Technical Contents

Engineering Guide: Sla Print Service

Engineering Insight Precision in Additive Manufacturing Beyond SLA Misconceptions

Precision engineering remains the non-negotiable cornerstone of high-stakes manufacturing, particularly when additive processes intersect with mission-critical applications. A frequent point of confusion within the B2B sector involves the term “SLA print service.” Stereolithography (SLA) utilizes photopolymer resins cured by UV light, excelling in rapid prototyping and visual models. However, SLA fundamentally lacks the material properties, thermal stability, and dimensional accuracy required for functional end-use metal components in aerospace, defense, or precision machinery. Confusing SLA with metal additive manufacturing (AM) technologies like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) risks significant project failures. True precision in metal AM demands rigorous control over laser parameters, inert atmospheres, powder characteristics, and post-processing – far exceeding the capabilities of resin-based systems.

At Wuxi Lead Precision Machinery, we specialize exclusively in high-precision metal manufacturing, including advanced metal AM. Our engineering protocols treat precision not as a target but as a systemic outcome. This means controlling tolerances down to ±0.02mm consistently across builds, managing microscopic grain structures for optimal mechanical performance, and implementing multi-axis inspection protocols traceable to national standards. Our experience delivering components for Olympic-caliber sporting equipment – where minute deviations directly impact athlete performance and safety – and stringent military subcontracting – where failure is not an option – forged our uncompromising approach. These projects demanded not just meeting specifications, but engineering predictability into every micron of the build process, from digital file validation through final surface finishing.

Understanding the technical boundaries between processes is vital for client success. The table below clarifies why SLA is unsuitable for metal part production and highlights the precision benchmarks expected from industrial metal AM:

| Parameter | SLA (Resin-Based) | Industrial Metal AM (DMLS/SLM) | Critical for Metal End-Use |

|---|---|---|---|

| Material | Photopolymer Resins | Stainless Steel, Inconel, Ti6Al4V | High strength, temp resistance |

| Typical Accuracy | ±0.1 – 0.3 mm | ±0.02 – 0.05 mm | Functional fit, assembly |

| Layer Thickness | 25 – 100 microns | 20 – 50 microns | Surface finish, detail |

| Max Operating Temp | < 100°C | > 800°C (material dependent) | Real-world service conditions |

| Key Application | Concept Models, Molds | Flight Hardware, Hydraulic Components | Mission-critical function |

Precision in metal AM transcends initial build accuracy. It encompasses thermal management during printing to prevent warpage, stress-relief strategies, precision machining of critical interfaces, and non-destructive testing validation. Wuxi Lead integrates these stages within a single controlled workflow, eliminating handoff errors common in fragmented supply chains. Our clients in energy, defense, and advanced automation rely on this holistic precision – knowing that a turbine blade or actuator component must perform identically whether manufactured today or two years from now. When evaluating additive capabilities, scrutinize the demonstrable precision history in metal, not just the printer technology. True engineering value lies in the proven ability to transform complex digital designs into physically reliable, high-tolerance metal assets, consistently and at scale. This is where Olympic and military-grade standards become your operational reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance industries, including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a robust 5-axis CNC machining platform, enabling us to produce complex, high-accuracy components from a wide range of engineering-grade metals such as stainless steel, titanium, aluminum alloys, and high-temperature superalloys. Our 5-axis CNC systems provide simultaneous multi-directional cutting, allowing for intricate geometries, reduced setup cycles, and superior surface finishes—critical for mission-critical applications where precision and reliability are non-negotiable.

Our machining centers are operated by certified engineers with over a decade of experience in high-mix, low-volume production environments. This expertise, combined with state-of-the-art Haas and DMG MORI 5-axis platforms, ensures optimal toolpath strategies, minimized thermal deformation, and consistent repeatability across production runs. We support both prototype development and serial production, with rapid turnaround times and full digital traceability from design to delivery.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), equipped with a VAST XT optical probe system for micron-level accuracy. Our CMM inspection routines follow ISO 10360 standards, with full first-article inspection (FAI) reports available upon request. Additionally, we perform in-process inspections, statistical process control (SPC) monitoring, and final quality audits to guarantee compliance with customer specifications and international standards.

Our metrology lab is temperature-controlled and certified to ISO 9001:2015, ensuring measurement stability and long-term data integrity. All inspection data is stored digitally for full part traceability, supporting industries with stringent documentation requirements such as AS9100 and ISO 13485.

The following table outlines the standard technical tolerances achievable through our 5-axis CNC and inspection processes under controlled conditions. These values represent typical production capabilities; tighter tolerances are available upon engineering review and feasibility assessment.

