Technical Contents

Engineering Guide: 3D Model Printing Service

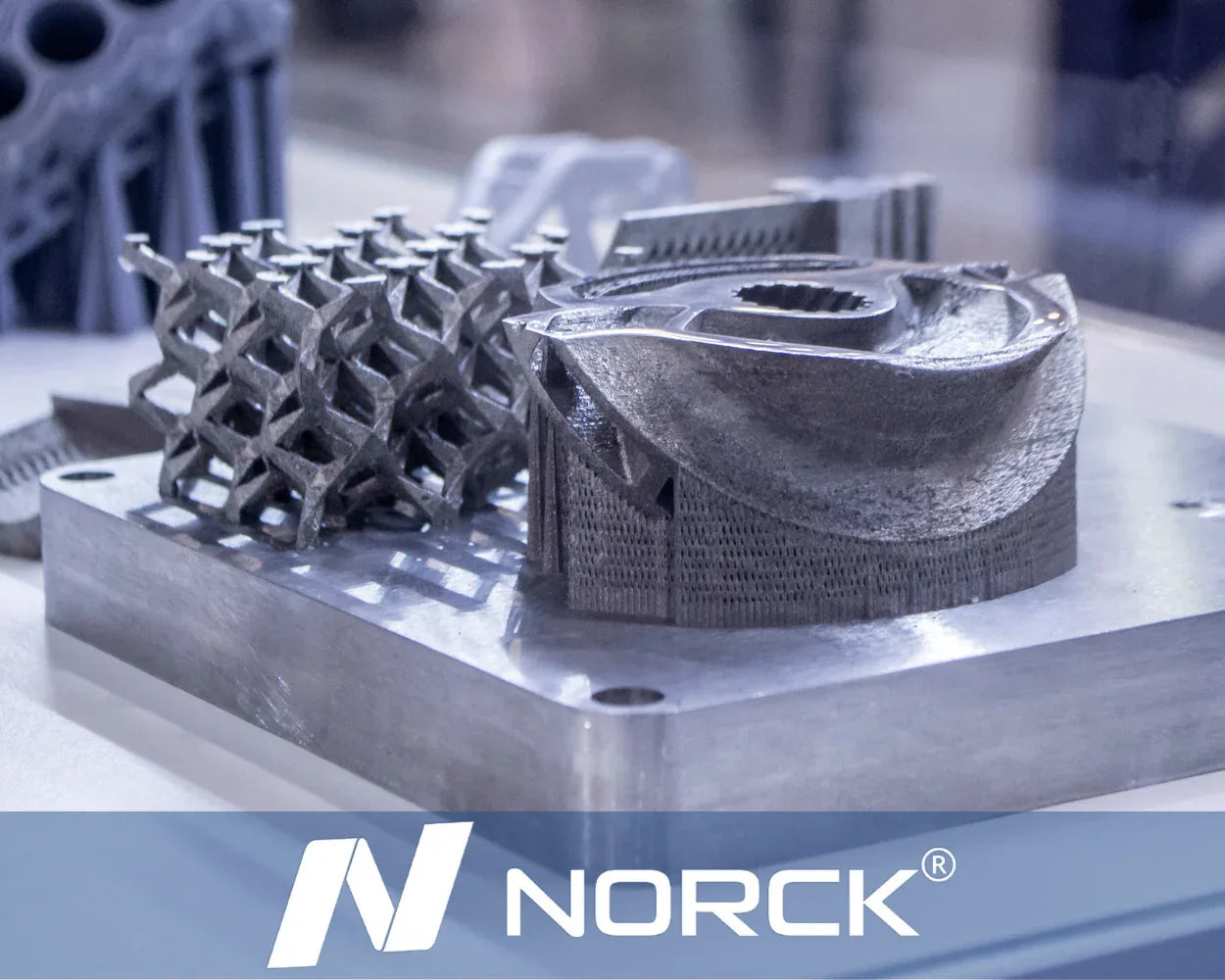

Engineering Insight Precision in Metal Additive Manufacturing

Precision defines the viability of metal additive manufacturing for mission-critical applications. While 3D model printing services offer unprecedented design freedom, inconsistent dimensional accuracy or material properties render parts unusable in aerospace, medical, or high-performance industrial contexts. True precision extends beyond the printer bed; it demands integrated process control from digital model validation through post-processing. At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering discipline, not merely a machine specification. Our approach ensures every printed component meets stringent geometric and metallurgical requirements, directly impacting client success in demanding sectors.

