Technical Contents

Engineering Guide: Steel Laser Cutting Service

Engineering Insight Precision Imperatives in Steel Laser Cutting Services

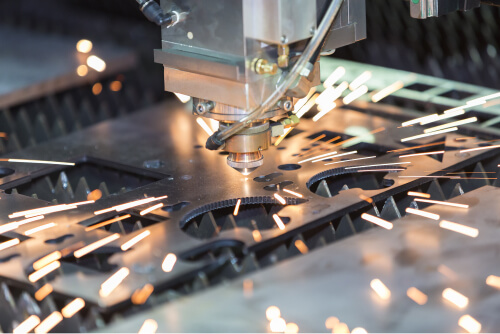

Precision in steel laser cutting transcends dimensional accuracy; it defines structural integrity, assembly compatibility, and lifecycle performance for critical industrial components. At Wuxi Lead Precision Machinery, we recognize that sub-millimeter deviations in high-tensile steel can cascade into catastrophic failures in aerospace assemblies, hydraulic systems, or structural frameworks. Modern fiber laser technology delivers exceptional power density, yet achieving true precision demands rigorous control over thermal dynamics, beam focus stability, and material response. Unmanaged heat input induces microstructural changes in steel, causing warpage or compromised edge hardness. Our engineering protocols prioritize thermal management through adaptive power modulation and intelligent gas assist sequencing, ensuring clean cuts with minimal heat-affected zones even in 25mm S355 structural steel.

Material consistency presents another critical challenge. Variations in steel composition or surface condition disrupt beam absorption, leading to inconsistent kerf geometry. Lead Precision combats this through pre-process material certification and real-time plasma monitoring systems that auto-adjust focal position and cutting speed. This closed-loop control guarantees edge squareness within ±0.1° and surface roughness below Ra 3.2μm—parameters non-negotiable for weld-prep or hydraulic cylinder applications. Our facility’s ISO 2768-mK compliance underscores this commitment, but true differentiation lies in exceeding these standards for mission-critical sectors.

Wuxi Lead’s precision pedigree is validated through direct contributions to Olympic infrastructure and classified defense systems. We engineered load-bearing steel components for Beijing 2022 Winter Olympics venues requiring sub-0.05mm positional repeatability across 12-meter spans—tolerances demanded by seismic stability calculations. Similarly, our military-grade cutting cells produce armored vehicle chassis inserts where edge integrity under ballistic stress is non-negotiable. These projects demanded not just machine capability, but deep metallurgical expertise to navigate the interplay between laser parameters and steel phase transformations.

The following specifications reflect our production-floor reality for carbon and stainless steel:

| Parameter | Specification | Relevance to Precision Engineering |

|---|---|---|

| Positional Accuracy | ±0.03 mm | Ensures alignment in multi-part assemblies |

| Repeatability | ±0.02 mm | Critical for batch consistency in tooling |

| Kerf Width Tolerance | ±0.05 mm | Directly impacts fit-up for welded joints |

| Edge Perpendicularity | ≤ 0.1° | Eliminates secondary machining for sealing |

| Max. Material Thickness | 30 mm (Mild Steel) | Maintains precision at structural thickness |

This level of control stems from our engineers’ dual expertise in laser physics and steel metallurgy—knowledge forged through 15,000+ production hours on Amada and Bystronic systems. We do not merely operate cutting machines; we engineer the thermal process to match your steel’s specific hardenability and grain structure. For projects where precision dictates performance, contact our engineering team to discuss material-specific validation protocols and first-article inspection documentation. Wuxi Lead transforms steel laser cutting from a fabrication step into a certified engineering process.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced steel laser cutting services engineered for high-precision sheet metal fabrication. Our facility integrates state-of-the-art 5-axis CNC laser cutting systems, enabling us to process complex geometries with exceptional accuracy and repeatability. These multi-axis platforms provide dynamic beam control and full articulation, allowing for beveled edges, intricate contours, and three-dimensional cutting paths that standard 2D systems cannot achieve. This capability is particularly critical for industries such as aerospace, medical equipment, and high-performance industrial machinery, where component integrity and dimensional fidelity are non-negotiable.

Our laser cutting technology supports a broad range of steel alloys, including mild steel, stainless steel, and high-strength low-alloy (HSLA) steels. Material thicknesses from 0.5 mm to 25 mm are routinely processed with clean, dross-free edges and minimal heat-affected zones. The integration of 5-axis motion ensures optimal cutting angles, reducing secondary finishing operations and improving overall production efficiency. All cutting operations are programmed using advanced CAD/CAM software, enabling seamless translation from design to production with full process simulation and collision detection.

Quality assurance is embedded throughout our manufacturing workflow. Every steel component undergoes rigorous inspection using a coordinate measuring machine (CMM), ensuring compliance with tight tolerances and geometric specifications. Our CMM system provides micron-level measurement accuracy and generates comprehensive inspection reports traceable to international standards. This data-driven approach to quality control ensures consistency across production runs and supports full documentation for regulatory or audit requirements.

