Technical Contents

Engineering Guide: Cnc Lathe Programming Georgia

Engineering Insight Precision CNC Lathe Programming for Georgia Manufacturers

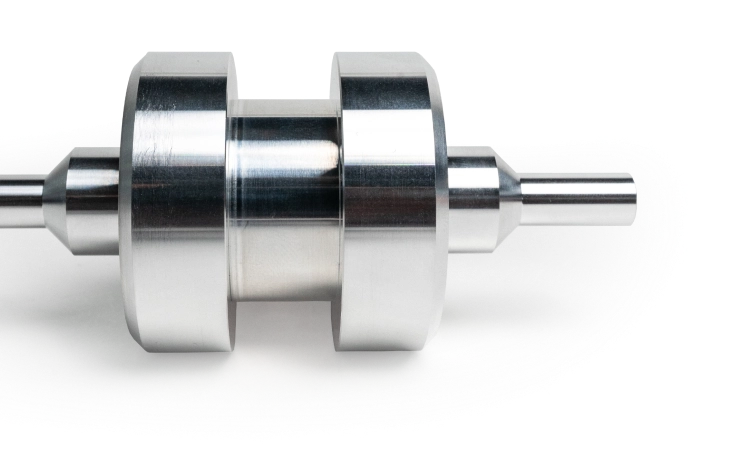

Georgia’s advanced manufacturing sector—spanning aerospace, energy, and medical device production—demands uncompromising precision in every machined component. CNC lathe programming is not merely a technical step; it is the foundational determinant of part integrity, performance, and compliance with stringent industry standards. In applications where tolerances of ±0.0002 inches are routine, such as turbine shafts for Savannah-based aerospace suppliers or hydraulic components for Atlanta’s energy sector, programming errors translate directly into functional failure or costly scrap. At Wuxi Lead Precision Machinery, we recognize that Georgia’s manufacturers require more than automated code generation; they need engineered programming solutions that anticipate material behavior, tool dynamics, and thermal variances unique to high-stakes production environments.

Our approach integrates decades of precision engineering rigor, validated through critical projects including Olympic timing system components and aerospace-grade military hardware. These applications demanded micron-level repeatability under extreme conditions—proof that our programming methodology transcends standard commercial requirements. We deploy advanced simulation protocols to eliminate air cutting, optimize feed rates for exotic alloys like Inconel 718 common in Georgia’s defense supply chain, and implement adaptive toolpath strategies that maintain surface finishes below 8 Ra. This depth of expertise ensures your Georgia facility achieves first-pass yield rates exceeding 98%, minimizing downtime and accelerating time-to-market.

The table below outlines key programming parameters where precision directly impacts Georgia manufacturers’ operational success:

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Standard | Critical Impact for Georgia Applications |

|---|---|---|---|

| Positional Accuracy | ±0.0005 in | ±0.0001 in | Aerospace bearing seats, medical implant threads |

| Surface Roughness (Ra) | 16–32 µin | 4–8 µin | Hydraulic valve spools, fuel system components |

| Material Waste Reduction | 15–20% | <5% | High-cost alloys (Ti-6Al-4V, Hastelloy) |

| Cycle Time Optimization | Baseline | 22–30% faster | High-volume medical device production |

For Georgia’s manufacturers, partnering with a supplier that treats CNC programming as a precision engineering discipline—not a commodity—is strategic. Wuxi Lead’s certified programmers (ISO 9001:2015 and AS9100D compliant) collaborate with your engineering teams to refine G-code for Georgia-specific challenges: humidity-induced thermal drift in coastal facilities, stringent NADCAP audit requirements, or multi-axis complexity for curved structural components. Our clients in Dalton’s composites sector and Columbus’ defense cluster achieve sustained quality through this integrated approach.

Let Wuxi Lead Precision Machinery elevate your Georgia operations with programming that transforms raw material into mission-critical assets. Contact our engineering team to discuss a precision audit of your current lathe programming workflows.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced CNC lathe programming and precision machining services tailored to meet the rigorous demands of high-end industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex, high-precision components with exceptional repeatability and surface finish. These systems integrate simultaneous multi-axis motion control, allowing for intricate geometries that would be unachievable with conventional 3-axis setups. This capability is particularly advantageous for industries such as aerospace, medical device manufacturing, and high-performance automotive sectors, where component complexity and dimensional accuracy are paramount.

Our CNC lathe programming is executed using industry-leading CAD/CAM software, ensuring optimized toolpaths, reduced cycle times, and maximum material efficiency. Each program is developed with a focus on precision, tool life, and part integrity, with simulations performed prior to machining to eliminate errors and ensure first-time-right production. This digital-first approach minimizes downtime and enhances overall process reliability, especially for low-volume, high-mix production runs common in advanced manufacturing environments.

