Technical Contents

Engineering Guide: Silver 3D Printing Service

Engineering Insight Silver 3D Printing Service Precision as Non-Negotiable

Silver 3D printing transcends standard additive manufacturing, demanding exceptional precision due to the material’s unique properties and critical end-use applications. Unlike common engineering alloys, high-purity silver presents significant challenges including high thermal conductivity, reflectivity, and sensitivity to oxidation during the build process. These factors directly impact dimensional accuracy, surface integrity, and functional performance. Micron-level deviations are unacceptable in sectors like aerospace thermal management, high-frequency electronics, and medical implants where electrical conductivity, thermal dissipation, and biocompatibility are paramount. Achieving consistent part density without internal defects requires precise laser parameter control, inert atmosphere management, and sophisticated thermal profiling throughout the build cycle. Surface roughness must be minimized post-processing to ensure optimal electrical contact or fluid flow characteristics, which cannot be compensated for if the as-printed geometry falls outside strict tolerances. Dimensional stability across complex geometries is equally critical, as silver components often integrate into tight-tolerance assemblies where misalignment causes system failure.

Wuxi Lead Precision Machinery addresses these complexities through engineered process control honed over years of delivering mission-critical metal components. Our silver additive manufacturing protocols are not generic adaptations but purpose-built solutions validated in Olympic-standard components requiring micron-perfect symmetry and defense sector applications demanding absolute reliability under extreme conditions. This heritage instills rigorous process discipline: real-time melt pool monitoring, closed-loop atmospheric control, and proprietary sintering algorithms ensure each layer meets exacting specifications. We treat material purity as foundational, starting with certified 99.95% Ag powder and maintaining contamination-free processing from build to post-finish. Our engineering team collaborates early in the design phase to optimize part orientation, support structures, and thermal pathways, preventing warpage and ensuring first-article success. This proactive approach minimizes costly iterations and accelerates time-to-qualification for clients operating in regulated industries.

The following specifications reflect our production capabilities for silver AM components, consistently achieved across customer programs:

| Parameter | Specification |

|---|---|

| Material Purity | 99.95% Ag minimum |

| Layer Thickness | 20 – 50 μm (process optimized) |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (As-Built) | Ra 10 – 15 μm |

| Surface Roughness (Polished) | Ra 0.8 – 1.6 μm |

| Minimum Feature Size | 0.15 mm |

| Build Volume | 150 x 150 x 100 mm |

| Post-Processing Options | Stress relief, HIP, precision polishing, plating |

Precision in silver 3D printing is not merely a technical target but a prerequisite for functional performance in high-stakes applications. Wuxi Lead Precision Machinery leverages its deep process mastery and stringent quality framework—proven in projects where failure is not an option—to deliver silver components that meet the most demanding engineering requirements. We transform the inherent challenges of silver additive manufacturing into reliable, repeatable production outcomes, ensuring your critical applications perform with unwavering integrity. Partner with us to convert complex silver part designs into certified, high-performance reality.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

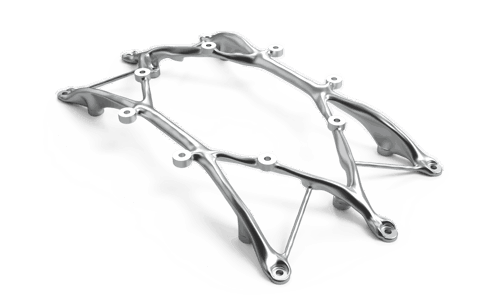

Wuxi Lead Precision Machinery delivers state-of-the-art manufacturing solutions tailored for high-performance industries such as aerospace, medical devices, and advanced electronics. Our silver 3D printing service is engineered to meet the most demanding specifications, combining additive innovation with subtractive precision. At the core of our technical capabilities is a fully integrated production environment that leverages 5-axis CNC machining to achieve complex geometries unattainable through conventional methods. This multi-axis technology enables simultaneous movement across five planes, allowing for continuous tool engagement and unparalleled accuracy on intricate silver alloy components.

