What are Punching Stamping Parts?

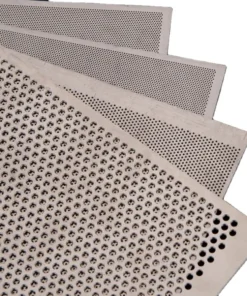

Punching stamping parts refer to metal parts that have been shaped, cut, or formed using a press machine and a stamping die. This process can produce parts with intricate designs and precise dimensions, making it a preferred choice for various industries. The essence of punching stamping lies in its ability to produce large quantities of parts with consistent quality and precision.

In the realm of manufacturing, the accuracy and quality of the parts play a pivotal role in the final product’s functionality and durability. This is where CNC (Computer Numerical Control) comes into play. CNC punching ensures that each part is crafted with the utmost precision, adhering to the specified dimensions and tolerances. This level of accuracy is paramount, especially in industries where even a minor discrepancy can lead to significant operational challenges or safety concerns.

Wuxi Lead Precision Machinery, a renowned name in the CNC machining sector in China, has been at the forefront of delivering top-notch punching stamping parts. With a keen focus on quality and precision, the company has catered to diverse client needs, ensuring that each part resonates with excellence and meets the industry standards.

The CNC Punching Process

CNC Punching, a subset of the broader stamping process, leverages the power of computer numerical control to achieve unparalleled precision in metal fabrication. Here’s a breakdown of how the CNC punching process unfolds:

- Design Phase: It all begins with a digital design, usually crafted using CAD (Computer-Aided Design) software. This design outlines the dimensions, shapes, and specifications of the desired part.

- Programming the Machine: The digital design is then converted into a set of instructions for the CNC machine. This ensures that the machine knows exactly where to punch, how hard to press, and the sequence of operations.

- Material Selection: Depending on the application, materials like aluminum, stainless steel, or brass are chosen. Wuxi Lead Precision Machinery offers a diverse range of materials, ensuring the right fit for every project.

- Punching: The CNC machine, equipped with the appropriate tools and dies, starts the punching process. It meticulously follows the instructions, ensuring each punch is precise and consistent with the design.

- Quality Check: Post-punching, each part undergoes a rigorous quality check. Wuxi Lead Precision Machinery’s robust QC team ensures that each part aligns with the set standards before it’s shipped out.

The advantages of CNC punching are manifold. Not only does it guarantee precision, but it also ensures repeatability, allowing for large-scale production without compromising on quality. Moreover, with the advancements in technology, CNC machines can now handle complex designs with ease, expanding the horizons of what’s possible in metal fabrication.

Types and Applications of CNC Punching Parts

The versatility of CNC punching is evident in the diverse types of parts it can produce and the myriad applications they cater to. Some of the prominent types include:

- Brackets: Used in various industries for mounting and support.

- Enclosures: Commonly seen in electronics to house components.

- Gears: Essential for machinery and automotive applications.

- Panels: Used in construction and machinery for protection and aesthetics.

Wuxi Lead Precision Machinery, with its state-of-the-art machinery and expertise, has been instrumental in producing these parts for various industries, including automotive, aerospace, electronics, and construction.

Why Choose Wuxi Lead Precision Machinery for CNC Punching Parts?

Choosing a reliable partner for your CNC punching needs is paramount, and Wuxi Lead Precision Machinery stands out for several reasons:

- High-Quality Assurance: With a stringent QC team in place, every part undergoes thorough inspections, ensuring they meet the highest standards.

- Swift Delivery: Time is of the essence in the manufacturing world. Wuxi Lead Precision Machinery is committed to dispatching products within the agreed delivery date, ensuring your projects stay on track.

- Exceptional Customer Service: With a team available around the clock, seven days a week, all your queries and concerns are addressed promptly.

- Advanced Machinery: The level of automation and advanced machinery ensures quick turnaround times, meeting your needs promptly.

Key Questions International Buyers Should Ask Their Chinese Suppliers

Engaging with international suppliers, especially from China, can be a daunting task. However, armed with the right questions, buyers can ensure a smooth and fruitful collaboration:

- What are your quality control measures? Understanding the QC process will give you insights into the product’s quality you can expect.

- Can you provide references or case studies from past projects? This will help gauge the supplier’s experience and reliability.

- What are the lead times for production and delivery? Timelines are crucial for project planning.

- Are there any additional costs involved, like shipping or customs duties? Hidden costs can affect the project’s budget, so it’s essential to clarify upfront.

- How do you handle after-sales service and warranty claims? Knowing the support you can expect post-purchase is vital.

FAQ Tips

- What’s the difference between CNC punching and CNC machining? While both are computer-controlled processes, CNC punching focuses on creating holes and shapes in metal sheets, while CNC machining involves removing material to produce a part.

- How do I choose between CNC punching and laser cutting? While both methods have their merits, CNC punching is faster and more cost-effective for larger runs, whereas laser cutting offers more intricate design possibilities.

- What materials can be CNC punched? Most metals, including aluminum, stainless steel, and brass, can be CNC punched. The choice depends on the application and desired properties.

In the ever-evolving landscape of manufacturing, CNC punching stands out as a beacon of precision and efficiency. And when it comes to CNC punching, Wuxi Lead Precision Machinery emerges as a trusted partner, offering unparalleled quality and bespoke solutions. Whether you’re a seasoned buyer or just starting, aligning with a reliable supplier like Wuxi Lead Precision Machinery ensures that your projects resonate with excellence and precision.