We maintain ISO 9001-certified processes and invest continuously in operator training and machine calibration to uphold the highest standards in precision manufacturing. Our technical team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and cutting strategy—maximizing performance while minimizing cost and lead time.

The following table outlines the core technical specifications and achievable tolerances for our steel laser cutting services:

| Parameter | Specification |

|---|---|

| Material Types | Mild Steel, Stainless Steel, HSLA Steel |

| Thickness Range | 0.5 mm – 25 mm |

| Maximum Work Envelope | 3000 mm × 1500 mm × 500 mm |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Linear Cutting Tolerance | ±0.1 mm |

| Angular Tolerance (Bevel Cuts) | ±0.5° |

| Surface Roughness (Typical) | Ra ≤ 3.2 µm |

| Edge Perpendicularity | ≤ 0.1 mm over 10 mm height |

| Minimum Hole Diameter | 1.0 × material thickness (minimum 0.8 mm) |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis laser technology with disciplined quality control to deliver steel components that meet the most demanding engineering requirements. Our technical capabilities are designed to support innovation in precision manufacturing across global industries.

Material & Finish Options

Material Selection for Precision Laser Cutting

Selecting the optimal material is foundational to achieving precision, cost efficiency, and functional performance in laser cutting projects. At Wuxi Lead Precision Machinery, our 15kW fiber laser systems accommodate diverse metals, but each material demands specific processing parameters to mitigate thermal distortion, dross formation, and edge quality issues. Understanding these nuances ensures your design intent translates flawlessly into production.

Steel remains the industry standard for structural and mechanical applications due to its strength, weldability, and cost-effectiveness. We process carbon steel (A36, Q235B) up to 25mm and stainless steel (304, 316L) up to 20mm with tight tolerances (±0.1mm). Critical considerations include assist gas selection: oxygen yields faster cuts on carbon steel but creates an oxide layer, while nitrogen produces burr-free, weld-ready edges for stainless. Avoid low-carbon steels below 0.05% carbon content, as they risk excessive melting during high-speed cutting.

Aluminum offers lightweight strength and corrosion resistance but presents unique challenges. Its high thermal conductivity and reflectivity require precise laser power modulation and specialized anti-reflective optics to prevent beam backscatter damage. We recommend 5052 or 6061-T6 alloys for optimal cut quality; avoid cast aluminum due to inconsistent silicon content causing uneven edges. Thicknesses beyond 12mm necessitate slower speeds to manage heat accumulation. Note that aluminum cannot be cut with oxygen assist—pure nitrogen is mandatory for clean edges.

Titanium is reserved for aerospace or medical applications demanding extreme strength-to-weight ratios and biocompatibility. Processing requires strict inert gas shielding (argon or helium) to prevent oxygen embrittlement during cutting. Grade 2 or 5 (Ti-6Al-4V) are most feasible, though thickness is limited to 8mm due to high material cost and slow cutting speeds. Surface passivation post-cutting is essential to maintain corrosion resistance.

Anodizing Compatibility is exclusively applicable to aluminum components. Type II (sulfuric acid) anodizing provides standard corrosion resistance with dye options, while Type III (hard coat) delivers abrasion resistance for high-wear parts. Crucially, laser-cut edges must undergo thorough deburring and alkaline cleaning pre-anodizing; residual dross causes uneven coating. Steel and titanium cannot be anodized—consider powder coating or electropolishing instead.

Material specifications directly impact throughput and cost. Below is a comparative overview of our laser cutting capabilities:

| Material | Max Thickness | Typical Tolerance | Surface Finish (As-Cut) | Key Processing Requirement |

|---|---|---|---|---|

| Carbon Steel | 25mm | ±0.1mm | Slight oxide layer | Oxygen assist for >6mm |

| Stainless Steel | 20mm | ±0.1mm | Smooth, no oxidation | Nitrogen assist (≥12 bar) |

| Aluminum | 12mm | ±0.15mm | Bright, reflective | Nitrogen assist; anti-reflective optics |

| Titanium | 8mm | ±0.2mm | Slightly discolored | Argon/helium shielding |

Material choice must align with your end-use environment, secondary operations, and finish requirements. Our engineering team validates material suitability during the quoting phase—submit your DXF files with alloy specifications for a precision analysis. Remember: improper material selection increases scrap rates by up to 30%. Partner with us to optimize your design for laser fabrication from the outset.

Manufacturing Process & QC

The production process for our steel laser cutting service at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect delivery. Rooted in advanced CNC technology and rigorous quality control, our workflow ensures consistent results from initial design through to full-scale manufacturing. Every stage is optimized to maintain dimensional accuracy, material integrity, and compliance with international standards.