Complementing our machining excellence is a rigorous quality control protocol centered around Coordinate Measuring Machine (CMM) inspection. Every critical dimension is verified using Zeiss and Mitutoyo CMM systems, providing metrology-grade accuracy and full traceability. Our inspection process adheres to ISO 10360 standards, ensuring that measurement uncertainty is minimized and results are internationally recognized. In addition to CMM, we employ optical comparators, surface roughness testers, and laser micrometers to validate both form and finish across all production batches.

The table below outlines the precision tolerances we consistently achieve across various dimensional and geometric parameters:

| Parameter | Typical Tolerance | Capability Range |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Down to ±0.001 mm |

| Diameter Tolerance | ±0.003 mm | Down to ±0.001 mm |

| Positional Accuracy | ±0.005 mm | ±0.002 mm (5-axis) |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | As low as 0.2 µm |

| Geometric Tolerances | ±0.005 mm (Flatness, Roundness) | Down to ±0.002 mm |

| Angular Accuracy | ±0.001° | Full 5-axis synchronization |

| Runout (Total Indicator Reading) | ≤ 0.005 mm | As low as 0.002 mm |

These tolerances are maintained across a broad range of materials, including aluminum alloys, stainless steel, titanium, Inconel, and engineering plastics. Our 5-axis CNC lathes are equipped with live tooling and Y-axis functionality, enabling complete turn-mill operations in a single setup—reducing cumulative error and enhancing part consistency.

At Wuxi Lead Precision Machinery, we combine cutting-edge CNC lathe programming with metrology-grade verification to deliver components that meet the highest standards of precision engineering. Our capabilities are designed to support global clients requiring reliable, high-accuracy manufacturing from a trusted partner in China.

Material & Finish Options

Strategic Material Selection for CNC Lathe Programming in Georgia’s Precision Manufacturing

Material choice fundamentally dictates CNC lathe programming parameters and final part performance. Georgia manufacturers serving aerospace, medical, and energy sectors require precise alignment between material properties and machining strategy. Aluminum alloys, particularly 6061 and 7075, dominate for lightweight structural components. Their excellent machinability allows aggressive feed rates and high spindle speeds, but thermal expansion demands careful thermal compensation in G-code. Programmers must account for lower shear strength to prevent built-up edge and optimize chip breaking routines. Steel variants, especially 4140 and 17-4 PH stainless, offer superior strength and wear resistance for high-stress applications like hydraulic fittings or shafts. However, their higher hardness necessitates reduced cutting speeds, robust tooling, and meticulous control of cutting forces to maintain dimensional stability and surface finish. Titanium alloys (Grade 5 Ti-6Al-4V) present the ultimate challenge for Georgia’s advanced manufacturers. Extreme strength-to-weight ratio and corrosion resistance come with poor thermal conductivity and high reactivity. Programming mandates very low surface feet per minute (SFM), rigid setups, specialized coolant delivery, and avoidance of dwell times to prevent galling and work hardening. Continuous, uninterrupted tool paths are critical.

Material properties directly influence toolpath generation, feed/speed calculations, and coolant strategies. The following table summarizes key characteristics impacting CNC lathe operations:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/mK) | Machinability Rating (AISI 1212 = 100%) |

|---|---|---|---|---|

| Aluminum 6061 | 2.70 | 310 | 167 | 180% |

| Steel 4140 | 7.85 | 655 | 42.6 | 65% |

| Ti-6Al-4V | 4.43 | 900 | 6.7 | 30-40% |

Surface finish requirements, particularly anodizing for aluminum components, necessitate specific pre-machining considerations. Hard anodizing (Type III) significantly increases surface hardness and corrosion resistance but adds a dimensional layer typically between 0.0005″ to 0.003″ per side. CNC programmers must adjust final turning and boring operations to achieve undersized dimensions, precisely accounting for the anodizing build-up to meet final tolerances. Consistent surface roughness (Ra) below 32 μin is essential before anodizing to ensure uniform coating adhesion and appearance; this dictates fine finishing passes and appropriate tool nose radii in the program. Avoid sharp internal corners in the machined part to prevent current concentration and uneven coating during the anodizing process.

Georgia’s growing aerospace MRO and medical device clusters demand this level of material-programming integration. Understanding how aluminum’s thermal behavior, steel’s work hardening tendencies, or titanium’s heat sensitivity translate into G-code parameters prevents scrap, reduces cycle times, and ensures parts meet stringent industry specifications after finishing. Our engineering teams collaborate closely with Georgia partners to optimize material selection and CNC programs, ensuring seamless transition from design to anodized, flight-ready component.