Our experience underscores this commitment. We have successfully delivered precision metal AM components for Beijing Winter Olympics infrastructure projects requiring sub-50-micron tolerances under extreme environmental conditions. Similarly, our work on classified defense systems demanded repeatable material integrity and dimensional stability unattainable through conventional methods alone. These projects validate our end-to-end process rigor, where each parameter is calibrated and monitored to eliminate variability. We understand that a 0.05mm deviation can compromise a turbine blade’s aerodynamic efficiency or a surgical implant’s biocompatibility. Therefore, our engineering team prioritizes build orientation simulation, in-situ monitoring, and rigorous post-build metrology to guarantee conformance.

The following table outlines critical precision metrics achievable through our certified metal AM processes compared to typical industry baselines. These figures represent our standard production capability for qualified materials like Ti-6Al-4V, Inconel 718, and 17-4PH stainless steel under controlled conditions.

| Parameter | Typical Industry Baseline | Wuxi Lead Precision Standard | Process Control Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.1 mm per 100mm | ±0.02 mm per 100mm | Real-time thermal compensation & closed-loop calibration |

| Surface Roughness (As-Built) | Ra 12-25 µm | Ra 8-15 µm | Optimized laser parameters & layer adhesion control |

| Material Density | 98-99.5% | ≥99.95% | In-situ melt pool monitoring & gas flow optimization |

| Mechanical Property Consistency | ±10% yield strength variation | ±3% yield strength variation | Certified powder management & atmosphere control |

Achieving this level requires deep materials science expertise and proprietary process validation protocols. We do not rely solely on machine OEM settings; our engineers develop application-specific parameter sets validated through destructive and non-destructive testing. This includes CT scanning for internal defect analysis and coordinate measuring machine (CMM) verification against the original 3D model. Such diligence minimizes costly scrap, reduces post-processing time, and ensures first-article success—critical for clients operating under tight regulatory frameworks or production deadlines.

For OEMs and tier-one suppliers, precision metal AM is not an experimental novelty but a strategic manufacturing lever. Wuxi Lead Precision Machinery provides the engineering backbone to transform complex 3D models into reliable, high-integrity metal components. Our Olympic and defense project heritage proves we deliver where tolerances are unforgiving and failure is not an option. Partner with us to convert your most challenging designs into precision realities, backed by data-driven process control and uncompromising quality standards.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our production floor is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and precision for intricate components that would be unattainable with conventional 3-axis equipment.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and reduced cycle times. This level of automation supports both low-volume prototyping and high-volume production runs with minimal variance. Materials commonly processed include aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and other high-strength, heat-resistant metals. Each machining operation is supported by advanced CAM programming and simulation software, ensuring optimal toolpaths, collision avoidance, and material removal rates.

To uphold the highest standards of dimensional accuracy, every production batch undergoes rigorous quality control protocols. Our metrology laboratory is anchored by a high-precision Coordinate Measuring Machine (CMM), capable of micron-level inspection across complex 3D geometries. The CMM system verifies critical features such as form, position, profile, and runout, generating detailed inspection reports traceable to international standards (ISO 9001:2015). All measurements are documented and available for customer review, providing full transparency and compliance with industry-specific certification requirements.

In addition to CMM inspection, we employ supplementary quality assurance methods including surface roughness testing, optical comparison, and first-article inspection (FAI) reporting. These processes ensure that every component not only meets but exceeds customer specifications and functional performance expectations.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 µm (typical 1.6–3.2 µm) |

| Minimum Wall Thickness | 0.5 mm (aluminum), 0.8 mm (steel/titanium) |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Repeatability | ±0.003 mm over multiple runs |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with a disciplined quality management system to deliver precision metal components that perform reliably in mission-critical applications. Our technical capabilities are designed to support innovation, reduce lead times, and ensure full compliance with global manufacturing standards.

