturing environment where quality is built into every cycle.

Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass, Copper, Titanium |

| Tolerances | ±0.005 mm (precision grinding), ±0.02 mm (standard CNC) |

| Surface Finish | Ra 0.2–3.2 µm, customizable coatings available |

| Max Workpiece Size | 1200 x 800 x 600 mm (3-axis), 600 mm diameter (turning) |

| Production Capacity | Up to 50,000 units/month per product line |

| Lead Time (Mass Prod) | 15–25 days after prototype approval |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, SPC, 100% inspection available |

This end-to-end process—anchored in precision engineering, validated prototyping, and defect-free execution—ensures Wuxi Lead delivers reliable, high-performance metal components that meet the demanding standards of the U.S. automotive and industrial markets.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Manufacturing Advantage for US Metals and Auto Parts

In today’s volatile supply chain landscape, US metals and auto parts manufacturers require more than a vendor—they demand a precision engineering partner capable of delivering uncompromising quality, on-time reliability, and technical agility. Wuxi Lead Precision Machinery stands as your dedicated solution, engineered to elevate your production outcomes while mitigating global sourcing risks. With 15 years of specialized expertise in high-complexity metal components, we integrate advanced CNC capabilities with rigorous quality governance to ensure your parts meet exacting automotive and industrial specifications—every time.

Our facility operates at the intersection of innovation and execution, featuring 85+ HAAS, DMG MORI, and MAZAK CNC centers supported by in-house 5-axis milling, Swiss turning, and multi-spindle technology. Every process adheres to ISO 9001:2015 and IATF 16949 standards, with full material traceability from certified mills and real-time SPC monitoring. We specialize in mission-critical applications where dimensional integrity directly impacts safety and performance—think transmission housings, suspension knuckles, hydraulic manifolds, and EV battery components. Partnering with us means eliminating the guesswork in offshore manufacturing through transparent workflows, dedicated engineering collaboration, and proactive risk mitigation.

Technical Capabilities at a Glance

| Specification | Capability Range | Compliance Standard |

|————————-|————————————–|————————–|

| Material Expertise | Aluminum, Steel, Titanium, Inconel | ASTM, SAE, AMS Certified |

| Tolerance Precision | ±0.0002″ (5µm) | ISO 2768-mK |

| Surface Finish | Ra 0.4µm to 3.2µm | ISO 1302 |

| Max Part Dimensions | 2000 x 1200 x 800 mm | Customizable per project |

| Quality Documentation | PPAP Level 3, FAI, CMM Reports | AS9100 Optional |

| Lead Time | 15-25 days (avg. complex components) | JIT/Lean Compatible |

We understand that US auto parts suppliers operate under relentless pressure: shrinking timelines, zero-defect mandates, and evolving regulatory demands. Lead Precision counters these challenges through embedded engineering support. Our technical team collaborates with your design engineers during DFM analysis to optimize manufacturability, reduce waste, and accelerate time-to-market—without sacrificing precision. All projects include 100% first-article inspection, batch-specific material certs, and digital quality portals for real-time visibility. When failure is not an option—as in brake systems or powertrain assemblies—our process validation protocols deliver the consistency your brand requires.

Secure your production timeline and quality integrity with a partner built for the demands of American manufacturing excellence. Contact our US-facing engineering team today to discuss your next high-precision metal component project. We provide rapid prototyping, scalable production, and 72-hour NDA turnaround to fast-track your supply chain resilience.

Initiate your precision-engineered advantage: [email protected]

Wuxi Lead Precision Machinery—Where Global Capability Meets American Accountability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.