Our 5-axis CNC systems are equipped with high-speed spindles and advanced toolpath control, ensuring minimal material waste and optimal surface finish. This is critical when working with silver, a material valued for its electrical conductivity and reflectivity but prone to microstructural inconsistencies if not machined under precise thermal and mechanical conditions. By combining additive layering with precision CNC post-processing, we achieve tight tolerances and superior part integrity, making our service ideal for functional prototypes and end-use components alike.

Quality assurance is embedded throughout the manufacturing workflow. Every silver 3D printed component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional conformity to the original CAD model. The CMM system operates with sub-micron resolution, capable of validating complex contours, bore alignments, and positional tolerances across freeform surfaces. This metrology-grade verification is essential for clients requiring full traceability and compliance with ISO 9001 and AS9100 standards.

In addition to geometric accuracy, we perform material certification and surface roughness analysis to confirm the functional performance of each component. Our quality control protocols are designed to support high-mix, low-volume production runs without compromising repeatability or inspection depth.

The following table outlines the standard technical specifications achievable through our silver 3D printing and 5-axis CNC finishing process:

| Parameter | Specification |

|---|---|

| Material | High-purity silver (Ag999), Silver-copper alloys |

| Build Envelope (Additive) | Up to 250 mm x 250 mm x 300 mm |

| 5-Axis CNC Accuracy | ±0.005 mm |

| Surface Roughness (As-Built) | Ra 6.3 μm (typical), down to Ra 0.8 μm post-CNC |

| Dimensional Tolerance | ±0.025 mm for features < 50 mm |

| Minimum Feature Size | 0.3 mm (lattice), 0.1 mm (CNC engraving) |

| Wall Thickness (Minimum) | 0.2 mm (as-printed), 0.15 mm (CNC refined) |

| CMM Inspection Resolution | 0.001 mm |

| Lead Time (Average) | 7–12 business days (including QC) |

Wuxi Lead Precision Machinery ensures that every silver 3D printed component meets the highest benchmarks in precision, consistency, and performance. Our technical capabilities are built to support next-generation applications where conductivity, precision, and reliability are non-negotiable.