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 | Up to 500 mm |

| Angular Tolerance | ±0.05° | ±0.02° | Measured via CMM |

| Positional Tolerance | ±0.012 | ±0.008 | GD&T compliant |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | As machined; polish optional |

| Geometric Tolerance (Flatness, Runout) | ±0.015 mm | ±0.005 mm | Verified by CMM |

| Feature Size (Minimum) | 0.5 mm | 0.3 mm | Drill/mill depending on material |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver components that meet the most demanding technical requirements. Our integrated approach ensures that every part conforms to design intent, performs reliably in application, and exceeds the expectations of global OEMs and engineering partners.

Material & Finish Options

Material Selection for Precision Metal Components: Aluminum, Steel, Titanium & Anodizing

Confusion often arises between additive processes like SLA resin printing and precision metal manufacturing. Wuxi Lead Precision Machinery specializes in high-tolerance CNC machining, milling, and turning of solid metal stock—not polymer-based SLA. For demanding B2B applications requiring structural integrity, thermal stability, and long-term reliability, selecting the optimal metal alloy and surface finish is paramount. This guide addresses critical considerations for Aluminum, Steel, and Titanium alloys within our subtractive manufacturing process, including essential anodizing specifications.

Material choice directly impacts component performance, manufacturability, and cost. Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio, excellent machinability, and inherent corrosion resistance. They are ideal for aerospace brackets, automotive housings, and consumer electronics enclosures where weight savings are critical. Carbon and alloy steels, such as 4140, 1018, and 304/316 stainless, provide superior strength, hardness, and wear resistance. These are the foundation for hydraulic components, shafts, tooling, and marine hardware requiring high load capacity and durability. Titanium alloys, primarily Grade 5 (Ti-6Al-4V), deliver unparalleled strength-to-weight ratios, exceptional corrosion resistance in harsh environments, and biocompatibility. They are indispensable for critical aerospace structural parts, medical implants, and chemical processing equipment, though machining requires specialized tooling and processes due to lower thermal conductivity and work hardening tendencies.

Anodizing is a vital electrochemical surface treatment primarily for aluminum, significantly enhancing corrosion resistance, wear properties, and providing a base for coloring. Type II (Sulfuric Acid) anodizing offers moderate thickness (0.7-25 µm) for general industrial use and dyeing. Type III (Hard Anodizing) creates a much denser, thicker coating (25-100+ µm), delivering superior abrasion resistance and electrical insulation for high-wear applications like pistons or military hardware. Our facility achieves precise control over coating thickness, hardness, and color consistency per ASTM B580 and MIL-A-8625 standards.

Key mechanical properties guide initial material screening. Refer to the comparative specifications below.

| Material Alloy | Density (g/cm³) | Tensile Strength (MPa) | Key Corrosion Resistance | Typical Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (Atmospheric) | Excellent (A1) |

| Aluminum 7075-T6 | 2.8 | 572 | Fair (Requires coating) | Good (A2) |

| Steel 4140 | 7.85 | 655 | Poor (Rusts) | Moderate (B2) |

| Stainless 304 | 8.0 | 515 | Excellent | Fair (C1) |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | Poor (D2) |

Selecting the right combination of base metal and finish is not merely technical—it is a strategic decision impacting total cost of ownership. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced CNC capabilities to advise clients on optimal material and surface treatment selection. We rigorously validate material certifications and anodizing parameters to ensure your components meet the most stringent aerospace, medical, and industrial performance requirements. Partner with us to transform your precision metal component specifications into reality.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes in custom metal manufacturing. Our systematic approach spans three critical phases: Design, Prototyping, and Mass Production. Each stage is tightly controlled to ensure that every component meets the highest standards of quality, functionality, and dimensional accuracy.

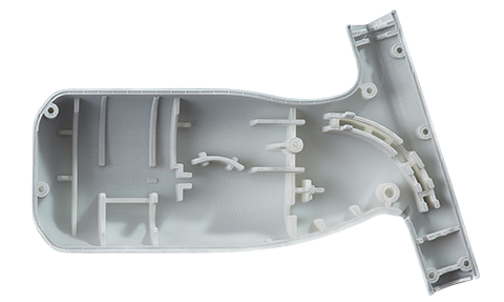

Design begins with a comprehensive review of customer specifications, including CAD models, material requirements, tolerances, and application context. Our engineering team conducts a Design for Manufacturability (DFM) analysis to optimize geometry, minimize stress points, and ensure compatibility with our advanced CNC and SLA-based indirect metal printing workflows. This phase integrates simulation tools to predict thermal behavior, structural integrity, and surface finish, reducing downstream risks. Client feedback is incorporated iteratively to finalize the design before moving forward.