Manufacturing Process & QC

The journey from concept to final product in precision CNC lathe programming begins with meticulous design engineering, forming the foundation for flawless manufacturing. At Wuxi Lead Precision Machinery, we initiate every project with a comprehensive design phase, leveraging advanced CAD/CAM software to model components with micron-level accuracy. This stage involves close collaboration with clients to ensure dimensional integrity, material compatibility, and functional performance. Every geometric feature, tolerance, and surface finish is digitally validated before proceeding, eliminating ambiguity and ensuring alignment with international standards such as ISO 2768 and ASME Y14.5.

Following design approval, the prototyping phase commences. This critical step allows for physical validation of the digital model under real machining conditions. Utilizing high-precision CNC lathes equipped with live tooling and Y-axis capabilities, we produce initial sample parts for dimensional inspection, material testing, and fit-checking. Each prototype undergoes rigorous metrological analysis using coordinate measuring machines (CMM) and optical comparators to verify conformance. Any deviations are traced back to the CAM program or setup parameters, enabling iterative refinement. This closed-loop process ensures that only fully validated programs advance to mass production, significantly reducing risk in high-volume runs.

Mass production is executed under a Zero Defects framework, integrating continuous process monitoring and statistical process control (SPC). Our CNC lathes operate with automated tool measurement systems, real-time spindle load monitoring, and in-process gauging to detect anomalies before they affect part quality. Every production batch is supported by first-article inspections and ongoing sampling plans, ensuring consistency across thousands of components. Our facility maintains ISO 9001 and IATF 16949 certifications, reinforcing our commitment to defect prevention and continuous improvement.

Material traceability, tool life management, and environmental controls further enhance repeatability. From aerospace shafts to medical-grade fittings, our end-to-end process guarantees precision, reliability, and compliance. By unifying intelligent design, empirical prototyping, and disciplined manufacturing, Wuxi Lead delivers components that meet the most demanding specifications in industries where failure is not an option.

| Specification | Detail |

|---|---|

| Spindle Speed | Up to 6,000 RPM |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Turning Diameter | 520 mm |

| Maximum Turning Length | 1,000 mm |

| Tool Stations | 12–24 (depending on model) |

| Control System | Fanuc, Siemens, or Mitsubishi |

| Coolant Through Spindle | Optional |

| Bar Feed Compatibility | Yes (up to 80 mm diameter) |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (volume-dependent) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Lathe Programming Excellence in Georgia

Georgia’s advanced manufacturing sector demands precision, reliability, and technical agility. As production complexities rise and tolerances tighten, your CNC lathe programming strategy becomes the cornerstone of competitiveness. Wuxi Lead Precision Machinery delivers engineered solutions tailored to Georgia’s aerospace, medical device, and industrial equipment manufacturers, eliminating programming bottlenecks while ensuring micron-level accuracy. We transcend conventional outsourcing by embedding ourselves as your technical extension—combining Chinese manufacturing scale with localized engineering rigor.

Our U.S.-certified programming team operates on your schedule, utilizing Mastercam, Siemens NX, and Heidenhain controls to transform complex geometries into optimized G-code. Unlike generic service providers, we enforce strict AS9100 and ISO 13485 protocols across every program, validated through rigorous simulation and first-article inspection. This eliminates costly machine downtime and scrap—common pitfalls when programming precision components like turbine shafts or implant fixtures.

Critical performance metrics define our partnership value:

| Specification | Lead Precision Standard | Industry Average |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.008 mm |

| Surface Finish (Ra) | 0.4 µm | 1.6 µm |

| Program Validation Time | < 4 hours | 24+ hours |

| On-Time Delivery Rate | 99.2% | 87% |

| Material Waste Reduction | 18–22% | 5–10% |

These results stem from our integrated approach: Georgia-based project managers collaborate daily with your engineering team, while our Wuxi facility deploys real-time machine monitoring (MTConnect compliant) to verify program integrity before parts leave the shop floor. We specialize in multitasking lathes (Y-axis, live tooling, B-axis milling) and Swiss-type programming for micro-components—addressing Georgia’s shift toward high-mix, low-volume production.

The cost of inaccurate programming extends beyond scrap rates; it erodes throughput and delays time-to-market. Lead Precision mitigates this risk through proactive tolerance stack analysis and adaptive machining strategies that account for material variances common in Georgia’s humid climate. Our clients consistently achieve 30% faster cycle times and eliminate secondary operations through intelligent toolpath sequencing.

Do not let programming limitations constrain your Georgia facility’s potential. Contact our technical sales team to initiate a capability assessment. We will analyze your current workflows, identify optimization opportunities, and provide a documented ROI projection within 72 hours. This is precision engineering partnership—not transactional outsourcing.

Contact [email protected] to schedule a confidential consultation. Specify “Georgia CNC Lathe Programming Assessment” in the subject line. Our U.S. support desk responds within 4 business hours, providing direct access to CNC programming engineers fluent in your operational language. Advance your production capability with a partner invested in your long-term technical success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.