Material & Finish Options

Material Selection for Precision Metal 3D Printing

Selecting the optimal material is critical for achieving performance, durability, and cost efficiency in metal additive manufacturing. At Wuxi Lead Precision Machinery, we prioritize materials that align with your application’s mechanical demands, environmental exposure, and functional lifecycle. Aluminum, steel, and titanium dominate high-end industrial applications due to their distinct properties. Aluminum alloys offer an exceptional strength-to-weight ratio and thermal conductivity, making them ideal for aerospace components, heat exchangers, and lightweight structural parts. Steel variants, particularly stainless steel 304L and 17-4PH, provide superior corrosion resistance, hardness, and weldability for medical instruments, automotive subsystems, and marine hardware. Titanium Ti-6Al-4V stands unmatched in high-stress, high-temperature environments like jet engine parts and biomedical implants, combining biocompatibility with extreme fatigue resistance.

Anodizing is a pivotal secondary process for aluminum components, enhancing surface durability and corrosion protection. Unlike paint or plating, anodizing integrates a protective oxide layer directly into the metal substrate. Type II (sulfuric acid) anodizing delivers standard wear resistance and dye compatibility for consumer-facing parts, while Type III (hardcoat) anodizing achieves 50–70 μm thickness for aerospace and military applications requiring MIL-A-8625 compliance. This process maintains dimensional precision—critical for tight-tolerance assemblies—and improves adhesion for subsequent coatings. Note that anodizing is exclusive to aluminum; steel and titanium require alternative finishes like passivation or PVD coating.

Material performance must be evaluated against quantifiable metrics. Below are key specifications for common alloys in metal 3D printing:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Machinability Post-Print |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Drones, heat sinks, brackets | Excellent |

| Stainless Steel 304L | 580 | 8.0 | Surgical tools, valves, chemical pumps | Good |

| Titanium Ti-6Al-4V | 900 | 4.4 | Aircraft fittings, prosthetics, racing | Moderate |

Choosing between these materials hinges on your project’s non-negotiable requirements. For weight-sensitive aerospace assemblies, aluminum’s lightness outweighs steel’s hardness. In saline environments, titanium’s inertness justifies its higher cost over stainless steel. Always factor in post-processing: while aluminum accepts anodizing seamlessly, titanium requires specialized handling to avoid embrittlement. At Wuxi Lead, our engineering team collaborates with you to simulate material behavior under operational stress, ensuring your selection meets ISO 2768-mK tolerances and ASTM F42 standards. This precision eliminates costly rework and accelerates time-to-market—transforming material choice from a technical decision into a strategic advantage.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless metal manufacturing begins with advanced design integration. Our engineering team collaborates directly with clients to analyze 3D model printing service requirements, ensuring geometric feasibility, material compatibility, and functional performance. Utilizing industry-leading CAD/CAM software such as SolidWorks, Siemens NX, and Autodesk PowerMill, we convert conceptual models into production-ready digital blueprints. Every design undergoes rigorous simulation for thermal behavior, stress distribution, and tolerance stack-up, minimizing risk before physical production. This digital validation ensures that all components meet exacting specifications for fit, form, and function, aligning with ISO 9001:2015 standards and client-specific quality benchmarks.

Prototyping: Validating Performance with Zero Compromise

Once the design is finalized, we initiate the prototyping phase using high-precision 3D metal printing technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS). These additive manufacturing processes enable rapid fabrication of complex geometries unachievable through traditional methods. Each prototype is machined from premium-grade metals such as 316L stainless steel, Inconel 718, Ti-6Al-4V, and AlSi10Mg, selected based on operational requirements. Post-printing, prototypes undergo CNC finishing, heat treatment, and surface optimization to match final production conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) and 3D laser scanning, ensuring tolerances are held within ±0.005 mm. Functional testing—including pressure, fatigue, and assembly validation—confirms performance under real-world conditions. This iterative verification process eliminates design flaws early, reducing downstream risk and accelerating time-to-market.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into high-volume manufacturing. Our automated production cells integrate 5-axis CNC machining, precision grinding, and robotic part handling to maintain consistency across batches. Statistical process control (SPC) monitors critical parameters in real time, enabling immediate correction of deviations. Each component is traceable via laser marking and digital process logs, supporting full auditability. In-process inspections occur at every stage, with final quality assurance conducted under controlled environmental conditions. All finished parts comply with stringent surface finish and geometric dimensioning requirements.