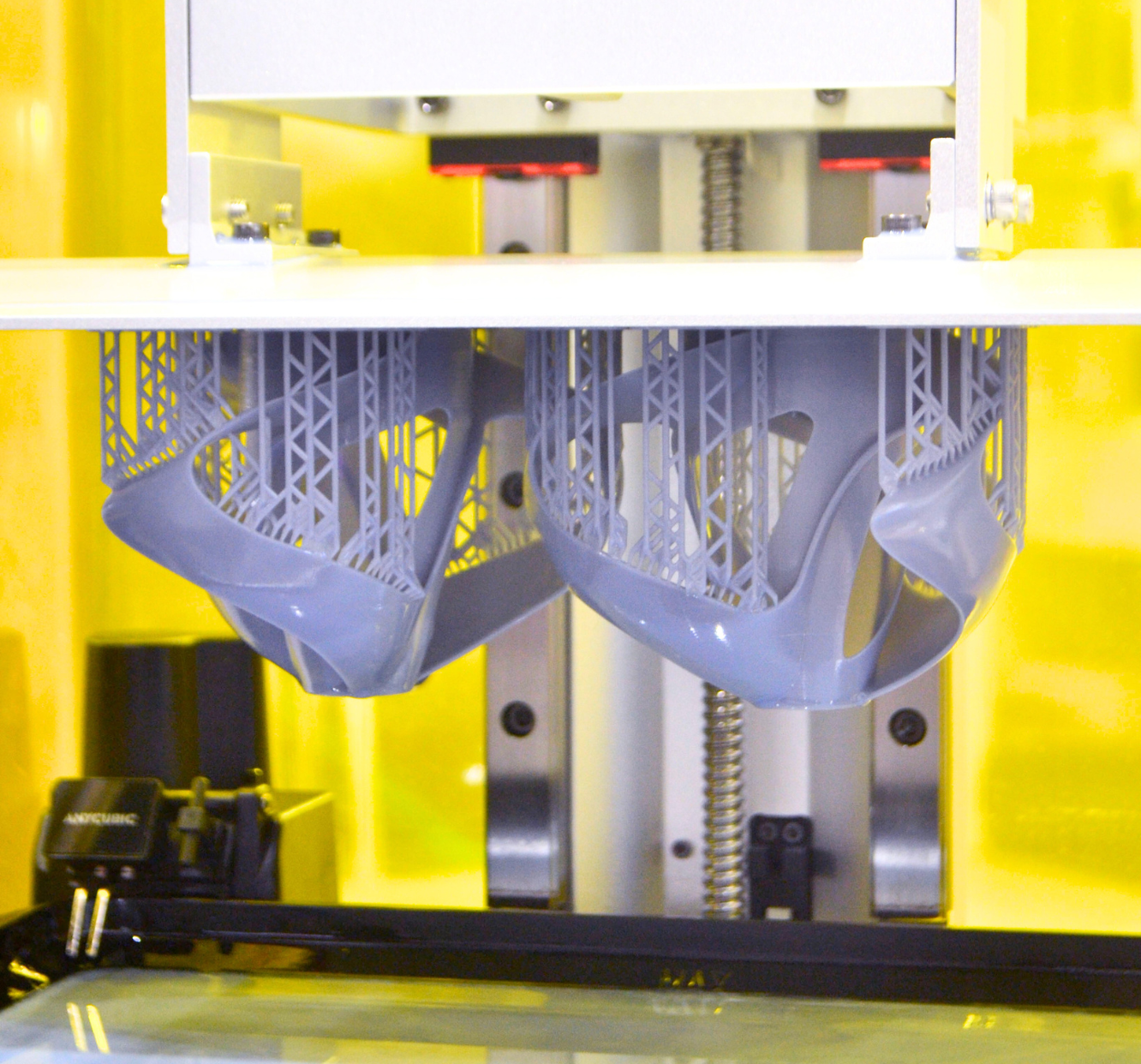

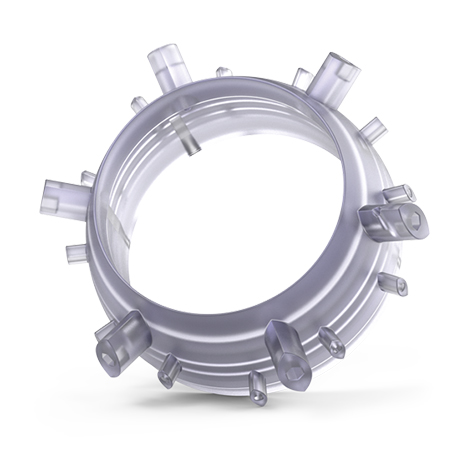

Prototyping follows design validation using our high-resolution SLA print service as part of an indirect metal manufacturing pathway. In this method, precision SLA 3D printing produces highly detailed polymer patterns, which are then used in investment casting to create metal components. These prototypes replicate the final part’s geometry with micron-level accuracy, allowing for functional testing, fit checks, and performance validation under real-world conditions. Each prototype undergoes rigorous metrology inspection using coordinate measuring machines (CMM) and optical scanners to verify conformity to specifications. Any deviations trigger immediate corrective action, ensuring only flawless designs advance.