Material & Finish Options

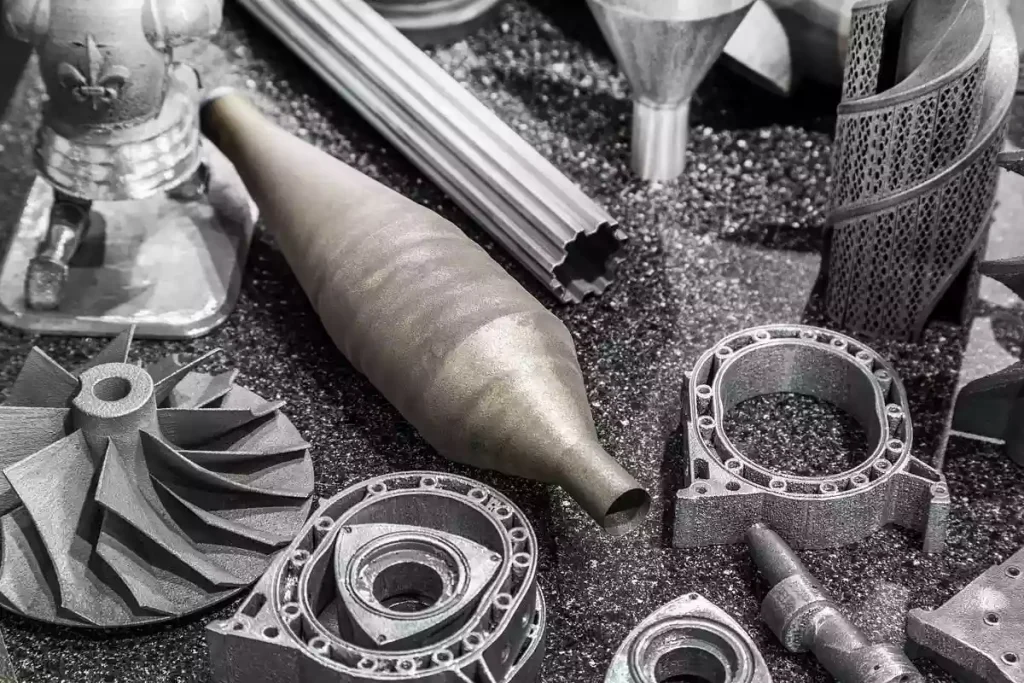

Material Selection for Precision Metal 3D Printing

Material choice fundamentally impacts the performance, cost, and manufacturability of your 3D printed metal components. At Wuxi Lead Precision Machinery, we specialize in optimizing material selection for demanding applications in aerospace, medical, and industrial automation. Understanding the distinct properties of aluminum, steel, and titanium alloys is critical for achieving your design intent with silver-finish compatible post-processing.

Aluminum alloys, particularly AlSi10Mg, offer an exceptional strength-to-weight ratio and excellent thermal conductivity. This makes them ideal for lightweight structural components, heat exchangers, and complex housings where weight reduction is paramount. While inherently silvery, aluminum readily accepts anodizing for enhanced surface hardness, wear resistance, and precise color control, including high-quality silver finishes. Its lower density reduces material cost and build time compared to denser metals.

Stainless steel variants, especially 316L, provide superior corrosion resistance, high strength, and biocompatibility. This alloy is the standard for marine environments, chemical processing equipment, and medical implants requiring long-term durability in harsh conditions. The as-printed surface has a characteristic metallic sheen suitable for many industrial applications. Achieving a consistent silver aesthetic typically involves precision polishing followed by optional passivation, though anodizing is not applicable to steel.

Titanium Ti6Al4V stands unmatched for its extraordinary strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosion. It is the material of choice for critical aerospace components, high-performance automotive parts, and permanent surgical implants. The as-built surface exhibits a distinctive dark gray metallic appearance. While titanium cannot be anodized for color like aluminum, specialized polishing and surface treatments can achieve a bright, reflective silver-like finish meeting stringent aesthetic and functional requirements. HIP densification is often recommended for critical titanium parts.

The following table summarizes key mechanical properties of our most utilized alloys for precision 3D printing:

| Material | Alloy Type | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Applications |

|---|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 2.67 | 400 – 450 | 250 – 300 | 8 – 12 | Lightweight structures, heat sinks |

| Stainless Steel | 316L | 7.98 | 550 – 650 | 300 – 400 | 35 – 45 | Marine, medical, chemical |

| Titanium | Ti6Al4V | 4.43 | 900 – 1000 | 800 – 880 | 10 – 15 | Aerospace, medical implants |

Anodizing is a critical post-processing step exclusively for aluminum components to achieve durable, high-quality silver finishes. Our integrated finishing capabilities ensure precise control over oxide layer thickness and dyeing, meeting exact color specifications while enhancing surface protection. For steel and titanium, alternative surface engineering processes like electropolishing or PVD coatings are employed to reach the desired silver appearance and performance characteristics. Partner with Wuxi Lead to select the optimal material and finishing strategy for your precision metal additive manufacturing project.

Manufacturing Process & QC

Design Phase: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the silver 3D printing process begins with a rigorous design phase, where engineering accuracy meets functional intent. Each project starts with a detailed review of customer CAD models, followed by a Design for Additive Manufacturing (DfAM) analysis. Our engineering team evaluates structural integrity, thermal behavior, and material efficiency to optimize geometry for both performance and printability. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are employed when necessary to validate performance under operational loads. This phase ensures manufacturability while minimizing post-processing requirements. All design iterations are documented and approved through a formal sign-off process, ensuring alignment with client specifications and industry standards such as ISO 13485 and AS9100.