Below are key production specifications maintained across our facility:

| Parameter | Capability |

|---|---|

| Material Range | Stainless Steel, Titanium, Aluminum, Inconel, Tool Steel |

| Tolerance Control | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Part Size | 500 × 500 × 400 mm (printing), 800 × 600 × 550 mm (machining) |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Mass Production) | 15–25 days (scalable to 10,000+ units/month) |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, 100% Inspection Option |

Through seamless integration of design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers uncompromising quality—ensuring zero defects and complete client confidence in every component produced.

Why Choose Wuxi Lead Precision

Forge Mission-Critical Metal Components with Lead Precision Engineering

When mission-critical metal components demand uncompromising precision, material integrity, and on-time delivery, your choice of manufacturing partner becomes a strategic imperative. Wuxi Lead Precision Machinery stands as your dedicated engineering ally, transforming complex 3D model printing service requirements into certified, production-ready metal parts. We bridge the gap between advanced additive design and rigorous industrial application, ensuring every component meets the exacting standards demanded by aerospace, medical device, energy, and high-performance automotive sectors. Our integrated facility in Wuxi, China, operates under stringent ISO 9001:2015 quality management protocols, providing the controlled environment and traceability essential for regulated industries.

Our engineering-grade metal printing capabilities are built upon industrial-scale, dual-laser systems operating within inert atmospheres. We specialize in processing demanding alloys where performance is non-negotiable. The table below details our core production specifications, reflecting the precision achievable for your most challenging projects.

| Parameter | Capability | Notes |

|---|---|---|

| Supported Materials | Stainless Steel 316L, 17-4PH; Inconel 718, 625; Titanium Ti6Al4V ELI; Aluminum AlSi10Mg | Full material certification available |

| Standard Build Volume | 250 x 250 x 325 mm | Custom chamber configurations possible |

| Typical Accuracy | ± 0.05 mm per 100 mm | Achieved on qualified, stabilized parts |

| Surface Finish (As-Built) | Ra 12 – 25 µm | Post-processing options available |

| Secondary Operations | Precision CNC machining, HIP, Heat Treatment, Shot Peening, CMM Inspection | In-house capabilities ensure continuity |

Beyond the printer, our value lies in deep metallurgical expertise and end-to-end process ownership. Our engineering team collaborates from the initial 3D model review, identifying potential printability risks and optimizing support structures for minimal distortion and post-processing. We implement rigorous in-process monitoring and mandatory post-build heat treatment cycles tailored to each alloy, ensuring consistent microstructure and mechanical properties that meet or exceed ASTM/AMS standards. Every part undergoes comprehensive dimensional verification via coordinate measuring machines (CMM), with full inspection reports provided. This systematic approach eliminates the guesswork often associated with metal additive manufacturing, delivering parts you can deploy with confidence.

Choosing Lead Precision means partnering with engineers who speak your language and understand the consequences of failure. We prioritize transparency, providing real-time production updates and proactive communication on any process deviations. Our facility is structured for scalability, supporting both rapid prototyping and low-to-mid volume production runs with identical quality controls. Reduce your supply chain risk and accelerate time-to-market with a partner committed to your success from digital model to certified metal component.

Initiate your next high-stakes metal printing project with engineering certainty. Contact our technical sales team directly at [email protected]. Provide your 3D model file and application requirements; we will respond within one business day with a detailed manufacturability assessment and formal quotation. Let Lead Precision become the precision engine driving your innovation forward.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.