Mass Production leverages the validated prototype as the benchmark for full-scale output. We employ automated CNC machining, robotic casting systems, and in-line quality monitoring to maintain consistency across batches. Every production run is governed by Statistical Process Control (SPC) methodologies, with real-time data tracking of critical parameters such as temperature, pressure, and dimensional drift. Our facility operates under ISO 9001-certified processes, ensuring full traceability from raw material to finished part.

To support this workflow, we maintain strict environmental and equipment calibration standards, minimizing variability and eliminating common sources of defects. All personnel are trained in lean manufacturing and Six Sigma principles, reinforcing our zero-defect philosophy across every operation.

The following table outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.02 mm |

| Surface Finish (as cast) | Ra 0.8 – 1.6 µm |

| Maximum Part Size | 300 mm × 300 mm × 200 mm |

| Materials Supported | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718 |

| SLA Layer Resolution | 25 – 100 µm |

| Production Lead Time (Mass) | 15–25 days (batch of 500 units) |

| Quality Standards | ISO 9001, ISO 13485 (medical), AS9100 (aerospace) |

Through seamless integration of design intelligence, prototyping fidelity, and disciplined mass production, Wuxi Lead Precision Machinery delivers custom metal components with uncompromising quality and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Additive Solutions

In the demanding landscape of high-integrity metal component production, selecting a manufacturing partner transcends transactional relationships. It requires a strategic alliance grounded in engineering excellence, material science expertise, and unwavering commitment to your project’s success. Wuxi Lead Precision Machinery stands as your definitive partner for advanced metal additive manufacturing, specifically engineered to meet the rigorous demands of aerospace, medical, energy, and precision industrial sectors. Our SLA-derived metal printing capabilities—leveraging cutting-edge binder jetting and laser powder bed fusion technologies—deliver complex geometries impossible through traditional methods, without sacrificing the metallurgical integrity or fatigue resistance critical to mission-critical applications. We do not merely produce parts; we solve your most challenging design and performance constraints through collaborative engineering from prototype to serial production.

Our integrated facility in Wuxi operates under ISO 9001:2015 and IATF 16949 quality management systems, ensuring every component undergoes rigorous validation protocols. This includes in-process melt pool monitoring, full-build CT scanning for internal defect detection, and post-processing heat treatments calibrated to your material’s phase diagram. The result is certified dimensional accuracy, repeatable mechanical properties, and surface finishes meeting ASME B46.1 standards—eliminating costly downstream rework and accelerating time-to-market. Below details our core metal additive specifications for immediate project integration:

| Process Capability | Material Options | Tolerance Range | Build Envelope (mm) | Surface Roughness (Ra) | Lead Time (Prototype) |

|---|---|---|---|---|---|

| Binder Jetting | 17-4PH SS, 316L, Inconel 625, Ti-6Al-4V | ±0.05 mm | 400 x 250 x 250 | 8–12 µm | 7–10 business days |

| Laser Powder Bed Fusion | Maraging Steel, AlSi10Mg, CoCr, Pure Copper | ±0.03 mm | 250 x 250 x 300 | 5–8 µm | 5–8 business days |

| Hybrid Post-Processing | Including HIP, CNC contouring, polishing | ±0.01 mm | N/A | 0.8–1.6 µm | Custom quote |

This technical foundation is amplified by our engineering-first engagement model. Our applications team collaborates with your design engineers during DfAM (Design for Additive Manufacturing) reviews, identifying weight-saving lattices, thermal management channels, or assembly consolidations that unlock transformative performance gains. We provide full material traceability with certified mill test reports and mechanical property validation per ASTM F3301/F3318, ensuring compliance with FAA, FDA, or PED directives. When failure is not an option, our zero-defect culture and investment in Siemens NX-driven process simulation deliver parts you can certify with confidence.

The future of precision metal manufacturing demands a partner who anticipates complexity and executes flawlessly. Wuxi Lead Precision Machinery combines Chinese manufacturing scale with German-engineered process control, offering globally competitive pricing without compromise on quality. Do not navigate your next high-stakes project with a vendor—forge an engineering partnership. Contact our technical sales team directly at [email protected] to initiate a confidential design consultation. Include your project specifications and target application requirements; we will respond within 24 business hours with a validated process plan and feasibility assessment. Elevate your component performance—partner with the precision leader trusted by tier-1 aerospace integrators and innovative medical OEMs worldwide. Your breakthrough begins with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.