Prototyping: Validating Functionality and Fit

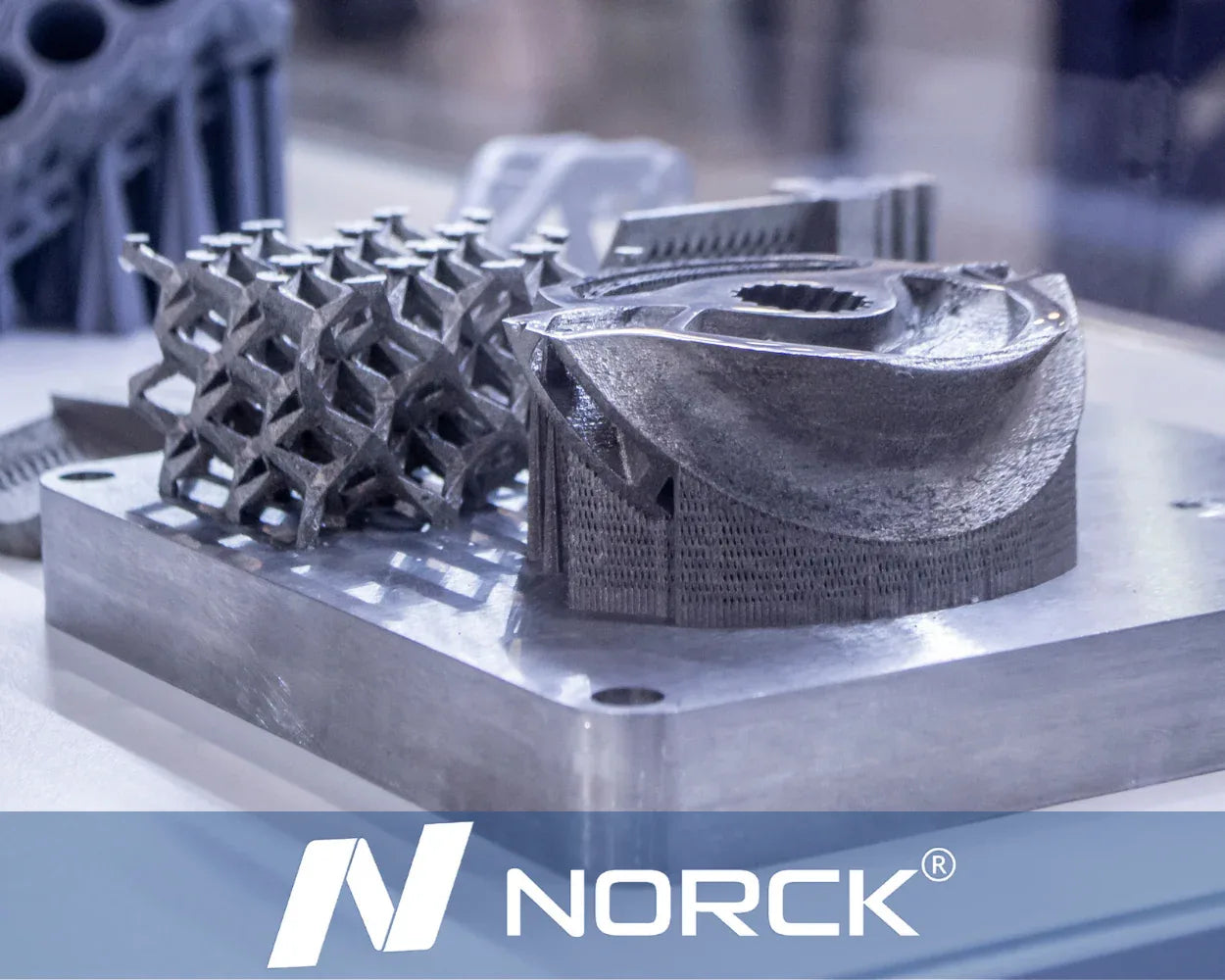

Once the design is finalized, we proceed to prototyping using our industrial-grade silver metal 3D printing systems. Prototypes are manufactured in high-purity silver (Ag999) via selective laser melting (SLM) technology, enabling intricate geometries unachievable through traditional methods. Each prototype undergoes full dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify conformity within tolerances as tight as ±0.02 mm. Surface roughness, density, and electrical conductivity are tested to ensure material properties meet required benchmarks. This stage allows clients to validate form, fit, and function before committing to full-scale production. Feedback from testing is integrated rapidly, with turnaround for revised prototypes typically within 5–7 working days.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into mass production. Our facility leverages automated build preparation, in-process monitoring, and real-time melt pool analysis to maintain consistency across batches. Each print job is supported by a full production quality plan, including first-article inspection (FAI), statistical process control (SPC), and 100% lot traceability. Post-processing—including support removal, stress relieving, precision machining, and surface finishing—is performed in-house under controlled conditions. Final parts undergo non-destructive testing (NDT) and are packaged with full inspection reports. Our zero-defect philosophy is enforced through a closed-loop corrective action system, ensuring continuous improvement and compliance.