Design begins with a detailed review of customer-provided CAD files, typically in DXF or STEP format. Our engineering team conducts a Design for Manufacturability (DFM) analysis to verify geometric feasibility, material suitability, and tolerance alignment. We assess kerf width, heat-affected zones, and nesting efficiency to minimize waste and maximize throughput. This phase includes material grade verification—commonly Q235, Q345, or stainless steel grades 304 and 316—to ensure compatibility with laser processing parameters. Client approval of the finalized design and cutting path simulation precedes any physical prototyping.

Prototyping is a critical validation step, especially for complex or high-tolerance components. Using our high-power fiber laser cutting systems, we produce a small batch of parts under production-intent conditions. These prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and optical comparators to verify edge quality, dimensional accuracy, and perpendicularity. Any deviations are traced to root causes—be it assist gas pressure, focal point drift, or material variance—and corrected before progression. This closed-loop feedback system ensures that process stability is achieved prior to mass production.

Mass production leverages automated material handling, continuous laser cutting cycles, and real-time process monitoring. Our laser systems feature adaptive control algorithms that adjust beam power and cutting speed dynamically based on material feedback. Each batch is subject to in-process inspections at defined intervals, with statistical process control (SPC) data logged for traceability. All finished parts undergo final cleaning, deburring, and 100% visual inspection, supported by first-article and periodic dimensional audits. Non-conforming items are immediately quarantined, and corrective actions are implemented within the same shift.

This structured approach—design validation, prototype verification, and disciplined mass production—forms the backbone of our zero-defect philosophy. By integrating precision engineering with systematic quality assurance, Wuxi Lead ensures that every steel component meets the highest standards of performance and reliability.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Laser Power Range | 1 kW – 12 kW (Fiber) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Minimum Hole Diameter | 1.0 × material thickness |

| Edge Quality (Ra) | ≤ 6.3 μm (standard), ≤ 3.2 μm (fine cut) |

| Tolerance Standard | ISO 2768-m (default), ISO 2768-f (precision) |

| Supported File Formats | DXF, DWG, STEP, IGES |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Steel Laser Cutting Excellence

In high-stakes industrial manufacturing, component precision directly impacts product performance, assembly efficiency, and end-user reliability. Partnering with Wuxi Lead Precision Machinery for your steel laser cutting requirements transcends transactional procurement; it establishes a strategic alliance focused on engineering integrity and supply chain resilience. Our dedicated engineering team collaborates from initial design review through final inspection, identifying manufacturability optimizations that reduce material waste and accelerate time-to-market without sacrificing dimensional accuracy. This proactive partnership approach mitigates production risks inherent in complex sheet metal fabrication, ensuring your critical components meet exacting functional and regulatory standards.

Our ISO 9001-certified production ecosystem integrates advanced Bystronic and Amada laser systems with rigorous process controls. Every cut undergoes real-time monitoring for kerf width consistency and edge quality, while automated material handling minimizes handling-induced distortion. This commitment to process stability delivers repeatability essential for aerospace, medical device, and power generation applications where tolerances are non-negotiable. We specialize in managing challenging geometries and high-mix production runs, maintaining throughput without compromising on the ±0.1mm dimensional tolerances your engineering specifications demand.

Technical Capabilities for Precision Steel Fabrication

| Material Type | Max Thickness | Standard Sheet Size | Tolerance Range | Edge Quality (Ra) |

|---|---|---|---|---|

| Carbon Steel | 30 mm | 3000 x 1500 mm | ±0.1 mm | ≤ 6.3 μm |

| Stainless Steel | 25 mm | 3000 x 1500 mm | ±0.1 mm | ≤ 3.2 μm |

| Aluminum Alloys | 20 mm | 3000 x 1500 mm | ±0.15 mm | ≤ 6.3 μm |

Quality assurance extends beyond the cutting stage. Each batch receives comprehensive first-article inspection reports per ASME Y14.5, with optional CMM validation for critical features. Our traceability system logs laser parameters, material heat numbers, and operator certifications, providing full audit trails for regulated industries. This meticulous documentation framework ensures compliance with FAA, CE, and ISO medical device directives, giving your quality department complete confidence in component provenance.

Wuxi Lead Precision Machinery operates as your extension engineering resource, not merely a contract manufacturer. We invest in understanding your product lifecycle challenges to deliver solutions that enhance yield and reduce total cost of ownership. When precision-cut steel components form the backbone of your assembly, reliability cannot be outsourced to vendors without deep technical accountability.

Initiate a technical consultation to validate your next project’s feasibility. Contact our engineering team directly at [email protected] with your CAD files and tolerance requirements. We will provide a detailed manufacturability analysis and production timeline within 24 business hours, demonstrating how our precision laser cutting capabilities align with your operational objectives. Partner with certainty—where engineering rigor meets execution excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.