Technical Specifications of Silver 3D Printing Process

| Parameter | Specification |

|---|---|

| Material | Silver (Ag999), purity ≥ 99.9% |

| Printing Technology | Selective Laser Melting (SLM) |

| Layer Thickness | 20–50 μm |

| Build Envelope | Up to 250 × 250 × 300 mm |

| Dimensional Tolerance | ±0.02 mm (standard), tighter on request |

| Surface Roughness (as-printed) | Ra 6–12 μm |

| Density | ≥ 99.95% |

| Post-Processing Options | CNC Machining, Polishing, Plating, Annealing |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

Every stage of our silver 3D printing service is engineered for repeatability, reliability, and excellence—ensuring clients receive precision-manufactured components that meet the highest standards of performance and quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Silver 3D Printing Excellence

In the demanding realm of high-value metal additive manufacturing, precision engineering meets material science. Wuxi Lead Precision Machinery delivers industrial-grade silver 3D printing services engineered for applications where conductivity, biocompatibility, and intricate geometry are non-negotiable. Our direct metal laser sintering (DMLS) and binder jetting platforms transform pure silver feedstock into mission-critical components for aerospace thermal management, medical implants, and luxury electronics. We eliminate the compromise between complex design freedom and material integrity, ensuring every part meets stringent aerospace AS9100 and medical ISO 13485 standards.

Our technical capabilities are defined by measurable precision and repeatability. The table below outlines core specifications for our silver additive processes:

| Parameter | DMLS Silver Printing | Binder Jet Silver Printing |

|---|---|---|

| Material Purity | 99.95% Ag (ASTM B700) | 99.9% Ag (sintered) |

| Minimum Feature Size | 50 μm | 100 μm |

| Surface Roughness (as-built) | Ra 8–12 μm | Ra 15–20 μm |

| Build Volume | 250 x 250 x 325 mm | 400 x 250 x 250 mm |

| Layer Thickness | 20–30 μm | 50–100 μm |

| Post-Processing Options | HIP, Precision Polishing, Plating | Sintering, Infiltration, CNC Finishing |

| Lead Time (Standard) | 7–10 business days | 5–8 business days |

Beyond technical execution, we integrate as your strategic manufacturing partner. Our engineering team collaborates from initial design validation through to serial production, conducting rigorous DFAM analysis to optimize part orientation, support structures, and thermal management for silver’s unique sintering behavior. We maintain full material traceability with certified mill test reports and provide comprehensive first-article inspection (FAI) documentation per AS9102. Confidentiality is paramount: all projects operate under strict NDA protocols with secure data handling aligned with IATF 16949 requirements.

The true value of partnering with Lead Precision lies in mitigating your production risk while accelerating time-to-market. We absorb the capital expenditure and technical overhead of maintaining calibrated, state-of-the-art silver printing systems—freeing your engineers to focus on innovation. Our in-house metrology lab, equipped with 5-axis CMM and X-ray CT scanning, ensures dimensional accuracy down to ±15 μm, eliminating costly supply chain surprises.

Initiate your next high-stakes silver component project with confidence. Contact our technical sales engineering team at [email protected] to schedule a confidential consultation. Specify your application requirements, target volumes, and quality standards. We will respond within 24 business hours with a tailored capability assessment and prototype timeline. For urgent RFQs, include “Silver Priority” in the subject line to expedite review. Trust Wuxi Lead Precision Machinery—where atomic-level material control meets industrial-scale delivery. Your precision demands our partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.